Professional Documents

Culture Documents

Grundfos Tpe2!50!240 N A F A Bqqe

Grundfos Tpe2!50!240 N A F A Bqqe

Uploaded by

Luca OvidiuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grundfos Tpe2!50!240 N A F A Bqqe

Grundfos Tpe2!50!240 N A F A Bqqe

Uploaded by

Luca OvidiuCopyright:

Available Formats

GRUNDFOS DATA BOOKLET

TPE2 50-240-N-A-F-A-BQQE

Grundfos Pump 98416615

Thank you for your interest in our products

Please contact us for more information, or visit our website

https://www.lenntech.com/grundfos/TPE00/98416615/TPE2-50-240-N-A-F-A-BQQE.html

info@lenntech.com

tel. +31-15-261.09.00

fax. +31-15-261.62.89

BE > THINK > INNOVATE

Position Qty. Description

1 TPE2 50-240-N A-F-A-BQQE

Product No.: 98416615

Single-stage, close-coupled, volute pump with in-line suction and discharge ports of identical diameter.

The pump is of the top-pull-out design, i.e. the power head (motor, pump head and impeller) can be

removed for maintenance or service while the pump housing remains in the pipework.

The shaft seal is according to EN 12756. Pipework connection is via PN 16 DIN flanges (EN 1092-2

and ISO 7005-2).

The pump is fitted with a fan-cooled, permanent-magnet synchronous motor. The motor includes a

frequency converter and PI controller in the motor terminal box. This enables continuously variable

control of the motor speed, which again enables adaptation of the performance to a given requirement.

Further product details

A control panel on the motor terminal box enables setting of required setpoint as well as setting of

pump to "Min." or "Max." operation or to "Stop". The Grundfos Eye indicator on the control panel

provides visual indication of pump status:

- "Power on": Motor is running (rotating green indicator lights) or not running (permanently green

indicator lights)

- "Warning": Motor is still running (rotating yellow indicator lights) or has stopped (permanently

yellow indicator lights)

- "Alarm": Motor has stopped (flashing red indicator lights).

Communication with the pump is possible by means of the Grundfos GO Remote (accessory). The

remote control enables further settings as well as reading out of a number of parameters such as

"Actual value", "Speed", "Power input" and total "Power consumption".

The product's minimum efficiency index (MEI) is greater or equal to 0.70. This is by the Commission

Regulation (EU) considered as an indicative benchmark for best-performing water pump available on

the market as from 1 January 2013.

Pump

Pump housing and pump head are electrocoated to improve the corrosion resistance.

Electrocoating includes:

1) Alkaline-based cleaning.

2) Pretreatment with zinc phosphate coating.

3) Cathodic electrocoating (epoxy).

4) Curing of paint film at 200-250 °C.

1: Pump housing

2: Impeller

3: Neck ring

4: Pump head/motor stool

5: Stub shaft

Printed from Grundfos Product Centre [2018.02.043]

TWINPUMP=D}The twin-head pump is designed with two parallel power-heads. A flap valve in the common

discharge port is opened by the flow of the pumped liquid and prevents backflow of liquid into the idle pump head.

The pump housing is provided with a replaceable stainles steel/PTFE neck ring to reduce the amount of

liquid running from the discharge side of the impeller to the suction side. The impeller is secured to the

shaft with a nut.

The pump is fitted with an unbalanced rubber bellows seal with torque transmission across the spring

and around the bellows. Due to the bellows, the seal does not wear the shaft, and the axial movement

is not prevented by deposits on the shaft.

Primary seal:

- Rotating seal ring material: Silicon carbide (SiC)

- Stationary seat material: Silicon carbide (SiC)

This material pairing is used where higher corrosion resistance is required. The high hardness of this

material pairing offers good resistance against abrasive particles.

Secondary seal material: EPDM (ethylene-propylene rubber)

EPDM has excellent resistance to hot water. EPDM is not suitable for mineral oils.

The motor stool forms connection between the pump housing and the motor, and is equipped with a

manual air vent screw for venting of the pump housing and the shaft seal chamber. The sealing

between motor stool and pump housing is an O-ring.

The central part of the motor stool is provided with guards for protection against the shaft and coupling.

The pump stub shaft is fastened directly on the motor shaft with key and set screws.

Motor

The motor is a totally enclosed, fan-cooled motor with principal dimensions to IEC and DIN standards.

Electrical tolerances comply with IEC 60034.

The motor efficiency is classified as IE5 in accordance with IEC 60034-30-2.

The motor requires no external motor protection. The motor control unit incorporates protection against

slow- and quick-rising temperatures, e.g. constant overload and stalled conditions.

The terminal box holds terminals for these connections:

- one dedicated digital input

- two analog inputs, 0(4)-20 mA, 0-5 V, 0-10 V, 0.5 - 3.5 V

- 5 V voltage supply to potentiometer and sensor

- one configurable digital input or open-collector output

- Grundfos Digital Sensor input and output

- 24 V voltage supply for sensors

- two signal relay outputs (potential-free contacts)

- GENIbus connection

- interface for Grundfos CIM fieldbus module.

Technical data

Liquid:

Pumped liquid: Water

Liquid temperature range: -25 .. 120 °C

Liquid temperature during operation: 20 °C

Density: 998.2 kg/m³

Technical:

Speed for pump data: 5500 rpm

Rated flow: 33.1 m³/h

Rated head: 19.6 m

Actual impeller diameter: 74 mm

Primary shaft seal: BQQE

Curve tolerance: ISO9906:2012 3B

Materials:

Pump housing: Cast iron

EN-JL1040

ASTM A48-40 B

Impeller: Composite PES/PP 30% GF

Printed from Grundfos Product Centre [2018.02.043]

Position Qty. Description

Installation:

Range of ambient temperature: -20 .. 50 °C

Maximum operating pressure: 16 bar

Flange standard: DIN

Pipe connection: DN 50

Pressure rating: PN 16

Port-to-port length: 280 mm

Flange size for motor: 56C

Electrical data:

Motor type: 90LC

IE Efficiency class: IE5

Rated power - P2: 2.2 kW

Mains frequency: 50 Hz

Rated voltage: 3 x 380-500 V

Rated current: 4,35-3,55 A

Cos phi - power factor: 0,91-0,85

Rated speed: 480-5900 rpm

Efficiency: 90,1%

Enclosure class (IEC 34-5): IP55

Insulation class (IEC 85): F

Others:

Minimum efficiency index, MEI ≥: 0.7

ErP status: EuP Standalone/Prod.

Net weight: 29.1 kg

Gross weight: 36.3 kg

Shipping volume: 0.1 m³

Printed from Grundfos Product Centre [2018.02.043]

98416615 TPE2 50-240-N 50 Hz

H TPE2 50-240-N, 3*460 V eta

[m] [%]

24

100 %

22

20

90 %

18

16

80 %

14

12

70 %

10 100

60 %

8 80

6 50 % 60

4 40 % 40

2 20

25 %

20 %

0 0

0 5 10 15 20 25 30 35 40 45 50 Q [m³/h]

P NPSH

[kW] [m]

3.0 60

2.5 50

P1 (motor+freq.converter)

2.0 40

P2

1.5 30

1.0 20

0.5 10

0.0 0

Printed from Grundfos Product Centre [2018.02.043]

H TPE2 50-240-N, 3*460 V eta

Description Value [m] [%]

General information:

Product name: TPE2 50-240-N A-F-A-BQQE 24

Product No: 98416615 100 %

22

EAN number: 5711494653751

Technical: 20

Speed for pump data: 5500 rpm 18

90 %

Rated flow: 33.1 m³/h

16

Rated head: 19.6 m

80 %

Head max: 240 dm 14

Actual impeller diameter: 74 mm

12

Primary shaft seal: BQQE 70 %

Curve tolerance: ISO9906:2012 3B 10 100

Pump version: A 60 %

8 80

Model: A

Materials: 6 50 % 60

Pump housing: Cast iron 4 40 % 40

EN-JL1040

2 25 % 20

ASTM A48-40 B 20 %

Impeller: Composite PES/PP 30% GF 0 0

0 10 20 30 40 Q [m³/h]

Material code: A

P NPSH

Installation: [kW] [m]

Range of ambient temperature: -20 .. 50 °C

Maximum operating pressure: 16 bar 2.5 50

P1 (motor+freq.converter)

Flange standard: DIN

2.0 40

Connect code: F P2

Pipe connection: DN 50 1.5 30

Pressure rating: PN 16

1.0 20

Port-to-port length: 280 mm

Flange size for motor: 56C 0.5 10

280

91

75

Liquid:

165

50

158

0.0 0

Pumped liquid: Water

Liquid temperature range: -25 .. 120 °C

Liquid temperature during 20 °C

operation: 158

158

158

Density: 998.2 kg/m³

Electrical data:

Motor type: 90LC

469

IE Efficiency class: IE5

162

Rated power - P2: 2.2 kW

Mains frequency: 50 Hz 50 165

Rated voltage: 3 x 380-500 V

72

75 91 280

Rated current: 4,35-3,55 A

134

Cos phi - power factor: 0,91-0,85

Rated speed: 480-5900 rpm

122

Efficiency: 90,1%

Enclosure class (IEC 34-5): IP55

134

Insulation class (IEC 85): F

Motor protec: YES

Motor No: 99138046

Controls:

L1 L1

Control panel: HMI200 - Standard L2 L2

L3 L3

Function Module: FM300 - Advanced PE

Others: NC

C1

NO

Minimum efficiency index, MEI ≥: 0.7 NC

C2

ErP status: EuP Standalone/Prod.

NO

18 GND

OC DI

+24 V*

11 DI4/OC2

Net weight: 29.1 kg 19

17

Pt100/1000

Pt100/1000

12 AO

Gross weight: 36.3 kg +24 V* +24 V* +24 V*/5 V* +5 V* 9

14

GND

AI3

1 DI2

Shipping volume: 0.1 m³ 21

20

LiqTec

GND

22 LiqTec

Config. file no: 98819282 +24 V*

OC

GND

DI

10

4

DI3/OC1

AI1

+24 V* +24 V* +24 V*/5 V* 2 DI1

5 +5 V

6 GND

A GENIbus A

Y GENIbus Y

B GENIbus B

3 GND

15 +24 V

8 +24 V

26 +5 V

23 GND

+24 V* +24 V*

25 GDS TX

+24 V*/5 V*

24 GDS RX

+5 V* 7 AI2

Printed from Grundfos Product Centre [2018.02.043]

98416615 TPE2 50-240-N 50 Hz

cos phi TPE250-240-N + 90LC 2.2 kW 3*460 V, 50 Hz I

eta [A]

eta

cos phi

0.8 4.0

I

0.6 3.0

0.4 2.0

0.2 1.0

0.0 0.0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0 2.1 P2 [kW]

n P1

[rpm] [kW]

n

5000 5.0

4000 4.0

3000 3.0

P1 (motor+freq.converter)

2000 2.0

1000 1.0

n = 100 %

0 0.0

Printed from Grundfos Product Centre [2018.02.043]

98416615 TPE2 50-240-N 50 Hz

158 158

158

469

162

50 165

72

75 91 280

134

122

134

Note! All units are in [mm] unless others are stated.

Disclaimer: This simplified dimensional drawing does not show all details.

Printed from Grundfos Product Centre [2018.02.043]

98416615 TPE2 50-240-N 50 Hz

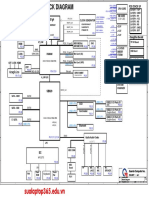

L1 L1

L2 L2

L3 L3

PE

NC

C1

NO

NC

C2

NO

18 GND

OC DI

+24 V*

11 DI4/OC2

19 Pt100/1000

17 Pt100/1000

12 AO

+24 V* +24 V*/5 V* +5 V* 9 GND

+24 V*

14 AI3

1 DI2

21 LiqTec

20 GND

22 LiqTec

OC DI

+24 V* GND

10 DI3/OC1

4 AI1

+24 V* +24 V* +24 V*/5 V* 2 DI1

5 +5 V

6 GND

A GENIbus A

Y GENIbus Y

B GENIbus B

3 GND

15 +24 V

8 +24 V

26 +5 V

23 GND

25 GDS TX

+24 V* +24 V* +24 V*/5 V*

24 GDS RX

+5 V* 7 AI2

Note! All units are in [mm] unless others are stated.

Printed from Grundfos Product Centre [2018.02.043]

Disclaimer: The information about the Grundfos pump in this document may be outdated.

Data may be subject to alterations without further notice.

Please contact us to verify the data above is still accurate/up-to-date.

All information is copyright Grundfos.

info@lenntech.com

www.lenntech.com

tel. +31-15-261.09.00

fax. +31-15-261.62.89

You might also like

- Airport Literature StudyDocument15 pagesAirport Literature StudySoundar Rajan100% (2)

- Grundfos - TP 150 220 4 A F A BAQEDocument12 pagesGrundfos - TP 150 220 4 A F A BAQEYoesoef HasyimNo ratings yet

- Grundfos - TP 25 50 2 A O A GQQEDocument11 pagesGrundfos - TP 25 50 2 A O A GQQEJovisa MaricNo ratings yet

- Grundfos - CR 15 10 A F A E HQQE PDFDocument15 pagesGrundfos - CR 15 10 A F A E HQQE PDFdimasNo ratings yet

- Grundfos - TP 40 120 2 A F A BUBEDocument13 pagesGrundfos - TP 40 120 2 A F A BUBEjuan saezNo ratings yet

- CRN32-14 A-F-G-V-HQQV 3x400/690 50 HZ: Grundfos Pump 96122405Document14 pagesCRN32-14 A-F-G-V-HQQV 3x400/690 50 HZ: Grundfos Pump 96122405Hamed YazidiNo ratings yet

- Grundfos - CR 10 16 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 16 A FJ A E HQQEJafar SidiqNo ratings yet

- Grundfos - CR 5 4 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 4 A A A E HQQE PDFabhe prasetyaNo ratings yet

- CR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Document15 pagesCR1-33 A-FGJ-A-E-HQQE 3x400D 50HZ: Grundfos Pump 96513309Muhammad GhufranNo ratings yet

- Grundfos NK 100 400 415 Eup A2 F A e BaqeDocument14 pagesGrundfos NK 100 400 415 Eup A2 F A e BaqePedro Luis ParedesNo ratings yet

- Grundfos - CRI 3 23 A P I E HQQEDocument15 pagesGrundfos - CRI 3 23 A P I E HQQEHeinium DannemannNo ratings yet

- Grundfos CR 5 13 A FGJ A e HqqeDocument15 pagesGrundfos CR 5 13 A FGJ A e HqqeRadu-Stefan MusatNo ratings yet

- Grundfos - CM10 3 A R G V AQQVDocument12 pagesGrundfos - CM10 3 A R G V AQQVD Manmath RaoNo ratings yet

- Grundfos - CR 10 4 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 4 A FJ A E HQQErosneyNo ratings yet

- Grundfos - CRN 15 4Document15 pagesGrundfos - CRN 15 4Hamed YazidiNo ratings yet

- Grundfos - CR 10 2 A FJ A E HQQEDocument15 pagesGrundfos - CR 10 2 A FJ A E HQQEMario PatarroyoNo ratings yet

- Grundfos - NB 50 250 254 A F2 A E BAQEDocument13 pagesGrundfos - NB 50 250 254 A F2 A E BAQEHoria AliNo ratings yet

- Further Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEDocument10 pagesFurther Product Details: Position Qty. Description CRE 64-2-2 A-F-A-E-HQQEitsirc67No ratings yet

- Grundfos - CR 5 3 A A A E HQQE PDFDocument15 pagesGrundfos - CR 5 3 A A A E HQQE PDFabhe prasetyaNo ratings yet

- CRN15-08 A-FGJ-G-E-HQQE 3x400/690 50 HZ: Grundfos Pump 96501965Document15 pagesCRN15-08 A-FGJ-G-E-HQQE 3x400/690 50 HZ: Grundfos Pump 96501965PysasaIrapuatoNo ratings yet

- Project: Reference Number: 98479659 (Without Lloyd's Client: Client Number: - ContactDocument7 pagesProject: Reference Number: 98479659 (Without Lloyd's Client: Client Number: - Contactjavahz74No ratings yet

- Qty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsDocument7 pagesQty. Description CR 10-2 A-A-A-E-HQQE: Further Product DetailsBrata PatandeanNo ratings yet

- Grundfos - SL1 50 65 22 2 50D CDocument13 pagesGrundfos - SL1 50 65 22 2 50D CThilina Lakmal Edirisingha100% (1)

- Sea Water Intake PumpDocument10 pagesSea Water Intake PumpmbgprsmsNo ratings yet

- Grundfos - CR 10 3A FJ A E HQQEDocument15 pagesGrundfos - CR 10 3A FJ A E HQQEArleene Mariano SalazarNo ratings yet

- Grundfos - NK 125 315 317 A2 F A E BAQEDocument14 pagesGrundfos - NK 125 315 317 A2 F A E BAQEMaryasa RobedNo ratings yet

- Grundfos - SEG 40 31 2 50BDocument17 pagesGrundfos - SEG 40 31 2 50BMarina CoskovicNo ratings yet

- CR 1517 AfaehqqeDocument4 pagesCR 1517 Afaehqqerizkidwi639No ratings yet

- Further Product Details: Position Qty. Description NB 150-500/521 A-F 2-A-BAQEDocument8 pagesFurther Product Details: Position Qty. Description NB 150-500/521 A-F 2-A-BAQEitsirc67No ratings yet

- Datasheetcr 3210 AfaehqqeDocument7 pagesDatasheetcr 3210 Afaehqqedtt000001No ratings yet

- Grundfos CRN 1s 10 A FGJ G e HqqeDocument15 pagesGrundfos CRN 1s 10 A FGJ G e HqqeANDRESNo ratings yet

- Grundfos - CM10 2 A R A E AQQEDocument11 pagesGrundfos - CM10 2 A R A E AQQEmanusnair247No ratings yet

- Grundfos Cm3 2 A R I e AqqeDocument12 pagesGrundfos Cm3 2 A R I e Aqqevksolarsystems2020No ratings yet

- NK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Document14 pagesNK125-315/336A2F2AE-SBAQE: Grundfos Pump 98318597Geovanni MZNo ratings yet

- POMPA Grundfos CM 5-2Document2 pagesPOMPA Grundfos CM 5-2Deby Eka ChandraNo ratings yet

- Grundfos CRN 3 3 A FGJ G e HqqeDocument15 pagesGrundfos CRN 3 3 A FGJ G e Hqqewmgb249529No ratings yet

- Jockey Pump 96517052 - CR - 520 - AFGJAEHQQEDocument8 pagesJockey Pump 96517052 - CR - 520 - AFGJAEHQQEShafa AlmaliyaNo ratings yet

- Grundfos CRI 5 3 A FGJ I E HQQE UnlockedDocument15 pagesGrundfos CRI 5 3 A FGJ I E HQQE UnlockedLEONARD CHRISTOPHER LIMANJAYANo ratings yet

- Grundfos Pompa PDFDocument9 pagesGrundfos Pompa PDFAnastasia Lova DiantoroNo ratings yet

- Grundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetDocument13 pagesGrundfos CR 1 8 A FGJ A E HQQE 96537544 DatasheetLeduța DomnescuNo ratings yet

- Qty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CRE 45-2-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateVitor AntunesNo ratings yet

- Grundfos CM5-3Document13 pagesGrundfos CM5-3Kiyimba DanielNo ratings yet

- Jockey Pump Balsam (Grundfosh) PDFDocument11 pagesJockey Pump Balsam (Grundfosh) PDFm khaeronNo ratings yet

- Qty. Description CR 10-22 A-FJ-A-E-HQQE: Company Name: Created By: Phone: DateDocument20 pagesQty. Description CR 10-22 A-FJ-A-E-HQQE: Company Name: Created By: Phone: DaterosneyNo ratings yet

- QCS - Secondary PumpDocument2 pagesQCS - Secondary PumpAhmed NabilNo ratings yet

- CR - 3 31 - A FGJ A e Hqqe PDFDocument17 pagesCR - 3 31 - A FGJ A e Hqqe PDFLeduța DomnescuNo ratings yet

- Grundfos - CM1 5 A R I E AQQEDocument13 pagesGrundfos - CM1 5 A R I E AQQEVimal KalariaNo ratings yet

- CR 5 9 A A A e HqqeDocument5 pagesCR 5 9 A A A e HqqeAlexander Ramos GutierrezNo ratings yet

- Brosur Grondfus CR 5-32Document7 pagesBrosur Grondfus CR 5-32CV Aliance JayaNo ratings yet

- Qty. Description CR 15-3 A-F-A-E-HQQE: Company Name: Grundfos Created By: Phone: DateDocument9 pagesQty. Description CR 15-3 A-F-A-E-HQQE: Company Name: Grundfos Created By: Phone: DateohyeungNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description NB 80-250/247 AF2ABQQEDocument9 pagesCompany Name: Created By: Phone: Date:: Qty. Description NB 80-250/247 AF2ABQQEriyas.hvacworkNo ratings yet

- Company Name: Created By: Phone: Date:: Qty. Description CR 20-12 A-F-A-E-HQQEDocument7 pagesCompany Name: Created By: Phone: Date:: Qty. Description CR 20-12 A-F-A-E-HQQEGusEgy GrundfosNo ratings yet

- Sample G Form CCC - UpdateDocument11 pagesSample G Form CCC - UpdateMohdNo ratings yet

- Grundfos - SP 5A 21Document12 pagesGrundfos - SP 5A 21godbugNo ratings yet

- Qty. Description CR 45-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateDocument2 pagesQty. Description CR 45-3-2 A-F-A-E-HQQE: Company Name: Created By: Phone: DateJulio César MirandaNo ratings yet

- Grundfos CR 3 2 A FGJ A e HqqeDocument10 pagesGrundfos CR 3 2 A FGJ A e HqqeSani PoulouNo ratings yet

- SP14-15 Rp2 4"3X380-415/50 4.0kW: Grundfos Pump 98699358Document12 pagesSP14-15 Rp2 4"3X380-415/50 4.0kW: Grundfos Pump 98699358Media PlatformNo ratings yet

- Grundfos CR 15 2 A F A e HqqeDocument11 pagesGrundfos CR 15 2 A F A e HqqeFKIANo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 12 2f17 Vegetarian Argumentative EssayDocument7 pages12 2f17 Vegetarian Argumentative Essayapi-413258549No ratings yet

- New WITTMANN Robots For Large and Small Injection Molding MachinesDocument4 pagesNew WITTMANN Robots For Large and Small Injection Molding MachinesMonark HunyNo ratings yet

- Pablocastillo PDFDocument44 pagesPablocastillo PDFPabloNo ratings yet

- Lecture 4Document24 pagesLecture 4Geeta AroraNo ratings yet

- Structural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormDocument30 pagesStructural Engineering Professor Step III: Ucsd Academic Biography/Bibliography FormCesar Paul Purihuaman MoraNo ratings yet

- (HMI-LP-RT30 + R131-A - User Manual) A06 - ENDocument110 pages(HMI-LP-RT30 + R131-A - User Manual) A06 - ENrehanNo ratings yet

- Tax System SriLankaDocument44 pagesTax System SriLankamandarak7146No ratings yet

- ManvantaraDocument3 pagesManvantaraafterragnarokNo ratings yet

- MCQ - AcousticsDocument16 pagesMCQ - AcousticsRomeo Espenida0% (1)

- Ex 4Document4 pagesEx 420-MCE-63 SYED HASSAN KUMAILNo ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- 9701 s02 ErDocument14 pages9701 s02 ErHubbak KhanNo ratings yet

- Combustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningDocument17 pagesCombustion Engineering, Heat Transfer, Refrigeration Engineering, & Air ConditioningNicole Mae AllosadaNo ratings yet

- Structural and Literary DevicesDocument40 pagesStructural and Literary Devicesapi-237159930No ratings yet

- BEL PE Question Papers For ECE With Answers - 6 Knowledge AddaDocument14 pagesBEL PE Question Papers For ECE With Answers - 6 Knowledge AddaVishwanand ThombareNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- Exercise # 1: Statistics and ProbabilityDocument6 pagesExercise # 1: Statistics and ProbabilityAszyla ArzaNo ratings yet

- KDIGO CKD MBD Quick Reference Guide June 2022Document11 pagesKDIGO CKD MBD Quick Reference Guide June 2022Esy LNo ratings yet

- Form 67 Delivery Unloading and Loading of Materials and PlantDocument6 pagesForm 67 Delivery Unloading and Loading of Materials and PlantMohamed MedhioubNo ratings yet

- Contoh Form Rko Obat PRB Per ApotekDocument19 pagesContoh Form Rko Obat PRB Per ApoteksaddamNo ratings yet

- DC Jow Ga Beginner CurriculumDocument2 pagesDC Jow Ga Beginner CurriculumKevinNo ratings yet

- (A) Design - Introduction To Transformer DesignDocument16 pages(A) Design - Introduction To Transformer DesignZineddine BENOUADAHNo ratings yet

- Da0bl7mb6d0 Rev DDocument44 pagesDa0bl7mb6d0 Rev DFerreira da CunhaNo ratings yet

- Arthur Lumley Davi̇ds-Sultan Ii. Mahmuta-1832Document318 pagesArthur Lumley Davi̇ds-Sultan Ii. Mahmuta-1832cengizozakinciNo ratings yet

- Anthropological Thought Session by DR G. VivekanandaDocument277 pagesAnthropological Thought Session by DR G. Vivekanandahamtum7861No ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- Bsme 3-B: Me 114 - Heat Transfer Bachelor of Science in Mechanical EngineeringDocument3 pagesBsme 3-B: Me 114 - Heat Transfer Bachelor of Science in Mechanical EngineeringJethro Briza GaneloNo ratings yet

- 9852 1880 01 Maintenance Instructions ROC L7CR IIDocument102 pages9852 1880 01 Maintenance Instructions ROC L7CR IIphongNo ratings yet