Professional Documents

Culture Documents

Weld-On Structural Adhesives: Product Reference Guide

Weld-On Structural Adhesives: Product Reference Guide

Uploaded by

marklaforestOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld-On Structural Adhesives: Product Reference Guide

Weld-On Structural Adhesives: Product Reference Guide

Uploaded by

marklaforestCopyright:

Available Formats

Reference Guide 09-26-06 10/3/06 7:53 AM Page 1

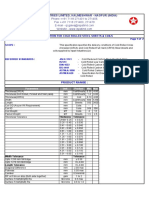

WELD-ON® STRUCTURAL ADHESIVES PRODUCT REFERENCE GUIDE

Ratio Mixed Viscosity Tensile

Features, Benefits Working Fixture A:B Density (10 3 cps) Strength 2 Shear

& Time1 Time1 Volume gm/ml A-Comp. psi Strength 3

Series Applications Adhesive min. min. Weight lb/gal B-Comp. % Elongation psi

SS100 Color Stabilized (White) SS115 12-18 >30 10:1 1.02 A: 150-220 2,800-3,200 2,000-2,400

UV Stabilized SS140 35-45 >80 5.68:1 8.45 B: 90-130 >140

Intermediate Shear Strength

High Toughness

• 490 ml Cartridge or Bulk

• Composites, Plastics, Primed Metals

SS200 General Purpose (Off White)6 SS208 8-12 >25 10:1 0.99 A: 170-220 2,000-2,500 2,400-2,800

Maximum Toughness SS214 17-22 >35 7.69:1 8.22 B: 70-180 >200

High Shear Strength SS218 35-45 >80

• 490 ml Cartridge or Bulk

• Composites, Plastics, Primed Metals

SS230 HV Large Structures (Gray)6 SS230 HV 25-130 45-260 4 10:1 0.99 A: 900-1300 3,000-4,000 1,400-1,5003

Gap Fill up to 1.5”, Non Sag 8.4:1 8.25 B: 80-180 150-230 1,850-2,2005

Intermediate Shear Strength

Maximum Toughness

• Bulk, 5 and 50-gallons

• Composites, Plastics, Primed Metals

SS300 Metal Bonder (Black)6 SS305 4-6 >15 10:1 1.02 A: 180-250 2,000-2,200 2,500-2,800

Primerless Metal Bonding SS315 13-17 >30 8.75:1 8.51 B: 80-120 100-125

Low Read Through SS316 14-18 >25

High Shear Strength SS340 35-45 >80

High Toughness

• 490 ml Cartridge or Bulk

• Composites, Plastics, Metals

SS500 High Strength Adhesive (Amber) SS505 4-6 >15 1:1 1.00 A: 40-70 4,000-5,000 3,500-4,000

Thermoplastics and Composites SS515 15-20 >30 1.05:1 8.29 B: 40-70 >50

Maximum Shear Strength

Tough

• 400 ml Cartridge or Bulk

• Composites, Plastics, Primed Metals

SS600 General Purpose (Black)6 SS605 4-6 >15 10:1 0.99 A: 150-200 2,600-3,000 2,700-3,200

Excellent Flow Characteristics SS610 8-12 >25 8.44:1 8.24 B: 80-120 >140

High Shear Strength SS620 15-20 >35

High Toughness

• 490 ml Cartridge or Bulk

• Composites, Plastics, Primed Metals

SS1100p General Purpose 1:1 (Amber) SS1105 4-6 >15 1:1 1.013 A: 70-100 2,500-3,500 2,500-3,000

Difficult to Bond Plastics & Galvanized SS1115 13-17 >35 1.05:1 8.45 B: 80-120 >100

High Shear Strength

High Toughness

• 50 and 400 ml Cartridges or Bulk

• Composites, Plastics, Primed Metals

SS1300p General Purpose Composite (Black)6 SS1305 4-6 >15 10:1 1.02 A: 180-250 1,700-2,200 2,500-3,000

Low Read Through SS1310 13-17 >30 8.75:1 8.50 B: 80-120 100-170

High Shear Strength

High Toughness

• 490 ml Cartridge or Bulk

• Composites, Plastics, Primed Metals

SS1500p General Purpose 1:1 (Amber) SS1505 4-6 >15 1:1 0.98 A: 80-120 2,500-3,100 2,700-3,200

Primerless Metal Bonder SS1515 12-16 >30 1.08:1 8.17 B: 100-140 >80

Maximum Shear Strength SS1530 25-35 >60

High Toughness SS1560 50-70 >140

• 50 and 400 ml Cartridges or Bulk

• Composites, Plastics, Metals

Notes: 1. Working/fixture times at 75°F unless noted. Fixture time is minimum recommended time in fixture.

2. All mechanical properties are based on post cure cycle, 1 hour @ 82°C.

3. ASTM D1002 - 6061 Aluminum treated with MP100 Metal Primer (no primer needed with SS300 and SS1500 series).

Bond strength attainable on other materials is limited and controlled by the strength and stiffness of the substrate.

4. Single adhesive, selection of four activators. Please refer to the product data sheet for more specific information.

5. ASTM D5868 - typical single lap shear strength of FRP to FRP bond.

6. Cured adhesive colors are for products offered in cartridges. Several other colors are possible with products sold in bulk.

p. Preliminary data - New Product Series.

Visit our website at: www.ipscorp.com

Toll-free: 1-877-IPS-GLUE (1-877-477-4583) • FAX: (919)-598-2439

IPS Structural Adhesives, Inc., 600 Ellis Road, Durham, NC 27703 Ref-Guide 09/06

You might also like

- CM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NoteDocument2 pagesCM April 2015 An Intro To As - nzs2312.2 Part 2 Hot Dip Gal Tech NotemarklaforestNo ratings yet

- Compact and Beautiful Design (结构紧凑,外观优美) Explosion Proof (Ex d BT6 and CT6) (高等级隔爆) Many Size and Many Type (多品种,多规格)Document9 pagesCompact and Beautiful Design (结构紧凑,外观优美) Explosion Proof (Ex d BT6 and CT6) (高等级隔爆) Many Size and Many Type (多品种,多规格)Mariam Matamala FarranNo ratings yet

- ACRALOCK Structural AdhesivesDocument2 pagesACRALOCK Structural AdhesivesVesna NikolicNo ratings yet

- ASTM A516 GR 70 N Pressure Vessel Plate: Sin Thai Special Steel Co., LTDDocument1 pageASTM A516 GR 70 N Pressure Vessel Plate: Sin Thai Special Steel Co., LTDHaidarHussainiNo ratings yet

- Shop 304 / 304L Stainless Steel PipeDocument2 pagesShop 304 / 304L Stainless Steel PipeCeratita ClarkNo ratings yet

- Material Characteristics PDFDocument4 pagesMaterial Characteristics PDFELTIPAZONo ratings yet

- Profile Carbide Modular Shrink System Inserts ParametersDocument8 pagesProfile Carbide Modular Shrink System Inserts ParametersLaxman KumarNo ratings yet

- AISI 52100 Chrome Steel Data Sheet: Simply Bearings LTD Authorised Precision Ball and Roller Distributors in The UKDocument1 pageAISI 52100 Chrome Steel Data Sheet: Simply Bearings LTD Authorised Precision Ball and Roller Distributors in The UKZehNo ratings yet

- TS-347 TientaiDocument1 pageTS-347 TientaiOscar JimenezNo ratings yet

- Precision Cutting Tools PDFDocument16 pagesPrecision Cutting Tools PDFHoang Truong DinhNo ratings yet

- Beryllium Copper (C17200) DatasheetDocument2 pagesBeryllium Copper (C17200) Datasheetjr_satishNo ratings yet

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- Applications Characteristics: For Inter-Metallic AbrasionDocument1 pageApplications Characteristics: For Inter-Metallic AbrasionThanuja PereraNo ratings yet

- Clark Manor Improvements August 2016Document26 pagesClark Manor Improvements August 2016Gabriel Achacoso MonNo ratings yet

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsDocument4 pagesIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- ASSAB Tool Steel Performance Comparison ChartDocument1 pageASSAB Tool Steel Performance Comparison ChartNugroho Faris Sudrajat100% (2)

- AISI 52100 Chrome Steel Data Sheet: Simply Bearings LTD Authorised Precision Ball and Roller Distributors in The UKDocument1 pageAISI 52100 Chrome Steel Data Sheet: Simply Bearings LTD Authorised Precision Ball and Roller Distributors in The UKdikatokNo ratings yet

- McMaster - About Plastics Doc 8574KACDocument3 pagesMcMaster - About Plastics Doc 8574KACkristechnikNo ratings yet

- MURAFLEX 2020 Low RizeDocument4 pagesMURAFLEX 2020 Low RizeanisyariskiNo ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- Cu ZN 15Document2 pagesCu ZN 15wjjt6chgtmNo ratings yet

- Vibratory Disc Mill RS 200Document3 pagesVibratory Disc Mill RS 200MGRenJcNo ratings yet

- Steel Sucker RodDocument1 pageSteel Sucker RodSantii CampitelliNo ratings yet

- Filler Metal 70s-6Document1 pageFiller Metal 70s-6Hugo RodriguezNo ratings yet

- Aço 1.4301 - INOX 304Document3 pagesAço 1.4301 - INOX 304Rhani NogueiraNo ratings yet

- Cu - of - Cw008aDocument2 pagesCu - of - Cw008ap.designNo ratings yet

- Cu ZN 20Document2 pagesCu ZN 20wjjt6chgtmNo ratings yet

- Material Yield Stress COMPARITIVE DATADocument4 pagesMaterial Yield Stress COMPARITIVE DATAshNo ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsirinaNo ratings yet

- Diehl Metall Strips MB30 V2 M-SM PDFDocument2 pagesDiehl Metall Strips MB30 V2 M-SM PDFVinoth KumarNo ratings yet

- Metric DIN 7 SpecDocument6 pagesMetric DIN 7 SpecGülinNo ratings yet

- Salem Product CatalogueDocument6 pagesSalem Product Cataloguedramilt0% (1)

- Vautid100 EnglDocument1 pageVautid100 EnglRamona CrangasNo ratings yet

- Strength Grade of Bolts and ScrewDocument2 pagesStrength Grade of Bolts and ScrewmuathNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- S690QLDocument1 pageS690QLSave EngineeringNo ratings yet

- Repair Clamp ListBrewcoPowersealRepairClamps2008Document25 pagesRepair Clamp ListBrewcoPowersealRepairClamps2008Jaya DiNo ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Spiral Wound Gasket SPW123Document2 pagesSpiral Wound Gasket SPW123Łukasz OlszewskiNo ratings yet

- HUSWire ProductsDocument10 pagesHUSWire ProductsMaître DumèNo ratings yet

- Data Sheet BISALLOY 500-STEELDocument1 pageData Sheet BISALLOY 500-STEELFery FebryantoNo ratings yet

- Primer Painted PDFDocument1 pagePrimer Painted PDFMandiri 045No ratings yet

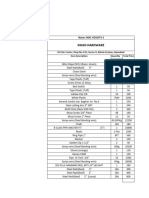

- Ref # Qty Description Details Unit Price Total PriceDocument2 pagesRef # Qty Description Details Unit Price Total PriceJASONNo ratings yet

- Stainless Steel 304 Data SheetDocument2 pagesStainless Steel 304 Data SheetBahtiar SetiawanNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- ST52-3 (Plate)Document1 pageST52-3 (Plate)Sholhan AzizNo ratings yet

- Tenalloy 120G: LOW ALLOY STEEL (High Strength)Document1 pageTenalloy 120G: LOW ALLOY STEEL (High Strength)Devender NegiNo ratings yet

- Carbon Hollow Bar: (32 To 250 MM OD) (254 To 610 MM OD)Document2 pagesCarbon Hollow Bar: (32 To 250 MM OD) (254 To 610 MM OD)Richard Vica CalvoNo ratings yet

- Die Tool GradesDocument13 pagesDie Tool Gradesdarwin_huaNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- ITW Product Catalog4Document1 pageITW Product Catalog4johnNo ratings yet

- MAc Heights 1Document8 pagesMAc Heights 1Ali AwanNo ratings yet

- Super Tensile Blue Data SheetDocument1 pageSuper Tensile Blue Data Sheetdapp.70No ratings yet

- BS 4360 50eeDocument1 pageBS 4360 50eeTimNo ratings yet

- 1 Gala Bronze Y-Strainer Fig 7654 SMDocument1 page1 Gala Bronze Y-Strainer Fig 7654 SMNon Etabas Gadnatam100% (1)

- 309-16 Data SheetDocument1 page309-16 Data Sheetdapp.70No ratings yet

- Diamond and CBN WheelsDocument22 pagesDiamond and CBN WheelsM. AguiarNo ratings yet

- SS 302HQ, Type 302HQ, WNR 1.4567, UNS S30430, AISI 302HQ, Grade 302HQDocument3 pagesSS 302HQ, Type 302HQ, WNR 1.4567, UNS S30430, AISI 302HQ, Grade 302HQpierocarnelociNo ratings yet

- SuperblueDocument1 pageSuperblueFranklin CastilloNo ratings yet

- SEQ-SEW-1303-4 A: Seq Water Service ProvidersDocument1 pageSEQ-SEW-1303-4 A: Seq Water Service ProvidersmarklaforestNo ratings yet

- Specifications: Limitorque MX Selection DataDocument18 pagesSpecifications: Limitorque MX Selection DatamarklaforestNo ratings yet

- Constitution For Sample Pty LTDDocument20 pagesConstitution For Sample Pty LTDmarklaforestNo ratings yet

- Rtt-Ind-001 Rev 9 (No 13 Solvent) 11092017 JfoDocument11 pagesRtt-Ind-001 Rev 9 (No 13 Solvent) 11092017 JfomarklaforestNo ratings yet

- Rotork Profibus ControlDocument16 pagesRotork Profibus ControlmarklaforestNo ratings yet

- Bridco Load Rated 2016Document16 pagesBridco Load Rated 2016marklaforestNo ratings yet

- Queensland Government GazetteDocument53 pagesQueensland Government GazettemarklaforestNo ratings yet

- Ss300 Series Property Table: Units Methods Environments SS340 (A) SS605B SS305 (A) SS605B SS315 (A) SS605BDocument2 pagesSs300 Series Property Table: Units Methods Environments SS340 (A) SS605B SS305 (A) SS605B SS315 (A) SS605BmarklaforestNo ratings yet

- Chemical Resistance Guide: Resin SelectionDocument4 pagesChemical Resistance Guide: Resin SelectionmarklaforestNo ratings yet

- SS300 React Vs TempDocument1 pageSS300 React Vs TempmarklaforestNo ratings yet

- Manual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066Document2 pagesManual Guides Knife Gate Valves f952 Gland Packing Instructions Larger Sizes Keystone en en 2719066marklaforestNo ratings yet

- VCB22 Series - Data Sheet (En)Document11 pagesVCB22 Series - Data Sheet (En)marklaforest0% (1)

- Q LD Procurement PolicyDocument20 pagesQ LD Procurement PolicymarklaforestNo ratings yet

- ISO Tolerances For Holes (ISO 286-2) : Over IncDocument1 pageISO Tolerances For Holes (ISO 286-2) : Over IncmarklaforestNo ratings yet

- ARDEX RA 88 DatasheetDocument4 pagesARDEX RA 88 Datasheetmarklaforest0% (1)

- CPV Process Valve ActuatorDocument12 pagesCPV Process Valve ActuatormarklaforestNo ratings yet

- Atlas Grade Datasheet 316 Rev Jan 2011 PDFDocument2 pagesAtlas Grade Datasheet 316 Rev Jan 2011 PDFmarklaforestNo ratings yet

- Dunlop Builder's Bond 0114Document2 pagesDunlop Builder's Bond 0114marklaforestNo ratings yet

- Power That Moves: Large-Diameter Cylinder DSBG With Tie RodsDocument2 pagesPower That Moves: Large-Diameter Cylinder DSBG With Tie RodsmarklaforestNo ratings yet

- Driving Motors Driving Motors: Oem OemDocument1 pageDriving Motors Driving Motors: Oem OemmarklaforestNo ratings yet

- Ghar Par Makeup Karne Ke Sahi Tarike 5 Makeup Tips in HindiDocument3 pagesGhar Par Makeup Karne Ke Sahi Tarike 5 Makeup Tips in HindiGovindNo ratings yet

- B1 Questions QN001: Form Questions Which Ask For The Underlined WordsDocument2 pagesB1 Questions QN001: Form Questions Which Ask For The Underlined WordsMirjana Paunovic100% (1)

- The Excretory/ Urinary System: Lecture By: Marri Jmelou M. Roldan, MSCDocument29 pagesThe Excretory/ Urinary System: Lecture By: Marri Jmelou M. Roldan, MSCHeaven SolNo ratings yet

- 26148-220-V1B-EVC0-00157 (002) - Unilineal BTDocument4 pages26148-220-V1B-EVC0-00157 (002) - Unilineal BTDomingo esteban perez ceballoNo ratings yet

- H&C Analysis Unit 3 09Document22 pagesH&C Analysis Unit 3 09Seenu PusuluruNo ratings yet

- State Wise Members of JAC For Organizing Senior Citizens National Protest Day - 16 Aufgust 2010Document2 pagesState Wise Members of JAC For Organizing Senior Citizens National Protest Day - 16 Aufgust 2010api-27224201No ratings yet

- 2019 X470 Class 01 - Intro and HVAC SystemsDocument86 pages2019 X470 Class 01 - Intro and HVAC SystemsAseem GoyalNo ratings yet

- Norme SangeDocument2 pagesNorme SangePS NINo ratings yet

- FDARDocument22 pagesFDARBer Anne Jaropojop Tahil100% (1)

- ECLOS-Difference Course OutlineDocument3 pagesECLOS-Difference Course OutlineJosé Manuel Valdez RevillaNo ratings yet

- Gps PDFDocument1 pageGps PDFcyderNo ratings yet

- Construction and Logistics Plan For: 56a - 60 North RD, Three Bridges, Crawley. RH10 1RHDocument24 pagesConstruction and Logistics Plan For: 56a - 60 North RD, Three Bridges, Crawley. RH10 1RHCivil Engineer100% (1)

- Drug Education and Vice ControlDocument16 pagesDrug Education and Vice ControlSinagTalaNo ratings yet

- Author Guidline. CPSPDocument4 pagesAuthor Guidline. CPSPMuhammad MoazzamNo ratings yet

- Nursing Care Plan: DATE: March 2, 2021Document1 pageNursing Care Plan: DATE: March 2, 2021Grascia SchneiderNo ratings yet

- Ultra High Temperature 100HTL Adhesive Transfer Tapes: Technical Data November, 2006Document4 pagesUltra High Temperature 100HTL Adhesive Transfer Tapes: Technical Data November, 2006Iris SoonNo ratings yet

- Hormonal CoordinationDocument4 pagesHormonal Coordinationtalithaonkabetse723No ratings yet

- STS PrelimsDocument9 pagesSTS PrelimsKatrina PeñaNo ratings yet

- Criminology AssignmentDocument30 pagesCriminology AssignmentAnany UpadhyayNo ratings yet

- 2023.08.08 - Letter To AUSA GravesDocument2 pages2023.08.08 - Letter To AUSA GravesNew York PostNo ratings yet

- Geriatric Considerations in NursingDocument8 pagesGeriatric Considerations in NursingSathish Rajamani100% (6)

- Rr410802 Chemical Reaction Engineering IIDocument9 pagesRr410802 Chemical Reaction Engineering IISrinivasa Rao G100% (1)

- Synthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDocument29 pagesSynthesis of Reactive Mgo From Reject Brine Via The Addition of Nh4OhDl Divakar LNo ratings yet

- Assembly Features: Removable Terminal BlueDocument5 pagesAssembly Features: Removable Terminal Bluemuhammad mustajabNo ratings yet

- Mentalidad Positiva 4 PDFDocument28 pagesMentalidad Positiva 4 PDFmagdalenaNo ratings yet

- Answersheet Week8Document2 pagesAnswersheet Week8Daniel AlcantaraNo ratings yet

- Chem Jeem SeptDocument62 pagesChem Jeem SeptStephen SatwikNo ratings yet

- What Is The Role of Literature Review in Research ProcessDocument7 pagesWhat Is The Role of Literature Review in Research Processc5qz47smNo ratings yet

- PDFDocument8 pagesPDFDiego A Moreno PNo ratings yet

- 17 - Guide To Asbestos For IndustryDocument73 pages17 - Guide To Asbestos For Industryraul_bsuNo ratings yet