Professional Documents

Culture Documents

Monohydrate Process PFD Revision Date 7-28-19 PDF

Monohydrate Process PFD Revision Date 7-28-19 PDF

Uploaded by

VaanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monohydrate Process PFD Revision Date 7-28-19 PDF

Monohydrate Process PFD Revision Date 7-28-19 PDF

Uploaded by

VaanCopyright:

Available Formats

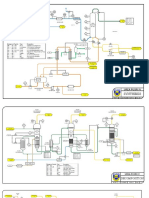

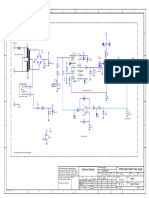

PRODUCTION OF SODIUM CARBONATE FORM TRONA ORE VIA MONOHYDRATE PROCESS

CO2 & 5 H2O

H2O Activated

ST-102 Carbon

9

Crushed ST-103

trona ore

3 Dissolved Suspended

Trona @150 oC Na2CO3 Solids Na2CO3

1 2

Ore 4 6 7 8

CR - 101 CA -

ST-101 101 AD - 101 FP - 101

@300 oC CL - 101 CL - 102

85 % Crude

Na2CO3 & 15 %

insoluble H2O

10

60 % Solid

content 13 11

2 % Free 30 %

6 % Free Na2CO3 @

Moisture Moisture @

100 oC 40 oC &

0.89 atm

Bulk Density: Soda 18 17 16

0.99-1.04 g/cm3 Ash SC - 001 CE - 001

12 steam

D-101 @150 OC 14

ST-104

E - 102 E - 101

15

LEGEND

ST-101 - Trona Ore Storage CA-101 - Rotary Kiln E-101 - Evaporator 1

ST-102 - Water Storage Tank AD-101 - Agitated Dissolver E-102 - Evaporator 2

ST-103 - Activated Carbon Storage CL-101 - Clarifier 1 CE-101 - Centrifuge

ST-104 - Sodium Carbonate Storage CL-102 - Clarifier D-101 - Drier

CR-101 - Crusher FP-101 - Filter Press SC-101 - Screener

You might also like

- Production of Acetaldehyde Via Oxidation of Ethylene: LegendDocument1 pageProduction of Acetaldehyde Via Oxidation of Ethylene: LegendCarissa TejioNo ratings yet

- Orange CR120H PreampDocument1 pageOrange CR120H PreampHelson Jader RochaNo ratings yet

- Activation of Unreactive Bonds and Organic SynthesisDocument274 pagesActivation of Unreactive Bonds and Organic SynthesisShirlene BarbosaNo ratings yet

- Sasing activity5PFD PDFDocument1 pageSasing activity5PFD PDFAlyza Abadies SasingNo ratings yet

- Training PODFA: Clinker Cooler POLYTRACK - Design and FunctionDocument62 pagesTraining PODFA: Clinker Cooler POLYTRACK - Design and FunctionДен Стаднік100% (1)

- E22246 ZDocument1 pageE22246 Zclubsport350zNo ratings yet

- PFD 12-09-22 HenDocument1 pagePFD 12-09-22 HenrismalitaNo ratings yet

- PFD - PRETREATMENT - LATEST (2) - Seen and CommentDocument1 pagePFD - PRETREATMENT - LATEST (2) - Seen and CommentFakrul HakimiNo ratings yet

- Valvoline ™ ALL-FLEET™ E900 PLUS SAE 10W-30Document2 pagesValvoline ™ ALL-FLEET™ E900 PLUS SAE 10W-30samsoon80No ratings yet

- MASCID1012 DistilledCoconutFattyAcid Rev.01 070618.Document1 pageMASCID1012 DistilledCoconutFattyAcid Rev.01 070618.Nur CahyaningrumNo ratings yet

- LOI Triple HHH LLC 23 November 2019 EN590 100K MT 01Document2 pagesLOI Triple HHH LLC 23 November 2019 EN590 100K MT 01Henny Tandika100% (1)

- Synthesis Urea Pusri Iv: Urea Reactor DC-101 GB-101 A/B GB-102Document5 pagesSynthesis Urea Pusri Iv: Urea Reactor DC-101 GB-101 A/B GB-102anjarNo ratings yet

- Argo 12Document1 pageArgo 12Георгий ДогаруNo ratings yet

- Acibenzolar-S-methyl Cloquintocet-Mexyl 2,3-DichloronitrobenzeneDocument4 pagesAcibenzolar-S-methyl Cloquintocet-Mexyl 2,3-DichloronitrobenzeneAlexSNo ratings yet

- Low Cement Dense Castables / Calcestruzzi Densi A Basso Cemento / Betons Denses A Basse Teneur en Ciment / Dichte Lc-BetoneDocument2 pagesLow Cement Dense Castables / Calcestruzzi Densi A Basso Cemento / Betons Denses A Basse Teneur en Ciment / Dichte Lc-Betoneasad razaNo ratings yet

- Organic Chemistry Compounds 1Document20 pagesOrganic Chemistry Compounds 1silvio1980100% (3)

- Stable Isotope Characteristics of Archaean Gold DepositsDocument22 pagesStable Isotope Characteristics of Archaean Gold DepositsRegina EfraimNo ratings yet

- 820241-05-060-00-En Cross Index - Pipe and Valve SpecificationsDocument2 pages820241-05-060-00-En Cross Index - Pipe and Valve SpecificationsJorge FerrerNo ratings yet

- Jurnal International Alkohol Fenol 1Document8 pagesJurnal International Alkohol Fenol 1Fitra NamikzNo ratings yet

- Measurement of SilicaDocument4 pagesMeasurement of SilicaKumaraswamyNo ratings yet

- Heat Exchanger ReportDocument20 pagesHeat Exchanger ReportMuhammad AwaisNo ratings yet

- Drawing 4Document1 pageDrawing 4Pratiwi Putri LimNo ratings yet

- Sound To Light UnitDocument3 pagesSound To Light UnitPhilip CardonaNo ratings yet

- Base Oil - Tds Drilling NewDocument1 pageBase Oil - Tds Drilling NewNohelysNo ratings yet

- Jordan Petroleum Refinery Co. Ltd. Kerosene Specification QS-PL 111 Laboratories & Quality Control DepartmentDocument1 pageJordan Petroleum Refinery Co. Ltd. Kerosene Specification QS-PL 111 Laboratories & Quality Control DepartmentMohammed NuseirNo ratings yet

- SPL Simulator DiagDocument1 pageSPL Simulator DiagIlhamNo ratings yet

- Splitting 6 6 TPH Cps Pfad Feed 150 Tons Per DayDocument1 pageSplitting 6 6 TPH Cps Pfad Feed 150 Tons Per Dayrizky efrinaldoNo ratings yet

- A A B B C C D D E E F F G G H H: Title TitleDocument2 pagesA A B B C C D D E E F F G G H H: Title Titleitalo ferreiraNo ratings yet

- Complete Water Analysis For Power GenerationDocument12 pagesComplete Water Analysis For Power GenerationRaymund GatocNo ratings yet

- Sound of SilenceDocument1 pageSound of SilenceSaraNo ratings yet

- 104 13479 Mob02918 DSH 420 J 0018 - 1Document3 pages104 13479 Mob02918 DSH 420 J 0018 - 1Roberto Capcha SernaNo ratings yet

- Gold Crown AvionicsDocument50 pagesGold Crown AvionicsJavierNo ratings yet

- SV20-61-02-v1Document1 pageSV20-61-02-v1Micky CorrowNo ratings yet

- Sec 4Document1 pageSec 4Restu DanikaNo ratings yet

- IC9101 SLC5012M Driver de Leds: Canal1 Canal2 Canal1 Canal2Document1 pageIC9101 SLC5012M Driver de Leds: Canal1 Canal2 Canal1 Canal2jacobo jimenez100% (1)

- Acibenzolar-S-methyl Cloquintocet-Mexyl 2,3-DichloronitrobenzeneDocument4 pagesAcibenzolar-S-methyl Cloquintocet-Mexyl 2,3-DichloronitrobenzeneAlexSNo ratings yet

- Summary of Mass Balance Raw Grinding Mill System PT. Holcim Indonesia NAR 1Document3 pagesSummary of Mass Balance Raw Grinding Mill System PT. Holcim Indonesia NAR 1Ammar ZakyNo ratings yet

- Temperature Sensitive Switch For Solar Collector: Tom HenskensDocument2 pagesTemperature Sensitive Switch For Solar Collector: Tom HenskensJohn SmithNo ratings yet

- Organic Chemistry Compounds 6Document40 pagesOrganic Chemistry Compounds 6silvio1980No ratings yet

- Poster-Consumable Data-1Document4 pagesPoster-Consumable Data-1Lipika GayenNo ratings yet

- Lab Report-Squeeze CMT@L.L5 (In) - 3847 (M) - Aghar 20-NDC114Document2 pagesLab Report-Squeeze CMT@L.L5 (In) - 3847 (M) - Aghar 20-NDC114mohammad teimuriNo ratings yet

- 3xvx1wmf 2Document1 page3xvx1wmf 2recrutementee.2020No ratings yet

- BT Oil Lab - Hpu - 09-10.06.2022Document1 pageBT Oil Lab - Hpu - 09-10.06.2022Faizhal ROGNo ratings yet

- Organic Chemistry Compounds 9Document30 pagesOrganic Chemistry Compounds 9silvio1980No ratings yet

- Oil Inlet Oil Outlet Water Outlet Water Inlet: StandardDocument2 pagesOil Inlet Oil Outlet Water Outlet Water Inlet: StandardbcachNo ratings yet

- CDUDocument41 pagesCDUsidhuysn100% (2)

- Welding Consumable ChartDocument2 pagesWelding Consumable ChartAfetNo ratings yet

- Ke Utilitas Pengolahan Limbah Naoh Pellet: AquadestDocument1 pageKe Utilitas Pengolahan Limbah Naoh Pellet: AquadestAmbrosius AdityaNo ratings yet

- Overview KilangDocument6 pagesOverview KilangArShyhy Citcuit ArsyamaliaNo ratings yet

- WPS316LL Register Rev.00Document1 pageWPS316LL Register Rev.00Massimo FumarolaNo ratings yet

- Filler Metal P92Document33 pagesFiller Metal P92Elisa del RealNo ratings yet

- Organic Chemistry Compounds 11Document48 pagesOrganic Chemistry Compounds 11silvio1980No ratings yet

- ETI 1994 04 OCR Page 0024Document1 pageETI 1994 04 OCR Page 0024Jianghong ShenNo ratings yet

- Post Concrete ChimneyDocument1 pagePost Concrete ChimneySubhakanta SwainNo ratings yet

- Adi Statie de Lipit SP200Document1 pageAdi Statie de Lipit SP200Marincus AdrianNo ratings yet

- Schedule of Lintel Beam, Beam, Slab, Stair Cases.: 4 - T16 Vertical BarDocument1 pageSchedule of Lintel Beam, Beam, Slab, Stair Cases.: 4 - T16 Vertical BarAnandan HrNo ratings yet

- Les Faisal 20 November 2022Document8 pagesLes Faisal 20 November 2022faisal adhiNo ratings yet

- Ammonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesDocument16 pagesAmmonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesVaanNo ratings yet

- CR 102Document13 pagesCR 102VaanNo ratings yet

- Crystallizer CR - 101: Technological Institute of The PhilippinesDocument13 pagesCrystallizer CR - 101: Technological Institute of The PhilippinesVaanNo ratings yet

- Ammonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesDocument16 pagesAmmonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesVaanNo ratings yet

- Crystallizer CR - 101: Technological Institute of The PhilippinesDocument14 pagesCrystallizer CR - 101: Technological Institute of The PhilippinesVaanNo ratings yet

- Crystallizer CR - 102: Technological Institute of The PhilippinesDocument13 pagesCrystallizer CR - 102: Technological Institute of The PhilippinesVaanNo ratings yet

- EDDocument46 pagesEDVaanNo ratings yet

- Crystallizer CR - 102: Technological Institute of The PhilippinesDocument13 pagesCrystallizer CR - 102: Technological Institute of The PhilippinesVaanNo ratings yet

- Attrition Mill: Technological Institute of The PhilippinesDocument2 pagesAttrition Mill: Technological Institute of The PhilippinesVaanNo ratings yet

- Process Selection - Trona Ore REVISEDocument17 pagesProcess Selection - Trona Ore REVISEVaanNo ratings yet

- RC 101Document15 pagesRC 101VaanNo ratings yet

- Technological Institute of The Philippines: (Aq) 2 (L) 2 3(s) 3(s)Document17 pagesTechnological Institute of The Philippines: (Aq) 2 (L) 2 3(s) 3(s)VaanNo ratings yet

- Technological Institute of The Philippines: (Aq) 2 (L) 4 (Aq) 3(s) 4 3(s)Document12 pagesTechnological Institute of The Philippines: (Aq) 2 (L) 4 (Aq) 3(s) 4 3(s)VaanNo ratings yet

- BiochemDocument3 pagesBiochemVaanNo ratings yet

- Process Selection v7Document90 pagesProcess Selection v7VaanNo ratings yet

- Environmental Eng'gDocument2 pagesEnvironmental Eng'gVaan100% (1)

- Gen ChemDocument3 pagesGen ChemVaanNo ratings yet

- Checal 1Document2 pagesChecal 1VaanNo ratings yet

- EECODocument2 pagesEECOVaanNo ratings yet

- Analytical ChemDocument2 pagesAnalytical ChemVaanNo ratings yet

- 4500 - PH Value (H+) PDFDocument5 pages4500 - PH Value (H+) PDFClaudia BarreraNo ratings yet

- Nitrogen Cycle QuestionsDocument11 pagesNitrogen Cycle Questionsoghieghie jattoNo ratings yet

- Chem 11-12 2122Document4 pagesChem 11-12 2122Kaib PelaezNo ratings yet

- 820 PDFDocument907 pages820 PDFBabar Khan NiaziNo ratings yet

- Possibilities For The Use of Alternative Fuels in Cement Industry - FLSmidthDocument4 pagesPossibilities For The Use of Alternative Fuels in Cement Industry - FLSmidthmohamadi42100% (1)

- 8. Đề Thi Thử TN THPT 2021 - Môn Tiếng Anh - Nhóm GV MGB - Đề 8 - File Word Có Lời Giải Chi TiếtDocument6 pages8. Đề Thi Thử TN THPT 2021 - Môn Tiếng Anh - Nhóm GV MGB - Đề 8 - File Word Có Lời Giải Chi TiếtLiên NguyễnNo ratings yet

- Report On Industrial Training at Goldfish: PHARMA PVT - LTD (Kukatpally, Hyderabad)Document25 pagesReport On Industrial Training at Goldfish: PHARMA PVT - LTD (Kukatpally, Hyderabad)Ramya G100% (1)

- Cholesterol Liquicolor CHOD-PAPDocument1 pageCholesterol Liquicolor CHOD-PAPmaarboleda1100% (2)

- 21 April 2023Document4 pages21 April 2023devNo ratings yet

- Product Brochure XM7 60-15Document1 pageProduct Brochure XM7 60-15Rashdan HarunNo ratings yet

- Advanced Chromatographic TechniquesDocument9 pagesAdvanced Chromatographic Techniquesmsabubakar100% (1)

- Separation of Olefin-Paraffin Mixtures by Reactive Absorption in A Membrane ContactorDocument7 pagesSeparation of Olefin-Paraffin Mixtures by Reactive Absorption in A Membrane ContactorAlfredo OrtizNo ratings yet

- Astm E1148-2002Document1 pageAstm E1148-2002ilsilopez1303No ratings yet

- KNS1042 Metals Part1 W8Document29 pagesKNS1042 Metals Part1 W8justine2109No ratings yet

- Crystals: Preparation of Potassium Dichromate Crystals From The Chromite Concentrate by Microwave Assisted LeachingDocument11 pagesCrystals: Preparation of Potassium Dichromate Crystals From The Chromite Concentrate by Microwave Assisted LeachingDhruv NagpalNo ratings yet

- General Chemistry Ii: WEEK 3-4Document71 pagesGeneral Chemistry Ii: WEEK 3-4Roseman TumaliuanNo ratings yet

- Harris Regulator ManualDocument12 pagesHarris Regulator ManualButton DavidsonNo ratings yet

- Chemical Selection Guide - V5Document22 pagesChemical Selection Guide - V5Yavuz SolmazNo ratings yet

- 10.1080@10408398.2019.1650717Document30 pages10.1080@10408398.2019.1650717Rizka AnandaNo ratings yet

- Hydrogen Energy, Economy and StorageDocument15 pagesHydrogen Energy, Economy and StorageLe NhanNo ratings yet

- Ineos Chequered Environmental Track Record in EuropeDocument27 pagesIneos Chequered Environmental Track Record in EuropeFood and Water WatchNo ratings yet

- DFL E-29 Gel and LotionDocument39 pagesDFL E-29 Gel and LotionFersan AngelesNo ratings yet

- Guidelines For Corrosion Protetion and Coating Systems WWW - Gl-Group - Com Infoservices Rules Pdfs GL Vi-10-2 eDocument42 pagesGuidelines For Corrosion Protetion and Coating Systems WWW - Gl-Group - Com Infoservices Rules Pdfs GL Vi-10-2 ewilfran villegas100% (1)

- Oxyacetylene Welding (OAW)Document26 pagesOxyacetylene Welding (OAW)athyrahNo ratings yet

- Synthetic Fibres & Plastics Class 8Document3 pagesSynthetic Fibres & Plastics Class 8Pushpa KumariNo ratings yet

- 920.10 Sulfuro en PlantasDocument1 page920.10 Sulfuro en Plantaslizeth rico quinteroNo ratings yet

- Coordination MCQDocument11 pagesCoordination MCQMohammad Khaier KaliliNo ratings yet

- CSIR Chemical Sciences Solved December 2012Document57 pagesCSIR Chemical Sciences Solved December 2012Srinidhi A BelieverNo ratings yet

- Improvement of Diesel Fuel Properties by Using AdditivesDocument11 pagesImprovement of Diesel Fuel Properties by Using AdditivesManoj S KNo ratings yet