Professional Documents

Culture Documents

Building

Building

Uploaded by

arghyaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Building

Building

Uploaded by

arghyaCopyright:

Available Formats

Weighed purchase

In comparison, when weighed purchasing policy is applied based on ABC class, for example C class

monthly (every four weeks) delivery with re-order point of three weeks' supply, B class bi-weekly

delivery with re-order point of 2 weeks' supply, A class weekly delivery with re-order point of 1

week's supply, total number of delivery in 4 weeks will be (A 200×4=800)+(B 400×2=800)+(C

3,400×1=3,400)=5,000 and average inventory will be (A 75%×1.5weeks)+(B 15%x3 weeks)+(C

10%×3.5 weeks)=1.925 weeks' supply.

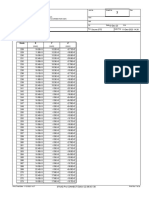

Comparison of "equal" and "weighed" purchase (4 weeks span)

Equal purchase Weighed purchase

% of

ABC No of

total No of No of note

class items average average

value delivery delivery

supply supply

in 4 in 4

level level

weeks weeks

same delivery

frequency, safety stock

2.5 1.5 reduced from 2.5 to 1.5

A 200 75% 800 800

weeks weeksa weeksa, require tighter

control with more man-

hours.

increased safety stock

level by 20%, delivery

2.5

B 400 15% 1600 800 3 weeks frequency reduced to

weeks

half. Fewer man-hours

required.

increased safety stock

from 2.5 to 3.5 weeks'

supply, delivery

2.5 3.5

C 3400 10% 13,600 3,400 frequency is one

weeks weeks

quarter. Drastically

reduced man-hour

requirement.

average inventory value

2.5 1.925

Total 4,000 100% 16,000 5,000 reduced by 23%,

weeks weeks

delivery frequency

reduced by 69%.

Overall reduction of

man-hour requirement.

a)

A class item can be applied much tighter control like JIT daily delivery. If daily delivery with one day

stock is applied, delivery frequency will be 4,000 and average inventory level of A class item will be

1.5 days' supply and total inventory level will be 1.025 weeks' supply, a reduction of inventory by

59%. Total delivery frequency is also reduced to half from 16,000 to 8,200.

Result

By applying weighed control based on ABC classification, required man-hours and inventory level

are drastically reduced.

Alternate way of finding ABC analysis:-

The ABC concept is based on Pareto's law.[9] If too much inventory is kept, the ABC analysis can be

performed on a sample. After obtaining the random sample, the following steps are carried out for

the ABC analysis.

Step 1: Compute the annual usage value for every item in the sample by multiplying the annual

requirements by the cost per unit.

Step 2: Arrange the items in descending order of the usage value calculated above.

Step 3: Make a cumulative total of the number of items and the usage value.

Step 4: Convert the cumulative total of the number of items and usage values into a percentage

of their grand totals.

Step 5: Draw a graph connecting cumulative % items and cumulative % usage value. The graph

is divided approximately into three segments, where the curve sharply changes its shape. This

indicates the three segments A, B and C.

You might also like

- MarCom-WG-194-A FRAMEWORK FOR EARLY CONTRACTOR INVOLVEMENTDocument183 pagesMarCom-WG-194-A FRAMEWORK FOR EARLY CONTRACTOR INVOLVEMENTABID Mohamed100% (2)

- Deacc506 23241 1Document2 pagesDeacc506 23241 1Sants ShadyNo ratings yet

- 1.hair Loss Blueprint ReviewDocument2 pages1.hair Loss Blueprint ReviewJunior GomesNo ratings yet

- Rural Marketing Project ReportDocument35 pagesRural Marketing Project Reportkamdica100% (12)

- What Are The Two Basic Systems of Cost Accounting and Under What Conditions May Each Be Used AdvantageouslyDocument2 pagesWhat Are The Two Basic Systems of Cost Accounting and Under What Conditions May Each Be Used Advantageouslygazer beam100% (1)

- Sample SLA TableDocument6 pagesSample SLA Tableanon_123380852No ratings yet

- Feasibility Study For Assembly of Bicycle Project Proposal Business Plan in Ethiopia. - Haqiqa Investment Consultant in EthiopiaDocument1 pageFeasibility Study For Assembly of Bicycle Project Proposal Business Plan in Ethiopia. - Haqiqa Investment Consultant in EthiopiaSuleman100% (2)

- ABC AnalysisDocument14 pagesABC AnalysisS I D D H A N TNo ratings yet

- Project Management: Audiobook Companion PDFDocument13 pagesProject Management: Audiobook Companion PDFJoão Paulo SouzaNo ratings yet

- CR ModelDocument3 pagesCR ModelscnmsNo ratings yet

- ABC AnalysisDocument7 pagesABC AnalysisKunal ShriyanNo ratings yet

- IOM Group Assignment 267046Document6 pagesIOM Group Assignment 267046BalazsNo ratings yet

- Standard Costing Full ChapterDocument41 pagesStandard Costing Full Chaptergadiyasiddhi0No ratings yet

- Performance Objectives Blending SupervisorDocument5 pagesPerformance Objectives Blending Supervisorkelvinalphonce97No ratings yet

- Unit 2 - Material - Labour PROBLEMSDocument8 pagesUnit 2 - Material - Labour PROBLEMSVismaya SNo ratings yet

- Operations Management: Functions of InventoryDocument12 pagesOperations Management: Functions of InventoryTrường MinhNo ratings yet

- AP TransportationDocument2 pagesAP TransportationZenedel De JesusNo ratings yet

- E Portfolio Rubric 1Document1 pageE Portfolio Rubric 1adingme143No ratings yet

- Gen Physics 1 Midterm Exam - TosDocument1 pageGen Physics 1 Midterm Exam - TosCrisanta GanadoNo ratings yet

- Notes 3 Loads CharacteristicsDocument5 pagesNotes 3 Loads CharacteristicsRandy jr. WacasNo ratings yet

- Supply Chain Map-1Document1 pageSupply Chain Map-1deepak devassiaNo ratings yet

- Ejercicio SC GLASSDocument4 pagesEjercicio SC GLASSvictor vasquezNo ratings yet

- Impact of Food Descriptions On Consumer Purchase IntentionDocument15 pagesImpact of Food Descriptions On Consumer Purchase IntentionNafiza Anzum SaimaNo ratings yet

- Day 8 Inventory ManagementDocument56 pagesDay 8 Inventory Managementv_ratNo ratings yet

- CPI India Flexibility February 2019Document80 pagesCPI India Flexibility February 2019harikveeNo ratings yet

- Role of Cycle Inventory in SCMDocument13 pagesRole of Cycle Inventory in SCMASHARNo ratings yet

- Om l5 Capacity ManagementDocument31 pagesOm l5 Capacity ManagementAthahNo ratings yet

- Unit 4 - POM-IIDocument214 pagesUnit 4 - POM-IIrishavNo ratings yet

- Inventory Management: A Further Look: By: DR Aatma MaharajhDocument35 pagesInventory Management: A Further Look: By: DR Aatma MaharajhAnton WilliamsNo ratings yet

- Week 1 Grade 9Document3 pagesWeek 1 Grade 9Christopher CalimagNo ratings yet

- Red-E-Set: Cost Justification WorksheetDocument2 pagesRed-E-Set: Cost Justification WorksheetXavier J. Aguilar GarcíaNo ratings yet

- Statistics Assignment FinalDocument9 pagesStatistics Assignment Finalrohanfyaz00No ratings yet

- Uber-Exercise v3Document23 pagesUber-Exercise v3Loik-mael NysNo ratings yet

- Angella's Monthly Performance Assessment March 2023Document4 pagesAngella's Monthly Performance Assessment March 2023nansubuga evaNo ratings yet

- Lecture Notes - Mathematical Analysis - DR OtooDocument102 pagesLecture Notes - Mathematical Analysis - DR OtooRichardNo ratings yet

- Cost Behavior Pattern: Engr Irish VillalobosDocument33 pagesCost Behavior Pattern: Engr Irish VillalobosBobbles D LittlelionNo ratings yet

- Scorecard Spreadsheet - 4Document5 pagesScorecard Spreadsheet - 4Raja Mohan MurugiahNo ratings yet

- Case 2Document2 pagesCase 2joshlutocNo ratings yet

- Star Comprehensive Insurance PolicyDocument10 pagesStar Comprehensive Insurance PolicySIMON DSOUZANo ratings yet

- Chapter 4 - Inventory ManagementDocument37 pagesChapter 4 - Inventory ManagementHello WorldNo ratings yet

- Managing Improving Performance - Key Performance IndicatorsDocument4 pagesManaging Improving Performance - Key Performance IndicatorsCosmos AfagachieNo ratings yet

- Cost Reductions Via KanbansDocument2 pagesCost Reductions Via KanbansBrendan CrowleyNo ratings yet

- EnerCon - MTF PresentationDocument20 pagesEnerCon - MTF PresentationiarabuyagmailcomNo ratings yet

- Planning & Managing Inventory in Supply Chain: Cycle Inventory, Safety Inventory, ABC Inventory & Product AvailabilityDocument24 pagesPlanning & Managing Inventory in Supply Chain: Cycle Inventory, Safety Inventory, ABC Inventory & Product AvailabilityAsma ShoaibNo ratings yet

- Basic Questions Standard CostingDocument9 pagesBasic Questions Standard Costinganisasheikh83No ratings yet

- Star Comprehensive Insurance PolicyDocument18 pagesStar Comprehensive Insurance PolicyManikandan RNo ratings yet

- Callueng - Action Plan - For January-June 2022Document7 pagesCallueng - Action Plan - For January-June 2022marjorieeabarraNo ratings yet

- Datos Generales, - 2da ParteDocument2 pagesDatos Generales, - 2da ParteLuis GuamuchNo ratings yet

- Inventory ManagementDocument41 pagesInventory ManagementRishbha patelNo ratings yet

- Indicadores Supply ChainDocument18 pagesIndicadores Supply ChainDavid SantoNo ratings yet

- Lean OverviewDocument29 pagesLean OverviewSudhakar KarnanNo ratings yet

- Layout para Apresentação de KPIDocument13 pagesLayout para Apresentação de KPIHanna Ribeiro Sol MartinsNo ratings yet

- Double Entry SystemDocument5 pagesDouble Entry SystemCurtison ScotlandNo ratings yet

- Accounting and Management DDocument2 pagesAccounting and Management DKarìũki Wa MbìgìNo ratings yet

- Chapter 5 SCMDocument25 pagesChapter 5 SCMFirzam AmirNo ratings yet

- Noc19 Te01 Assignment4Document3 pagesNoc19 Te01 Assignment4Tanishq AwasthiNo ratings yet

- EnMS Webinar 3 Report Energy MetersDocument20 pagesEnMS Webinar 3 Report Energy Metersudula wadugeNo ratings yet

- GiftDocument17 pagesGiftShree PadhiyarNo ratings yet

- Process CostingDocument4 pagesProcess CostingANGELINE ORENSENo ratings yet

- Week 1 Grade 9 1QDocument3 pagesWeek 1 Grade 9 1QChristopher CalimagNo ratings yet

- Presentation Slides For Chapter 15Document15 pagesPresentation Slides For Chapter 15amgad monirNo ratings yet

- Cost Behavior PowerpointDocument50 pagesCost Behavior PowerpointPrecious SanchezNo ratings yet

- CNN 2023-Insight-Dashboard-4Document43 pagesCNN 2023-Insight-Dashboard-4Panji NovantaraNo ratings yet

- ReverseAuctionMethod Part5Document1 pageReverseAuctionMethod Part5arghyaNo ratings yet

- Sourav Rev1 - Part3Document3 pagesSourav Rev1 - Part3arghyaNo ratings yet

- ReverseAuctionMethod Part4Document1 pageReverseAuctionMethod Part4arghyaNo ratings yet

- ReverseAuctionMethod Part3Document1 pageReverseAuctionMethod Part3arghyaNo ratings yet

- ReverseAuctionMethod Part2Document1 pageReverseAuctionMethod Part2arghyaNo ratings yet

- Case-I:: 20. How Do I Get The Payment Receipt For The Payment I Made?Document1 pageCase-I:: 20. How Do I Get The Payment Receipt For The Payment I Made?arghyaNo ratings yet

- ReverseAuctionMethod Part1Document1 pageReverseAuctionMethod Part1arghyaNo ratings yet

- How Estimahow Estimation Is Done: SamplingDocument2 pagesHow Estimahow Estimation Is Done: SamplingarghyaNo ratings yet

- Notice Inviting E-TenderDocument8 pagesNotice Inviting E-TenderarghyaNo ratings yet

- FAQs IOCL Online EMD - Part4Document1 pageFAQs IOCL Online EMD - Part4arghyaNo ratings yet

- Case-III:: 23. Still Having Query? orDocument1 pageCase-III:: 23. Still Having Query? orarghyaNo ratings yet

- FAQs IOCL Online EMD - Part3Document1 pageFAQs IOCL Online EMD - Part3arghyaNo ratings yet

- EstimateDocument1 pageEstimatearghyaNo ratings yet

- Gateway" Where You Will Get The List of Banks in A Drop Down. Select Your Bank. This WillDocument1 pageGateway" Where You Will Get The List of Banks in A Drop Down. Select Your Bank. This WillarghyaNo ratings yet

- Quick Deposits: 1. What Is Online EMD?Document1 pageQuick Deposits: 1. What Is Online EMD?arghyaNo ratings yet

- BuildingDocument2 pagesBuildingarghyaNo ratings yet

- BuildingDocument1 pageBuildingarghyaNo ratings yet

- R Must Be Small Enough That The Current Through D Keeps D in Reverse Breakdown. The Value of ThisDocument2 pagesR Must Be Small Enough That The Current Through D Keeps D in Reverse Breakdown. The Value of ThisarghyaNo ratings yet

- Doping P-N Junction Electrons TunnelDocument3 pagesDoping P-N Junction Electrons TunnelarghyaNo ratings yet

- Practice+Test OverviewDocument2 pagesPractice+Test OverviewJuaymah MarieNo ratings yet

- 2022 Last Minute Tips in Commercial Law by Dean Sergio CenizaDocument19 pages2022 Last Minute Tips in Commercial Law by Dean Sergio CenizaEvita IgotNo ratings yet

- Provisions Relevant To Women R.A. 11054Document23 pagesProvisions Relevant To Women R.A. 11054Kevin LavinaNo ratings yet

- Reviewer in Economic DevelopmentDocument25 pagesReviewer in Economic DevelopmentFeane LamasanNo ratings yet

- Payslip 20230417170111Document2 pagesPayslip 20230417170111Iragavan IndraNo ratings yet

- Realtor%20 Excel%20 SpreadsheetDocument93 pagesRealtor%20 Excel%20 SpreadsheetMuhammad Uzair PanhwarNo ratings yet

- MTH601-MidTerm-solved MCQ Mega File 2Document14 pagesMTH601-MidTerm-solved MCQ Mega File 2kiranNo ratings yet

- Debit Credit Cards DBBLDocument11 pagesDebit Credit Cards DBBLImranNo ratings yet

- Bill To Ship To: Signed by Ramesh Natarajan Date: 2023.06.24 13:35:13 IST Location: ChennaiDocument1 pageBill To Ship To: Signed by Ramesh Natarajan Date: 2023.06.24 13:35:13 IST Location: ChennaiVivek KhannaNo ratings yet

- Atta Chakki PlantDocument77 pagesAtta Chakki PlantarifmukhtarNo ratings yet

- Power BI - Revenue - Industry Agnostic Revenue - Analysis - Step-by-Step GuideDocument15 pagesPower BI - Revenue - Industry Agnostic Revenue - Analysis - Step-by-Step GuideGian Carlo Gonzales AnastacioNo ratings yet

- Barclays US and European Banks Shaken, and StirredDocument25 pagesBarclays US and European Banks Shaken, and StirredS CNo ratings yet

- (DSPACE) CodersTrust - Kaisary Jahan - 111 171 146Document32 pages(DSPACE) CodersTrust - Kaisary Jahan - 111 171 146Selim KhanNo ratings yet

- Hoozan Pirozmand ResumeDocument1 pageHoozan Pirozmand Resumelnvraman4570No ratings yet

- Enterprise AI Transformation in 2024Document128 pagesEnterprise AI Transformation in 2024avinashr139No ratings yet

- ProjectManager Project Closure Template NDDocument11 pagesProjectManager Project Closure Template NDVocika MusixNo ratings yet

- KLM Hazop Rev 3 PDFDocument3 pagesKLM Hazop Rev 3 PDFWisam HusseinNo ratings yet

- CEA 2023 NotificationDocument5 pagesCEA 2023 Notificationrama chandra marndiNo ratings yet

- $15.7 Trillion Game Changer: Total Economic Impact of AI in The Period To 2030Document3 pages$15.7 Trillion Game Changer: Total Economic Impact of AI in The Period To 2030An ĪsNo ratings yet

- A Study On Impact of Green Marketing Tools' On PDFDocument41 pagesA Study On Impact of Green Marketing Tools' On PDFSiva VidhyaNo ratings yet

- Instant Download Calculus Hybrid 10th Edition Larson Test Bank PDF Full ChapterDocument32 pagesInstant Download Calculus Hybrid 10th Edition Larson Test Bank PDF Full ChapterJosephCraiggmax100% (10)

- Ridi Antyaningrum - KapulagaDocument8 pagesRidi Antyaningrum - KapulagaridiantyaningrumNo ratings yet

- The Inox Group Is A WellDocument7 pagesThe Inox Group Is A WellPriyanshu SharmaNo ratings yet

- Cost CH 1Document18 pagesCost CH 1kareem abozeedNo ratings yet

- Assignment/ Tugasan - Integrated Case StudyDocument11 pagesAssignment/ Tugasan - Integrated Case StudySYARAH NURDIYANAH BINTI SAFRUDDIN STUDENTNo ratings yet