Professional Documents

Culture Documents

RNMPC Applied To A Nonlinear Model of A

RNMPC Applied To A Nonlinear Model of A

Uploaded by

jsotofmet4918Copyright:

Available Formats

You might also like

- Measuring and Managing Process Performance: QuestionsDocument4 pagesMeasuring and Managing Process Performance: QuestionsAshik Uz ZamanNo ratings yet

- Amman Master PlanDocument205 pagesAmman Master Planomaroyoun100% (9)

- Zhang IEEE Transactions Industrial Electronics 2017bDocument9 pagesZhang IEEE Transactions Industrial Electronics 2017bviktorija bezhovskaNo ratings yet

- Analysis and Validation of A Run-Of-Mine Ore Grinding Mill Circuit Model For Process ControlDocument15 pagesAnalysis and Validation of A Run-Of-Mine Ore Grinding Mill Circuit Model For Process ControlHubert Ventura HinostrozaNo ratings yet

- Slide Mode Control (SMC)Document14 pagesSlide Mode Control (SMC)Jaol1976No ratings yet

- Control Engineering Practice Volume 1 Issue 6 1993 OllDocument9 pagesControl Engineering Practice Volume 1 Issue 6 1993 OllAhmed AbassNo ratings yet

- A Systematic Review On MEMS GyroscopeDocument6 pagesA Systematic Review On MEMS GyroscopeArjun KapoorNo ratings yet

- Meyer Coal 2014Document23 pagesMeyer Coal 2014Molote Erwin MalieheNo ratings yet

- Design of Neuro Fuzzy Sliding Mode Controller For Active Magnetic Bearing Control SystemDocument12 pagesDesign of Neuro Fuzzy Sliding Mode Controller For Active Magnetic Bearing Control Systemxiaoqi dengNo ratings yet

- Design of CMOS Ring Oscillator Using CMODEDocument7 pagesDesign of CMOS Ring Oscillator Using CMODExyz91229111412No ratings yet

- Dynamic Hybrid Modeling and Simulation of Grinding-Flotation CircuitsDocument15 pagesDynamic Hybrid Modeling and Simulation of Grinding-Flotation CircuitsDirceu NascimentoNo ratings yet

- Robotic Non-Destructive InspectionDocument8 pagesRobotic Non-Destructive InspectionFadhli AzinnuddinNo ratings yet

- INFERENTIAL MEASUREMENT OF SAG MILL PARAMETERS 5 MPC Simulation PDFDocument18 pagesINFERENTIAL MEASUREMENT OF SAG MILL PARAMETERS 5 MPC Simulation PDFNaurizbek NaukaNo ratings yet

- Micro Hex Apo DoDocument8 pagesMicro Hex Apo DoelzirakuzaNo ratings yet

- A Design Approach of Higher Oscillation VCO Made of CS Amplifier With Varying Active LoadDocument10 pagesA Design Approach of Higher Oscillation VCO Made of CS Amplifier With Varying Active Loadanon_701088587No ratings yet

- Robust Tracking Control of An Ironless Linear Motor With Continuous Motion Nominal Characteristic Trajectory Following ControllerDocument6 pagesRobust Tracking Control of An Ironless Linear Motor With Continuous Motion Nominal Characteristic Trajectory Following ControllerUGNo ratings yet

- Design and Development of Low-Cost Room Temperature Electric Field Poling System For The Fabrication of Quasi-Phase Matching DevicesDocument11 pagesDesign and Development of Low-Cost Room Temperature Electric Field Poling System For The Fabrication of Quasi-Phase Matching DevicesKrish PandiyanNo ratings yet

- The Research and Simulation of CSMACA Mechanism ofDocument6 pagesThe Research and Simulation of CSMACA Mechanism ofcristina comanescuNo ratings yet

- Robust Backstepping Sensorless Speed Control of PMSM UsingDocument6 pagesRobust Backstepping Sensorless Speed Control of PMSM UsingNguyễn Văn HoàNo ratings yet

- Doc1 1Document5 pagesDoc1 1Corvo Do BecoNo ratings yet

- 03 - Thomson Et Al - Current Signature Analysis To Detect Induction Motors FaultsDocument9 pages03 - Thomson Et Al - Current Signature Analysis To Detect Induction Motors FaultsCar AljaNo ratings yet

- Energies 15 02689 v2Document17 pagesEnergies 15 02689 v2Mohit KaundalNo ratings yet

- Application of Robotics For The Nuclear Power Plants in KoreaDocument5 pagesApplication of Robotics For The Nuclear Power Plants in KoreaAbhilasha SaksenaNo ratings yet

- Evaluation of Progressive Deterioration of A Squirrel-Cage Rotor, With A Condition Monitoring System That Implements The Sideband MethodologyDocument6 pagesEvaluation of Progressive Deterioration of A Squirrel-Cage Rotor, With A Condition Monitoring System That Implements The Sideband MethodologyLeo ArguijoNo ratings yet

- Robust Sliding Mode Control For Robot ManipulatorsDocument10 pagesRobust Sliding Mode Control For Robot Manipulatorshoàng nguyễnNo ratings yet

- Control in GrindingDocument4 pagesControl in GrindingalnemangiNo ratings yet

- Topics in (Nano) Biotechnology: Microfabrication TechniquesDocument111 pagesTopics in (Nano) Biotechnology: Microfabrication TechniquestprakashtceNo ratings yet

- Adaptive Optimal Control Sustem of Ore Large Crushing ProcessDocument8 pagesAdaptive Optimal Control Sustem of Ore Large Crushing ProcessJuan SierraNo ratings yet

- PID-SMC Controller For A 2-DOF Planar Robot: February 2019Document6 pagesPID-SMC Controller For A 2-DOF Planar Robot: February 2019Khôi PhiNo ratings yet

- Rapid Fabrication of Al-Based Bulk-Form Nanocomposites With Novel Reinforcement and Enhanced Performance by Selective Laser MeltingDocument4 pagesRapid Fabrication of Al-Based Bulk-Form Nanocomposites With Novel Reinforcement and Enhanced Performance by Selective Laser Meltingsam jebarajNo ratings yet

- A Comparison Between A Flotation Mini Pilot Plant and A Copper Concentrator Mill PDFDocument9 pagesA Comparison Between A Flotation Mini Pilot Plant and A Copper Concentrator Mill PDFErick De la CruzTapiaNo ratings yet

- Fabrication and Control of A 6-DOF Magnetic Levitation Stage With Nanopositioning CapabilityDocument6 pagesFabrication and Control of A 6-DOF Magnetic Levitation Stage With Nanopositioning CapabilityDileep SettyNo ratings yet

- 2 DoDocument4 pages2 DoYeferson Eusebio Lloclla EscobarNo ratings yet

- An Efficient Differential Conditional Capturing Energy Recovery Flip-Flop DesignDocument6 pagesAn Efficient Differential Conditional Capturing Energy Recovery Flip-Flop DesignRaghul RamasamyNo ratings yet

- Microprocessors and Microsystems: L. Senthil Murugan, P. MaruthupandiDocument7 pagesMicroprocessors and Microsystems: L. Senthil Murugan, P. MaruthupandiSung Ryoung LimNo ratings yet

- Minerals Engineering: C.W. Steyn, C. SandrockDocument11 pagesMinerals Engineering: C.W. Steyn, C. SandrockMario Alejandro Leon GaticaNo ratings yet

- Modified Winding Function Approach To Stator Fault Modelling of Synchronous GeneratorDocument6 pagesModified Winding Function Approach To Stator Fault Modelling of Synchronous GeneratormohammadNo ratings yet

- بحث 4Document8 pagesبحث 4hayderNo ratings yet

- Precision Engineering: Nicholas W. Horvath, Matthew A. Davies, Steven R. PattersonDocument9 pagesPrecision Engineering: Nicholas W. Horvath, Matthew A. Davies, Steven R. PattersonLeonNo ratings yet

- On-Line Detection of Defects in Layered Manufacturing: Is Use ADocument6 pagesOn-Line Detection of Defects in Layered Manufacturing: Is Use AShahrzad GhasemiNo ratings yet

- Discrete-Time LQG Dynamic Controller Design Using Plant Markov ParametersDocument8 pagesDiscrete-Time LQG Dynamic Controller Design Using Plant Markov ParametersRaminptNo ratings yet

- Modi Ed Power Rate Sliding Mode Control For Robot Manipulator Based On Particle Swarm OptimizationDocument13 pagesModi Ed Power Rate Sliding Mode Control For Robot Manipulator Based On Particle Swarm OptimizationIAES International Journal of Robotics and AutomationNo ratings yet

- Modeling and SimulationDocument10 pagesModeling and Simulationoumaima ghzNo ratings yet

- Design of A Telescopic Fully Differential OTADocument7 pagesDesign of A Telescopic Fully Differential OTAUdai ValluruNo ratings yet

- Ucmp Unit Iv Part ADocument6 pagesUcmp Unit Iv Part Arx135rakeshNo ratings yet

- Model Predictive Control of Laser Metal Deposition: Yangbo Liu Liuping Wang Milan BrandtDocument13 pagesModel Predictive Control of Laser Metal Deposition: Yangbo Liu Liuping Wang Milan BrandtBryant Bruce Picon YangNo ratings yet

- Design of MEMS Switch For RF ApplicationsDocument3 pagesDesign of MEMS Switch For RF ApplicationsSanthoshiniRajanNo ratings yet

- Model Identification For Dragline Swing Assist Control DesignDocument6 pagesModel Identification For Dragline Swing Assist Control DesignMateen MahdiNo ratings yet

- 0073 - FI - A Combined MPC For Milling and Flotation - A Simulation StudyDocument7 pages0073 - FI - A Combined MPC For Milling and Flotation - A Simulation StudymahfoudNo ratings yet

- A Comparison of High Pressure Roller Mill and Conventional GrindingDocument4 pagesA Comparison of High Pressure Roller Mill and Conventional GrindingLi ZethNo ratings yet

- 1.1 Introduction To Conventional and Non Conventional MachiningDocument42 pages1.1 Introduction To Conventional and Non Conventional MachiningDida KhalingNo ratings yet

- Four-Cable-Driven Parallel Robot: Xuejun Jin, Dae Ik Jun, Andreas Pott, Sukho Park, Jong-Oh Park and Seong Young KoDocument5 pagesFour-Cable-Driven Parallel Robot: Xuejun Jin, Dae Ik Jun, Andreas Pott, Sukho Park, Jong-Oh Park and Seong Young KoAlonso ChuizNo ratings yet

- Ok 2017 MODELO MOLINO LeRoux - EKF - 2017Document20 pagesOk 2017 MODELO MOLINO LeRoux - EKF - 2017Hubert Ventura HinostrozaNo ratings yet

- Frequency Response Measurements For Switching Power Supplies Slup121Document13 pagesFrequency Response Measurements For Switching Power Supplies Slup121shrikrisNo ratings yet

- A 6.78 MHZ Single-Stage Wireless Power Transmitter Using A 3-Mode Zero-Voltage Switching Class-D PADocument11 pagesA 6.78 MHZ Single-Stage Wireless Power Transmitter Using A 3-Mode Zero-Voltage Switching Class-D PAZhongpeng LiangNo ratings yet

- IJAER Paper2Document6 pagesIJAER Paper2DaveNo ratings yet

- Applications of AFM in Semiconductor R&D and Manufacturing at 45 NM Technology Node and BeyondDocument12 pagesApplications of AFM in Semiconductor R&D and Manufacturing at 45 NM Technology Node and BeyondSourav PradhanNo ratings yet

- Adaptive Torque Pulsation Compensation For A High-Torque DC Brushless Permanent Magnet MotorDocument6 pagesAdaptive Torque Pulsation Compensation For A High-Torque DC Brushless Permanent Magnet Motorfong jeffNo ratings yet

- International Journal of Pressure Vessels and Piping: SciencedirectDocument7 pagesInternational Journal of Pressure Vessels and Piping: SciencedirectKurra SrikanthNo ratings yet

- Casting Blemishes and Supply Chain Relationship in Cast Iron FoundryDocument8 pagesCasting Blemishes and Supply Chain Relationship in Cast Iron FoundryVittal SBNo ratings yet

- Design of Rotating Wheel For Dip Test of Polymeric InsulatorsDocument4 pagesDesign of Rotating Wheel For Dip Test of Polymeric InsulatorsTrung Nguyễn QuangNo ratings yet

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- Work Index Materiales CompositosDocument14 pagesWork Index Materiales Compositosjsotofmet4918No ratings yet

- Froth Recovery Measurement in Plant Scale Flotation CellsDocument7 pagesFroth Recovery Measurement in Plant Scale Flotation Cellsjsotofmet4918No ratings yet

- Kinetics of Froth Flotation of Naturally Hydrophobic Solids With DifferentDocument10 pagesKinetics of Froth Flotation of Naturally Hydrophobic Solids With Differentjsotofmet4918No ratings yet

- Quarry Fines MinimisationDocument14 pagesQuarry Fines Minimisationjsotofmet4918No ratings yet

- Mineral Traps For Greenhouse Gases in Mine TailingsDocument336 pagesMineral Traps For Greenhouse Gases in Mine Tailingsjsotofmet4918No ratings yet

- A Sustainable Legacy Utilizing Mine Assets Post-Closure Island PDFDocument10 pagesA Sustainable Legacy Utilizing Mine Assets Post-Closure Island PDFjsotofmet4918No ratings yet

- Assessment of Waste Rock Weathering Characteristics at TheDocument260 pagesAssessment of Waste Rock Weathering Characteristics at Thejsotofmet4918No ratings yet

- Reclamation Measures at Equity Silver Mines LimitedDocument10 pagesReclamation Measures at Equity Silver Mines Limitedjsotofmet4918No ratings yet

- Chloride Leaching For ChalcopyriteDocument179 pagesChloride Leaching For Chalcopyritejsotofmet4918No ratings yet

- 0 EDEM For Postdoc AppDocument19 pages0 EDEM For Postdoc Appjsotofmet4918No ratings yet

- Control of Slimes Coating in Mineral SuspensionsDocument12 pagesControl of Slimes Coating in Mineral Suspensionsjsotofmet4918No ratings yet

- Reay 1975Document6 pagesReay 1975jsotofmet4918No ratings yet

- Kvarla1991 PDFDocument21 pagesKvarla1991 PDFjsotofmet4918No ratings yet

- OR2456 MaxiLoader P04Document2 pagesOR2456 MaxiLoader P04jacques PerronNo ratings yet

- Zte Lte FDD Lr18 Feature ListDocument57 pagesZte Lte FDD Lr18 Feature ListDhananjay Shrivastav100% (3)

- ThinkPad T460p Platform SpecificationsDocument1 pageThinkPad T460p Platform SpecificationsSim Shih HengNo ratings yet

- Hiab-658 Ficha TecnicaDocument2 pagesHiab-658 Ficha Tecnicaanmec20No ratings yet

- Tendernotice 1Document70 pagesTendernotice 1paulNo ratings yet

- Public Administration Unit-9 Scientific Management-F.W. TaylorDocument9 pagesPublic Administration Unit-9 Scientific Management-F.W. TaylorDeepika Sharma100% (2)

- Damped Oscillations - Forced Oscillations and ResonanceDocument27 pagesDamped Oscillations - Forced Oscillations and ResonanceVirgilioNo ratings yet

- Wilgamuwa Heengaga Water Supply Project: Schedule Symbol Description QuantityDocument1 pageWilgamuwa Heengaga Water Supply Project: Schedule Symbol Description QuantityGayan IndunilNo ratings yet

- Mixture: (Alligations)Document4 pagesMixture: (Alligations)krish masterjeeNo ratings yet

- Siswanto, Rian Wahyu Edi Sarwono, Aris Setyawan, Dedet Hermawan SetabudiDocument4 pagesSiswanto, Rian Wahyu Edi Sarwono, Aris Setyawan, Dedet Hermawan SetabudiGuntur PrawiraNo ratings yet

- Xforce PDocument6 pagesXforce PRAB HFRNo ratings yet

- Swivel Joints EngDocument24 pagesSwivel Joints Enghendry_hdwNo ratings yet

- 05958317Document4 pages05958317Fari PratomosiwiNo ratings yet

- Effect of Spray Rails and Wedges On The Performance of Semi-Displacement HullsDocument12 pagesEffect of Spray Rails and Wedges On The Performance of Semi-Displacement HullsAnggaGustamaNo ratings yet

- Fluid Mechanics ManualDocument41 pagesFluid Mechanics ManualrajmaljatNo ratings yet

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (2)

- Entity-Relationship Modelling (IEEE)Document6 pagesEntity-Relationship Modelling (IEEE)akshaymadan04No ratings yet

- JMF Ac - Base 2015 CobaDocument68 pagesJMF Ac - Base 2015 CobaCahyo 03No ratings yet

- Miller Guide For Gtaw NewDocument32 pagesMiller Guide For Gtaw NewKentDemeterioNo ratings yet

- Pneumatic Test ProcedureDocument7 pagesPneumatic Test ProcedureDeepu ChandranNo ratings yet

- Internal Checking of Plywood Formwork For Top Slab Containment Tank. Comment ACTDocument3 pagesInternal Checking of Plywood Formwork For Top Slab Containment Tank. Comment ACTMuhammad Ghazaly HatalaNo ratings yet

- 100-00101-00 - 01 RiEye User Guide Issue 3Document21 pages100-00101-00 - 01 RiEye User Guide Issue 3AngeloNo ratings yet

- Art & Science of Continuous Emissions Monitoring SystemsDocument44 pagesArt & Science of Continuous Emissions Monitoring SystemshuyNo ratings yet

- Chiller InductorDocument2 pagesChiller InductorAlberto Steven Ospino GómezNo ratings yet

- Toefl - Americans Are Too Dependant On CarsDocument5 pagesToefl - Americans Are Too Dependant On CarsAmi BarnesNo ratings yet

- Portotecnica General Catalogue 2018 - High Pressure WashersDocument172 pagesPortotecnica General Catalogue 2018 - High Pressure WashersTimo LilienbergNo ratings yet

- Lte SCFTDocument20 pagesLte SCFTkashireddy100% (1)

- Fabrication of Cylindrical Cam Shaper MachineDocument11 pagesFabrication of Cylindrical Cam Shaper MachineretechNo ratings yet

RNMPC Applied To A Nonlinear Model of A

RNMPC Applied To A Nonlinear Model of A

Uploaded by

jsotofmet4918Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RNMPC Applied To A Nonlinear Model of A

RNMPC Applied To A Nonlinear Model of A

Uploaded by

jsotofmet4918Copyright:

Available Formats

RNMPC Applied to a Nonlinear Model of a

ROM Ore Milling Circuit

L.C. Coetzee ∗ I.K. Craig ∗∗ E.C. Kerrigan ∗∗∗

∗

MINTEK, Private Bag X 3015, Randburg, 2125, South Africa.

(Email: loutjiec@mintek.co.za, Tel: +27 11 709 4174)

∗∗

Department of Electrical, Electronic and Computer Engineering,

University of Pretoria, Pretoria, 0002, South Africa.

(Email: icraig@postino.up.ac.za)

∗∗∗

Department of Aeronautics and Department of Electrical and

Electronic Engineering, Imperial College London, Exhibition Road,

London SW7 2AZ, United Kingdom.

(Email: e.kerrigan@imperial.ac.uk)

Abstract: This paper presents simulation results of applying robust nonlinear model predictive

control (RNMPC) to a nonlinear model of a run-of-mine (ROM) ore milling circuit. The model

consists of nonlinear modules for the individual process units of the milling circuit, which allow

arbitrary milling circuit configurations to be modelled. This study aims to cast a complex

problem of a run-of-mine ore milling circuit into a robust nonlinear model predictive control

framework without losing the flexibility of the modularised nonlinear model and implement the

robust nonlinear model predictive controller using open-source software modules.

Keywords: Robust nonlinear model predictive control, run-of-mine ore milling circuit,

RNMPC, ROM

1. INTRODUCTION are present. This is accomplished by incorporating an

explicit description of the uncertainties and disturbances

into the prediction model of the controller. The controller

The ROM ore milling circuit plays an important role in then usually calculates the optimal control sequence or

processing mined ore. This forms part of the comminution feedback laws that optimise a given objective function for

process of liberating the desired metals or minerals from the worst-case realisation of the system as defined by the

the ore. At the heart of the milling circuit is usually a ball, worst-case objective function.

rod, semi-autogenous or autogenous mill.

There are a number of ways to approach RNMPC.

The milling process is complicated by significant input Some authors, such as Mhaskar and Kennedy (2008) and

and plant uncertainties, because the feed ore forms part Mhaskar et al. (2006, 2005) use Lyapunov stability theory

of the grinding medium and the variation in feed ore to formulate the RNMPC that also defines the set of initial

contributes to the input uncertainty. The feed ore distri- conditions that will satisfy the stability conditions. This

bution in terms of hardness and size affects the breakage ensures that the controller is feasible for the initial state

kinetics and contributes to the plant uncertainties. Proper and as a result remains feasible for all future states under

design of the milling circuit alone cannot eliminate the control.

disturbances. Feedback control systems play an important

part in reducing the effects of disturbances and increasing Bravo et al. (2006) and Limon et al. (2005) use reachable

efficiency (Craig and MacLeod, 1995). sets to describe the predicted state evolution subject

to uncertainty and disturbances inside their controller

In milling circuits it is difficult to control important vari- formulations.

ables such as the product particle size, because indepen-

dent control of the amount, size and hardness of the Lazar et al. (2008); Limon et al. (2006) and Magni et al.

grinding medium in the mill is not possible. This causes (2003) developed a closed-loop min-max RNMPC. Being

significant uncontrollable disturbances and uncertain plant closed-loop, the effect of feedback is taken into considera-

dynamics (Craig and MacLeod, 1995). tion when predicting the future state trajectories subject

to uncertainty and disturbances, which reduces the spread

Applying robust nonlinear control, such as RNMPC, fur- in predicted future state trajectories compared to open-

ther simplifies the process by eliminating the need for loop formulations. This reduced spread in trajectories,

different simulation and control models. The nonlinear increases the feasible region of the controller and reduces

nature and the uncertainties are explicitly incorporated in the conservatism of the controller.

the controller to provide the best performance and stability

trade-off. Robust control aims to guarantee stability and The RNMPC controller presented in this paper is based

improved performance when uncertainty and disturbances on an open-loop min-max scheme, which might cause the

IFACMMM 2009. Viña del Mar, Chile, 14 -16 October 2009.

controller to be conservative and have a reduced feasible

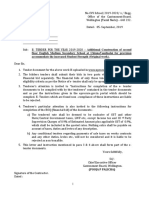

region. Particle Size (PSE)

The RNMPC is implemented using open source modules Cyclone Feed (CFF)

that have good numerical stability. Open source software

has the added advantage of allowing tight integration of Sump Water

the software modules for optimisation purposes by mod- (SFW)

ifying the source code, which is not always possible with

proprietary software. Furthermore, open source software

is usually available free of charge. Implementing the con- Solids Feed (MFS)

troller with open source modules reduces the time needed Mill Water (MIW) Mill Load

to obtain a working controller compared to writing all the (LOAD) Sump

software modules in-house. Steel Balls (MFB) Level

(SLEV)

This study aims to (1) cast a complex problem of a

ROM ore milling circuit into a RNMPC framework, (2)

implement the RNMPC efficiently using open-source soft-

ware components, and (3) describes practically motivated

Fig. 1. Run-of-mine ore milling circuit.

simulation results of the mill model being controlled by a

RNMPC controller. 1a and 2) as well as power consumption and throughput

(objectives 2 and 4).

2. ROM MILLING CIRCUIT DESCRIPTION

2.2 Milling Circuit Model

The circuit is fed gold-bearing ore at about 100 tons/hour

and grinds it down to a product with a particle size The variables of the milling circuit (Fig. 1) that are typ-

of 80% smaller than 75 µm (P80 = 75µm). The ROM ically controlled are the product particle-size (PSE), the

mill is operated in closed circuit with a hydrocyclone fraction of mill volume filled with material (LOAD) and

that separates the fine material (product) from the coarse the level of slurry in the sump (SLEV). The inputs to the

material (out-of-specification material), which is recycled milling circuit that are typically manipulated automati-

to the mill. The gold is then extracted through a leaching cally are the volumetric flowrate of water to the sump

process downstream. (SFW), the volumetric flowrate of slurry to the cyclone

A typical mill has dimensions of 5 m in diameter and (CFF), the mass feed rate of solids to the mill (MFS), the

a length of 9 m. The mill is supported by pressurised- volumetric flowrate of water to the mill inlet (MIW) and

oil circumferential bearings. The mill features lifter bars mass feed rate of steel balls to the mill (MFB). Steel balls,

and solid white-iron liners and it is operated at 90% of which are usually added to the mill feed by the operator

critical speed (Stanley, 1987). The mill discharges slurry in discrete quantities, will for this study be treated as a

through an end-discharge grate into a sump. The slurry continuous variable.

is diluted with water in the sump and pumped to the The feed ore consists of rocks (that do not discharge from

hydrocyclone for classification. The hydrocyclone has an the mill), coarse ore (out-of-specification that do discharge

internal diameter of 1 m. The underflow of the cyclone, from the mill) and fine ore (in-specification material). The

water and feed ore constitute the mill feed. composition of the feed is described by the fraction that

consists of fines (αf ) and fraction that consists of rock

2.1 Objectives in Mill Control (αr ).

A complete description of the model is given in Coetzee

The control of the milling circuit has multiple objectives,

et al. (2009). The parameters that describe the ore and

firstly to stabilise the system and secondly to optimise

steel ball hardness (φf , φr and φb ) inside the mill, the cy-

the economics of the process (Hulbert, 1989). The eco-

clone classification (εc and αsu ) and the feed composition

nomic objective is divided into sub-objectives that each

(αf and αr ) are shown in Table 1.

contributes to the overall economic objective of the milling

process. A set of possible sub-objectives for the milling

circuit are to (Craig and MacLeod, 1995): 3. ROBUST NONLINEAR MODEL PREDICTIVE

CONTROL

(1) improve product quality

(a) by increasing grind fineness, and

NMPC utilises a nonlinear model to predict the behaviour

(b) decreasing the fluctuations in product size,

of the plant and calculate the optimal control moves or

(2) maximise throughput,

control laws with regard to a specified objective function.

(3) minimise the amount of steel that is consumed for

NMPC is derived from nonlinear optimal control over a

each ton of fines produced, and

constant or varying time interval into the future [tk , tk +T ].

(4) to minimise the power consumed for each ton of fines

Only the first control move or control law is implemented

produced, etc.

and a new state measurement is taken. The nonlinear

The objectives above are interrelated and require trade- optimal control problem is then recalculated for the new

offs to be made. The main trade-offs are between particle time interval [tk+1 , tk+1 + T ], which leads to receding

size of the product and the throughput of solids (objectives horizon control (Mayne et al., 2000).

IFACMMM 2009. Viña del Mar, Chile, 14 -16 October 2009.

Table 1. Parameter values for milling circuit. method (Diehl et al., 2005). This is accomplished by

dividing the prediction horizon [0, T ] into N discrete time

ParamNominal Min Max %∆ Description

Fraction of fines in the ore.

intervals called nodes t1 0 < t2 < t3 < · · · < tk < · · · <

αf 0.1 0.05 0.15 50

[dimensionless] tN −1 < tN T where the sampling time is defined as

Fraction of rock in the ore. τs tk+1 − tk .

αr 0.1 0.05 0.15 50

[dimensionless]

Power needed for a ton of The functions of time x(·) and u(·) are replaced by their

φf 28 14 42 50

fines produced. [kW·hr/ton] values at the nodes xk ∈ Rnx and uk ∈ Rnu for k =

Rock abrasion factor. 1, . . . , N and some form of interpolation between nodes.

φr 69 55 83 20

[kW·hr/ton] The inputs (uk ) are kept piece-wise constant between

φb 94 89 99 5

Steel abrasion factor. nodes. The resulting nonlinear controlled discrete-time

[kW·hr/ton] system is xk+1 fk (xk , uk , p̃), k = 1, 2, . . . , N − 1. The

Coarse split.

εc 184 175 193 5 nonlinear optimal control problem can now be cast into

[dimensionless]

Fraction solids in

the following nonlinear parameter optimisation problem

αsu 0.16 0.15 0.17 5

underflow. [dimensionless]

min φ(s, q) (4)

s,q

The nonlinear optimal control problem is to find a control

profile u(·) such that it minimises some scalar performance s.t. g(s, q, p̃, xk ) = 0 (5)

index i = 1, . . . , nc ,

θi,j (sj , qj ) ≤ 0, (6)

j = 1, . . . , N − 1,

min φc (x, u, T ) (1)

x,u where φ : RN ·nx ×R(N −1)·nu → R is the performance func-

s.t. ẋ(t) = fc (x(t), u(t), p̃), x1 x(0) ∀t ∈ [0, T ] (2) tion to be optimised, g : RN ·nx × R(N −1)·nu × R(N −1)·np ×

Rnx → RN ·nx is the equality constraint function that

θc (x, u) ≤ 0 (3) describes the discrete time system dynamics, θi,j : Rnx ×

where x : [0, T ] → R is the state trajectory, u :

nx Rnu → R, i = 1, . . . , nc , j = 1, . . . , N − 1 are the inequal-

[0, T ] → Rnu is the control trajectory, x(t) ∈ Rnx is the ity constraint functions, si ∈ Rnx , i = 1, . . . , N are the

state vector, ẋ(t) ∈ Rnx is the state sensitivities to time, estimated state parameters, qi ∈ Rnu , i = 1, . . . , N − 1 are

u(t) ∈ Rnu is the control vector, (x, u) → φc (x, u, T ) is the the control parameters, p̃ (p̃, . . . , p̃) ∈ R(N −1)np is the

scalar performance function, (x, u) → θc (x, u, T ) is the sequence of nominal model parameters, s (s1 , . . . , sN ) is

inequality constraints function, p̃ ∈ Rnp is the nominal the state sequence and q (q1 , . . . , qN −1 ) is the control

parameter vector and fc : Rnx × Rnu × Rnp → Rnx is the sequence to be optimised in the nonlinear optimisation

ordinary differential equation describing the dynamics of problem (Diehl et al., 2005).

the plant. The plant dynamics are time-invariant and each

optimal control problem can therefore be solved from time The scalar performance function is defined as

t1 = 0 without affecting the result. The initial state value N

−1

x1 ∈ Rnx is the currently measured state of the system. φ(s, q) Li (si , qi ) + E(sN , qN −1 ) (7)

T i=1

For the sequel the ordered pair (a, b) aT bT is

where the scalar interval performance indexes are defined

defined as a column vector.

as Li (si , qi ) h(si , qi )T Qh(si , qi ) + ∆qiT R∆qi where Q

Plant models, such as the mill circuit model described and R represent the weighting matrices on the outputs

above, always differ from the real system owing to incom- and controls respectively, h : Rnx × Rnu → Rny is the

plete modelling, parameter uncertainty and unmodelled function that maps the current state and control vector

disturbances. The NMPC developed earlier in (Coetzee to the output vector using nominal model parameters and

et al., 2008) will be extended to explicitly deal with model ∆qi qi −qi−1 . The output vector consists of PSE, LOAD,

parameter uncertainty . Consider an uncertain parameter SLEV, Rheology factor (ϕ), THROUGHPUT and mill

vector p ∈ Rnp and nominal parameter vector p̃ ∈ Rnp , motor power draw (Pmill ). The terminal performance index

which are assumed to be restricted to a generalised ball is defined as E(sN , qN −1 ) h(sN , qN −1 )T P h(sN , qN −1 )

P = {p ∈ Rnp | p − p̃ ≤ 1} defined by using a suitable where P is the terminal cost weighting matrix. The equal-

norm · in Rnp (Diehl et al., 2006). ity constraint function describing the discrete time system

A suitable uncertainty description for the parameters is dynamics is defined

as

box uncertainty where the upper pu and lower pl bounds on xk − s1 ,

f1 (s1 , q1 , p1 ) − s2 ,

the parameters

p are known: P {p ∈ R np

|p ≤ p ≤ p } =

l

box u

� −1 � pl +pu g(s, q, p, xk ) .. (8)

p ∈ Rnp | diag pu −p l

p − ≤ 1 , where the

.

2 2

∞

centre of the box is defined as p̄ pl +p u

∈ Rnp . In general fN −1 (sN −1 , qN −1 , pN −1 ) − sN .

2

the centre of the box p̄ and the nominal parameter vector To add uncertainty into an optimisation problem, a min-

p̃ do not have to be the same point (p̃ = p̄). max optimisation can be done (Diehl et al., 2006; Ma and

The nonlinear optimal control problem, consisting of a Braatz, 2001). The worst-case values for the cost φ(s, q) is

system with continuous dynamics, needs to be discretised defined as ψ(q) maxs,p φ(s, q) s.t. g(s, q, p, xk ) = 0

in order to be cast in terms of a nonlinear parameter and the worst-case values for the constraint functions

optimisation problem, using the direct multiple shooting θi,j (sj , qj ) are defined as ωi,j (qj ) maxs,p θi,j (sj , qj )

IFACMMM 2009. Viña del Mar, Chile, 14 -16 October 2009.

s.t. g(s, q, p) = 0 where pi ∈ Pbox , i = 1, . . . N − 1 Table 2. Simulation Summary.

is defined as the unknown time varying model parame-

(N −1) Variable Value Variable Value

ters and p (p1 , . . . , pN −1 ) ∈ Pbox is defined as the Prediction Horizon

sequence of time varying model parameters. The worst- (T )

60 s Nodes (N ) 6

case cost and constraint functions are calculated by max- Sampling Time (τs ) 10 s Simulation time 260 min

imising the cost function and constraint functions with

(N −1)

regard to the model parameter sequence p ∈ Pbox and Table 2. The milling circuit model contains large parame-

state values s ∈ R (N ·nx )

. The worst-case cost function ter uncertainties; this is especially true of the parameters

ψ(q) is then minimised by choosing the control moves related to the composition of the feed ore and the hardness

q (q0 , q1 , . . . , qN −1 ) ∈ R((N −1)·nu ) subject to the worst- of the ore, which has an impact on the energy needed

case constraints ωi,j , i = 1, . . . , nc , j = 1, . . . , N − 1. to grind a ton of ore. The parameter variations used in

the simulation study are shown in Table 1. The parameter

This min-max optimisation problem is difficult to solve vector changes every 200 s, to allow the parameter distur-

for general nonlinear systems. The optimisation problem bances to sufficiently impact the simulation. The parame-

can however be simplified by approximating the worst- ters follow a uniform distribution to produce large changes

case calculations for the cost ψ̃ (s, q) and the constraints in the parameter values in order to properly demonstrate

ω̃i,j (s, q) , i = 1, . . . , nc , j = 1, . . . , N − 1. The ap- the disturbance rejection capabilities of the controller.

proximation of the worst-case cost ψ̃ (s, q) and constraints The milling circuit is simulated at the operating point as

ω̃i,j (s, q) can be done through liberation of the system described by the “OP” column in Table 3. The constraints

dynamics g (s, q, p, xk ) = 0, the cost φ(s, q) and constraint of the milling circuit are described by the “Min” and “Max”

θi,j (sj , qj ) functions. columns in Table 3. Metric ton is used throughout this

The approximation of the worst-case cost ψ (s, q) by paper. The weighting of the variables by Q and R in the

ψ̃ (s, q), is defined by a convex optimisation problem objective function (7) is described by the “W” column in

Table 3 and chosen based on the performance criteria of

∂φ(s, q) Section 2.1. Further, P = Q with no terminal constraints

max φ(s, q) + ∆s (9) (θN (sN ) ∈ Rnx ). The inputs are normalised according

∆s,∆p ∂s to their maximum range and outputs are normalised

∂g (s, q, p̄, xk ) ∂g (s, q, p̄, xk ) according to their setpoints in the objective function.

s.t. ∆s + ∆p = 0,(10)

∂s ∂p

Feed ore hardness and composition changes are major dis-

∆pl ≤ 1, l = 1, . . . , N − 1, (11) turbances that milling circuit controllers have to contend

and the approximation of the worst-case constraints with, especially when the feed ore is switched between

ωi,j (s, q) by ω̃i,j (s, q) are defined as feeds that originate from different stockpiles. A feed ore

hardness increase is simulated by increasing the power

∂θi,j (sj , qj ) needed to produce a ton of fines (φf ) by 50% at time

max θi,j (sj , qj ) + ∆s (12) 10 min. A feed ore composition change is simulated by

∆s,∆p ∂s

increasing the fraction of the feed consisting of rock (αr )

∂g (s, q, p̄, xk ) ∂g (s, q, p̄, xk ) by 50% at time 100 min. These disturbances are very large

s.t. ∆s + ∆p = 0,(13)

∂s ∂p but not uncommon in practice.

∆pl ≤ 1, l = 1, . . . , N − 1, (14) Coetzee et al. (2009) investigated the disturbance rejection

where ∆s ∈ R(N ·nx ) , p̄ (p̄, . . . , p̄) ∈ R(N −1)·np is a capability of the RNMPC and found it to be very good.

sequence of parameters at the centre of the box, ∆pl pl − This simulation scenario investigates the ability of the

p̄ ∈ Rnp is the deviation of the model parameters from RNMPC to follow a large setpoint change in PSE in the

the centre of the box and ∆p (∆p1 , . . . , ∆pN −1 ) ∈ presence of large disturbances described above.

R(N −1)·np is defined as the sequence of model parameter MFS (see Fig. 2) represents the throughput of new feed ore

deviations. The approximate min-max problem to the mill, while THROUGHPUT (see Fig. 2) represents

the product throughput that is sent downstream for fur-

min ψ̃(s, q) (15) ther processing. At steady state, these two values should be

s,q

i = 1, . . . , nc , Table 3. Constraints and operating point.

s.t. ω̃i,j (s, q) ≤ 0, (16)

j = 1, . . . , N − 1.

Variable Min Max OP Weight Units

g (s, q, p̄, xk ) = 0 (17) MIW 0 100 33 0.01 m3/hour

can be solved efficiently by casting it into a form that MFS 0 200 100 0.01 tons/hour

preserves the sparsity of the problem as well as smooth MFB 0 4 2 0.01 tons/hour

3

CFF 400 500 442 0.01 m /hour

objective and constraint functions (Diehl et al., 2006). m3/hour

SFW 0 400 267 0.01

PSE 60 90 80 100 % < 75µm

4. SIMULATION AND RESULTS LOAD 30 50 45 100 m3

SLEV 2 9.5 5.0 1 m3

In this simulation scenario the “actual” plant differs from ϕ 0 1 0.51 0 dimensionless

the nominal model. The prediction horizon, sampling time, THROUGHPUT 100 0 200 1 tons/hour

number of nodes and simulation time are summarised in Pmill 0 2000 2000 0 kW

IFACMMM 2009. Viña del Mar, Chile, 14 -16 October 2009.

90 500

(% < 75 µ m)

(m / hour)

80

CFF

70

3

PSE

60 0

0 50 100 150 200 250 0 50 100 150 200 250

200

(tons / hour)

(% Full)

40

LOAD

100

MFS

20 0

0 50 100 150 200 250 0 50 100 150 200 250

100 500

(m / hour)

(% Full)

SLEV

50

SFW

3

0 0

0 50 100 150 200 250 0 50 100 150 200 250

100

THROUGHPUT

200

(m / hour)

(tons / hour)

100 50

MIW

3

0 0

0 50 100 150 200 250 0 50 100 150 200 250

1 5

(m / hour)

Rheology

Factor

0.5

MFB

3

0 0

0 50 100 150 200 250 0 50 100 150 200 250

2000

Pmill (kW)

(kg/m )

1.4

3

CFD

1000

1.3

0 1.2

0 50 100 150 200 250 0 50 100 150 200 250

Time (minutes) Time (minutes)

Fig. 2. RNMPC: Controlled variables (PSE, LOAD, SLEV and THROUGHPUT ), manipulated variables (CFF, MFS,

SFW, MIW and MFB) and other important variables (Rheology Factor, Pmill and CFD). The dashed lines indicate

the constraints on the variable and the vertical dotted lines indicate the start of the disturbance events. The

dash-dot line indicates the setpoint.

the same. The throughput settles at a lower value, because ore hardness disturbance by increasing MIW relative to

the feed ore hardness was increased, thus deviating from MFS in order to reduce the mill discharge density to

the nominal operating conditions. The controller reduces maintain PSE at setpoint. The increase of MIW relative

THROUGHPUT in order to maintain PSE at setpoint, to MFS leads to an increase in the rheology factor and

which is weighted as being more important. the RNMPC increases MFB (see Fig. 2) to compensate

for the higher rheology factor in order to maintain proper

The PSE setpoint is lowered from 80% to 70% at time 100

breakage conditions inside the mill.

min to increase THROUGHPUT, because THROUGH-

PUT and PSE is inversely proportional. At time 100 min, the controller further increases MIW

and as a result increases the rheology factor that leads

PSE (see Fig. 2) is controlled through changing the cut

to a decrease in MPOW. The drop in MPOW results in

of the cyclone. The cut of the cyclone is changed through

a coarser grind and, therefore, a decrease in PSE from

the CFF (see Fig. 2) and the cyclone feed density (CFD).

80% to 70%. This strategy is not ideal, because reducing

The CFD (see Fig. 2) can be changed by changing the mill

grinding efficiency decreases THROUGHPUT when the

discharge density through the ratio of MIW (see Fig. 2) to

PSE setpoint is lowered, but the strategy is consistent with

MFS and, more importantly, by changing the sump slurry

the weightings of the variables (see Table 3). The control

density through SFW (see Fig. 2). The controller therefore

strategy can be corrected by removing the weighting on

has three degrees of freedom with which to control the

SLEV and increasing the weighting on MIW relative to the

PSE. The SLEV (see Fig. 2) is given a setpoint, because

other MVs, which should result in the RNMPC changing

most operators do not trust the controller if it allows SLEV

PSE with SFW and CFF, rather than MIW and CFF, and,

to vary too much. The weighting on SLEV is, however,

therefore, maintain grinding efficiency of the mill and as a

very low (see Table 3) to allow the controller to vary SLEV

result increase THROUGHPUT when the PSE setpoint is

when needed in order to control more important variables,

lowered.

such as PSE.

PSE and LOAD are maintained at their desired setpoints

under RNMPC (see Fig. 2) regardless of the active distur- 5. CONCLUSIONS

bances.

The rheology factor (see Fig. 2) is a function of the The results of a practically motivated simulation show that

water and solids inside the mill. The RNMPC manipulates an RNMPC controller can successfully control important

MIW and MFS to maximise throughput by maintaining milling circuit variables in the face of large disturbances

optimum breakage conditions inside the mill, which are that are not uncommon in practice. The simulation results

obtained when the rheology factor is at the optimum show that the correct weightings of the variables in the

value of 0.51. The controller compensates for the feed RNMPC objective function is very important to produce

the correct behaviour.

IFACMMM 2009. Viña del Mar, Chile, 14 -16 October 2009.

The RNMPC was implemented using open-source optimi- Craig, I.K. and MacLeod, I.M. (1995). Specification

sation software IPOPT (Kawajir et al., 2006) and open- framework for robust control of a run-of-mine ore milling

source automatic differentiation software CppAD (Lougee- circuit. Control Engineering Practice, 3(5), 621–630.

Heimer, 2003). The simulation executed with an aver- Diehl, M., Bock, H.G., and Kostina, E. (2006). An approx-

age time of about 26 s and a maximum time of 123 s imation technique for robust nonlinear optimization.

per iteration on a Dell PowerEdge 1955 blade with Intel Mathematical Programming: Series A and B, 107(1),

Xeon 5140 (Dual-Core) 2.33GHz processor, 2GB RAM 213–230.

and 1333MHz FSB. The current RNMPC implementation Diehl, M., Bock, H.G., and Schloder, J.P. (2005). A

is not feasible for practical implementation, because the real-time iteration scheme for nonlinear optimization in

maximum and average calculation times are much longer optimal feedback control. SIAM Journal on Control and

than the recommended sampling time of 10 s (Craig and Optimization, 43(5), 1714–1736.

MacLeod, 1995). Hulbert, D.G. (1989). The state of the art in the control

of milling circuits. In 6th IFAC Symposium on Automa-

Tuning the controller will include the selection of the

tion in Mining, Mineral and Metal Processing (Buenos

prediction horizon for stability and performance, while

Aires).

maintaining a reasonable calculation time. The computa-

Kawajir, Y., Laird, C., and Wachter, A. (2006). Introduc-

tion time can also be reduced by using less nodes without

tion to Ipopt: A tutorial for downloading, installing, and

affecting the prediction horizon T , leading to an effective

using Ipopt, Revision: 799. Carnegie Mellon University,

shorter control horizon. The control algorithm is hampered

Pittsburgh, PA, USA. URL https://projects.coin-

mainly by a large number of slack variables for imple-

or.org/Ipopt.

menting robustness and the Hessian calculations. With

Lazar, M., Munoz de la Pena, D., Heemels, W.P.M.H.,

the continuous increase in computing power, this should

and Alamo, T. (2008). On input-to-state stability of

become less of an issue in the foreseeable future.

min-max nonlinear model predictive control. Systems &

The simulation further assumed full-state feedback which Control Letters, 57(1), 39–48.

is not available on real plants. Typically the controlled Limon, D., Alamo, T., Salas, F., and Camacho, E.F.

variables would be measured online (Wei and Craig, 2009) (2006). Input to state stability of min-max MPC con-

from which an observer would be needed to infer the model trollers for nonlinear systems with bounded uncertain-

states. ties. Automatica, 42(5), 797–803.

Limon, D., Bravo, J.M., Alamo, T., and Camacho, E.F.

The adoption of advanced control by the mineral process- (2005). Robust MPC of constrained nonlinear systems

ing industry will probably be determined by the trade- based on interval arithmetic. IEE Proceedings of Control

off between the added complexity of implementing and Theory and Applications, 152(3), 325–332.

maintaining an advanced controller such as RNMPC, and Lougee-Heimer, R. (2003). The Common Optimiza-

the benefits that can be derived from such an imple- tion INterface for Operations Research. IBM Jour-

mentation. Results given in this paper suggest that if a nal of Research and Development, 47(1), 57–66. URL

milling circuit regularly experiences large changes in feed http://www.coin- or.org/CppAD/.

ore hardness and composition, when for example the feed Ma, D.L. and Braatz, R.D. (2001). Worst-case analysis

ore is switched between feeds that originate from different of finite-time control policies. IEEE Transactions on

stockpiles, RNMPC might well warrant a closer look. Control Systems Technology, 9(5), 766–774.

Magni, L., De Nicolao, G., Scattolini, R., and Allgöwer,

ACKNOWLEDGEMENTS F. (2003). Robust model predictive control of nonlinear

discrete-time systems. International Journal of Robust

This paper is published with the permission of Mintek. and Nonlinear Control, 13, 229–246.

This work was sponsored by the Nation Research Foun- Mayne, D.Q., Rawlings, J.B., Rao, C.V., and Scokaert,

dation of South Africa, Mintek and the University of P.O.M. (2000). Constrained model predictive control:

Pretoria. Thanks to Dr. Dave Hulbert of Mintek for the Stability and optimality. Automatica, 36, 789–814.

nonlinear milling circuit model and for discussions on the Mhaskar, P., El-Farra, N.H., and Christofides, P.D. (2005).

modelling and control of milling circuits. Robust hybrid predictive control of nonlinear systems.

Automatica, 41(2), 209–217.

Mhaskar, P., El-Farra, N.H., and Christofides, P.D. (2006).

REFERENCES Stabilization of nonlinear systems with state and control

constraints using Lyapunov-based predictive control.

Bravo, J.M., Alamo, T., and Camacho, E.F. (2006). Ro- Systems & Control Letters, 55(8), 650–659.

bust MPC of constrained discrete-time nonlinear sys- Mhaskar, P. and Kennedy, A.B. (2008). Robust model pre-

tems based on approximated reachable sets. Automatica, dictive control of nonlinear process systems: Handling

42(10), 1745–1751. rate constraints. Chemical Engineering Science, 63(2),

Coetzee, L.C., Craig, I.K., and Kerrigan, E.C. (2008). 366–375.

Nonlinear model predictive control of a run-of-mine ore Stanley, G.G. (1987). The extractive metallurgy of gold

milling circuit. In proceedings of the 17th IFAC World in South Africa. Technical Report Vol 1, South African

Congress, July 6-11. Seoul, Korea. Institute of Mining and Metallurgy, Johannesburg.

Coetzee, L.C., Craig, I.K., and Kerrigan, E.C. (2009). Wei, D. and Craig, I.K. (2009). Grinding mill circuits – A

Robust nonlinear model predictive control of a run-of- survey of control and economic concerns. International

mine ore milling circuit. IEEE Transactions on Control Journal of Mineral Processing, 90(1-4), 56 – 66.

Systems Technology, accepted for publication.

IFACMMM 2009. Viña del Mar, Chile, 14 -16 October 2009.

You might also like

- Measuring and Managing Process Performance: QuestionsDocument4 pagesMeasuring and Managing Process Performance: QuestionsAshik Uz ZamanNo ratings yet

- Amman Master PlanDocument205 pagesAmman Master Planomaroyoun100% (9)

- Zhang IEEE Transactions Industrial Electronics 2017bDocument9 pagesZhang IEEE Transactions Industrial Electronics 2017bviktorija bezhovskaNo ratings yet

- Analysis and Validation of A Run-Of-Mine Ore Grinding Mill Circuit Model For Process ControlDocument15 pagesAnalysis and Validation of A Run-Of-Mine Ore Grinding Mill Circuit Model For Process ControlHubert Ventura HinostrozaNo ratings yet

- Slide Mode Control (SMC)Document14 pagesSlide Mode Control (SMC)Jaol1976No ratings yet

- Control Engineering Practice Volume 1 Issue 6 1993 OllDocument9 pagesControl Engineering Practice Volume 1 Issue 6 1993 OllAhmed AbassNo ratings yet

- A Systematic Review On MEMS GyroscopeDocument6 pagesA Systematic Review On MEMS GyroscopeArjun KapoorNo ratings yet

- Meyer Coal 2014Document23 pagesMeyer Coal 2014Molote Erwin MalieheNo ratings yet

- Design of Neuro Fuzzy Sliding Mode Controller For Active Magnetic Bearing Control SystemDocument12 pagesDesign of Neuro Fuzzy Sliding Mode Controller For Active Magnetic Bearing Control Systemxiaoqi dengNo ratings yet

- Design of CMOS Ring Oscillator Using CMODEDocument7 pagesDesign of CMOS Ring Oscillator Using CMODExyz91229111412No ratings yet

- Dynamic Hybrid Modeling and Simulation of Grinding-Flotation CircuitsDocument15 pagesDynamic Hybrid Modeling and Simulation of Grinding-Flotation CircuitsDirceu NascimentoNo ratings yet

- Robotic Non-Destructive InspectionDocument8 pagesRobotic Non-Destructive InspectionFadhli AzinnuddinNo ratings yet

- INFERENTIAL MEASUREMENT OF SAG MILL PARAMETERS 5 MPC Simulation PDFDocument18 pagesINFERENTIAL MEASUREMENT OF SAG MILL PARAMETERS 5 MPC Simulation PDFNaurizbek NaukaNo ratings yet

- Micro Hex Apo DoDocument8 pagesMicro Hex Apo DoelzirakuzaNo ratings yet

- A Design Approach of Higher Oscillation VCO Made of CS Amplifier With Varying Active LoadDocument10 pagesA Design Approach of Higher Oscillation VCO Made of CS Amplifier With Varying Active Loadanon_701088587No ratings yet

- Robust Tracking Control of An Ironless Linear Motor With Continuous Motion Nominal Characteristic Trajectory Following ControllerDocument6 pagesRobust Tracking Control of An Ironless Linear Motor With Continuous Motion Nominal Characteristic Trajectory Following ControllerUGNo ratings yet

- Design and Development of Low-Cost Room Temperature Electric Field Poling System For The Fabrication of Quasi-Phase Matching DevicesDocument11 pagesDesign and Development of Low-Cost Room Temperature Electric Field Poling System For The Fabrication of Quasi-Phase Matching DevicesKrish PandiyanNo ratings yet

- The Research and Simulation of CSMACA Mechanism ofDocument6 pagesThe Research and Simulation of CSMACA Mechanism ofcristina comanescuNo ratings yet

- Robust Backstepping Sensorless Speed Control of PMSM UsingDocument6 pagesRobust Backstepping Sensorless Speed Control of PMSM UsingNguyễn Văn HoàNo ratings yet

- Doc1 1Document5 pagesDoc1 1Corvo Do BecoNo ratings yet

- 03 - Thomson Et Al - Current Signature Analysis To Detect Induction Motors FaultsDocument9 pages03 - Thomson Et Al - Current Signature Analysis To Detect Induction Motors FaultsCar AljaNo ratings yet

- Energies 15 02689 v2Document17 pagesEnergies 15 02689 v2Mohit KaundalNo ratings yet

- Application of Robotics For The Nuclear Power Plants in KoreaDocument5 pagesApplication of Robotics For The Nuclear Power Plants in KoreaAbhilasha SaksenaNo ratings yet

- Evaluation of Progressive Deterioration of A Squirrel-Cage Rotor, With A Condition Monitoring System That Implements The Sideband MethodologyDocument6 pagesEvaluation of Progressive Deterioration of A Squirrel-Cage Rotor, With A Condition Monitoring System That Implements The Sideband MethodologyLeo ArguijoNo ratings yet

- Robust Sliding Mode Control For Robot ManipulatorsDocument10 pagesRobust Sliding Mode Control For Robot Manipulatorshoàng nguyễnNo ratings yet

- Control in GrindingDocument4 pagesControl in GrindingalnemangiNo ratings yet

- Topics in (Nano) Biotechnology: Microfabrication TechniquesDocument111 pagesTopics in (Nano) Biotechnology: Microfabrication TechniquestprakashtceNo ratings yet

- Adaptive Optimal Control Sustem of Ore Large Crushing ProcessDocument8 pagesAdaptive Optimal Control Sustem of Ore Large Crushing ProcessJuan SierraNo ratings yet

- PID-SMC Controller For A 2-DOF Planar Robot: February 2019Document6 pagesPID-SMC Controller For A 2-DOF Planar Robot: February 2019Khôi PhiNo ratings yet

- Rapid Fabrication of Al-Based Bulk-Form Nanocomposites With Novel Reinforcement and Enhanced Performance by Selective Laser MeltingDocument4 pagesRapid Fabrication of Al-Based Bulk-Form Nanocomposites With Novel Reinforcement and Enhanced Performance by Selective Laser Meltingsam jebarajNo ratings yet

- A Comparison Between A Flotation Mini Pilot Plant and A Copper Concentrator Mill PDFDocument9 pagesA Comparison Between A Flotation Mini Pilot Plant and A Copper Concentrator Mill PDFErick De la CruzTapiaNo ratings yet

- Fabrication and Control of A 6-DOF Magnetic Levitation Stage With Nanopositioning CapabilityDocument6 pagesFabrication and Control of A 6-DOF Magnetic Levitation Stage With Nanopositioning CapabilityDileep SettyNo ratings yet

- 2 DoDocument4 pages2 DoYeferson Eusebio Lloclla EscobarNo ratings yet

- An Efficient Differential Conditional Capturing Energy Recovery Flip-Flop DesignDocument6 pagesAn Efficient Differential Conditional Capturing Energy Recovery Flip-Flop DesignRaghul RamasamyNo ratings yet

- Microprocessors and Microsystems: L. Senthil Murugan, P. MaruthupandiDocument7 pagesMicroprocessors and Microsystems: L. Senthil Murugan, P. MaruthupandiSung Ryoung LimNo ratings yet

- Minerals Engineering: C.W. Steyn, C. SandrockDocument11 pagesMinerals Engineering: C.W. Steyn, C. SandrockMario Alejandro Leon GaticaNo ratings yet

- Modified Winding Function Approach To Stator Fault Modelling of Synchronous GeneratorDocument6 pagesModified Winding Function Approach To Stator Fault Modelling of Synchronous GeneratormohammadNo ratings yet

- بحث 4Document8 pagesبحث 4hayderNo ratings yet

- Precision Engineering: Nicholas W. Horvath, Matthew A. Davies, Steven R. PattersonDocument9 pagesPrecision Engineering: Nicholas W. Horvath, Matthew A. Davies, Steven R. PattersonLeonNo ratings yet

- On-Line Detection of Defects in Layered Manufacturing: Is Use ADocument6 pagesOn-Line Detection of Defects in Layered Manufacturing: Is Use AShahrzad GhasemiNo ratings yet

- Discrete-Time LQG Dynamic Controller Design Using Plant Markov ParametersDocument8 pagesDiscrete-Time LQG Dynamic Controller Design Using Plant Markov ParametersRaminptNo ratings yet

- Modi Ed Power Rate Sliding Mode Control For Robot Manipulator Based On Particle Swarm OptimizationDocument13 pagesModi Ed Power Rate Sliding Mode Control For Robot Manipulator Based On Particle Swarm OptimizationIAES International Journal of Robotics and AutomationNo ratings yet

- Modeling and SimulationDocument10 pagesModeling and Simulationoumaima ghzNo ratings yet

- Design of A Telescopic Fully Differential OTADocument7 pagesDesign of A Telescopic Fully Differential OTAUdai ValluruNo ratings yet

- Ucmp Unit Iv Part ADocument6 pagesUcmp Unit Iv Part Arx135rakeshNo ratings yet

- Model Predictive Control of Laser Metal Deposition: Yangbo Liu Liuping Wang Milan BrandtDocument13 pagesModel Predictive Control of Laser Metal Deposition: Yangbo Liu Liuping Wang Milan BrandtBryant Bruce Picon YangNo ratings yet

- Design of MEMS Switch For RF ApplicationsDocument3 pagesDesign of MEMS Switch For RF ApplicationsSanthoshiniRajanNo ratings yet

- Model Identification For Dragline Swing Assist Control DesignDocument6 pagesModel Identification For Dragline Swing Assist Control DesignMateen MahdiNo ratings yet

- 0073 - FI - A Combined MPC For Milling and Flotation - A Simulation StudyDocument7 pages0073 - FI - A Combined MPC For Milling and Flotation - A Simulation StudymahfoudNo ratings yet

- A Comparison of High Pressure Roller Mill and Conventional GrindingDocument4 pagesA Comparison of High Pressure Roller Mill and Conventional GrindingLi ZethNo ratings yet

- 1.1 Introduction To Conventional and Non Conventional MachiningDocument42 pages1.1 Introduction To Conventional and Non Conventional MachiningDida KhalingNo ratings yet

- Four-Cable-Driven Parallel Robot: Xuejun Jin, Dae Ik Jun, Andreas Pott, Sukho Park, Jong-Oh Park and Seong Young KoDocument5 pagesFour-Cable-Driven Parallel Robot: Xuejun Jin, Dae Ik Jun, Andreas Pott, Sukho Park, Jong-Oh Park and Seong Young KoAlonso ChuizNo ratings yet

- Ok 2017 MODELO MOLINO LeRoux - EKF - 2017Document20 pagesOk 2017 MODELO MOLINO LeRoux - EKF - 2017Hubert Ventura HinostrozaNo ratings yet

- Frequency Response Measurements For Switching Power Supplies Slup121Document13 pagesFrequency Response Measurements For Switching Power Supplies Slup121shrikrisNo ratings yet

- A 6.78 MHZ Single-Stage Wireless Power Transmitter Using A 3-Mode Zero-Voltage Switching Class-D PADocument11 pagesA 6.78 MHZ Single-Stage Wireless Power Transmitter Using A 3-Mode Zero-Voltage Switching Class-D PAZhongpeng LiangNo ratings yet

- IJAER Paper2Document6 pagesIJAER Paper2DaveNo ratings yet

- Applications of AFM in Semiconductor R&D and Manufacturing at 45 NM Technology Node and BeyondDocument12 pagesApplications of AFM in Semiconductor R&D and Manufacturing at 45 NM Technology Node and BeyondSourav PradhanNo ratings yet

- Adaptive Torque Pulsation Compensation For A High-Torque DC Brushless Permanent Magnet MotorDocument6 pagesAdaptive Torque Pulsation Compensation For A High-Torque DC Brushless Permanent Magnet Motorfong jeffNo ratings yet

- International Journal of Pressure Vessels and Piping: SciencedirectDocument7 pagesInternational Journal of Pressure Vessels and Piping: SciencedirectKurra SrikanthNo ratings yet

- Casting Blemishes and Supply Chain Relationship in Cast Iron FoundryDocument8 pagesCasting Blemishes and Supply Chain Relationship in Cast Iron FoundryVittal SBNo ratings yet

- Design of Rotating Wheel For Dip Test of Polymeric InsulatorsDocument4 pagesDesign of Rotating Wheel For Dip Test of Polymeric InsulatorsTrung Nguyễn QuangNo ratings yet

- High Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorFrom EverandHigh Order Large Eddy Simulation for Shock-Boundary Layer Interaction Control by a Micro-ramp Vortex GeneratorNo ratings yet

- Work Index Materiales CompositosDocument14 pagesWork Index Materiales Compositosjsotofmet4918No ratings yet

- Froth Recovery Measurement in Plant Scale Flotation CellsDocument7 pagesFroth Recovery Measurement in Plant Scale Flotation Cellsjsotofmet4918No ratings yet

- Kinetics of Froth Flotation of Naturally Hydrophobic Solids With DifferentDocument10 pagesKinetics of Froth Flotation of Naturally Hydrophobic Solids With Differentjsotofmet4918No ratings yet

- Quarry Fines MinimisationDocument14 pagesQuarry Fines Minimisationjsotofmet4918No ratings yet

- Mineral Traps For Greenhouse Gases in Mine TailingsDocument336 pagesMineral Traps For Greenhouse Gases in Mine Tailingsjsotofmet4918No ratings yet

- A Sustainable Legacy Utilizing Mine Assets Post-Closure Island PDFDocument10 pagesA Sustainable Legacy Utilizing Mine Assets Post-Closure Island PDFjsotofmet4918No ratings yet

- Assessment of Waste Rock Weathering Characteristics at TheDocument260 pagesAssessment of Waste Rock Weathering Characteristics at Thejsotofmet4918No ratings yet

- Reclamation Measures at Equity Silver Mines LimitedDocument10 pagesReclamation Measures at Equity Silver Mines Limitedjsotofmet4918No ratings yet

- Chloride Leaching For ChalcopyriteDocument179 pagesChloride Leaching For Chalcopyritejsotofmet4918No ratings yet

- 0 EDEM For Postdoc AppDocument19 pages0 EDEM For Postdoc Appjsotofmet4918No ratings yet

- Control of Slimes Coating in Mineral SuspensionsDocument12 pagesControl of Slimes Coating in Mineral Suspensionsjsotofmet4918No ratings yet

- Reay 1975Document6 pagesReay 1975jsotofmet4918No ratings yet

- Kvarla1991 PDFDocument21 pagesKvarla1991 PDFjsotofmet4918No ratings yet

- OR2456 MaxiLoader P04Document2 pagesOR2456 MaxiLoader P04jacques PerronNo ratings yet

- Zte Lte FDD Lr18 Feature ListDocument57 pagesZte Lte FDD Lr18 Feature ListDhananjay Shrivastav100% (3)

- ThinkPad T460p Platform SpecificationsDocument1 pageThinkPad T460p Platform SpecificationsSim Shih HengNo ratings yet

- Hiab-658 Ficha TecnicaDocument2 pagesHiab-658 Ficha Tecnicaanmec20No ratings yet

- Tendernotice 1Document70 pagesTendernotice 1paulNo ratings yet

- Public Administration Unit-9 Scientific Management-F.W. TaylorDocument9 pagesPublic Administration Unit-9 Scientific Management-F.W. TaylorDeepika Sharma100% (2)

- Damped Oscillations - Forced Oscillations and ResonanceDocument27 pagesDamped Oscillations - Forced Oscillations and ResonanceVirgilioNo ratings yet

- Wilgamuwa Heengaga Water Supply Project: Schedule Symbol Description QuantityDocument1 pageWilgamuwa Heengaga Water Supply Project: Schedule Symbol Description QuantityGayan IndunilNo ratings yet

- Mixture: (Alligations)Document4 pagesMixture: (Alligations)krish masterjeeNo ratings yet

- Siswanto, Rian Wahyu Edi Sarwono, Aris Setyawan, Dedet Hermawan SetabudiDocument4 pagesSiswanto, Rian Wahyu Edi Sarwono, Aris Setyawan, Dedet Hermawan SetabudiGuntur PrawiraNo ratings yet

- Xforce PDocument6 pagesXforce PRAB HFRNo ratings yet

- Swivel Joints EngDocument24 pagesSwivel Joints Enghendry_hdwNo ratings yet

- 05958317Document4 pages05958317Fari PratomosiwiNo ratings yet

- Effect of Spray Rails and Wedges On The Performance of Semi-Displacement HullsDocument12 pagesEffect of Spray Rails and Wedges On The Performance of Semi-Displacement HullsAnggaGustamaNo ratings yet

- Fluid Mechanics ManualDocument41 pagesFluid Mechanics ManualrajmaljatNo ratings yet

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (2)

- Entity-Relationship Modelling (IEEE)Document6 pagesEntity-Relationship Modelling (IEEE)akshaymadan04No ratings yet

- JMF Ac - Base 2015 CobaDocument68 pagesJMF Ac - Base 2015 CobaCahyo 03No ratings yet

- Miller Guide For Gtaw NewDocument32 pagesMiller Guide For Gtaw NewKentDemeterioNo ratings yet

- Pneumatic Test ProcedureDocument7 pagesPneumatic Test ProcedureDeepu ChandranNo ratings yet

- Internal Checking of Plywood Formwork For Top Slab Containment Tank. Comment ACTDocument3 pagesInternal Checking of Plywood Formwork For Top Slab Containment Tank. Comment ACTMuhammad Ghazaly HatalaNo ratings yet

- 100-00101-00 - 01 RiEye User Guide Issue 3Document21 pages100-00101-00 - 01 RiEye User Guide Issue 3AngeloNo ratings yet

- Art & Science of Continuous Emissions Monitoring SystemsDocument44 pagesArt & Science of Continuous Emissions Monitoring SystemshuyNo ratings yet

- Chiller InductorDocument2 pagesChiller InductorAlberto Steven Ospino GómezNo ratings yet

- Toefl - Americans Are Too Dependant On CarsDocument5 pagesToefl - Americans Are Too Dependant On CarsAmi BarnesNo ratings yet

- Portotecnica General Catalogue 2018 - High Pressure WashersDocument172 pagesPortotecnica General Catalogue 2018 - High Pressure WashersTimo LilienbergNo ratings yet

- Lte SCFTDocument20 pagesLte SCFTkashireddy100% (1)

- Fabrication of Cylindrical Cam Shaper MachineDocument11 pagesFabrication of Cylindrical Cam Shaper MachineretechNo ratings yet