Professional Documents

Culture Documents

Footstool: Build Time

Footstool: Build Time

Uploaded by

Hector Gomez de la Torre MarquinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Footstool: Build Time

Footstool: Build Time

Uploaded by

Hector Gomez de la Torre MarquinaCopyright:

Available Formats

Footstool

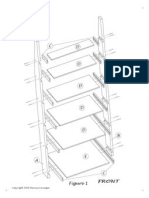

The final piece of our Adirondack furniture suite is

this stylish and easy to build footstool. With angles

and lines that mimic the other two pieces, and a

gentle angle on which to rest your feet, you can

relax in comfort and satisfaction after building these

pieces.

With the same simple joinery techniques, coated

screws and waterproof glue, this piece will also last

for years of enjoyment.

BUILD TIME

Cutting parts: 1 - 2 hours

Assembly: 1 hour

Finishing: 2 hours

Total: 4 - 5 hours

GET MORE PROJECT PLANS AT www.yellawood.com 1

Footstool

TOOLS

Miter saw A

Table saw

Drill/driver

Jig saw X2

1/8” drill bit

Damp rag to wipe up excess glue

SUPPLIES

X2

(1) 1 x 5 x 8’

(1) 1 x 4 x 8’

1 ¼” deck screws

2” deck screws

Waterproof wood glue C

X2

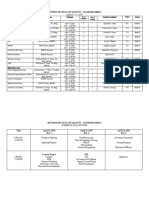

CUT LIST X2

A (2) ¾ x 3 ½ x 15"

B (2) ¾ x 4 ½ x 10"

C (2) ¾ x 2 x 15"

E

D (2) ¾ x 3 x 14"

X7

E (7) ¾ x 2 x 16 ½"

GET MORE PROJECT PLANS AT www.yellawood.com 2

Footstool

1/4” Space between slat

E

E Leg detail

E

E B

E

E

11 /2" 12"

1

E

2 /2"

1

22 1/2° bevels

(A)

D

Rail detail

o

45

B

D

1 o

22 /2

12 /4"

1

Feet Detail

A 45°

22½° 1½"

3"

GET MORE PROJECT PLANS AT www.yellawood.com 3

Footstool

BUILDING STEPS

01 Cut all pieces to length and rip all slats to width

according to dimensions on cut list. Layout the

feet profiles (A) according to illustration detail.

You can cut the 45° angles on your miter saw

using the 1 ½” mark as the beginning point for

your cut. Lay out the 22 ½° angles using a speed

square and cut those with a jig saw.

02 Square a line 2 ½” up from the bottom of both

legs (B). Mark the center point of the bottom edge

of the legs and another down the back face of the

feet. Line up the 2 ½” line flush and square with

the top edge of the feet and lined up with the

center points. Attach with glue and 1 ¼” screws.

03 Attach stretchers (C) to the edges of the legs with

glue and 1 ¼” screws. Keep the bottom edges

flush.

04 When both stretchers are attached to one side,

attach the other foot/leg assembly in the same

manner.

05 Mark the center points along the top edges of the

legs and rails (D), line up those marks and attach

the rails to the legs keeping top edges flush.

GET MORE PROJECT PLANS AT www.yellawood.com 4

Footstool

BUILDING STEPS

06 Set your table saw fence to a width of 1 ½” and tilt

the blade to 22 1/2°. Take four slats and one by one

place the bottom face against the table and rip one

edge. This will leave you with a face that is still 2”

wide to match the other slats, but the bottoms will

follow the angles of the rails.

07 Attach beveled slats to both ends of the footstool

with glue and 2” screws, keeping the unbeveled

edge even with the end points of the rails. Be sure

to drill through your slat pilot holes and into the rail

edge to prevent splitting.

08 Lay out the rest of your slats, mating the beveled

slat edges with each other and filling the middle

with unbeveled slats. Put ¼” spacers between

each slat. Attach with glue and 2” screws.

09 Sand all edges and surfaces smooth (the beveled

edges of the two end slats will have to be sanded

down to “level out” with the faces of their mating

slats). Apply waterproofing finish according to

manufacturer instructions.

GET MORE PROJECT PLANS AT www.yellawood.com 5

FASTENER AND HARDWARE

INFORMATION SHEET

For interior or exterior applications We recommend you contact the aluminum

Use fasteners and hardware that are in building products manufacturer for its

compliance with the manufacturer’s recommendations regarding use of its aluminum

recommendations and the building codes for products in contact with treated wood in ground

their intended use. As with any good design and contact applications or when exposed to salt

construction practices, treated wood should not water, brackish water, or chlorinated water, such as

be used in applications where trapped moisture swimming pools or hot tubs.

or water can occur. Where design and/or actual

conditions allow for constant, repetitive or long Also check with the aluminum building products

periods of wet conditions, only stainless steel manufacturer regarding compatibility with other

fasteners should be used. chemicals and cleaning agents and the use of their

aluminum products in commercial, industrial, and

For exterior applications specialty applications such as boat construction.

The following minimum galvanization levels may

be used for connectors, joist hangers,

fasteners and other hardware that are placed in

direct contact with exterior applications of

micronized copper treated wood:

• Fasteners - nails, screws, etc.

ASTM – A 153 (1 oz/ft²)

• Hardware - connectors, joist hangers, etc.

ASTM – A 653 G90 (0.90 oz/ft²)

The effects of other building materials within a YellaWood® brand pressure treated products

given assembly, along with environmental factors, are treated with copper and other preservatives

should also be considered when selecting the (the “Preservatives”) and preservative methods,

appropriate hardware and fasteners to use for a systems, and technologies of unrelated third

given project containing treated wood. parties. For details regarding the Preservatives,

methods, systems, and technologies used by

Great Southern Wood Preserving, Incorporated,

Stainless Steel fasteners and hardware are see http://www.greatsouthernwood.com/products/

required for Permanent Wood Foundations below yellawood or write us at P.O. Box 610, Abbeville,

grade and are recommended for use with treated AL 36310. Ask dealer for warranty details or visit

wood in other severe exterior applications such as http://www.greatsouthernwood.com/products/

swimming pools, salt water exposure, etc. - Type warranties. For important handling and other

304 and 316 are recommended grades to use. information concerning our products or for a

copy of the YellaWood® brand Material Safety

Data Sheet (MSDS), please visit us at www.

Aluminum building products may be placed in

greatsouthernwood.com or write us at P.O. Box

direct contact with YellaWood® brand products 610, Abbeville, AL 36310. YellaWood® and the

used for interior uses and above ground exterior yellow tag are federally registered trademarks of

applications such as decks, fencing, and Great Southern Wood Preserving, Incorporated.

landscaping projects. Examples of aluminum

products include siding, roofing, gutters, door and Great Southern Wood Preserving, Incorporated

window trim, flashing, nails, fasteners and other makes no warranties expressed or implied as to the

hardware connectors. However, direct contact of fitness for a particular purpose of this plan.

treated products and aluminum building products

should be limited to code-compliant construction

applications that provide proper water drainage

and do not allow the wood to be exposed to

standing water or water immersion.

GET MORE PROJECT PLANS AT www.yellawood.com 6

IMPORTANT INFORMATION

• Consult the end tag to determine which • Mold growth can and does occur on the surface

preservative or preservative system was used of many products, including untreated and

in the treatment of that particular product. treated wood, during prolonged surface exposure

YellaWood® brand products may be used in to excessive moisture conditions. To remove

direct contact with aluminum building products mold from the treated wood surface, wood

when limited to code-compliant construction should be allowed to dry. Typically, mild soap and

applications that provide proper water drainage water can be used to remove remaining surface

and do not allow the wood to be exposed to mold. For more information visit www.epa.gov.

standing water or water immersion. • Projects should be designed and installed in

• Use fasteners and other hardware that are in accordance with federal, state and local building

compliance with building codes for the intended codes and ordinances governing construction in

use. your area, and in accordance with the National

• Do not burn preserved wood. Design Specifications (NDS) and the Wood

• Wear a dust mask and goggles when cutting or Handbook.

sanding wood.

• Wear gloves when working with wood.

• Some preservative may migrate from the treated

wood into soil/water or may dislodge from the

treated wood surface upon contact with skin.

• Wash exposed skin areas thoroughly.

• All sawdust and construction debris should be

cleaned up and disposed of after construction. Disposal Recommendations:

• Wash work clothes separately from other Preserved wood may be disposed of

household clothing before reuse. in landfills or burned in commercial

• Preserved wood should not be used where it may or industrial incinerators or boilers

come into direct or indirect contact with drinking in accordance with federal, state and

water, except for uses involving incidental contact local regulations.

such as fresh water docks and bridges.

• Do not use preserved wood under circumstances

when the preservative may become a component

of food, animal feed or beehives.

• Do not use preserved wood as mulch.

• Only preserved wood that is visibly clean and

free of surface residue should be used.

• If the wood is to be used in an interior application

and becomes wet during construction, it should

be allowed to dry before being covered or

enclosed.

• If you desire to apply a paint, stain, clear water

repellent or other finish to your preservative-

treated wood, we recommend following

the manufacturer’s instructions and label of

the finishing product. Before you start, we

recommend you apply the finishing product to

a small exposed test area before finishing the

entire project to ensure it provides the intended

result before proceeding.

GET MORE PROJECT PLANS AT www.yellawood.com 7

You might also like

- Bank Santander UK NEWDocument1 pageBank Santander UK NEWTuma NiceNo ratings yet

- Everest Case FinalDocument12 pagesEverest Case FinalZainab Chitalwala67% (3)

- Deck Cargo Barge 270 Feet 4Document2 pagesDeck Cargo Barge 270 Feet 4Rino ErmawanNo ratings yet

- Interview QuestionsDocument2 pagesInterview QuestionsRam Krishna Vodnala100% (2)

- HSE Legal and Other RequirementsDocument7 pagesHSE Legal and Other RequirementsAjas AjuNo ratings yet

- MH12Document102 pagesMH12rguzmanabundisNo ratings yet

- Adirondack Chair HackDocument15 pagesAdirondack Chair HackHector Gomez de la Torre MarquinaNo ratings yet

- Caution: Compose - Panel Mounted Wood/Veneer & Metal Shelves Active Components®Document4 pagesCaution: Compose - Panel Mounted Wood/Veneer & Metal Shelves Active Components®hadeershahine299No ratings yet

- Imagenes Producto Archivo L-sd180Document7 pagesImagenes Producto Archivo L-sd180Doble AlNo ratings yet

- Model D3012-D3016 Wood Clamp Hardware Kit: Instruction SheetDocument4 pagesModel D3012-D3016 Wood Clamp Hardware Kit: Instruction SheetMihai ViteazuNo ratings yet

- Big BookcaseDocument2 pagesBig BookcasebehaosziNo ratings yet

- BDI Instructions - Corridor 8173Document16 pagesBDI Instructions - Corridor 8173BradNo ratings yet

- Delta Composites, L.L.CDocument1 pageDelta Composites, L.L.CMd Maruful Islam MarufNo ratings yet

- Filtro de Cromo Ensamble Planos IiDocument7 pagesFiltro de Cromo Ensamble Planos IilunaNo ratings yet

- SP Deck Cargo Barge 270 FeetDocument2 pagesSP Deck Cargo Barge 270 Feetantonsugiarto20_7049100% (2)

- DIY Outdoor Sofa PDFDocument11 pagesDIY Outdoor Sofa PDFandrei simionNo ratings yet

- Dacor Dyo130s Design GuideDocument2 pagesDacor Dyo130s Design GuideElla MariaNo ratings yet

- Submittal: '' MODEL L-SD-1/2Document1 pageSubmittal: '' MODEL L-SD-1/2Jorge Luis Benitez CorreaNo ratings yet

- Updated Shop DrawingDocument6 pagesUpdated Shop DrawingAli Nasser100% (1)

- Adirondack Chair Project Diagram: QT T W LDocument8 pagesAdirondack Chair Project Diagram: QT T W LGeoNo ratings yet

- Medidas Disco FriccionDocument1 pageMedidas Disco FriccionWilliam VillamizarNo ratings yet

- BookshelfDocument4 pagesBookshelfJerry Kn100% (2)

- PROYECTO VIVIENDA UNIFAMILIAR - JAUJA ModelDocument1 pagePROYECTO VIVIENDA UNIFAMILIAR - JAUJA ModelMANUEL RAMOS LAURANo ratings yet

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableVia CreazionemxNo ratings yet

- Lemonade Stand Project Diagram RevDocument6 pagesLemonade Stand Project Diagram Revmel ChiffonNo ratings yet

- Grinder Table 3Document1 pageGrinder Table 3Last Son of AbrahamNo ratings yet

- Modular Bookcase Project DiagramDocument7 pagesModular Bookcase Project DiagramDony RamdhaniNo ratings yet

- Figure A: Sled PiecesDocument4 pagesFigure A: Sled PiecesNooriRekaniNo ratings yet

- TERMINAL LUG - Comply With IEC61238-1: Copper Cables OnlyDocument4 pagesTERMINAL LUG - Comply With IEC61238-1: Copper Cables OnlyJustice KNo ratings yet

- Drawing 13Document1 pageDrawing 13Seth WhittingtonNo ratings yet

- Ductable Fan Coil Unit: Product Selection DataDocument26 pagesDuctable Fan Coil Unit: Product Selection DataNelson MartinsNo ratings yet

- Dumy Rack RXP501 PDFDocument1 pageDumy Rack RXP501 PDFTuyenNo ratings yet

- Anchor Bolt Plan Finished Floor at 100'-0": Drawing Is Not To ScaleDocument12 pagesAnchor Bolt Plan Finished Floor at 100'-0": Drawing Is Not To ScaleInoshan Madushika JayawickramaNo ratings yet

- Laboratory Exercise No. 3 Cabagnot Piolo Julius GDocument4 pagesLaboratory Exercise No. 3 Cabagnot Piolo Julius GCabagnot Piolo JuliusNo ratings yet

- Rustic Sunflower Frame Plan: Illustration 1Document2 pagesRustic Sunflower Frame Plan: Illustration 1Feng Shu jiNo ratings yet

- Classic Entry BenchDocument5 pagesClassic Entry BenchO'Neil JonesNo ratings yet

- Trolist Uputezaglodanjeprijevod6Document1 pageTrolist Uputezaglodanjeprijevod6Mirza CaticNo ratings yet

- Entry Message Center Project DiagramDocument4 pagesEntry Message Center Project DiagramSaleha KhanNo ratings yet

- TuyauDocument1 pageTuyaun7ptrzt4bgNo ratings yet

- Big Samudaya Final Structural DrawingsDocument19 pagesBig Samudaya Final Structural DrawingsAdithya HullathiNo ratings yet

- Formwork and Shoring Arrangement of Pouring Segment 1 Formwork and Shoring Arrangement of Pouring Segment 2Document4 pagesFormwork and Shoring Arrangement of Pouring Segment 1 Formwork and Shoring Arrangement of Pouring Segment 2WES QingNo ratings yet

- Unit E2 Unit E2: Level 5Document2 pagesUnit E2 Unit E2: Level 5ch420No ratings yet

- Drawing Aw220nxt23 PDFDocument1 pageDrawing Aw220nxt23 PDFnormNo ratings yet

- Drawing Aw220nxt23 PDFDocument1 pageDrawing Aw220nxt23 PDFnormNo ratings yet

- DrawingDocument8 pagesDrawingapi-371765257No ratings yet

- C and K SystemDocument3 pagesC and K SystemKamal AlkurdiNo ratings yet

- DrawingDocument8 pagesDrawingapi-371757299No ratings yet

- A53-1Document1 pageA53-1erenkc87No ratings yet

- Slab/Mat Curtailment - Column Strip: 'A' 'C' Top BarsDocument9 pagesSlab/Mat Curtailment - Column Strip: 'A' 'C' Top BarsHimang JainNo ratings yet

- Smoke Test-ModelDocument1 pageSmoke Test-Modeltribowo pangestuNo ratings yet

- One Rockin' Horse Project Diagram: Ease All Edges GDocument1 pageOne Rockin' Horse Project Diagram: Ease All Edges GPedroPablo GonzalezNo ratings yet

- Plan Poupée Mobile TourDocument1 pagePlan Poupée Mobile TourNicolas BouchetNo ratings yet

- AssemblyvdpDocument11 pagesAssemblyvdpapi-341296279No ratings yet

- Crouse Hinds Gup Junction Boxes Catalog PageDocument1 pageCrouse Hinds Gup Junction Boxes Catalog PageLloyd CorpuzNo ratings yet

- 5 Technical Drawing AssignmentDocument1 page5 Technical Drawing AssignmentsisurebirthNo ratings yet

- Valve Seat 1.0: A A Section A-A Scale 2: 1Document1 pageValve Seat 1.0: A A Section A-A Scale 2: 1Cao Đào NamNo ratings yet

- ShopNotes #93 (Vol 16) - Router Accesories & Add Ons PDFDocument53 pagesShopNotes #93 (Vol 16) - Router Accesories & Add Ons PDFSteveNo ratings yet

- Magnetic Track 34mm Drawing For Ext.Document1 pageMagnetic Track 34mm Drawing For Ext.Rahul RajNo ratings yet

- Mezclado RaDocument1 pageMezclado RaMarcel PiersonNo ratings yet

- Irfp 460 PBFDocument1 pageIrfp 460 PBFprnchaNo ratings yet

- TIP TIP: Shop Shop Shop ShopDocument1 pageTIP TIP: Shop Shop Shop ShopMaryline TecherNo ratings yet

- Leaning ShelfDocument5 pagesLeaning ShelfaosbordNo ratings yet

- Flange TableDocument1 pageFlange TableMussie BekeleNo ratings yet

- Pipe Rolls & Saddles: Complete Pipe Roll StandDocument2 pagesPipe Rolls & Saddles: Complete Pipe Roll StandPedro GarciaNo ratings yet

- Quick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesFrom EverandQuick & Easy Block Tool: 102 Rotary-Cut Quilt Blocks in 5 Sizes, Simple Cutting Charts, Helpful Reference, TablesRating: 3 out of 5 stars3/5 (2)

- Journal Home GridDocument1 pageJournal Home Grid03217925346No ratings yet

- Test WudhuDocument20 pagesTest WudhuAmirah HusnaNo ratings yet

- Digam SeriesDocument14 pagesDigam SeriesNguyễn Quang TrânNo ratings yet

- GX-K/GF-K Series SpecificationsDocument4 pagesGX-K/GF-K Series SpecificationsJohn AltamiranoNo ratings yet

- Geared Drive Mixer: Mobile: +91 9820268595Document1 pageGeared Drive Mixer: Mobile: +91 9820268595Anil SharmaNo ratings yet

- Cozy Mark IVDocument8 pagesCozy Mark IVproxymo1100% (1)

- CH 34Document8 pagesCH 34Qassem MohaidatNo ratings yet

- Manual Cheetah XIDocument158 pagesManual Cheetah XIAbel MamaniNo ratings yet

- OP-FIB Field Isolator Box STD PDFDocument2 pagesOP-FIB Field Isolator Box STD PDFzsmithNo ratings yet

- Technical Presentation Coating Paint ApplicationDocument39 pagesTechnical Presentation Coating Paint ApplicationRengarajan Thiruvengadaswamy100% (2)

- UnicalDocument4 pagesUnicalAan StiawanNo ratings yet

- Post of Executive Trainee (CSL) - 2018Document3 pagesPost of Executive Trainee (CSL) - 2018AbhidrawNo ratings yet

- 2001-Xvert SM PDFDocument19 pages2001-Xvert SM PDFqmeyNo ratings yet

- 206-00 General InfoDocument16 pages206-00 General InfoMiguel AngelNo ratings yet

- HP TrimDocument2 pagesHP TrimSumeet DasNo ratings yet

- Lav C., Staley D. & Olsen T., (2004), Practical Design Considerations For Application of GIS MV SwitchgearDocument8 pagesLav C., Staley D. & Olsen T., (2004), Practical Design Considerations For Application of GIS MV SwitchgearRicardo Rivas ZuñigaNo ratings yet

- PM100P - ManualDocument8 pagesPM100P - ManualAlin VasileNo ratings yet

- TDRGuide FuelTransferPumpDocument23 pagesTDRGuide FuelTransferPumpRon Padilla100% (1)

- Attachment To SDO Memo No 96 S. 2024Document2 pagesAttachment To SDO Memo No 96 S. 2024LoidaCarameNo ratings yet

- CDCVF2505 3.3-V Clock Phase-Lock Loop Clock Driver: 1 Features 3 DescriptionDocument24 pagesCDCVF2505 3.3-V Clock Phase-Lock Loop Clock Driver: 1 Features 3 DescriptionBeroxi MihaiNo ratings yet

- The Digital Radiography SystemDocument9 pagesThe Digital Radiography SystemReza Apa Ja'erNo ratings yet

- 4 1 Digital EquityDocument1 page4 1 Digital Equityapi-315868526No ratings yet

- RSM72-6-320P-340P/5BB 72 Cell 320-340Wp 1500VDC 17.5%: High Performance Polycrystalline ModuleDocument2 pagesRSM72-6-320P-340P/5BB 72 Cell 320-340Wp 1500VDC 17.5%: High Performance Polycrystalline ModuleTiago MottaNo ratings yet

- A1365232859 - 19469 - 27 - 2020 - Lecture 26 March Ate304Document24 pagesA1365232859 - 19469 - 27 - 2020 - Lecture 26 March Ate304sanjay poudelNo ratings yet

- 063 - Global RoamingDocument4 pages063 - Global RoamingJonathan RiveraNo ratings yet