Professional Documents

Culture Documents

3.0 General Handling: 3.1 Cutting and Machining

3.0 General Handling: 3.1 Cutting and Machining

Uploaded by

satnamCopyright:

Available Formats

You might also like

- The Freelance Content Marketing Writer Find Your Perfect Clients, Make Tons of Money and Build A Business You Love (Gregory Jennifer Goforth) (Z-Library)Document219 pagesThe Freelance Content Marketing Writer Find Your Perfect Clients, Make Tons of Money and Build A Business You Love (Gregory Jennifer Goforth) (Z-Library)Mara Relunia-Ayen100% (1)

- Mobilization Plan VDocument3 pagesMobilization Plan Vyamanta_raj100% (1)

- Mse Notes - Unit - 2Document12 pagesMse Notes - Unit - 2337-ME- KIRTHAN DEVADIGANo ratings yet

- 14 Material and Heat Treatment of Jigs &Document18 pages14 Material and Heat Treatment of Jigs &GV RagunathanNo ratings yet

- 2600, 2400, 2300 FOGGERS: User'S ManualDocument2 pages2600, 2400, 2300 FOGGERS: User'S Manualver_at_work100% (1)

- Unit-2 Part-5Document9 pagesUnit-2 Part-5Tisha MishraNo ratings yet

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- Bt1 MetalsDocument21 pagesBt1 MetalsJeric LaureanoNo ratings yet

- Cast IronDocument18 pagesCast IronPhoenix KukuruyukNo ratings yet

- Clad Plates Forming & WeldingDocument9 pagesClad Plates Forming & WeldingMohammed Khalid KhanNo ratings yet

- Basic Maintenance Aspects PDFDocument194 pagesBasic Maintenance Aspects PDFHumaid ShaikhNo ratings yet

- Unit 4 - Engineering CeramicsDocument20 pagesUnit 4 - Engineering Ceramicsmaximus4682No ratings yet

- 26 WorkshopDocument32 pages26 WorkshopSándor SzabóNo ratings yet

- A Guide To CNC Router MaterialsDocument4 pagesA Guide To CNC Router MaterialsAlejandro Gutiérrez OrtízNo ratings yet

- Engineering Materials MEE 110: Dr. M. Tauqeer AnwarDocument13 pagesEngineering Materials MEE 110: Dr. M. Tauqeer AnwarAli HassanNo ratings yet

- ProjectDocument34 pagesProjectSTAR PRINTINGNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- Mse Notes - Unit - 3Document11 pagesMse Notes - Unit - 3337-ME- KIRTHAN DEVADIGANo ratings yet

- Pas CTG Tur Cer-Cermet enDocument36 pagesPas CTG Tur Cer-Cermet enshumi27No ratings yet

- 3.cutting Tool MaterialsDocument14 pages3.cutting Tool MaterialsSatyajéèt KankeNo ratings yet

- Welding of Cast IronDocument35 pagesWelding of Cast IronincaurcoNo ratings yet

- Zinc Flake CoatingsDocument1 pageZinc Flake CoatingsDinh TuNo ratings yet

- Cutting Tool MaterialsDocument3 pagesCutting Tool MaterialsManish KumarNo ratings yet

- Format Classtest 3 IronsDocument5 pagesFormat Classtest 3 IronsVaibhav BhosaleNo ratings yet

- Basic Workshop PDFDocument15 pagesBasic Workshop PDFniyati DesaiNo ratings yet

- Cutting Tool Materials ME MechanicalDocument4 pagesCutting Tool Materials ME MechanicalManish Kumar100% (1)

- Non Ferrous Metals and Alloys CH5 DDUDocument97 pagesNon Ferrous Metals and Alloys CH5 DDUPratik ThakerNo ratings yet

- Crisp notes of Material in industryDocument17 pagesCrisp notes of Material in industryInceptionNo ratings yet

- Guide Cast Iron WeldingDocument8 pagesGuide Cast Iron WeldingAgustine SetiawanNo ratings yet

- Type of Steel and Cast Iron Lec7Document29 pagesType of Steel and Cast Iron Lec7shresthasamir743No ratings yet

- Presentation On: Non-Ferrous MetalsDocument56 pagesPresentation On: Non-Ferrous MetalsMohd AnasNo ratings yet

- CeramicsDocument34 pagesCeramicsArun Raj A CNo ratings yet

- Properties of ASISI CodeDocument16 pagesProperties of ASISI CodeTribhuwan MishraNo ratings yet

- 00 Preventing Corrosion in AluminumDocument1 page00 Preventing Corrosion in AluminumReylourd PunzalNo ratings yet

- Note CHP 4 Material Science 281 Uitm Em110Document52 pagesNote CHP 4 Material Science 281 Uitm Em110bino_ryeNo ratings yet

- Lec 02Document19 pagesLec 02أمير حامد100% (1)

- Bead and Mesh PDFDocument7 pagesBead and Mesh PDFjerconsNo ratings yet

- Welding Is The Process of Permanently Joining Two or More Metal Parts, by Melting BothDocument3 pagesWelding Is The Process of Permanently Joining Two or More Metal Parts, by Melting BothSuleman KhanNo ratings yet

- How To Weld S Duplex SsDocument47 pagesHow To Weld S Duplex Sszebra9368No ratings yet

- SS 409M WeldingDocument12 pagesSS 409M WeldingwentropremNo ratings yet

- Partie 3Document34 pagesPartie 3vincent.guilbault7894No ratings yet

- Aluminium, Copper and Its AlloysDocument14 pagesAluminium, Copper and Its AlloysManiesh LokapurNo ratings yet

- Cutting Tool MaterialDocument41 pagesCutting Tool MaterialDheerajOmprasadNo ratings yet

- Teromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionDocument2 pagesTeromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionJuan Carlos EspinozaNo ratings yet

- Steel: Stones Bricks Cement ConcreteDocument46 pagesSteel: Stones Bricks Cement ConcreteKaushik RNo ratings yet

- Surface Hardening: - Core With Fine Pearlite, Surface MartensiticDocument28 pagesSurface Hardening: - Core With Fine Pearlite, Surface MartensiticRaghuNo ratings yet

- Chem-114-Metals-1Document44 pagesChem-114-Metals-1Elein MarceloNo ratings yet

- Non Ferrous MaterialsDocument51 pagesNon Ferrous MaterialsDhana LakshmiNo ratings yet

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghNo ratings yet

- Welding of Nickel AlloysDocument12 pagesWelding of Nickel AlloysErick HoganNo ratings yet

- GougingDocument4 pagesGougingmail_younes6592No ratings yet

- ME 6402 Manufacturing Technology II Unit - IDocument14 pagesME 6402 Manufacturing Technology II Unit - Iananda narayananNo ratings yet

- Metal Cutting and Machine ToolsDocument131 pagesMetal Cutting and Machine Toolsthirumalaikumaran100% (1)

- Buehler's Guide To Sample PreparationDocument74 pagesBuehler's Guide To Sample PreparationGowtham GanesanNo ratings yet

- Thermal GougingDocument2 pagesThermal Gougingdinar tunjungNo ratings yet

- Stainless Steel in ConstructionDocument23 pagesStainless Steel in ConstructionMohamed KaramNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

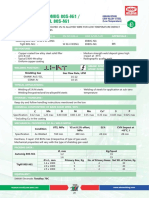

- Tigfil Cuni: Classification: ApprovalsDocument1 pageTigfil Cuni: Classification: ApprovalssatnamNo ratings yet

- CWC-BookletF1 59Document1 pageCWC-BookletF1 59satnamNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 pageAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 pageAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 5Document1 pageCWC-BookletF1 5satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 3Document1 pageCWC-BookletF1 3satnamNo ratings yet

- CWC-BookletF1 4Document1 pageCWC-BookletF1 4satnamNo ratings yet

- CWC-BookletF1 2Document1 pageCWC-BookletF1 2satnamNo ratings yet

- Absorption and Diffusion of Hydrogen in SteelsDocument12 pagesAbsorption and Diffusion of Hydrogen in SteelsadipanNo ratings yet

- HUAWEI P10 Lite Quick Start Guide (WAS-LX1, 02, 21 Lans, Dual, NEU) PDFDocument188 pagesHUAWEI P10 Lite Quick Start Guide (WAS-LX1, 02, 21 Lans, Dual, NEU) PDFritastoicaNo ratings yet

- MT6781 Android ScatterDocument34 pagesMT6781 Android ScatterOliver FischerNo ratings yet

- Ranitidine Injection, USP PDFDocument7 pagesRanitidine Injection, USP PDFNur AlfiahNo ratings yet

- Machines 07 00042 PDFDocument21 pagesMachines 07 00042 PDFguterresNo ratings yet

- TM Promo NameDocument10 pagesTM Promo NameCristel Simbol TinguhaNo ratings yet

- Manual de Operacion y Perforadora Atlas Copco Roc PDFDocument70 pagesManual de Operacion y Perforadora Atlas Copco Roc PDFkos0911No ratings yet

- FMD 2022 Half Year Activity Report - FinalDocument78 pagesFMD 2022 Half Year Activity Report - FinalPaul WaltersNo ratings yet

- 1 s2.0 S0360128509000604 Main PDFDocument37 pages1 s2.0 S0360128509000604 Main PDFNurul AkmamNo ratings yet

- Log FileDocument51 pagesLog FileGopalakrishna Devulapalli100% (1)

- OOP Week 2Document34 pagesOOP Week 2鄭力愷No ratings yet

- OooooobbbbbbDocument134 pagesOooooobbbbbbAmedin TemamNo ratings yet

- F. C. 43 (See Rule 7.8) : Signature of Drawing Officer With DateDocument2 pagesF. C. 43 (See Rule 7.8) : Signature of Drawing Officer With Dateazad100% (1)

- Qlik Certification Program FAQ enDocument6 pagesQlik Certification Program FAQ ensmederevac1977No ratings yet

- Oktober 2016Document18 pagesOktober 2016Taufiq RahmanNo ratings yet

- HRM 822 Group Assignment 1Document12 pagesHRM 822 Group Assignment 1Dhruvi RajNo ratings yet

- Funny Short StoriesDocument43 pagesFunny Short StorieschicankzNo ratings yet

- Chap 6 SolnsDocument2 pagesChap 6 SolnsjoNo ratings yet

- 000000000001000458Document90 pages000000000001000458Dante Filho100% (2)

- Civil Suit 164 of 2013Document6 pagesCivil Suit 164 of 2013Diana WangamatiNo ratings yet

- Competencies For OD PractitionerDocument6 pagesCompetencies For OD PractitionerAanchal GargNo ratings yet

- CV Rajamohan P - Project Manager MEPDocument4 pagesCV Rajamohan P - Project Manager MEPDheeraj Chowdary DhanekulaNo ratings yet

- Chapter 1 - Slope Deflection Method For Statically Indeterminate BeamsDocument6 pagesChapter 1 - Slope Deflection Method For Statically Indeterminate BeamsTharshini GobiNo ratings yet

- Sbi Life EshieldDocument6 pagesSbi Life EshieldAnkit VyasNo ratings yet

- Career Essay Eng 1302Document4 pagesCareer Essay Eng 1302Madison MorenoNo ratings yet

- Incident Record FormDocument2 pagesIncident Record FormMark Joel AguilaNo ratings yet

- Optimization of The Setup Position of A Workpiece For Five-Axis Machining To Reduce Machining TimeDocument13 pagesOptimization of The Setup Position of A Workpiece For Five-Axis Machining To Reduce Machining TimeHungTranNo ratings yet

3.0 General Handling: 3.1 Cutting and Machining

3.0 General Handling: 3.1 Cutting and Machining

Uploaded by

satnamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.0 General Handling: 3.1 Cutting and Machining

3.0 General Handling: 3.1 Cutting and Machining

Uploaded by

satnamCopyright:

Available Formats

3.

0 General Handling

The precautions required for handling • Plates and sheets are best stored 3.1 Cutting and Machining

copper-nickels will be familiar to any vertically in covered racks.

fabricator who routinely handles materials • Walking over sheets should be Copper-nickels can be cut using most

like stainless steels and aluminium alloys, avoided. conventional cutting processes, with the

but may be new to those used to dealing • Plastic film may be interposed exception of oxy-fuel cutting. High-speed

with only carbon steels. between the sheet and rolls when abrasive wheels work well for bevelling

roll forming. edges and trimming material. Band saws

Cleanliness is paramount: contamination • Grease and paint should be kept or shears may be used for cutting, but

can cause cracking and porosity during away from the surface, particularly allowance made for the alloys’ relative

heat treatment or welding and may affect near edges of weld preparations; all softness and ductility. Plasma-arc cutting

the corrosion resistance of the alloy. trace of marking crayons must be is fast, accurate and economical. Laser and

Ideally, fabrication should be done in an removed before making a joint. abrasive water jet cutting are also possible.

area devoted solely to copper-nickel alloys. • Stainless steel brushes should be

Where this is impracticable, the standard of used, and tools such as grinding Although copper-nickels are not as readily

care of the material should be well above discs should not be interchanged machined as free-cutting brass, they are

that necessary for carbon steels. between copper-nickel and other much easier to machine than materials,

materials. such as stainless steels, which work harden

• Sheets should remain in their • Openings of pipes and fittings must rapidly: they can be ranked with aluminium

packing until needed and should be be protected on completion of bronze and phosphor bronze alloys. More

separated - normally by protective fabrication to prevent ingress of dirt details and recommendations are given

material - to avoid abrasion. etc. before installation. in ‘Recommended Machining Parameters for

Copper and Copper Alloys’, DKI Monograph i.18.

Plasma cutting copper-nickel plate

(Courtesy Eucaro Buntmetall GmbH)

6 | Copper-Nickel Welding and Fabrication

53

You might also like

- The Freelance Content Marketing Writer Find Your Perfect Clients, Make Tons of Money and Build A Business You Love (Gregory Jennifer Goforth) (Z-Library)Document219 pagesThe Freelance Content Marketing Writer Find Your Perfect Clients, Make Tons of Money and Build A Business You Love (Gregory Jennifer Goforth) (Z-Library)Mara Relunia-Ayen100% (1)

- Mobilization Plan VDocument3 pagesMobilization Plan Vyamanta_raj100% (1)

- Mse Notes - Unit - 2Document12 pagesMse Notes - Unit - 2337-ME- KIRTHAN DEVADIGANo ratings yet

- 14 Material and Heat Treatment of Jigs &Document18 pages14 Material and Heat Treatment of Jigs &GV RagunathanNo ratings yet

- 2600, 2400, 2300 FOGGERS: User'S ManualDocument2 pages2600, 2400, 2300 FOGGERS: User'S Manualver_at_work100% (1)

- Unit-2 Part-5Document9 pagesUnit-2 Part-5Tisha MishraNo ratings yet

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- Bt1 MetalsDocument21 pagesBt1 MetalsJeric LaureanoNo ratings yet

- Cast IronDocument18 pagesCast IronPhoenix KukuruyukNo ratings yet

- Clad Plates Forming & WeldingDocument9 pagesClad Plates Forming & WeldingMohammed Khalid KhanNo ratings yet

- Basic Maintenance Aspects PDFDocument194 pagesBasic Maintenance Aspects PDFHumaid ShaikhNo ratings yet

- Unit 4 - Engineering CeramicsDocument20 pagesUnit 4 - Engineering Ceramicsmaximus4682No ratings yet

- 26 WorkshopDocument32 pages26 WorkshopSándor SzabóNo ratings yet

- A Guide To CNC Router MaterialsDocument4 pagesA Guide To CNC Router MaterialsAlejandro Gutiérrez OrtízNo ratings yet

- Engineering Materials MEE 110: Dr. M. Tauqeer AnwarDocument13 pagesEngineering Materials MEE 110: Dr. M. Tauqeer AnwarAli HassanNo ratings yet

- ProjectDocument34 pagesProjectSTAR PRINTINGNo ratings yet

- Select Arc Brochure On Ni Alloy Welding ProductsDocument6 pagesSelect Arc Brochure On Ni Alloy Welding Productsharan2000No ratings yet

- Mse Notes - Unit - 3Document11 pagesMse Notes - Unit - 3337-ME- KIRTHAN DEVADIGANo ratings yet

- Pas CTG Tur Cer-Cermet enDocument36 pagesPas CTG Tur Cer-Cermet enshumi27No ratings yet

- 3.cutting Tool MaterialsDocument14 pages3.cutting Tool MaterialsSatyajéèt KankeNo ratings yet

- Welding of Cast IronDocument35 pagesWelding of Cast IronincaurcoNo ratings yet

- Zinc Flake CoatingsDocument1 pageZinc Flake CoatingsDinh TuNo ratings yet

- Cutting Tool MaterialsDocument3 pagesCutting Tool MaterialsManish KumarNo ratings yet

- Format Classtest 3 IronsDocument5 pagesFormat Classtest 3 IronsVaibhav BhosaleNo ratings yet

- Basic Workshop PDFDocument15 pagesBasic Workshop PDFniyati DesaiNo ratings yet

- Cutting Tool Materials ME MechanicalDocument4 pagesCutting Tool Materials ME MechanicalManish Kumar100% (1)

- Non Ferrous Metals and Alloys CH5 DDUDocument97 pagesNon Ferrous Metals and Alloys CH5 DDUPratik ThakerNo ratings yet

- Crisp notes of Material in industryDocument17 pagesCrisp notes of Material in industryInceptionNo ratings yet

- Guide Cast Iron WeldingDocument8 pagesGuide Cast Iron WeldingAgustine SetiawanNo ratings yet

- Type of Steel and Cast Iron Lec7Document29 pagesType of Steel and Cast Iron Lec7shresthasamir743No ratings yet

- Presentation On: Non-Ferrous MetalsDocument56 pagesPresentation On: Non-Ferrous MetalsMohd AnasNo ratings yet

- CeramicsDocument34 pagesCeramicsArun Raj A CNo ratings yet

- Properties of ASISI CodeDocument16 pagesProperties of ASISI CodeTribhuwan MishraNo ratings yet

- 00 Preventing Corrosion in AluminumDocument1 page00 Preventing Corrosion in AluminumReylourd PunzalNo ratings yet

- Note CHP 4 Material Science 281 Uitm Em110Document52 pagesNote CHP 4 Material Science 281 Uitm Em110bino_ryeNo ratings yet

- Lec 02Document19 pagesLec 02أمير حامد100% (1)

- Bead and Mesh PDFDocument7 pagesBead and Mesh PDFjerconsNo ratings yet

- Welding Is The Process of Permanently Joining Two or More Metal Parts, by Melting BothDocument3 pagesWelding Is The Process of Permanently Joining Two or More Metal Parts, by Melting BothSuleman KhanNo ratings yet

- How To Weld S Duplex SsDocument47 pagesHow To Weld S Duplex Sszebra9368No ratings yet

- SS 409M WeldingDocument12 pagesSS 409M WeldingwentropremNo ratings yet

- Partie 3Document34 pagesPartie 3vincent.guilbault7894No ratings yet

- Aluminium, Copper and Its AlloysDocument14 pagesAluminium, Copper and Its AlloysManiesh LokapurNo ratings yet

- Cutting Tool MaterialDocument41 pagesCutting Tool MaterialDheerajOmprasadNo ratings yet

- Teromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionDocument2 pagesTeromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionJuan Carlos EspinozaNo ratings yet

- Steel: Stones Bricks Cement ConcreteDocument46 pagesSteel: Stones Bricks Cement ConcreteKaushik RNo ratings yet

- Surface Hardening: - Core With Fine Pearlite, Surface MartensiticDocument28 pagesSurface Hardening: - Core With Fine Pearlite, Surface MartensiticRaghuNo ratings yet

- Chem-114-Metals-1Document44 pagesChem-114-Metals-1Elein MarceloNo ratings yet

- Non Ferrous MaterialsDocument51 pagesNon Ferrous MaterialsDhana LakshmiNo ratings yet

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghNo ratings yet

- Welding of Nickel AlloysDocument12 pagesWelding of Nickel AlloysErick HoganNo ratings yet

- GougingDocument4 pagesGougingmail_younes6592No ratings yet

- ME 6402 Manufacturing Technology II Unit - IDocument14 pagesME 6402 Manufacturing Technology II Unit - Iananda narayananNo ratings yet

- Metal Cutting and Machine ToolsDocument131 pagesMetal Cutting and Machine Toolsthirumalaikumaran100% (1)

- Buehler's Guide To Sample PreparationDocument74 pagesBuehler's Guide To Sample PreparationGowtham GanesanNo ratings yet

- Thermal GougingDocument2 pagesThermal Gougingdinar tunjungNo ratings yet

- Stainless Steel in ConstructionDocument23 pagesStainless Steel in ConstructionMohamed KaramNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonRating: 4 out of 5 stars4/5 (1)

- Blacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithFrom EverandBlacksmithing on the Farm - With Information on the Materials, Tools and Methods of the BlacksmithNo ratings yet

- Forging Operations - Machine Forging, Forging Dies and Special Forging OperationsFrom EverandForging Operations - Machine Forging, Forging Dies and Special Forging OperationsNo ratings yet

- Tigfil Cuni: Classification: ApprovalsDocument1 pageTigfil Cuni: Classification: ApprovalssatnamNo ratings yet

- CWC-BookletF1 59Document1 pageCWC-BookletF1 59satnamNo ratings yet

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Document1 pageAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- Automig Cusn-A: Classification: Aws A/Sfa 5.7Document1 pageAutomig Cusn-A: Classification: Aws A/Sfa 5.7satnamNo ratings yet

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDocument1 pageAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Automig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060Document1 pageAutomig Nicu-7 / Tigfil Nicu-7: Ernicu-7 Sni 4060satnamNo ratings yet

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDocument1 pageAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 1100: Classification: Aws A/Sfa 5.10Document1 pageAUTOMIG 1100: Classification: Aws A/Sfa 5.10satnamNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Document1 pageAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNo ratings yet

- CWC-BookletF1 5Document1 pageCWC-BookletF1 5satnamNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADocument1 pageTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNo ratings yet

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADocument1 pageTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- CWC-BookletF1 9Document1 pageCWC-BookletF1 9satnamNo ratings yet

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Document1 pageTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- CWC-BookletF1 3Document1 pageCWC-BookletF1 3satnamNo ratings yet

- CWC-BookletF1 4Document1 pageCWC-BookletF1 4satnamNo ratings yet

- CWC-BookletF1 2Document1 pageCWC-BookletF1 2satnamNo ratings yet

- Absorption and Diffusion of Hydrogen in SteelsDocument12 pagesAbsorption and Diffusion of Hydrogen in SteelsadipanNo ratings yet

- HUAWEI P10 Lite Quick Start Guide (WAS-LX1, 02, 21 Lans, Dual, NEU) PDFDocument188 pagesHUAWEI P10 Lite Quick Start Guide (WAS-LX1, 02, 21 Lans, Dual, NEU) PDFritastoicaNo ratings yet

- MT6781 Android ScatterDocument34 pagesMT6781 Android ScatterOliver FischerNo ratings yet

- Ranitidine Injection, USP PDFDocument7 pagesRanitidine Injection, USP PDFNur AlfiahNo ratings yet

- Machines 07 00042 PDFDocument21 pagesMachines 07 00042 PDFguterresNo ratings yet

- TM Promo NameDocument10 pagesTM Promo NameCristel Simbol TinguhaNo ratings yet

- Manual de Operacion y Perforadora Atlas Copco Roc PDFDocument70 pagesManual de Operacion y Perforadora Atlas Copco Roc PDFkos0911No ratings yet

- FMD 2022 Half Year Activity Report - FinalDocument78 pagesFMD 2022 Half Year Activity Report - FinalPaul WaltersNo ratings yet

- 1 s2.0 S0360128509000604 Main PDFDocument37 pages1 s2.0 S0360128509000604 Main PDFNurul AkmamNo ratings yet

- Log FileDocument51 pagesLog FileGopalakrishna Devulapalli100% (1)

- OOP Week 2Document34 pagesOOP Week 2鄭力愷No ratings yet

- OooooobbbbbbDocument134 pagesOooooobbbbbbAmedin TemamNo ratings yet

- F. C. 43 (See Rule 7.8) : Signature of Drawing Officer With DateDocument2 pagesF. C. 43 (See Rule 7.8) : Signature of Drawing Officer With Dateazad100% (1)

- Qlik Certification Program FAQ enDocument6 pagesQlik Certification Program FAQ ensmederevac1977No ratings yet

- Oktober 2016Document18 pagesOktober 2016Taufiq RahmanNo ratings yet

- HRM 822 Group Assignment 1Document12 pagesHRM 822 Group Assignment 1Dhruvi RajNo ratings yet

- Funny Short StoriesDocument43 pagesFunny Short StorieschicankzNo ratings yet

- Chap 6 SolnsDocument2 pagesChap 6 SolnsjoNo ratings yet

- 000000000001000458Document90 pages000000000001000458Dante Filho100% (2)

- Civil Suit 164 of 2013Document6 pagesCivil Suit 164 of 2013Diana WangamatiNo ratings yet

- Competencies For OD PractitionerDocument6 pagesCompetencies For OD PractitionerAanchal GargNo ratings yet

- CV Rajamohan P - Project Manager MEPDocument4 pagesCV Rajamohan P - Project Manager MEPDheeraj Chowdary DhanekulaNo ratings yet

- Chapter 1 - Slope Deflection Method For Statically Indeterminate BeamsDocument6 pagesChapter 1 - Slope Deflection Method For Statically Indeterminate BeamsTharshini GobiNo ratings yet

- Sbi Life EshieldDocument6 pagesSbi Life EshieldAnkit VyasNo ratings yet

- Career Essay Eng 1302Document4 pagesCareer Essay Eng 1302Madison MorenoNo ratings yet

- Incident Record FormDocument2 pagesIncident Record FormMark Joel AguilaNo ratings yet

- Optimization of The Setup Position of A Workpiece For Five-Axis Machining To Reduce Machining TimeDocument13 pagesOptimization of The Setup Position of A Workpiece For Five-Axis Machining To Reduce Machining TimeHungTranNo ratings yet