Professional Documents

Culture Documents

PM 3 002348 en 01

PM 3 002348 en 01

Uploaded by

wilderness_666Copyright:

Available Formats

You might also like

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Danielson Pre-Observation Form 409Document2 pagesDanielson Pre-Observation Form 409api-28624516150% (2)

- Planetary Geared Machine P420 / 450: Technical CatalogDocument29 pagesPlanetary Geared Machine P420 / 450: Technical CatalogAli DiabNo ratings yet

- Controller With EMIDocument8 pagesController With EMIJms QuinteroNo ratings yet

- HRM301 Case StudyDocument3 pagesHRM301 Case StudyRatul50% (2)

- Orinoco Installation ManualDocument238 pagesOrinoco Installation ManualZoroastro Mo100% (1)

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- Introduction To Machine Learning: Jaime S. CardosoDocument52 pagesIntroduction To Machine Learning: Jaime S. CardosoErica Lopes100% (1)

- MRL E-Pack Assay Instructions For Tests and VerificationsDocument35 pagesMRL E-Pack Assay Instructions For Tests and VerificationsLe Huynh LongNo ratings yet

- ENG LiSA20-Fehlermeldungen R111Document36 pagesENG LiSA20-Fehlermeldungen R111Adarsh Manoharan100% (1)

- Barduva Screw Nut LiftsDocument16 pagesBarduva Screw Nut Liftswilderness_666No ratings yet

- Titan Full CatalogDocument57 pagesTitan Full CatalogTomas Hubner NeumannNo ratings yet

- Schindler 3300Document2 pagesSchindler 3300aadrian_xyzNo ratings yet

- HPV 600 PM Elevator Drive TM7323 - R4Document136 pagesHPV 600 PM Elevator Drive TM7323 - R4asif_9091No ratings yet

- Barduva Screw Nut LiftsDocument16 pagesBarduva Screw Nut Liftswilderness_666No ratings yet

- Bernoulli's PrincipleDocument15 pagesBernoulli's PrincipleDedy KristiantoNo ratings yet

- Advertising StrategyDocument8 pagesAdvertising StrategyRutika AjgaonkarNo ratings yet

- Marketing Report On McDonald'sDocument8 pagesMarketing Report On McDonald'sKristy Leung100% (1)

- CCROPP Best Pract Obesity Prev TMT PDFDocument288 pagesCCROPP Best Pract Obesity Prev TMT PDFharunnuranNo ratings yet

- Monstrous Encyclopedia A-B (Vol. 01) PDFDocument345 pagesMonstrous Encyclopedia A-B (Vol. 01) PDFFernando Luiz100% (8)

- AscensorDocument24 pagesAscensorBlass Hernández Castro100% (1)

- Hydraulic Car Frame WHF35 Direct and IndirectDocument38 pagesHydraulic Car Frame WHF35 Direct and Indirectmario escottoNo ratings yet

- Hydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20Document57 pagesHydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20mario escottoNo ratings yet

- PM 7 000338 en 01Document30 pagesPM 7 000338 en 01Anonymous N57sCcpiNo ratings yet

- RCF Replacement Kit ENGDocument32 pagesRCF Replacement Kit ENGMiguelin1306No ratings yet

- 1117 32 0013 Assembly Manual EngDocument31 pages1117 32 0013 Assembly Manual Engjavier ariasNo ratings yet

- Technical Information and Configuration: Progressive Safety Gear G01Document16 pagesTechnical Information and Configuration: Progressive Safety Gear G01Ali DiabNo ratings yet

- System Galaxy Quick Guide: Configuration and OperationDocument47 pagesSystem Galaxy Quick Guide: Configuration and OperationTushar ImranNo ratings yet

- Traccion EscalerasDocument16 pagesTraccion EscalerasRafael BrunoNo ratings yet

- 104 Door Control Board PM-SSCDocument16 pages104 Door Control Board PM-SSCKevin SilvaNo ratings yet

- 2011 Fermator Catalogue PDFDocument63 pages2011 Fermator Catalogue PDFeliorlopezbNo ratings yet

- 5elevator Installation Manual For Elevator With Machine Room V1.4 - 1Document113 pages5elevator Installation Manual For Elevator With Machine Room V1.4 - 1aneesh tNo ratings yet

- Tabel Status Shanghai ElevDocument4 pagesTabel Status Shanghai ElevAhmed Al-Rabayah0% (1)

- Mel 03 - 08C2 - ElenessaDocument1 pageMel 03 - 08C2 - ElenessaUmer FarooqNo ratings yet

- KONE - Machine Room Type - 1600 KG, Speed 2.5 PDFDocument1 pageKONE - Machine Room Type - 1600 KG, Speed 2.5 PDFNghia100% (1)

- Planos Schindler 2Document8 pagesPlanos Schindler 2equiser6131caNo ratings yet

- ECO Manual (CN En)Document55 pagesECO Manual (CN En)thi tran100% (1)

- JSA07039E-AB FES Maintenance and Operation Manual - PDF Manual EscaleraDocument63 pagesJSA07039E-AB FES Maintenance and Operation Manual - PDF Manual EscaleraEbert mancilla100% (1)

- MUSE ED Elevator: Installation ManualDocument29 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Preventive Maintenance Instruction For V3F16R Drive MODULE KM870400GDocument14 pagesPreventive Maintenance Instruction For V3F16R Drive MODULE KM870400GMarta Silva VenturaNo ratings yet

- (Mech. Safety System) K 602673-07Document38 pages(Mech. Safety System) K 602673-07Ali Diab100% (1)

- 763-000-100 - 2000 C-MOD Cathedral - Installation - E 2011-12-23 - ENGDocument76 pages763-000-100 - 2000 C-MOD Cathedral - Installation - E 2011-12-23 - ENGTaufik Hidayat KurniansyahNo ratings yet

- Schindler 3300 Ca Product Family Brochure PDFDocument32 pagesSchindler 3300 Ca Product Family Brochure PDFjorge barrerNo ratings yet

- Controller With EMIDocument11 pagesController With EMIMohammed Qaid AlathwaryNo ratings yet

- Modu-Tool Basic Operating Instructions PDFDocument2 pagesModu-Tool Basic Operating Instructions PDFAliRouyouNo ratings yet

- ATLAS 2 - 1-PL - DATA-v2.5-2009-EN PDFDocument11 pagesATLAS 2 - 1-PL - DATA-v2.5-2009-EN PDFzajednosexNo ratings yet

- Ba WSG-S1.2-3 v17 ENDocument94 pagesBa WSG-S1.2-3 v17 ENBrahim Chergui100% (1)

- 200cory Board DescriptionDocument2 pages200cory Board DescriptionChang ChangNo ratings yet

- Atlas Basic SP Instalation Manual enDocument39 pagesAtlas Basic SP Instalation Manual enISHAQNo ratings yet

- Hh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdDocument3 pagesHh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdRebecca DangNo ratings yet

- Schindler Drive Chain MaintenanceDocument9 pagesSchindler Drive Chain MaintenanceKevin aliNo ratings yet

- On Site Wiring, Travelling CableDocument3 pagesOn Site Wiring, Travelling CableAli DiabNo ratings yet

- Hoisting Motor FMP 160: Motors For Planetary GearsDocument8 pagesHoisting Motor FMP 160: Motors For Planetary GearsAli DiabNo ratings yet

- MCTC Ard C English 1Document11 pagesMCTC Ard C English 1Khaled ZakariaNo ratings yet

- Fermator PDFDocument2 pagesFermator PDFDavidNo ratings yet

- Arcode Geared Sp-16 Cpc-T.enDocument38 pagesArcode Geared Sp-16 Cpc-T.enAbdallh YassenNo ratings yet

- Tool Velino FT853Document12 pagesTool Velino FT853Polinho DonacimentoNo ratings yet

- 6300 Safety Componants Maint'Document14 pages6300 Safety Componants Maint'Pio Rodolfo100% (1)

- Gen2 CNDocument17 pagesGen2 CNMohammad Sami50% (2)

- F21aau4 8 PDFDocument34 pagesF21aau4 8 PDFjhfbty100% (1)

- TAC32 1 Op Ptas 6300pa3 y Pa4 Parcial PDFDocument14 pagesTAC32 1 Op Ptas 6300pa3 y Pa4 Parcial PDFViệt Thảo TrầnNo ratings yet

- DC81091Q00 Program Manual EngDocument52 pagesDC81091Q00 Program Manual EngJose Vicente Alvarez FernándezNo ratings yet

- 10 Aaa21700xDocument17 pages10 Aaa21700xasdf100% (1)

- Eco Electrification & Controller Diagrams PDFDocument94 pagesEco Electrification & Controller Diagrams PDFMiguel AngelNo ratings yet

- Schindler Modular Gearless Machines FMR355Document2 pagesSchindler Modular Gearless Machines FMR355Kar Keong LewNo ratings yet

- Prepared Oyama (July 2012) Rev. WIG-21 Checked T.Natsume Checked K.HaraDocument18 pagesPrepared Oyama (July 2012) Rev. WIG-21 Checked T.Natsume Checked K.HaraEtienneNo ratings yet

- Manual de Instalacion Ascensor Sanyo 1Document30 pagesManual de Instalacion Ascensor Sanyo 1Reina Yadyra Chasi CansingNo ratings yet

- Dienes Standard Knife Programme - Status 01 2022 - e 1Document16 pagesDienes Standard Knife Programme - Status 01 2022 - e 1wilderness_666No ratings yet

- Dimensionamento Depolveratore A Ciclone Portata Volumetrica (m3/h)Document2 pagesDimensionamento Depolveratore A Ciclone Portata Volumetrica (m3/h)wilderness_666No ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Molle A Scatto E Perni: Spring Latches and Ball StudsDocument1 pageMolle A Scatto E Perni: Spring Latches and Ball Studswilderness_666No ratings yet

- Correcting Elastic FEA Results For Local PlasticityDocument6 pagesCorrecting Elastic FEA Results For Local Plasticitywilderness_666No ratings yet

- 121 - NEXEN, Assembly Mag, Ballscrew Art-1Document4 pages121 - NEXEN, Assembly Mag, Ballscrew Art-1wilderness_666No ratings yet

- The Specter of The Giant Three: L B & S HDocument21 pagesThe Specter of The Giant Three: L B & S Hwilderness_666No ratings yet

- Scheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317Document1 pageScheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317wilderness_666No ratings yet

- Machine Design: Search Log in RegisterDocument8 pagesMachine Design: Search Log in Registerwilderness_666No ratings yet

- Flue Gas Cleaning PDFDocument3 pagesFlue Gas Cleaning PDFwilderness_666No ratings yet

- Piastrine UPNDocument10 pagesPiastrine UPNwilderness_666No ratings yet

- Understanding ConnectorsDocument16 pagesUnderstanding Connectorswilderness_666No ratings yet

- Design and Size DuctworkDocument6 pagesDesign and Size Ductworkwilderness_666No ratings yet

- Moments Shears and Reactions For Continuous Highway Bridges PDFDocument91 pagesMoments Shears and Reactions For Continuous Highway Bridges PDFwilderness_666No ratings yet

- Push Pull 1 PDFDocument3 pagesPush Pull 1 PDFwilderness_666No ratings yet

- Aalborg Universitet: Heiselberg, Per Kvols Topp, ClausDocument17 pagesAalborg Universitet: Heiselberg, Per Kvols Topp, Clauswilderness_666No ratings yet

- 41 - Design News RPS Article PDFDocument1 page41 - Design News RPS Article PDFwilderness_666No ratings yet

- How To Determine The Best Heat Treatment For Your PartsDocument10 pagesHow To Determine The Best Heat Treatment For Your Partswilderness_666No ratings yet

- 1.050 - Content Overview: Beam Elasticity - How To Sketch The Solution Another Example Transversal Shear in BeamsDocument4 pages1.050 - Content Overview: Beam Elasticity - How To Sketch The Solution Another Example Transversal Shear in Beamswilderness_666No ratings yet

- Research ProposalDocument4 pagesResearch ProposalMax Odeh100% (1)

- One Nation, One Education NEP Act: The New Era of Indian Education SystemDocument7 pagesOne Nation, One Education NEP Act: The New Era of Indian Education SystemLex OraculiNo ratings yet

- Module 4D Concepts On Growth and DevelopmentDocument118 pagesModule 4D Concepts On Growth and DevelopmentKristil ChavezNo ratings yet

- Film Study Worksheet Documentary Logos Pathos EthosDocument2 pagesFilm Study Worksheet Documentary Logos Pathos EthosGerardo E. Lopez MoralesNo ratings yet

- Daftar Pustaka: (Medline)Document14 pagesDaftar Pustaka: (Medline)nurfitriaNo ratings yet

- Analog and Digital Signal Processing by Ambardar (400 821)Document422 pagesAnalog and Digital Signal Processing by Ambardar (400 821)William's Limonchi Sandoval100% (1)

- Sapthami (Research Methodology)Document29 pagesSapthami (Research Methodology)sapthamiNo ratings yet

- Past Year Bio320 Plantae Week 10Document6 pagesPast Year Bio320 Plantae Week 10ayunna ayunniNo ratings yet

- The Palette Magazine 2011Document56 pagesThe Palette Magazine 2011101ThingsToDoNo ratings yet

- Sämäyik: in EnglishDocument30 pagesSämäyik: in EnglishShish Shah100% (1)

- Using Equations in Solving Age Problem Using Equations in Solving Age ProblemDocument18 pagesUsing Equations in Solving Age Problem Using Equations in Solving Age ProblemFatima UliNo ratings yet

- How To Write A Geotechnical Investigation Report - CivilblogDocument12 pagesHow To Write A Geotechnical Investigation Report - CivilblogOladunni AfolabiNo ratings yet

- Question Answers BilalDocument32 pagesQuestion Answers BilalMateen YousufNo ratings yet

- DLL 9 3rd w1Document4 pagesDLL 9 3rd w1Ramon FrejasNo ratings yet

- Exercise 2.6Document4 pagesExercise 2.6mohitgaba19No ratings yet

- 2nd Draft ULABDocument25 pages2nd Draft ULABKhairol NizamNo ratings yet

- RadioLink Theor enDocument29 pagesRadioLink Theor enNitish RoyNo ratings yet

- Web Hosting Server DetailsDocument11 pagesWeb Hosting Server DetailsTarun VBRSITNo ratings yet

- December 06Document36 pagesDecember 06Quy DangNo ratings yet

- Tpa Task 2 Final - ShafferDocument3 pagesTpa Task 2 Final - Shafferapi-608197412No ratings yet

- Synthesis Paper: Communities by Benedict Anderson, "I Am One of The Mountain People" by Macario TiuDocument2 pagesSynthesis Paper: Communities by Benedict Anderson, "I Am One of The Mountain People" by Macario TiuRaphaella Marie GupiteoNo ratings yet

- Line Dance ModuleDocument34 pagesLine Dance ModuleKim Ignatius GianganNo ratings yet

PM 3 002348 en 01

PM 3 002348 en 01

Uploaded by

wilderness_666Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PM 3 002348 en 01

PM 3 002348 en 01

Uploaded by

wilderness_666Copyright:

Available Formats

ID Unique PM.1.000255.

EN

Blatt/sheet D384MGB.000

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version C-22.07.2015

Geprüft/approved WAT/MZE

Operating instructions

*D384MGB$111*

Car Frame Series WCF Underslung 2:1 Suspension

D384MGB 07.2015

WITTUR Austira GmbH

Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-232

http://www.wittur.com • E-Mail: info.at@wittur.com

No part of this publication may be reproduced or We reserve the right to make alterations with respect

translated, even in part, without prior written to the specifications and figures in this manual.

permission from WITTUR Austria GmbH.

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.001

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

Contents Page

1 General information prior to installation

1.1 Description and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.002

1.2 Liability and guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.002

1.3 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.003

1.4 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.003

1.5 Safety gear name plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.004

1.6 Content of supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.005

2 Installation

2.1 Placing the bottom cross beam between the rails . . . . . . . . . . . . . . . . . . . . . . .D384MGB.007

2.2 Securing the uprights to lower cross beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.008

2.3 Installing Crosshead beam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.009

2.4 Installing Platform support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.010

2.5 Ring-, Balancing beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.011

2.6 Installing the diagonal rods or platform support . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.012

2.7 Travelling cable hanger and compensation chain fixings . . . . . . . . . . . . . . . . . .D384MGB.013

2.8 Load weighing device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.014

2.9 Securing the pulley beam below lower cross beam . . . . . . . . . . . . . . . . . . . . . .D384MGB.015

2.10Car installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.016

2.11Roping of the car frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.018

2.12Overspeed governor rope fixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.019

2.13Balancing of the car . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.020

2.14Adjustment of safety gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.021

2.14.1 Electrical installation of the safety gear switch . . . . . . . . . . . . . . . . . . .D384MGB.022

3 Function testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.023

4 Maintenance, inspection and repair

4.1 Maintenance and inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.024

4.2 Carrying out repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.025

4.2.1 Changing the guides/inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.025

4.2.2 Changing the rope pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.025

4.3 Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D384MGB.026

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.002

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

1 General information prior to installation

1.1 Description and functions The built-in safety devices are set, synchronized

and lead sealed ex-works, according to the order.

The car frame series WCF is a car frame used for For reasons of safety, it is forbidden to readjust

passenger-, passenger-goods and freight elevators. these settings once they have been made.

Because of its modularity structure and its variety

of different (optional) equipment (safety gears,

rope suspensions, ...) covers the WCF car frame a

wide range of use. 1.2 Liability and guarantee

The WCF Series can be also equipped with a brak- This instruction handbook is written for people

ing system, which safeguards against uncontrolled who are familiar with lift servicing and installa-

lift car movement in up direction. A non-direc- tion. Sufficient knowledge of lifts is essential.

tional speed governor with corresponding tension-

ing weight must be fitted if this braking system is WITTUR accept no responsibility for damage

used. caused by improper handling, or for damage

caused as a result of actions other than those stat-

The car frame operating range is defined as fol- ed in these operating instructions.

lows:

The WITTUR guarantee may be voided if parts

WCF10: other than those described in these instructions

• All up load ≤ 3000 kg (Q ≤ 1000 kg) are installed.

• Car depth ≤ 2100 mm

• Car width ≤ 2250 mm Unless stated otherwise, the following are not per-

WCF16: missible due to technical safety reasons:

• All up load ≤ 5000 kg (Q ≤ 1600 kg) • The use of safety gear devices or brake com-

• Car depth ≤ 2750 mm ponents other than those installed

• Car width ≤ 2650 mm • Carrying out modifications, of any kind, on

General: brake components

• Safety gear devices: Roller type SG • Destroying of seals

Progressive type SG • Frame modification

Bi-directional SG • Modification of the actuating mechanism

• Guide: Sliding guide shoe • Readjustment of settings have been made ex-

Roller guide shoe works

• Suspension: 2:1 with 2 pulleys below car • Carrying out faulty or improper maintenance,

Further options: maintenance or inspection checks

• Load weighing system • using unsuitable accessories, spare parts or

• Ring-, Balancing beams operating material which has neither been re-

• Compensation chain hanger leased by the WITTUR Company nor consists of

• Travelling cable hanger original WITTUR spare parts

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.003

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

1.3 Safety precautions Before starting installation work:

WITTUR machine installation or repair engineers Only properly trained personnel may carry

are chiefly responsible for the safe operation of out work, or be allowed access to the

machinery. installation site.

It is essential to comply with and keep abreast of - Attach safety devices to guard against falling

all safety rules and legal obligations in order to (platform or harnesses)

avoid personal / product damage during installa- - Cover any floor openings

tion, maintenance and repair work. - Secure installation tools or objects against

accidental falling

Important safety advice and danger warnings are - Lift shaft openings should be cordoned off

emphasised with the following symbols: and suitable warning signs should be erected

when working in shaft openings

General danger warning - Work involving electrical equipment should

only be carried out by an electrical engineer or

qualified personnel.

High danger risk warning (i.e. crushing 1.4 Preparation

edge, cutting edge etc.).

Before beginning installation work it is in your

own interest to ascertain the constructional and

spatial conditions. Where (workshop or on site)

Risk of damage to machinery parts (i.e. due and when which installation operations can or

to incorrect installation, or such like). must be carried out. It is recommended therefore,

taking into account all the given circumstances, to

plan the various operational sequences in advance,

rather than carrying them out prematurely and in

Important information sign an unconsidered manner.

On receipt of the delivery, the goods or compo-

nents should be checked for correctness and com-

pleteness with the order sheet

These operating instructions belong with the The details on the name plates should be com-

whole installation and must be kept in a safe place pared with the order sheet and also check:

at all times (i.e. drive room). - that the factory and order number correspond

- the rail head width and model

The proper assembly and installation of WITTUR - the total load (G)

car frames requires correspondingly well trained - the tripping speed

fitting engineers. The responsibility of training lies - for 2:1 suspension: the rope pulley diameter,

with the company appointed to carry out the the number of rope grooves and rope groove

work. diameter are suited to the ropes

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.004

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

1.5 Safety gear name plate

The safety gear device identification indicators are

located on the side of the safety block. These con-

sist of a name plate and a identification sticker.

Date of manufacture

Type test designation

and CE-label

Order number

(refer to delivery or order sheet)

Typ term

Mass to be gripped

Serial number

Fmax = (kg,lb)

Tripping speed v1 = (m/s,fpm)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.005

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

1.6 Content of supply

Blatt/sheet D384MGB.000 Blatt/sheet D7A4MGB.000

Car Frame Series WCF Datum/date 16.01.2002

Progr. type safety gear SGB01, SGB02, Datum/date 24.08.2001 Car type roller guides RG200 and RG300 Blatt/sheet D623MGB.000

Electronic load weighing Blatt/sheet D963MGB.000

Datum/date 12.11.2001 Datum/date 28.01.2002

Underslung Suspension 2:1 Stand/version 16.01.2002 SGB03, SGB05 Stand/version 24.08.2001 Stand/version 12.11.2001 device WLWD03 & WLWD06 Stand/version 28.01.2002

Geprüft/approved WAT/FLE Geprüft/approved WAT/FLE

Operating instructions Operating instructions Operating instructions Geprüft/approved BA/AD

Operating instructions

Geprüft/approved WAT/FLE

After delivery, check the lift car frame for damage Car Frame Series WCF Underslung Suspension 2:1 Progr. type safety gear

SGB01, SGB02, SGB03, SGB05

Car type roller guides RG200 and RG300 Electronic load weighing device

and for full delivery of parts. The content of sup-

D7A4MGB 02.2002

D384MGB 01.2002

11.2001

01.2002

ply covers:

D623MGB

D963MGB

WITTUR GmbH WITTUR GmbH WITTUR GmbH WITTUR GmbH

- Car frame operating instructions manual

Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Sowitschstrasse 1 • A-3270 Scheibbs, Austria Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-32 Sowitschstraße1, • A-3270 Scheibbs, Austria Sowitschstrasse 1 • A-3270 Scheibbs, Austria

Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-32 Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7483/42542-32 Tel. +43 (0) 7482/42542-0 • Fax +43 (0) 7482/42542-32

http://www.wittur.at • E-Mail: info@wittur.at

http://www.wittur.at • E-Mail: info@wittur.at http://www.wittur.at • E-Mail: info@wittur.at http://www.wittur.at • E-Mail: info@wittur.at

No part of this publication may be reproduced or We reserve the right to make alterations with respect Nachdruck, Übersetzung und Vervielfältigung in Änderungen gegenüber den in dieser Betriebsanlei- No part of this publication may be reproduced or We reserve the right to make alterations with respect No part of this publication may be reproduced or We reserve the right to make alterations with respect

translated, even in part, without prior written permis- to the specifications and figures in this manual. jeglicher Form - auch auszugsweise - bedürfen der tung aufgeführten Angaben und Abbildungen behal- translated, even in part, without prior written permis- to the specifications and figures in this manual. translated, even in part, without prior written permis- to the specifications and figures in this manual.

sion from WITTUR GmbH. schriftlichen Genehmigung der WITTUR AG. ten wir uns vor. sion from WITTUR GmbH. sion from WITTUR GmbH.

Änderungen vorbehalten! Subject to change without notice! Änderungen vorbehalten! Subject to change without notice!

Änderungen vorbehalten! Subject to change without notice! Änderungen vorbehalten! Subject to change without notice!

THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY

THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY THE LMC LIFTCOMPONENTS MANUFACTURING AND COMMERCE COMPANY

- Safety gear operating instructions manual

- Guide shoe operating instructions manual

- Load weighing device operating instr. man.

- Crosshead beam (pre-assembled)

- Bottom Cross beam incl. safety

gear housing

and synchronization

(pre-assembled)

- Skewed pulley beam with

suspension 2:1 underslung

skewed (US)

- Uprights

- 4 Diagonals

or 2 Diagonals

and 2 platform support

- Platform support

(incl. lower car fixing material)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.006

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

Accessories:

- Guide shoes or

- Upper car fixing (incl. isolation buffer)

- Screw packages

Optional parts:

- Load weighing device

- Ring/balancing beams (incl. balancing

weights)

- Compensation chain fixing

- Travelling cable hanger

- EBRA

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.007

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2 Installation

Car frame installation can either be carried tion of guide shoes.

out at the bottom of the lift shaft or on a

stable installation platform in the lift During installation the frame must be sup-

shaft. Also guide clamps could be used ported so that it does not rest on the

which can take the total load of frame and guides.

car!

The guide rails should have been already

(1)

properly set. The distance between the

guide rails should be checked before

installing the car frame.

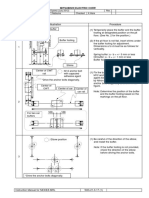

2.1 Placing the bottom cross beam

between the rails

The bottom cross beam is delivered pre-assembled.

It contains the safety gear, the synchronization (2-3)

and the buffer plate. The safety gear device is

bolted and synchronizedand.

Note the correct position of the cross beam

and of the skewed pulley beam in relation-

ship to the governor rope position (check

layout drawing).

Procedure:

(4)

(1) Place skewed pulley beam on bottom of the

shaft (only needed with suspension 2:1 under-

slung skewed car frame)

(2) Set cross beam at an angle (see Fig.)

(3) Clip one safety gear head onto the rail

(4) Turn Cross beam back into the horizontal posi-

tion, pushing the second safety gear device

onto the rail

(5) Adjust the cross beam in the middle of the

guide rails (safety gear gripping wedge must

(5)

overlap guide rail blade) (6)

Check that the beam is horizontal in the WRG150 Screw pack. 600213G..

lateral direction. WRG200, WRG300 Screw pack. SLG1 Screw package

(6) Fix the guide shoe to the safety gear housing. 600214G.. 600210G..

Adjust RGF125 (0,3 to 1mm clearance). For RGF125 Screw pack 900635G.. SLG2/3/4 Screw package

setting of the rest refer to operating instruc- 600211G..

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.008

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

(7) Lift OSG-lever by hand and (7) (8)

(8) ... secure it with a rope or wire around nearest

guide fixing

2.2 Securing the uprights to lower

cross beam

(1) Fit the aligning bolts in the threaded holes at

top of the uprights (1,4)

(2) Lift the uprights using the hole at the top and

a shackle

(3) Loosely bolt the uprights to the lower beam Aligning bolts

(4) Adjust the uprights in plumb and in centre to

Centre marking

the guide rails using the aligning bolts

Ensure aligning bolts are wound out to

M10x100 (2x)

allow easy installation.

Take care of tightening torque

Screw M16: 195Nm

M10x50

(2)

(5) Before tightening the screw joints, pack out

the spaces between upright and cross beam

with the shims provided

(4)

Make sure you use the correct bolt length.

Too long bolts can interfere with the safe-

ty gear.

Optional: Screw package

(5) Field package 600238G..

600241G..

Shim

(3)

M16x45 (WCF10)

M16x50 (WCF16)

M16x55 (WCF25)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.009

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.3 Installing Crosshead beam

The crosshead beam is delivered pre-assembled. It (3) Fit the guide shoe (optional EBRA) to the

contains the beams and adapter plates for the adapter plate (for setting refer to operating

guide shoes. instruction manuals of guide shoes)

WRG150 Screw pack 600213G..

(1) Lift in the crosshead beam into the uprights WRG200, WRG300 Screw pack 600214G..

(2) Fit the beam to the upright. If nacessary add RGF125 Screw pack 900635G..

shims between beam and upright. EBRA 602010G..

Take care of tightening torque

Screw M16: 195Nm

(3)

Remove lock-pin!

Restraining plate:

Rivet when installing (holes in

adapter plate and beam had to

be drilled at building site)

SLG1 Screw package

600210G..

SLG2, SLG3, SLG4 Screw package

600211G..

In case of car frame is used in seismic risk

(1)

zones, additional restraining plates (30mm

thick plate) will be placed between guide

shoe and adapter plate.

Optional:

(2) Screw package

(2)

Field package

600238G.. 600241G..

M16x45 (WCF10)

M16x50 (WCF16) Shim

M16x55 (WCF25)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.010

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

(4) Remove the aligning bolts (4)

2.4 Installing Platform support

The platform support is delivered pre-assembled. It

contains a beam including isolation springs and

car fixing plates. (1)

(1) Fit the platform support to the lower cross

beam (if ring beams are delivered, do not

tighten the screw joint) Shim

(2) Check that the profiles are horizontal. If nec-

essary, add shims between profile and beam. (2)

Take care of tightening torque

Screw M12: 80Nm

If asymetral platform is used,

the marking hole must be on the

main door side (see layout drawing).

Underslung parallel

(3) Remove the lock screws

(UP) only

(3)

Marcing hole

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.011

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.5 Ring-, Balancing beams

(optional)

Car frame with underslung skewed sus-

pension (US) has no ring beam.

(1) Remove the nuts and washers at the end of

the platform support beams

(2) Install the ring beams

(tighten the screw joint slightly)

Note position of balancing beam

(see layout drawing)

(3) Check the square by cross measurement

and adjust as necessary

(4) Tighten all platform support screw joints (1-2)

Take care of tightening torque

Screw M10: 46Nm

Screw M12: 80Nm

M10x20

(1)

(3)

M1=M2 +/-1mm

M2

M1

M12

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.012

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.6 Installing the diagonal rods (1-3) (1,3)

or Platform support (4)

(1) Bolt the fixing brackets to the uprights

Choice of fixing holes is depending on the

Optional:

isolation profile length.

Field package

M16x40 600241G..

(2) Bolt the adapters at both ends of the

platform support beams, if no ring

beams are fitted

Car frame with underslung skewed

suspension (US) has no ring beam.

(3) Install the adjustable diagonal rods Screw package

900913G09/10

Do not tighten the 4 nuts at the

lower ends of the support.

(4) Install the platform support (if ordered)

M12x40 / M12x50 (3)

(4) Screw package

900907G..

(2)

M12

Take care of tightening torque

Screw M10: 46Nm

M10x20

Screw M12: 80Nm

Screw M16: 195Nm

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.013

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.7 Travelling cable hanger and com-

pensation chain fixings

Before installing the car fix the cable

hanger and chain fixings to lower cross

beam (for position refer to layout draw-

ing).

Take care of tightening torque

Screw M12: 80Nm

Travelling cable hanger types:

Screw package

611604G..

Compensation chain

fixing types:

Screw package

611604G..

Take care of different fixing

methodes for different compen-

sation chain types.

Chain type: Other Chain

WF10, QL10 or types

similar

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.014

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.8 Load weighing device

For setup of the load weighing device WLWD refer

to the operating instruction manual.

(1) Fit the load weighing device as low as possible

in the lower cross beams

(2) If necessary add shims between beams and

fixing channel.

Do not undo the cable ties at this stage.

(1,2) Cable tie

Shim

M12x40

120+/-2mm

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.015

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.9 Securing the pulley beam below

lower cross beam

A separate pulley beam is only delivered with

underslung skewed suspension.

(1) Lift the pulley beam up under the lower cross

beam

(2) Position the 4 bases on top of the pulley beam

(3) Bolt the both beams together and fit the lock

pins

Take care of tightening torque (1)

Screw M16: 195Nm

(2,3)

Lock pin

M16x120

Base

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.016

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.10 Car installation Car floor fixing bolt

(1) Wind down the locking bolt

(2)

(2) Remove the car floor fixing bolts at the end of

the platform support beams

(3) Fit the car floor to the car frame (refer to the

operating instruction manual of car) (1)

(4) Adjust the car floor by using the centre limi-

tation device on the bottom of the platform

support beam Locking bolt

(5) Lock the floor by winding up the locking bolt

slightly against the fixing bolts (lock with fix-

ing nut)

Do not overtighten

(3-4)

(6) After car installation

adjust the locking bolt

centre limitation

device

(5)

(4)

14mm

Locking bolt

(6)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.017

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

(7) Fix the upper isolation to the car roof channel

(handtighten T-bolts)

(8) Push the isolation tight against the upright

(9) Tighten the T-bolts

Take care of tightening torque

Screw M10: 46Nm

T-bolt M10

(7-10)

WCF10 WCF16, WCF25

(10)Tighten the isolation studs slightly

Tighten the isolation studs so, that the

bracket can slide on the upright.

CF10

CF16, CF25

Isolation stud

(11)Tighten the diagonal rod nuts

(11)

Hand tighten the upper nuts and then

lock the lower nuts.

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.018

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.11 Roping of the car frame

(1) Remove the rope guards

(1)

Underslung skewed suspension (2)

(1) Buffer stroke

Underslung parallel suspension plate

(2) Pass the rope round the diverter pulleys under Ensure 3mm gap between 3mm

the car rope guard and rope.

When used number of ropes is less than

the number of grooves on the rope pulley,

the ropes should be put into the grooves

counting from inside (car frame) to out-

wards. (3)

(3) Re-fit the rope guards

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.019

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.12 Overspeed governor rope fixing

(1) Fix the rope fastener to the safety gear lever

(2) Install the overspeed governor rope OSG rope

others

Safety gear

lever

(1)

Package 392772G.. (2)

According ASME-A17.1

Rubber square

washer

(1)

Package 604139G01

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.020

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.13 Balancing of the car

(1) Set the L-profile in upper position with slight-

ly tightened screw joints

(2) Load the balancing beam with the weights L-profile

Rubber stripe

(3) Place rubber stripes on top of the weight

(4) Lower the L-profile (1-4)

(5) Fix the locking pieces

(6) Lock down the L-profile using lock screws Screw joint

(7) Tighten the screw joints M10x30

Take care of tightening torque (7) Weight

Screw M10: 46Nm

Platform support beam

Diagonals

Screw package

Balancing beam

615803G04

(5-6)

Lock screw M10x30

Weight

Locking piece

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.021

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.14 Adjustment of safety gear

The safety gear device (safety gear, synchroniza- (4) Adjust the safety gear in accordance with the

tion, safety gear contact) is delivered pre-adjusted. operating instruction manual of the corre-

Therefore no additional assembling of the safety sponding safety gear

gear device is needed.

Take care of required safety gear running

(1) Operate the safety gear lever by hand and clearance (referring also to the type of

check that both safety gears begin gripping at guide shoe used)

the same time

(2) ... If not, adjust the length of the

synchronization rod by using the

adjustment nut

(3) Check the safety gear contact

function - adjust if necessary

The contact must brake just

before safety gear gripping!

Safety gear lever

Contact

Safety gear

Synchronization rod

Synchronization rod

Adjustment nut

down safety down safety

gear gear

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.022

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

2.14.1 Electrical installation of the safety gear

switch Take note of the following when laying the

connection cable:

Work involving electrical equipment

should only be carried out by an electrical • that the single polarity cables have dou-

fitter or qualified personnel. ble insulation

• the use and laying of cables is governed

Before carrying out work, switch off all by the EMC

voltage to installation equipment.

The safety gear contact opens the lift in-

stallation’s remotely controlled safety cir-

cuit.

(1) Connect the safety gear contact

(2) Test the safety gear switch function

(3) Adjust the switch horizontally on its fixing

bracket

Adjusting dimension: 3-5 mm from the

guard peak

The contact must brake just before safety

gear gripping!

Safety gear switch (self reset type)

(1-3)

- use category: AC 15, A300

Ue/Ie 240V (3A) Safety gear switch

- thermal current: Ithe = 10A

- insulation voltage: Ui = 250V AC

- protection type: IP 43 11 12

- approved in accordance: VDE 0470 23 24

IEC/EN 60947-5-1

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.023

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

3 Function testing

Operational reliability of the installation is assured, Static & dynamic function testing

assuming that all guide lines were adhered to dur-

ing proper installation. The quality and function of The procedures differ according to the safety gear

individual components are subject to thorough device. Refer to the operating instructions of the

inspection and is checked before dispatch from relevant safety device.

our works. Once installation fitting is complete,

the lift car frame system should undergo an oper- Examine the lift car frame for changes

ational test before commissioning or before possi- after carrying out the safety gear test:

ble inspection from a technical institute. - deformation of components

- that the screws are firmly in place

First test run after installation - signs of damage or wear on the rope

pulleys, guides and suspension points

Before the first test run:

Clean the guide rails! Nobody should be in the lift car when car-

rying out test runs or functions tests!

Clear all people and objects from the lift

shaft before commencing the test run

Risk of crushing injuries!

The entire lift travel path should be slowly trav-

elled (in inspection mode) before the functions

tests. Attention should be paid to the clearance of

all fastened parts, especially with regards to the

guide brackets/safety gear devices. Find and

remove any protruding bolts or other dangerous

restrictions well in advance.

Safety clearance inspections at the bottom of the

shaft and shaft head (observe the applicable regu-

lations/guidelines):

- Check the following distances between the

shaft floor, after descending the shaft pas-

sage:

- Distance between guide - floor

- Distance between cross beam - floor

- Check the following distances to the shaft

ceiling, on completion of ascension of the lift

shaft:

- Distance between guide - ceiling

- Distance between rope pulleys - ceiling

- Distance between cross beam - ceiling

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.024

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

4 Maintenance, inspection and repair

4.1 Maintenance and inspection

The WITTUR lift car frame requires little servicing. The lift installation must be immediately

taken out of use should any damage or

Inspection checks must be carried out at regular irregularities to the lift car frame arise

intervals (minimum twice a year with each service) which could possibly impair operational

to guarantee safe operation. Alterations, damage safety.

or other irregularities should be reported, and

repaired if possible. Frequent servicing and control Please contact us at WITTUR if you have

checks not only make operation of the installation any problems or queries.

safer, but also ensure long and reliable service life.

Maintenance work should be expertly car-

It is recommended that control checks and servic- ried out with utmost care in order to guar-

ing be carried out before legally prescribed func- antee safe installation operation.

tional tests (e.g. before TÜV tests).

WITTUR car frame maintenance and inspection check list

General: Safety gear devices:

- Visual inspection for general irregularities (i.e. - Check the operation of the safety gear device

dirt build up, corrosion, deformation, fractur- at every service call. Refer to the operating

ing etc.) instructions of the installed safety device.

- Check the screw connections - The surface of the wedge area has to be clean.

Wedge and roller must not be cracked.

- Check the overspeed governor rope fixing

Lubricators:

- Replenish Rope pulley:

- Check the felt inserts for damage, replace if

necessary - Signs of wear on the rope pulley; replace if

necessary

- Check the condition of the rope pulley bear-

Guides: ings by listening to the running noise (refer to

the Chapter “Carrying out repairs”)

- Check inserts or rollers at every service call.

Replace the sliding inlays by new one if the

running clearance is more then 2mm (refer to Platform support (isolation beams):

the Chapter “Carrying out repairs”)

- Check visually that the platform support is not

twisted (release diagonal rods to untwist)

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.025

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

4.2 Carrying out repairs

The following repairs should be carried out on site

As a rule, damage or deformation of a car by qualified fitters/service personnel:

frame (i.e. as result of bending or heating)

cannot be repaired or straightened. The • The sanding down of rust (i.e. caused as result

damaged parts should be replaced. Only of damage to the undercoat) and application

use WITTUR spare parts. of a suitable paint sealant.

• Changing the guides / guide shoe inserts

Repairs should be expertly carried out with • Changing the rope pulleys

utmost care in order to guarantee safe

installation operation. Please contact WITTUR if for any reason

something is unclear, or you encounter

Follow all the local safety instructions dur- damage that cannot be repaired with the

ing the maintenance work. help of these instructions.

4.2.1 Changing the guides/inserts 4.2.2 Changing the rope pulley

The components for the guides which are subject- The rope pulleys can be delivered individually as

to-wear (sliding guides: inserts; roller guides: spare parts (refer to “Spare parts” chapter).

rollers) can be delivered individually as spare parts:

(see Chapter “Spare parts”). Procedures for changing a rope pulley:

The distance (play) to the rails (distance • Lower the lift car onto its contact buffer

between guides) must be readjusted after • Safeguard the counterweight against falling

replacement of the inserts and remount- • Release the ropes

ing. • Unscrew the complete rope pulley / axle / axle

bracket unit

• Dismantle rope pulley / axle / axle bracket unit

• Replace the rope pulley, and remount the parts

following the instructions above in reverse

order

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.026

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

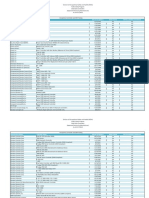

4.3 Spare parts list

Tab.1: Spare parts WCF Underslung 2:1 suspension

Component Type Spare part Number... Art. No.

Sliding guide shoe SLG1 Guide shoe rail width 9 mm 1 92410G09

10 mm 1 92410G10

16 mm 1 92410G16

SLG1A Guide shoe rail width 9 mm 1 92410G09A

10 mm 1 92410G10A

16 mm 1 92410G16A

SLG2 Guide shoe rail width 10 mm 1 92510G10

16 mm 1 92510G16

19 mm 1 92510G19

SLG2A Guide shoe rail width 10 mm 1 92510G10A

16 mm 1 92510G16A

19 mm 1 92510G19A

SLG3 Guide shoe rail width 16 mm 1 430365G16

19 mm 1 430365G19

SLG3A Guide shoe rail width 16 mm 1 430365G16A

19 mm 1 430365G19A

SLG9 Guide shoe rail width 9 mm 1 580220G09

10 mm 1 580220G10

16 mm 1 580220G16

19 mm 1 580220G19

Guide rail lubricator rail width 9 mm 1 86375G09

10 mm 1 86375G10

16 mm 1 86375G16

19 mm 1 86375G19

Sliding inlay (SLG1, SLG2, SLG3*) 9 mm 1 86854H09

10 mm 1 86854H10

Note: Fixing material to be ordered separat 16 mm 1 86854H16

19 mm 1 86854H19

Sliding inlay (SLG1A, SLG2A, SLG9, SLG3A*) 9 mm 1 85119H09

10 mm 1 85119H10

Note: Fixing material to be ordered separat 16 mm 1 85119H16

19 mm 1 85119H19

*) For SLG3 and SLG3A double number of sliding inlays is

required.

Änderungen vorbehalten! Subject to change without notice!

Blatt/sheet D384MGB.027

Car Frame Series WCF Datum/date 16.01.2002

Underslung 2:1 Suspension Stand/version 16.01.2002

Geprüft/approved WAT/MZE

Operating instructions

Tab. 2: Spare parts WCF Underslung 2:1 suspension

Component Type Spare part Number... Art. No.

Roller guide shoe WRG150 rail width 16 mm (Type “S”) 1 581271G16S

16 mm (Type “L”) 1 581271G16L

19 mm 1 581271G19

WRG150HD rail width 16 mm (Type “S”) 1 600653G16S

16 mm (Type “L”) 1 600653G16L

19 mm 1 600653G19

WRG200 rail width 16 mm (Type “S”) 1 169850G16S

16 mm (Type “L”) 1 169850G16L

19 mm 1 169850G19

Roller for WRG150 D150mm / 38mm wide 1 581274G03

(incl. axle) D150mm / 27mm wide * 1 581275G03

Roller for WRG150HD D150mm / 38mm wide 1 600655G03

(incl. axle) D150mm / 27mm wide * 1 600656G03

Roller for WRG200 D200mm / 38mm wide 1 168962G01

(incl. axle) D200mm / 27mm wide * 1 86344G01

RGF125 rail width 5-16mm 1 C1068

Rope pulley DR=330mm Rope DL=8mm 1 560224G03

(incl. bearings) DR=410mm Rope DL=8mm 1 505699G05

Rope DL=10mm 1 560226G03

DR=530mm Rope DL=10mm 1 560228G03

Rope DL=13mm 1 560229G03

DR=656mm Rope DL=13mm 1 560231G03

Rope DL=16mm 1 560232G03

*) For e.g. WRG150 type “S” (rail width 16mm only) ...

2 pcs. roller with 27mm width and 1 pcs. roller with

38mm width are required!

For all other types (“L” and 19mm rail width) 3 pcs.

roller with 38mm width are required!

!D384MGB!

Änderungen vorbehalten! Subject to change without notice!

You might also like

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Danielson Pre-Observation Form 409Document2 pagesDanielson Pre-Observation Form 409api-28624516150% (2)

- Planetary Geared Machine P420 / 450: Technical CatalogDocument29 pagesPlanetary Geared Machine P420 / 450: Technical CatalogAli DiabNo ratings yet

- Controller With EMIDocument8 pagesController With EMIJms QuinteroNo ratings yet

- HRM301 Case StudyDocument3 pagesHRM301 Case StudyRatul50% (2)

- Orinoco Installation ManualDocument238 pagesOrinoco Installation ManualZoroastro Mo100% (1)

- TM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsDocument64 pagesTM Pte 01 - Port 1.2: The PORT Technology - Technical DocumentsResul Şenay100% (1)

- Introduction To Machine Learning: Jaime S. CardosoDocument52 pagesIntroduction To Machine Learning: Jaime S. CardosoErica Lopes100% (1)

- MRL E-Pack Assay Instructions For Tests and VerificationsDocument35 pagesMRL E-Pack Assay Instructions For Tests and VerificationsLe Huynh LongNo ratings yet

- ENG LiSA20-Fehlermeldungen R111Document36 pagesENG LiSA20-Fehlermeldungen R111Adarsh Manoharan100% (1)

- Barduva Screw Nut LiftsDocument16 pagesBarduva Screw Nut Liftswilderness_666No ratings yet

- Titan Full CatalogDocument57 pagesTitan Full CatalogTomas Hubner NeumannNo ratings yet

- Schindler 3300Document2 pagesSchindler 3300aadrian_xyzNo ratings yet

- HPV 600 PM Elevator Drive TM7323 - R4Document136 pagesHPV 600 PM Elevator Drive TM7323 - R4asif_9091No ratings yet

- Barduva Screw Nut LiftsDocument16 pagesBarduva Screw Nut Liftswilderness_666No ratings yet

- Bernoulli's PrincipleDocument15 pagesBernoulli's PrincipleDedy KristiantoNo ratings yet

- Advertising StrategyDocument8 pagesAdvertising StrategyRutika AjgaonkarNo ratings yet

- Marketing Report On McDonald'sDocument8 pagesMarketing Report On McDonald'sKristy Leung100% (1)

- CCROPP Best Pract Obesity Prev TMT PDFDocument288 pagesCCROPP Best Pract Obesity Prev TMT PDFharunnuranNo ratings yet

- Monstrous Encyclopedia A-B (Vol. 01) PDFDocument345 pagesMonstrous Encyclopedia A-B (Vol. 01) PDFFernando Luiz100% (8)

- AscensorDocument24 pagesAscensorBlass Hernández Castro100% (1)

- Hydraulic Car Frame WHF35 Direct and IndirectDocument38 pagesHydraulic Car Frame WHF35 Direct and Indirectmario escottoNo ratings yet

- Hydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20Document57 pagesHydraulic Car Frame WLF03 / WLF06 / WLF10 / WLF16 / WLF20mario escottoNo ratings yet

- PM 7 000338 en 01Document30 pagesPM 7 000338 en 01Anonymous N57sCcpiNo ratings yet

- RCF Replacement Kit ENGDocument32 pagesRCF Replacement Kit ENGMiguelin1306No ratings yet

- 1117 32 0013 Assembly Manual EngDocument31 pages1117 32 0013 Assembly Manual Engjavier ariasNo ratings yet

- Technical Information and Configuration: Progressive Safety Gear G01Document16 pagesTechnical Information and Configuration: Progressive Safety Gear G01Ali DiabNo ratings yet

- System Galaxy Quick Guide: Configuration and OperationDocument47 pagesSystem Galaxy Quick Guide: Configuration and OperationTushar ImranNo ratings yet

- Traccion EscalerasDocument16 pagesTraccion EscalerasRafael BrunoNo ratings yet

- 104 Door Control Board PM-SSCDocument16 pages104 Door Control Board PM-SSCKevin SilvaNo ratings yet

- 2011 Fermator Catalogue PDFDocument63 pages2011 Fermator Catalogue PDFeliorlopezbNo ratings yet

- 5elevator Installation Manual For Elevator With Machine Room V1.4 - 1Document113 pages5elevator Installation Manual For Elevator With Machine Room V1.4 - 1aneesh tNo ratings yet

- Tabel Status Shanghai ElevDocument4 pagesTabel Status Shanghai ElevAhmed Al-Rabayah0% (1)

- Mel 03 - 08C2 - ElenessaDocument1 pageMel 03 - 08C2 - ElenessaUmer FarooqNo ratings yet

- KONE - Machine Room Type - 1600 KG, Speed 2.5 PDFDocument1 pageKONE - Machine Room Type - 1600 KG, Speed 2.5 PDFNghia100% (1)

- Planos Schindler 2Document8 pagesPlanos Schindler 2equiser6131caNo ratings yet

- ECO Manual (CN En)Document55 pagesECO Manual (CN En)thi tran100% (1)

- JSA07039E-AB FES Maintenance and Operation Manual - PDF Manual EscaleraDocument63 pagesJSA07039E-AB FES Maintenance and Operation Manual - PDF Manual EscaleraEbert mancilla100% (1)

- MUSE ED Elevator: Installation ManualDocument29 pagesMUSE ED Elevator: Installation ManualMoises PerelloNo ratings yet

- Preventive Maintenance Instruction For V3F16R Drive MODULE KM870400GDocument14 pagesPreventive Maintenance Instruction For V3F16R Drive MODULE KM870400GMarta Silva VenturaNo ratings yet

- (Mech. Safety System) K 602673-07Document38 pages(Mech. Safety System) K 602673-07Ali Diab100% (1)

- 763-000-100 - 2000 C-MOD Cathedral - Installation - E 2011-12-23 - ENGDocument76 pages763-000-100 - 2000 C-MOD Cathedral - Installation - E 2011-12-23 - ENGTaufik Hidayat KurniansyahNo ratings yet

- Schindler 3300 Ca Product Family Brochure PDFDocument32 pagesSchindler 3300 Ca Product Family Brochure PDFjorge barrerNo ratings yet

- Controller With EMIDocument11 pagesController With EMIMohammed Qaid AlathwaryNo ratings yet

- Modu-Tool Basic Operating Instructions PDFDocument2 pagesModu-Tool Basic Operating Instructions PDFAliRouyouNo ratings yet

- ATLAS 2 - 1-PL - DATA-v2.5-2009-EN PDFDocument11 pagesATLAS 2 - 1-PL - DATA-v2.5-2009-EN PDFzajednosexNo ratings yet

- Ba WSG-S1.2-3 v17 ENDocument94 pagesBa WSG-S1.2-3 v17 ENBrahim Chergui100% (1)

- 200cory Board DescriptionDocument2 pages200cory Board DescriptionChang ChangNo ratings yet

- Atlas Basic SP Instalation Manual enDocument39 pagesAtlas Basic SP Instalation Manual enISHAQNo ratings yet

- Hh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdDocument3 pagesHh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdRebecca DangNo ratings yet

- Schindler Drive Chain MaintenanceDocument9 pagesSchindler Drive Chain MaintenanceKevin aliNo ratings yet

- On Site Wiring, Travelling CableDocument3 pagesOn Site Wiring, Travelling CableAli DiabNo ratings yet

- Hoisting Motor FMP 160: Motors For Planetary GearsDocument8 pagesHoisting Motor FMP 160: Motors For Planetary GearsAli DiabNo ratings yet

- MCTC Ard C English 1Document11 pagesMCTC Ard C English 1Khaled ZakariaNo ratings yet

- Fermator PDFDocument2 pagesFermator PDFDavidNo ratings yet

- Arcode Geared Sp-16 Cpc-T.enDocument38 pagesArcode Geared Sp-16 Cpc-T.enAbdallh YassenNo ratings yet

- Tool Velino FT853Document12 pagesTool Velino FT853Polinho DonacimentoNo ratings yet

- 6300 Safety Componants Maint'Document14 pages6300 Safety Componants Maint'Pio Rodolfo100% (1)

- Gen2 CNDocument17 pagesGen2 CNMohammad Sami50% (2)

- F21aau4 8 PDFDocument34 pagesF21aau4 8 PDFjhfbty100% (1)

- TAC32 1 Op Ptas 6300pa3 y Pa4 Parcial PDFDocument14 pagesTAC32 1 Op Ptas 6300pa3 y Pa4 Parcial PDFViệt Thảo TrầnNo ratings yet

- DC81091Q00 Program Manual EngDocument52 pagesDC81091Q00 Program Manual EngJose Vicente Alvarez FernándezNo ratings yet

- 10 Aaa21700xDocument17 pages10 Aaa21700xasdf100% (1)

- Eco Electrification & Controller Diagrams PDFDocument94 pagesEco Electrification & Controller Diagrams PDFMiguel AngelNo ratings yet

- Schindler Modular Gearless Machines FMR355Document2 pagesSchindler Modular Gearless Machines FMR355Kar Keong LewNo ratings yet

- Prepared Oyama (July 2012) Rev. WIG-21 Checked T.Natsume Checked K.HaraDocument18 pagesPrepared Oyama (July 2012) Rev. WIG-21 Checked T.Natsume Checked K.HaraEtienneNo ratings yet

- Manual de Instalacion Ascensor Sanyo 1Document30 pagesManual de Instalacion Ascensor Sanyo 1Reina Yadyra Chasi CansingNo ratings yet

- Dienes Standard Knife Programme - Status 01 2022 - e 1Document16 pagesDienes Standard Knife Programme - Status 01 2022 - e 1wilderness_666No ratings yet

- Dimensionamento Depolveratore A Ciclone Portata Volumetrica (m3/h)Document2 pagesDimensionamento Depolveratore A Ciclone Portata Volumetrica (m3/h)wilderness_666No ratings yet

- TDS Nylon101Document2 pagesTDS Nylon101wilderness_666No ratings yet

- Molle A Scatto E Perni: Spring Latches and Ball StudsDocument1 pageMolle A Scatto E Perni: Spring Latches and Ball Studswilderness_666No ratings yet

- Correcting Elastic FEA Results For Local PlasticityDocument6 pagesCorrecting Elastic FEA Results For Local Plasticitywilderness_666No ratings yet

- 121 - NEXEN, Assembly Mag, Ballscrew Art-1Document4 pages121 - NEXEN, Assembly Mag, Ballscrew Art-1wilderness_666No ratings yet

- The Specter of The Giant Three: L B & S HDocument21 pagesThe Specter of The Giant Three: L B & S Hwilderness_666No ratings yet

- Scheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317Document1 pageScheda Tecnica Prodotto: Nylatron GSM Materiale Plastico 1317wilderness_666No ratings yet

- Machine Design: Search Log in RegisterDocument8 pagesMachine Design: Search Log in Registerwilderness_666No ratings yet

- Flue Gas Cleaning PDFDocument3 pagesFlue Gas Cleaning PDFwilderness_666No ratings yet

- Piastrine UPNDocument10 pagesPiastrine UPNwilderness_666No ratings yet

- Understanding ConnectorsDocument16 pagesUnderstanding Connectorswilderness_666No ratings yet

- Design and Size DuctworkDocument6 pagesDesign and Size Ductworkwilderness_666No ratings yet

- Moments Shears and Reactions For Continuous Highway Bridges PDFDocument91 pagesMoments Shears and Reactions For Continuous Highway Bridges PDFwilderness_666No ratings yet

- Push Pull 1 PDFDocument3 pagesPush Pull 1 PDFwilderness_666No ratings yet

- Aalborg Universitet: Heiselberg, Per Kvols Topp, ClausDocument17 pagesAalborg Universitet: Heiselberg, Per Kvols Topp, Clauswilderness_666No ratings yet

- 41 - Design News RPS Article PDFDocument1 page41 - Design News RPS Article PDFwilderness_666No ratings yet

- How To Determine The Best Heat Treatment For Your PartsDocument10 pagesHow To Determine The Best Heat Treatment For Your Partswilderness_666No ratings yet

- 1.050 - Content Overview: Beam Elasticity - How To Sketch The Solution Another Example Transversal Shear in BeamsDocument4 pages1.050 - Content Overview: Beam Elasticity - How To Sketch The Solution Another Example Transversal Shear in Beamswilderness_666No ratings yet

- Research ProposalDocument4 pagesResearch ProposalMax Odeh100% (1)

- One Nation, One Education NEP Act: The New Era of Indian Education SystemDocument7 pagesOne Nation, One Education NEP Act: The New Era of Indian Education SystemLex OraculiNo ratings yet

- Module 4D Concepts On Growth and DevelopmentDocument118 pagesModule 4D Concepts On Growth and DevelopmentKristil ChavezNo ratings yet

- Film Study Worksheet Documentary Logos Pathos EthosDocument2 pagesFilm Study Worksheet Documentary Logos Pathos EthosGerardo E. Lopez MoralesNo ratings yet

- Daftar Pustaka: (Medline)Document14 pagesDaftar Pustaka: (Medline)nurfitriaNo ratings yet

- Analog and Digital Signal Processing by Ambardar (400 821)Document422 pagesAnalog and Digital Signal Processing by Ambardar (400 821)William's Limonchi Sandoval100% (1)

- Sapthami (Research Methodology)Document29 pagesSapthami (Research Methodology)sapthamiNo ratings yet

- Past Year Bio320 Plantae Week 10Document6 pagesPast Year Bio320 Plantae Week 10ayunna ayunniNo ratings yet

- The Palette Magazine 2011Document56 pagesThe Palette Magazine 2011101ThingsToDoNo ratings yet

- Sämäyik: in EnglishDocument30 pagesSämäyik: in EnglishShish Shah100% (1)

- Using Equations in Solving Age Problem Using Equations in Solving Age ProblemDocument18 pagesUsing Equations in Solving Age Problem Using Equations in Solving Age ProblemFatima UliNo ratings yet

- How To Write A Geotechnical Investigation Report - CivilblogDocument12 pagesHow To Write A Geotechnical Investigation Report - CivilblogOladunni AfolabiNo ratings yet

- Question Answers BilalDocument32 pagesQuestion Answers BilalMateen YousufNo ratings yet

- DLL 9 3rd w1Document4 pagesDLL 9 3rd w1Ramon FrejasNo ratings yet

- Exercise 2.6Document4 pagesExercise 2.6mohitgaba19No ratings yet

- 2nd Draft ULABDocument25 pages2nd Draft ULABKhairol NizamNo ratings yet

- RadioLink Theor enDocument29 pagesRadioLink Theor enNitish RoyNo ratings yet

- Web Hosting Server DetailsDocument11 pagesWeb Hosting Server DetailsTarun VBRSITNo ratings yet

- December 06Document36 pagesDecember 06Quy DangNo ratings yet

- Tpa Task 2 Final - ShafferDocument3 pagesTpa Task 2 Final - Shafferapi-608197412No ratings yet

- Synthesis Paper: Communities by Benedict Anderson, "I Am One of The Mountain People" by Macario TiuDocument2 pagesSynthesis Paper: Communities by Benedict Anderson, "I Am One of The Mountain People" by Macario TiuRaphaella Marie GupiteoNo ratings yet

- Line Dance ModuleDocument34 pagesLine Dance ModuleKim Ignatius GianganNo ratings yet