Professional Documents

Culture Documents

Us2769807 PDF

Us2769807 PDF

Uploaded by

Yuminten Adr0 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

US2769807.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views2 pagesUs2769807 PDF

Us2769807 PDF

Uploaded by

Yuminten AdrCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

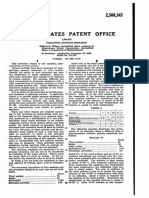

United States Patent Office 2,769,807

Patented Nov. 6, 1956

by weight at least equal to the amount of water, and

2,769,807 the temperature during said reaction being maintained

between 100 and 170° C.

PRODUCTION OF CAPROLACTAM The following examples serve to illustrate specific em

Lorraine Guy Donaruma, Woodbury, N.J., and David C.

bodiments of the method of carrying out the present

England, Wilmington, Del, assignors to E. I. du Poist invention, and they will be understood to be illustrative

de Nemours and Company, Wilmington, Del, a corpo only and not limiting the invention in any way.

ration of Delaware Example 1

No Drawing. Application May 21, 1954, 0 Thirteen parts of nitrocyclohexane was disssolved in

Serial No. 431,597 75 parts of water containing 4 parts of sodium hydroxide,

8 Claims. (C. 260-239.3) and nitromethane in an amount of 20 parts was added

to 190 parts of 95% sulfuric acid at 120-125 C. The

temperature of the mixture was then adjusted to about

The present invention relates to a process for the pro 15 120° C., and the sodium nitrocyclohexane solution was

duction of lactams. More particularly, the present in added to the nitromethane-sulfuric acid mixture at a rate

vention relates to a process whereby lactams can be pro such that the temperature of the mixture was held between

duced from water-soluble salts of nitrocycloalkanes in a 120 and 125° C. The mixture then was neutralized and

single reaction. extracted with chloroform. The chloroform was removed

Lactams are used for the production of polyamides 20 by distillation, and the residue was distilled under reduced

suitable for the manufacture of fabrics, films, fibers, coat pressure to produce 8.2 parts of caprolactam. This cor

ing compositions, and the like. Heretofore, the usual responds to a yield of 73%.

preparation of lactams has been by Beckmann rearrange The procedure of the foregoing example was employed

ment of oximes. Caprolactam, the most important mem in the following runs, the nitromethane being mixed with

ber of this class, has long been prepared by rearrange 25 the sulfuric acid at 120-125 C. before addition of the

ment of cyclohexanone oxime. However, it has been solution of the sodium salt of nitrocyclohexane (NCH).

Reactants Used (parts) Temperature (C.) Capro

of addition of So- lactam Yield

Run dium NCH solu- Pro- (Per

NCH NaOH HO CHNO; 95% tion to CH3NO2- duced cent)

H2SO4 H2SO4 Mixture (parts)

50 10 190 13-140 5.9 52

375 100 950 20-125 75 67

28 0 53 120-125 2 18

75 0 180 100-105 2 18

50 10 100 20-125 5 44

necessary to prepare the cyclohexanone oxime intermedi Example 2

ate by means of one or more reactions. For example,

the preparation of the oxime by treating nitrocyclohexane 40 A mixture prepared by the addition of 10 parts cf

or its salts with hydroxylamine, hydrogen, ammonia, nitromethane to 180 parts of 95% sulfuric acid at

amines, sulfides, olefins, alkylene oxides, and the like, 120-125 C. was cooled to about 120° C. To this inix

is well-known in the art. It is also known to prepare ture then was added an aqueous solution of ammonium

cyclohexanone oxime by treatment of cyclohexanone with nitrocyclohexane at a rate such that the temperature of

hydroxylamine, by treatment of cyclohexanone-bisulfite 45 the mixture was maintained between 120 and 130 C.

complexes with nitrous acid, and by like processes. Al The mixture was treated as in the foregoing examples to

though Such multi-step processes for the preparation of produce 6 parts of caprolactam, corresponding to a 53%

lactams have generally produced satisfactory products, yield.

the need has long been recognized for a process whereby Example 3

lactams could be prepared in a single reaction. 50 Twelve parts of nitrocyclopentane was dissolved in 75

An object of the present invention is to provide a parts of water containing 4 parts of sodium hydroxide,

process for the direct preparation of lactams. Another and nitromethane was added to concentrated sulfuric acid

object of the present invention is to provide a process as in Example 2. The sodium nitrocyclopentane solution

whereby lactams can be prepared in a single reaction. then was added to the nitromethane-sulfuric acid mixture

A still further object of the present invention is to provide 55 at a rate which maintained the mixture temperature be

an efficient process for converting water-soluble salts of tween 120 and 130 C. The mixture was worked up

nitrocycloalkanes to the corresponding lactams. Other according to the method of the foregoing examples to

objects will become apparent as the invention is further produce 8-valerolactam in an amount of 4.7 parts, which

described. corresponded to a yield of 46.5%.

It has been found that the foregoing objects can be 60

accomplished by reacting an aqueous solution of a water Example 4

soluble salt of a nitrocycloalkane with a sulfuric acid

solution of a primary nitro alkane, said sulfuric acid being Ten parts of nitromethane and a sodium nitrocyclo

present throughout the reaction in an amount by weight hexane solution, prepared by dissolving 13 parts of nitro

at least equal to the amount of water. 65 cyclohexane in 75 parts of water containing 4 parts of

in accordance with the process of the present invention, sodium hydroxide, were added simultaneously to 180

an aqueous solution of a water-soluble salt, e. g., an parts of 95% sulfuric acid, the rate of addition being so

alkali metal or ammonium salt, of a nitro cycloalkane, controlled as to hold the temperature of the mixture

e.g., nitrocyclohexane or nitrocyclopentane, is caused to between 120 and 140 C. The mixture was treated as

react with a sulfuric acid solution of a primary nitro 70 in the foregoing examples. Caprolactam was obtained

alkane, e.g., nitromethane or nitroethane, said sulfuric in an amount of 6.2 parts, which corresponded to a yield

acid being present throughout the reaction in an amount of 55%.

2,769,807

3 4

Example 5 carried out batchwise, but a continuous process is equally

A sodium nitrocyclohexane solution, prepared by the possible, for example, by continuously and simultane

method of Example 4, was added to a solution of 6 parts ously introducing the solution of the salt of the nitro

of nitromethane in 180 parts of 95% sulfuric acid (mixed cycloalkane and the nitro alkane into sulfuric acid and

at 120-125 C.). When the mixture was worked up by continuously removing the product therefrom, the

the method of the preceding examples, 5.8 parts of capro amount by weight of sulfuric acid in the reaction zone

lactam was obtained, corresponding to a 51% yield. being maintained at least equal to the amount of water

present.

Example 6 The invention has been described in detail in the fore

Nitrocyclohexane in an amount of 13 parts was dis O going. It will be understood that many variations can

solved in 75 parts of water containing 4 parts of sodium be introduced without departing from the scope of the

hydroxide, and this solution was added at 120-130° C. to invention. It is intended, therefore, that the invention be

a solution prepared by adding 8 parts of nitroethane to limited only by the following claims:

190 parts of 95% sulfuric acid at 120-125 C. The We claim:

procedure of the foregoing examples was employed in 15 1. A process for the preparation of lactams which

working up the mixture. Caprolactam was obtained in comprises reacting an aqueous solution of a water-soluble

an amount of 7.3 parts, corresponding to a yield of 65%. salt of a nitro cycloalkane with a sulfuric acid solution of

As the foregoing examples show, the highest yields are a primary nitro alkane, said sulfuric acid being present

obtained in the process of the invention when the tem throughout the reaction in an amount by weight at least

perature maintained during the reaction is between 120 20 equal to the amount of water and the temperature during

and 140 C. and when the primary nitro alkane is added said reaction being maintained between 100 and 170° C.

to the sulfuric acid prior to the addition of the salt 2. The process as claimed in claim 1 wherein the nitro

of the nitro compound. However, Run D of Example cycloalkane is nitrocyclohexane.

1 indicates that the process of the invention can be 3. The process as claimed in claim 1 wherein the nitro

operated as low as 100 C. Temperatures above 170 25 cycloalkane is nitrocyclopentane.

C. should be avoided because of excessive decomposition 4. The process as claimed in claim 1 wherein the

of the reactants. Example 4 shows that it is entirely in water-soluble salt of the nitro cycloalkane is an alkali

accord with the present invention to add the nitro alkane metal salt.

and the salt of the nitro compound simultaneously to the 5. The process as claimed in claim 1 wherein the water

sulfuric acid. The sulfuric acid should be present 30 soluble salt of the nitro cycloalkane is the ammonium

throughout the reaction in an amount by weight at least salt.

equal to the annount of water, although, as the examples 6. The process as claimed in claim 1 wherein the pri

show, higher concentrations of the acid are desirable. mary nitro alkane is nitromethane.

Although the process of the present invention has been 7. The process as claimed in claim 1 wherein the pri

primarily applied in the examples to the preparation of 35 mary nitro alkane is nitroethane.

lactams such as e-caprolactam and 8-valerolactam, the 8. The process as claimed in claim 1 wherein the molar

process is equally applicable to the production of other ratio of the nitro alkane to the salt of the nitro cyclo

lactams and substituted lactams, as for example, butyr alkane is at least 1/1.

olactam, enantholactam, caprylolactam, and substituted

caprolactams and valerolactams, and the like. Other 40 References Cited in the file of this patent

nitro cycloalkanes such as nitrocyclobutane, nitrocyclo UNITED STATES PATENTS

heptane, nitrocyclooctane, and substituted nitro cycloal 2,313,026 Schlack ---------------- Mar. 2, 1943

kanes can also be used as starting materials in the present 2,569,114 Novotny -------------- Sept. 25, 1951

process. The nitro compounds are employed in the form 45 2,634,269 England ---------------- Apr. 7, 1953

of their sodium and ammonium salts in the foregoing

examples, but the process of the invention is not limited FOREIGN PATENTS

to the use of these salts; the other water-soluble alkali 59,519 Netherlands ------------ June 16, 1947

metal salts can be employed. The nitromethane and OTHER REFERENCES

nitroethane can similarly be replaced in the present proc 50

ess by other primary nitro alkanes, e. g., 1-nitropropane. Nametkin et al.: Chem. Abst., vol. 44, col. 9362

In the foregoing, the process of the invention has been (1950).

You might also like

- The Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium HypochloriteDocument3 pagesThe Preparation of Methylamine Hydrochloride From Acetamide by Means of Calcium Hypochloritegeovani2100% (1)

- Preparation of Cyclohexene From CyclohexanolDocument7 pagesPreparation of Cyclohexene From CyclohexanolDumile Nombasa100% (5)

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Alchemy Journal - Vol.8 No.1 PDFDocument26 pagesAlchemy Journal - Vol.8 No.1 PDFancientwisdom2014100% (1)

- ' United States Patent Office : Ljatented Nov. 7, 195.0Document2 pages' United States Patent Office : Ljatented Nov. 7, 195.0Agape Ruth BaliloNo ratings yet

- Thioglycolic Acid ProductionDocument2 pagesThioglycolic Acid Productionfake77No ratings yet

- United States Patent 0: '3, l50, l74 ICCDocument2 pagesUnited States Patent 0: '3, l50, l74 ICCMuhammadAmdadulHoqueNo ratings yet

- pNO DPADocument4 pagespNO DPATri DoNo ratings yet

- ,425,500. Patented Aug. 8, 1922.: H. W., Matheson and G, E, GrattanDocument3 pages,425,500. Patented Aug. 8, 1922.: H. W., Matheson and G, E, GrattanrzgarNo ratings yet

- US1960211 (Sudah)Document3 pagesUS1960211 (Sudah)aris_nurhidayatNo ratings yet

- United States Patent-P Office: Patented July 18, 1939Document2 pagesUnited States Patent-P Office: Patented July 18, 1939dudge99No ratings yet

- US4780224Document4 pagesUS4780224Mohamad Reza JahanbakhshNo ratings yet

- United States Patent O?ice: 15H: LLQ?ZDocument3 pagesUnited States Patent O?ice: 15H: LLQ?ZadamNo ratings yet

- Cacl2 Concntrating - 1 PDFDocument2 pagesCacl2 Concntrating - 1 PDFvahidNo ratings yet

- United States Patent Office: Patented Nov. 7, 1950Document2 pagesUnited States Patent Office: Patented Nov. 7, 1950bayuminecraftNo ratings yet

- United States Patent (191 - (11) 4,052,458: Klein Et Al. (45) Oct. 4, 1977Document3 pagesUnited States Patent (191 - (11) 4,052,458: Klein Et Al. (45) Oct. 4, 1977bvritNo ratings yet

- United States Patent PO: Patented Nov. 20, 1956Document2 pagesUnited States Patent PO: Patented Nov. 20, 1956shenn0No ratings yet

- United States Patent Office: Patented Dec. 18, 1945Document3 pagesUnited States Patent Office: Patented Dec. 18, 1945Jarukit Jr JunjiewchaiNo ratings yet

- Organic Syntheses Vol 03 - Clarke - WileyDocument56 pagesOrganic Syntheses Vol 03 - Clarke - Wileyqscwdvefb71100% (1)

- US3054804Document2 pagesUS3054804rocioNo ratings yet

- US2838512Document2 pagesUS2838512eduard morarNo ratings yet

- KKKK - Us2918452Document5 pagesKKKK - Us2918452هیمن مNo ratings yet

- United States Patent Office: Patented Mar. 21, 1950Document2 pagesUnited States Patent Office: Patented Mar. 21, 1950alexNo ratings yet

- N Methyl AnilineDocument3 pagesN Methyl AnilineHitesh KendreNo ratings yet

- Patent Benzil KloridaDocument3 pagesPatent Benzil KloridaShochib Al FatihNo ratings yet

- United States Patent (15) 3,697,598: Leif Urban Folke Thorsen, Örn Primary Examiner-Retiri RaymondDocument7 pagesUnited States Patent (15) 3,697,598: Leif Urban Folke Thorsen, Örn Primary Examiner-Retiri RaymondSalsabila CacaNo ratings yet

- United States Patent Office: Patented June 29, 1948Document3 pagesUnited States Patent Office: Patented June 29, 1948jhartmann8No ratings yet

- United States Patent Office: Patented Apr. 7, 1953Document3 pagesUnited States Patent Office: Patented Apr. 7, 1953Syahrul SandreaNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0184498 A1Document10 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0184498 A1Debby Theresia SilabanNo ratings yet

- US2508343Document4 pagesUS2508343Ilham RamadhanNo ratings yet

- US2301231Document2 pagesUS2301231Abu Mejza'atNo ratings yet

- United States Patent Office: Patented Nov. 13, 1956Document2 pagesUnited States Patent Office: Patented Nov. 13, 1956karmilaNo ratings yet

- Acetyl Salicylate PDFDocument3 pagesAcetyl Salicylate PDFtechkasambaNo ratings yet

- Ethylene Urea JACS 1Document10 pagesEthylene Urea JACS 1tavolenNo ratings yet

- United States Patent OfficeDocument3 pagesUnited States Patent OfficefhafizfrNo ratings yet

- Dietanolamina 1955Document6 pagesDietanolamina 1955Leek AgoessNo ratings yet

- United States PatentDocument4 pagesUnited States Patentwiam wiamNo ratings yet

- United States Patent Office: Ch-Ch-OnDocument3 pagesUnited States Patent Office: Ch-Ch-OnChanachai PuckNo ratings yet

- Expt 05 - CyclohexeneDocument5 pagesExpt 05 - CyclohexeneMark Cliffton BadlonNo ratings yet

- US2343534 (Proses Sulit)Document4 pagesUS2343534 (Proses Sulit)aris_nurhidayatNo ratings yet

- Aiiii: July 7, 1942. E. Mazabraud 2,289,286Document3 pagesAiiii: July 7, 1942. E. Mazabraud 2,289,286Özlem YılmazNo ratings yet

- Preparation of Methylene Chloride (Greene 1879)Document2 pagesPreparation of Methylene Chloride (Greene 1879)j9cr4zrdxxNo ratings yet

- Exp 2Document7 pagesExp 2zanjinyadzaNo ratings yet

- Methylamine With EtohDocument16 pagesMethylamine With Etohjiskate77100% (1)

- Production of Sodium DithioniteDocument10 pagesProduction of Sodium DithioniteDhaval PadaliaNo ratings yet

- Sure. in The Ideal Case This A Diabatic Process IsDocument2 pagesSure. in The Ideal Case This A Diabatic Process IsvahidNo ratings yet

- Copolymerization of Styrene and Acrylonitrile in Aqueous DispersionDocument15 pagesCopolymerization of Styrene and Acrylonitrile in Aqueous DispersionPhilip ShihNo ratings yet

- Method of Preparing S Nitrofurfural DiacetateDocument8 pagesMethod of Preparing S Nitrofurfural DiacetateKarla VTNo ratings yet

- Reactions P-Hydroxybenzyl Alcohol Derivatives and Their Methyl Ethers With Molecular Chlorine'Document6 pagesReactions P-Hydroxybenzyl Alcohol Derivatives and Their Methyl Ethers With Molecular Chlorine'Sandipan SahaNo ratings yet

- Us 2741650Document3 pagesUs 2741650sinhleprovietNo ratings yet

- United States Patent Office: Patented Sept. 23, 1952Document2 pagesUnited States Patent Office: Patented Sept. 23, 1952ZDENKO SEBASTIAN CHAMERY CUEVASNo ratings yet

- US2373717Document2 pagesUS2373717Ruchita PoilkarNo ratings yet

- Design Report 1Document12 pagesDesign Report 123vikenNo ratings yet

- United States Patent Office: Patented Jan. 23, 1973Document2 pagesUnited States Patent Office: Patented Jan. 23, 1973Ahmad DawamNo ratings yet

- AADocument30 pagesAAAhmed MajidNo ratings yet

- United States Patent (19) : Hu Et AlDocument4 pagesUnited States Patent (19) : Hu Et AlSepti WidyaNo ratings yet

- Pentaeritritol 2Document6 pagesPentaeritritol 2Ibnul BaasithNo ratings yet

- Us 2413493Document4 pagesUs 2413493atomoscoNo ratings yet

- Us 5154800Document3 pagesUs 5154800Lukas EstivaresNo ratings yet

- Preparation of Dibenzyl Ketone and PhenylacetoneDocument1 pagePreparation of Dibenzyl Ketone and PhenylacetoneKybernetikumNo ratings yet

- Kinetics of Hydrogen Uptake and Release From Heteroaromatic Compounds For Hydrogen StorageDocument9 pagesKinetics of Hydrogen Uptake and Release From Heteroaromatic Compounds For Hydrogen Storagesj singhNo ratings yet

- Daftar PustakaDocument3 pagesDaftar PustakaSyahrul SandreaNo ratings yet

- Evaporative Cooling of Water in A Natural Draft Cooling TowerDocument12 pagesEvaporative Cooling of Water in A Natural Draft Cooling TowerSyahrul SandreaNo ratings yet

- Lampiran WW MANTAPDocument25 pagesLampiran WW MANTAPSyahrul SandreaNo ratings yet

- United States Patent Office: Patented Apr. 7, 1953Document3 pagesUnited States Patent Office: Patented Apr. 7, 1953Syahrul SandreaNo ratings yet

- RyanhobingocokDocument1 pageRyanhobingocokSyahrul SandreaNo ratings yet

- Nama: Kaditha Ayu Pratiwi Kelas: VDocument1 pageNama: Kaditha Ayu Pratiwi Kelas: VSyahrul SandreaNo ratings yet

- Chemistry - Paper - 1 - TZ1 - HL 2Document97 pagesChemistry - Paper - 1 - TZ1 - HL 2pablinsky05No ratings yet

- Chemical Reactions: Physical Vs Chemical ChangesDocument7 pagesChemical Reactions: Physical Vs Chemical ChangesIfra HassanNo ratings yet

- Physical-Science 11 Q1 MODULE 8 Collision-TheoryDocument10 pagesPhysical-Science 11 Q1 MODULE 8 Collision-TheoryDiane AguilarNo ratings yet

- Simulation of An Industrial Turbulent Uidized Bed Reactor For Partial Oxidation To Maleic AnhydrideDocument10 pagesSimulation of An Industrial Turbulent Uidized Bed Reactor For Partial Oxidation To Maleic AnhydrideCatalinaManjarresNo ratings yet

- ElectrochemistryDocument106 pagesElectrochemistrySeng IvanNo ratings yet

- Acid Sulphate Methods QLDDocument132 pagesAcid Sulphate Methods QLDharpacticoidNo ratings yet

- Na + CL ! Nacl: Guided NotesDocument4 pagesNa + CL ! Nacl: Guided NotesSalina SalujaNo ratings yet

- Lab 15 - Effects of Catalyst On Reaction RateDocument2 pagesLab 15 - Effects of Catalyst On Reaction Ratealextzhao1996No ratings yet

- (Notes) Haloalkanes and Haloarenes 1083007 2023 09-27-04 12Document10 pages(Notes) Haloalkanes and Haloarenes 1083007 2023 09-27-04 12hboy99287No ratings yet

- Ice 204 - Chapter 6 - Industrial CatalysisDocument38 pagesIce 204 - Chapter 6 - Industrial CatalysisTabitaKristinaNo ratings yet

- Vollhardt 6e Lecture PowerPoints - Chapter 12Document74 pagesVollhardt 6e Lecture PowerPoints - Chapter 12superfr3shmNo ratings yet

- EcDocument149 pagesEcsurendar17_raj3406No ratings yet

- Long-Range Electron Transfer in BiologyDocument231 pagesLong-Range Electron Transfer in BiologyBrightRiffNo ratings yet

- Sba ChemistryDocument19 pagesSba Chemistrykeshane JohnsonNo ratings yet

- Incho 2008 2019 Indian National Chemistry OlympiadDocument503 pagesIncho 2008 2019 Indian National Chemistry OlympiadgsbandreddyNo ratings yet

- Presentation of Polynuclear CompoundsDocument45 pagesPresentation of Polynuclear Compoundsjasmeet ghumanNo ratings yet

- Deleted Syllabus For Class 11Document11 pagesDeleted Syllabus For Class 11Rhythm AgrawalNo ratings yet

- Example Planning Experiment Form 4 and 5 Updated 2018Document37 pagesExample Planning Experiment Form 4 and 5 Updated 2018Melor DihatiNo ratings yet

- PDF Engineering Chemistry Fundamentals and Applications 2Nd Edition Shikha Agarwal Ebook Full ChapterDocument53 pagesPDF Engineering Chemistry Fundamentals and Applications 2Nd Edition Shikha Agarwal Ebook Full Chaptermargo.sepulveda944100% (3)

- Accepted Manuscript: Chemical Engineering and ProcessingDocument37 pagesAccepted Manuscript: Chemical Engineering and ProcessingALAADDIN SAEEDNo ratings yet

- Chapter 12 Organic Chemistry Some Basic Principles and TechniquesDocument34 pagesChapter 12 Organic Chemistry Some Basic Principles and TechniquesAnonymous 8VJhV1eI2yNo ratings yet

- GATE PSU Study Material Chemical Reaction EngineeringDocument20 pagesGATE PSU Study Material Chemical Reaction EngineeringRajat Yadav Yaduvanshi0% (1)

- SN1 ReactionDocument2 pagesSN1 ReactionAmlan KalitaNo ratings yet

- Synthesis Polar CompoundDocument29 pagesSynthesis Polar CompoundArchawin_mooNo ratings yet

- JEE Main Syllabus Free PDF DownloadDocument24 pagesJEE Main Syllabus Free PDF DownloadRaaghvendra singhNo ratings yet

- Pulp BleachingfDocument13 pagesPulp BleachingfJonathan MusendekaNo ratings yet

- ANSYS 15.0 Update For Improving Fluids Dynamics SimulationsDocument11 pagesANSYS 15.0 Update For Improving Fluids Dynamics Simulationsrkkumarcpri1No ratings yet

- Redox:1989: Ammeter Reading (A)Document9 pagesRedox:1989: Ammeter Reading (A)api-3826629100% (1)