Professional Documents

Culture Documents

MFRS500SUSB SH Rework Station With PCB Fixture and Hot Plate 600

MFRS500SUSB SH Rework Station With PCB Fixture and Hot Plate 600

Uploaded by

EthansunCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MFRS500SUSB SH Rework Station With PCB Fixture and Hot Plate 600

MFRS500SUSB SH Rework Station With PCB Fixture and Hot Plate 600

Uploaded by

EthansunCopyright:

Available Formats

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

All 3 functions of Hot Air Reflow, Desoldering Similar single system either

& Soldering work independent of each other not available or otherwise

No external Compressor required may cost more than 3 times

in-built Vacuum Pick-up lifts

large SMD IC gently without

damage to SMD pads PCB

ESD Safe RoHS

Compliant

Table Mat

60x120cm

“ESD” Safe

Single System suffices for SMD soldering, Thru-hole desoldering & SMD ICs reworking

Fine pitch SMD Soldering Thru-hole Soldering Large SMD IC Reworking Thru-hole Desoldering

Scope of Supply:

• MFRS-500SUSB Main Control Unit

• High Power Hot Air Pencil with in-built vacuum pick-up

• Adjustable PCB Fixture with UP/DOWN Hot Air Pencil Holder

• Soldering Pencil fitted with 2.4mm Chisel Soldering Tip

• Support Rack with Cleaning Sponge and Dry Cleaner

Gentle Bottom IR Pre-heating

• Desoldering Gun fitted with Desoldering Tip necessary to avoid warping

• Support Rack with Cleaning Sponge for Desoldering Gun of multilayer PCBs in rework

• ESD Safe Superfine Tip SMD Tweezer

• Spring loaded SMD Flux Pen Specifications

• Desoldering Wick 2.0mm width • Power : 1150 Watt

• Stannol Germany Solder Wire 0.7mm, 500 grams • Temperature Range

• ESD Safe Table Mat (60x120cm) - Soldering/Desoldering : 200°C ~ 480°C

• CK Tools Germany SMD Tip Cutter - Hot Air Pencil : 100°C ~ 500°C

• Weller Soldering Tip Activator • Airflow Range : upto 120 litre/minute

• ESD Safe Illuminated Magnifer • Vacuum Suction : 600mmHg

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

Hot Air Pencil Holder Stand with fine UP/DOWN movement combined with Adjustable

Printed Circuit Board (PCB) Fixture has provision to keep IR Pre-Heating Plate IRPH-4

The PCB Fixture retains and secures the PCB under repair and

allows positioning of the board in X and Y directions. It permits

PCBs upto a maximum size of 350mm x 280mm both single and

double sided to be accommodated in a perfectly flat condition.

It also incorporates a pivoting stand to mount the Hot Air Pencil.

This stand provides fine Up & Down movement of Hot Air Pencil

for raising and lowering it onto the component under repair. The

pre-heating plate IRPH-4 can be fitted under the PCB Fixture to

provide gentle bottom heating.

Features

• Hot Air Pencil Stand integrated with adjustable PCB

Fixture is also part of supply of this package

• Maximum PCB size: 350 x 280 mm

• PCB can be positioned in X & Y directions

• Pre-Heating Plate can be positioned under the PCB

• It has 4 adjustable foot to adjust the level of PCB holder.

UP/DOWN

Holder for movement

Hot Air

Pencil

Specifications

Adjustable

Coarse height range : 0 ~ 230mm PCB Holding

Fine height adjustment : 0 ~ 60mm Arms

Maximum width of PCB : 280mm

How to remove large SMD ICs ?

q Choose an appropriate hot air nozzle and fix

the PCB on PCB Fixture and position the

SMD IC exactly under the Hot Air Pencil.

q Adjust airflow and temperature between

400°C ~ 500°C depending upon the size of SMD IC. Adjustable foots

for level adjustment

q Adjust the temperature of bottom pre-heater so that the temperature

on the top side of PCB reaches around 120°C. Check the temperature

on the component using Thermocouple supplied with Pre-heat plate.

q Switch-on the hot air and blow hot air from small distance to pre-heat

the SMD IC to avoid any thermal shock to it.

q Lower the Hot Air Pencil on SMD IC and wait for solder to melt.

q Once the solder melts, switch-on the vacuum and lift the Hot Air Pencil,

the SMD IC will come with the nozzle due to integrated vacuum pick-up.

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

Digitally Programmable High Power infrared Pre-heating Plate 600 Watt Model IRPH-4

The IRPH-4 Pre-heating Plate enhances the effectiveness of the MFRS500SUSB systems. It provides bottom

heating to the PCB under repair, therefore minimizing the risk of thermal damage to expensive SMD ICs and

warping of expensive multilayer PCBs. Additionally it also speeds up the rework/repair process.

Display for SET Heating Area

and ACTUAL 130x130mm

temperatures

Display for

external

Thermocouple

temperature

Precise

temperature

control with

Port to plug-in digitized Push

external Thermocouple Buttons

Features:

• High quality, long life IR Ceramic Heating Elements ensure fast and even pre-heating with high efficiency

• in-built temperature measurement with thermocouple allows continuous monitoring of PCB temperature

• Pre-set temperature is achieved accurately and remains stable due to closed loop PID control design.

Specifications:

• Heating Power : 600 Watt • Temperature Sensor : K-type Thermocouple

• Plate Area : 130 x 130mm • Temperature Range : 50°C ~ 350°C

• Heating Source : IR Ceramic Heater • Measurement Range : 0 ~ 600°C

Why bottom Preheating is recommended ?

Today’s electronics design has higher density of

expensive devices on the multilayer PCBs which

inherently require gentle pre-heating of PCBs to

avoid thermal damaging of expensive SMD ICs,

and also must avoid warping of expensive PCBs.

If pre-heating is not used, it can lead to pad lifting,

delamination, warping and burning of expensive

PCBs and large SMD ICs during rework/repair. PCB warping/burning possibility without pre-heating

Beside these visible defects, the invisible defects

like internal layer cracking etc. will also result if

no gentle pre-heating is used.

To avoid above failures, PCBs will normally need

even pre-heating around 120°C on top side while

reworking. The Pre-heater model IRPH-4 serves

this purpose. PCBs are heated evenly and gently

from bottom side for safe reworking of SMD ICs.

Safe reworking of SMD ICs using bottom Preheater

.

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

1000 Watt high heat power and very powerful upto 120 litre/minute Hot Air Pencil

also has in-built Vacuum Pick-up provision for safe desoldering of large SMD ICs.

Gentle lifting by Vacuum Pick-up does not damage SMD Pads of expensive PCBs.

The ergonomic and powerful hot air pencil (1000 Watt) together with the extensive range of hot air nozzles

make this tool very versatile. Hot air nozzles are secured to the tool by press fitting. It has integrated in-built

powerful Vacuum Pick-up for gentle lifting of large SMD ICs during desoldering without any damage to SMD

pads of expensive PCBs. Temperature controlled Hot Air Pencil provides adjustable high volume of airflow.

Different Hot Air Nozzles are available for different SMD ICs.

in-built Vacuum Pick-up

lifts large SMD ICs gently

during reworking/repairing

Specifications of Hot Air Pencil

• Power: 1000 Watt

• Temperature Range: 100°C ~ 500°C

• Airflow Volume: upto 120 litre/minute

Wide range of Hot Air Nozzles available to desolder/solder miniature chip components

and even as large as 50 x 50 mm size Fine-Pitch SMD ICs like: QFPs, PLCCs, TSOPs

Large PLCCs LCC leadless Flat Packs Large QFPs as Ceramic Quad

like PLCC 84 Chip Carrier 208 & 304 Pins Thin SOP ICs

Flat Packs

NK2064 NK3131 NK3128

6.4mm dia Size: 4x10mm Size: 15x21mm

Suitable for Suitable for Suitable for

SMD Chips SOP 4.4x10 QFP 14x20

NK3136 NK3137 NK3264

Size: 19x19mm Size: 24x24mm Size: 39x39mm

Suitable for Suitable for Suitable for

PLCC 20x20 PLCC 25x25 QFP 40x40

Other size Hot Air Nozzles are also available as per customer’s requirement, please tell details of IC.

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

Unique design of Soldering Pencil for SMD and PTH soldering

The Soldering Pencil uses unbreakable heating element in coiled form encased

in metal tube with sensor placed very close to the soldering tip for precise control

of temperature. Push-fit design allows quick and easy change of Soldering Tips.

Specifications

• Heating Power : 90 Watt

• Temperature Range : 100°C ~ 500°C

• Tip to ground Potential : <2mV

• Tip to ground Resistance : <2Ω

Fine pitch SMD Soldering Thru-hole Soldering

Unique SMD Soldering Tip for soldering

fine pitch SMD ICs without bridging

Specially designed 200G-CM SMD Soldering Tip has

concave cavity to hold the molten solder. It helps to

solder one side of IC completely in a single shot by

dragging the soldering tip on the PCB tracks on which

the SMD IC is placed without any bridging.

Wide range of Soldering Tips are available for different soldering applications

Description Diagram Width A (mm) Thickness B (mm) Model

1.2 0.5 200G-1.2D

Chisel Tip C 2.4 0.5 200G-2.4D

B 16

3.2 0.5 200G-3.2D

Long

Chisel Tip C 5.0 0.5 200G-5LD

B

Pointed Tip Ø0.5 - 200G-B

17

Sloped Tip Ø3 - 200G-3C

16

SMD Tip 2 - 200G-2CM

3

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

Power & Control Unit of 3-in-1 Large SMD ICs & Thru-Hole Rework System

In-built Digitized Push Buttons

BRUSHLESS for temperature control

maintenance-free

Turbine for

hot air reflow Push Buttons for

Air Volume Control

Push Buttons for

Vacuum ON/OFF

Heating Channel

& Air Outlet for

LCD Display for Hot Air Pencil

Menu Functions to program Vacuum Outlet for

Temperature, Air Volume Desoldering Pencil

and Work Time

ON/OFF Heating Channel Heating Channel

Switch for Soldering Pencil for Desoldering Pencil

Power & Control Unit of Model MFRS500USB regulates temperature and flow of Hot Air Pencil. It also regulates

temperatures of Soldering Pencil and Desoldering Pencil precisely. It also regulates vacuum suction for

the Desoldering Pencil. Set and Actual Temperatures and Air Flow rate, all are displayed on its LCD Display.

Salient Features

• Provides 3 simultaneous functions of Hot Air Pencil, Soldering Pencil and Desoldering Pencil.

• Digitized controls provides precise settings for control of Temperatures and Air Flow Volume.

• Closed-loop temperature control ensures stability of Set Temperatures.

• ON/OFF switching of heating is designed during zero voltage cross-over to avoid any electrical

transients to the circuits.

• Password protection for menu functions to avoid changing of set parameters by the operators.

• Auto Sleep function for Hot Air Pencil, Soldering Pencil and Desoldering Pencil prolongs the life of

Heating Elements and Soldering/Desoldering Tips. Auto Sleep parameters are programmable.

• Built-in temperature offset programming for calibration to meet ISO 9000 requirements.

• It provides powerful vacuum suction for Desoldering Pencil without any external compressor.

• In-built Computer Interface for interconnection to external PC of customer

• Set parameters can be monitored on PC thru Monitoring Software

Easy-to-hold Desoldering Pencil for Desoldering Thru-Hole Components

Desoldering Pencil, with internal solder reservoir, desolders thru-hole components.

Finger Switch controls quick start of fast action vacuum pump.

Specifications

• Heating Power : 90 Watt

• Temperature Range : 200°C ~ 480°C

• Pump : Diaphragm

• Vacuum Pressure : 600mmHg

• Tip to ground Potential : <2mV

• Tip to ground Resistance : <2Ω

Desoldering Nozzles available to desolder different PTH components

P/N

A1005 1.0 2.5

A1006 1.3 3.0

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

Model MFRS500SUSB-SH Rework/Repair & Soldering Package for SMD Chips & ICs

reliable & caring since 1976

Just needs mains input power supply only • Hot Air Pencil has in-built Vacuum Pick-up for SMD ICs

Model MFRS500SUSB-SH Rework/Repair & Soldering Package also includes:

ESD Safe Illuminated Magnifier P/N: I228L ESD Safe Table Mat (60x120cm) 3-Layer

P/N: 8BM-612A

• ESD Safe Table Mat of size 60x120 cm with snap

buttons and Grounding Cord

“ESD” Safe

• 1 MOhm Resistor in

the grounding

wire for static

protection

• Lens size: 125mm diameter • Thickness 3 mm:

• Magnification: 3X Face layer: 0.2mm

• Durable spring-balanced laminated PVC,

arm for positioning Center layer: 2.7mm

• LED based illumination PVC foam,

• ESD Safe Bottom layer: 0.1mm laminated PVC

• Input Supply: 230 VAC, 50 Hz • Resistivity: Face, Center & Bottom 10M~1KMΩ/Sq,

Combination layer 1K~1MΩ/Sq

Stannol Germany Solder Wire, 0.7mm dia

S-Sn60Pb40, 0.7 mm, 500g Weller Germany Soldering Tip Activator

STANNOL® solder wire is a

for regeneration of oxidized

proven and reliable product

Soldering Tips

of Stannol research,

developed to meet high • Regular use will prolong

quality requirements in the life of Soldering Tips.

industrial electronic production as well as for • It is compatible with leadfree

quick rework. This solder wire is very efficient and non-leadfree solders

by its high activity, which results in quick spread • Rotate the hot ip on paste for regeneration.

of solder and electrical safe residues. It has a

halide activated rosin flux.

ESD Safe Precision SMD Cutter P/N: T3886

ESD Safe Straight SMD Tweezer P/N: ESD-14

• ESD Safe

for handling small parts and SMD components • Made from special tool steel

and fine wires blade, hardened for R

long-term cutting

performance

• Cutting capacity: Germany

copper wire 1.3mm dia.

• With ESD Safe coating “ESD” Safe • In-built spring action

• Super fine straight tip type • Hardened cutting edges

• Material: Stainless Steel • Length: 140mm “ESD” Safe

• Non-Magnetic

• Length: 110mm (approx.)

Spring Loaded SMD Flux Pen

High quality Desoldering Wick

For precision flux application in a convenient micro

width: 2.0mm; Length: 1.5 meter tip Pen format.

• High quality Desoldering

Wick with no clean flux Gently press the

• Pure oxygen-free copper wire chiseled tip against

• Width: 2.0 mm work surface to start the flow. The dispensing

• Length: 1.5 meter mechanism eliminates dripping, pooling & wastage.

Warranty is 12 months from the date of invoice. It excludes all consumable parts as Heating Elements,

shown trademarks are property of their respective owners. Temperature Sensors, Soldering/Desoldering/Hot Air Tips, Cleaning Sponges, Cleaning Brass Wool and mechanically damaged parts.

While the information contained herein in, has been carefully compiled to the best of our knowledge, nothing is intended as representation and warranty on our part; and no statement shall be construed as recommendation to infringe any of existing

patents. We accept no liability of whatsoever for any faults and errors in the information contained herein. Contents of this catalogue and specifications of the products, are subject to change without notice due to continuous improvements.

www.indeonline.in Landline: 0172 - 4640415 Cell Phone: 09316134502 Email: headoffice@indeonline.in

HO: Inde Enterprises, 745 Sector 8-B, Chandigarh 160009

headoffice@indeonline.in • 0172-4640415 & 4614415 reliable & caring since 1976

Please visit our website: http://www.indeonline.in for all products and to download data sheets

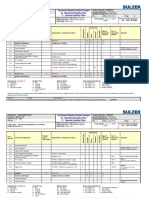

Few Supply References for Model MFRS400 & MFRS500SUSB

S.No. Customer Name Date of Sale Qty

1 Artek Systems, Panjim, Goa 13.09.2012 1

2 Alere Medical Pvt. Ltd. Delhi 24.08.2015 1

3 Analytical Electronics Services Pvt. Ltd.-Gandhinagar 07.10.2014 1

4 Ardee Hi Tech Pvt. Ltd. -Vishakapatanam 17.05.2014 1

5 Bharat Electronics Ltd., Ghaziabad 24.11.2012 1

6 Bharat Electronics Ltd., Jalahalli, Bangalore 06.06.2013 1

7 Bharat Heavy Electricals Ltd., Trichy 19.03.2013 1

8 Comfax Systems India- Ambala Cantt 25.04.2014 2

9 Communication Electronics-Star Antenna, New Delhi 08.09.2014 1

10 Defence Electronics Applications Lab- Dehradun 03.02.2014 1

11 Degree Controls Inc, Trivandrum 27.11.2012 1

12 Deluxe Enterprises, Jalandhar 19.03.2014 1

13 Deluxe Enterprises, Jalandhar 09.09.2013 1

14 DIG-New Delhi 17.07.2014 1

15 Electronics Corp. of India Ltd., Hyderabad 28.04.2011 1

16 Harish Electricals & Electronics, Chennai 27.04.2015 1

17 Hindustan Areonautics Ltd., Hyderabad 14.03.2015 3

18 Hindustan Areonautics Ltd., Hyderabad 04.05.2015 10

19 Hindustan Areonautics Ltd., Korwa 24.09.2011 8

20 Hindustan Areonautics Ltd., Korwa 31.01.2014 4

21 Hindustan Areonautics Ltd., Lucknow 28.02.2011 2

22 Horiba India Pvt. Ltd., New Delhi 30.07.2014 1

23 IND Micro Devices, Kolkata 21.02.2011 1

24 Indian Institute of Astrophysics, Ooty 10.01.2013 1

25 Indian Institute of Technology, New Delhi 21.03.2013 1

26 Indira Gandhi Centre for Atomic Research, Kalpakkam 03.01.2015 1

27 ISRO Inertial System Unit, Trivandrum 01.10.2014 1

HO: Inde Enterprises, 745 Sector 8-B, Chandigarh 160009

headoffice@indeonline.in • 0172-4640415 & 4614415 reliable & caring since 1976

Please visit our website: http://www.indeonline.in for all products and to download data sheets

28 ISRO Inertial Systems Unit, Trivandrum 08.10.2012 1

29 Kaynes Technology, Mysore 08.01.2013 1

30 Mediatek India Technologies Pvt. Ltd. 07.05.2015 1

31 National Aerospace Laboratories, Bangalore 25.03.2013 1

32 NTPC Ltd., Dadri 20.10.2014 1

33 Om Agencies, Kanpur 01.03.2012 1

34 P Statclean Solutions Pvt. Ltd, Delhi 31.01.2013 1

35 Raja Ramana Centre of Advanced Tech, Indore 19.09.2012 2

36 Rajshree Electro Systems, Thane 02.11.2013 1

37 Rajshree Electro Systems, Thane 24.03.2014 1

38 Rajshree Electro Systems, Thane 17.04.2015 1

39 Rajshree Electro Systems, Thane 20.08.2014 1

40 Rajshree Electro Systems, Thane 11.10.2014 5

41 Satish Dhawan Space Centre Shar AP, Saroharikota 22.11.2014 1

42 SEL Manufacturing Co. Ltd., Nawashahr 21.03.2013 1

43 Special Protection Group, New Delhi 16.04.2015 1

44 Suraj Enterprises, Bikaner 21.06.2013 1

45 SVP Laser Technologies Pvt. Ltd. 30.05.2015 1

46 Terminal Ballstics Research Lab, Chandigarh 18.12.2014 3

47 TM Controls, Kota 27.05.2014 1

48 Vardhaman Polytax Ltd., Nalagarh 11.01.2014 1

49 Vikram Sarabhai Space Centre, Trivendrum 24.07.2015 1

50 Vikram Sarabhai Space Centre, Thiruvanthpuram 08.12.2010 1

51 Vikram Sarabhai Space Centre, Thiruvanthpuram 15.05.2012 1

52 Volvo India Pvt. Ltd., Bangalore 30.08.2014 1

53 Yong India Power Systems Pvt. Ltd., Kolkata 29.05.2014 1

You might also like

- "2040" Documentary Name: - : Viewing QuestionsDocument3 pages"2040" Documentary Name: - : Viewing Questionsapi-562285277No ratings yet

- Course Manual: Emergency Management of Severe BurnsDocument123 pagesCourse Manual: Emergency Management of Severe BurnsFeliciaDewi50% (2)

- Studio 5000 Logix Designer Advanced Lab ManualDocument280 pagesStudio 5000 Logix Designer Advanced Lab ManualOtávio Martins100% (1)

- Fujifilm Finepix S1000fd Service ManualDocument112 pagesFujifilm Finepix S1000fd Service ManualAstronom SuceavaNo ratings yet

- Fujifilm Finepix s8000fdDocument134 pagesFujifilm Finepix s8000fdzilikonNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Optical Properties of Makrolon and ApecDocument28 pagesOptical Properties of Makrolon and ApecNabhan MohamedNo ratings yet

- MFRS500USB-GS SMD & PTH Work SystemDocument14 pagesMFRS500USB-GS SMD & PTH Work SystemDeepak GehlotNo ratings yet

- How To Solder The Chip ComponentsDocument19 pagesHow To Solder The Chip ComponentsjackNo ratings yet

- 90041-As Rev2Document2 pages90041-As Rev2Admir BašićNo ratings yet

- Desoldering Tool: Designed For Lead FreeDocument2 pagesDesoldering Tool: Designed For Lead FreeMarco Antonio Ortiz RomeroNo ratings yet

- SC18 Chapter 4Document14 pagesSC18 Chapter 4Amy BoothNo ratings yet

- Nokia Ipt ReportDocument18 pagesNokia Ipt ReportSridharan DharNo ratings yet

- IWISS Crimping ToolsDocument66 pagesIWISS Crimping Toolsv.kotekNo ratings yet

- 64-68 - BG - Soldering Stations2 - Sep-15 R1Document3 pages64-68 - BG - Soldering Stations2 - Sep-15 R1RamavallabhanNo ratings yet

- CP Repair Tools and EquipmentDocument68 pagesCP Repair Tools and EquipmentJay R BallonNo ratings yet

- Embedded Passive ComponentDocument62 pagesEmbedded Passive ComponentAbbas100% (1)

- PTS645 Series6 MM Tact SwitchesDocument6 pagesPTS645 Series6 MM Tact Switcheshgg2kNo ratings yet

- Application Note: Solderability of Smartled DevicesDocument3 pagesApplication Note: Solderability of Smartled DevicesMartinNo ratings yet

- GTS-65 (2-Layer) : Global Transmission Sleeve (Application Without Epoxy Primer)Document2 pagesGTS-65 (2-Layer) : Global Transmission Sleeve (Application Without Epoxy Primer)Carlos MtzNo ratings yet

- Moddis Moddrw Modacc ModsimDocument15 pagesModdis Moddrw Modacc ModsimDWIJ MEWADANo ratings yet

- DREAM 6800: Our Prototype Was Built On A Hardboard Base With A Perspex Cover To Protect and Show Oh' The PC BoardDocument1 pageDREAM 6800: Our Prototype Was Built On A Hardboard Base With A Perspex Cover To Protect and Show Oh' The PC BoardHernan BenitesNo ratings yet

- Soldering Guidelines and SMD Footprint DesignDocument13 pagesSoldering Guidelines and SMD Footprint DesignIgor PNo ratings yet

- How To Remove SMD Chip With Hot AirDocument10 pagesHow To Remove SMD Chip With Hot AirjackNo ratings yet

- Micro Soldering TipsDocument13 pagesMicro Soldering TipsJulian YellowSan NelNo ratings yet

- Datasheet CR0127838W21Document3 pagesDatasheet CR0127838W21Gerardo VillegasNo ratings yet

- Data Sheet: HLMP-RL20, HLMP-SL20Document9 pagesData Sheet: HLMP-RL20, HLMP-SL20Anonymous pMVR77x1No ratings yet

- User Manual: Description, Features & ApplicationsDocument4 pagesUser Manual: Description, Features & ApplicationsMhk KzwNo ratings yet

- Repair Manual 06 2018 Rev 5.0 PDFDocument50 pagesRepair Manual 06 2018 Rev 5.0 PDFKhaled AlamarnehNo ratings yet

- Advantages and Limitations of Electrical-Discharge Machining (EDM)Document20 pagesAdvantages and Limitations of Electrical-Discharge Machining (EDM)WongXinXinNo ratings yet

- Fan Coil UnitDocument16 pagesFan Coil UnitSivarajkumar GanesanNo ratings yet

- Laminator Mod - PCB Toner Transfer From ParchmentDocument7 pagesLaminator Mod - PCB Toner Transfer From Parchmentvali29No ratings yet

- Panasonic KX-FL511 ServiceManualDocument316 pagesPanasonic KX-FL511 ServiceManualLee OnNo ratings yet

- Conventional or Ram Edm (Die Sinker Edm)Document4 pagesConventional or Ram Edm (Die Sinker Edm)jjzoranNo ratings yet

- CONVENTIONAL or RAM EDM (DIE SINKER EDM) PDFDocument4 pagesCONVENTIONAL or RAM EDM (DIE SINKER EDM) PDFjjzoranNo ratings yet

- Tips For Achieving Perfect PCB SolderingDocument21 pagesTips For Achieving Perfect PCB SolderingjackNo ratings yet

- Lab Report (Wire Cut) DEMDocument15 pagesLab Report (Wire Cut) DEMAustenDagulNo ratings yet

- CD700 Welder BrochureDocument1 pageCD700 Welder BrochureVladoiu SorinNo ratings yet

- Wire Edm, Edg, EddgDocument23 pagesWire Edm, Edg, EddgKrishna GopalNo ratings yet

- Fujifilm Finepix s9000 s9500 SM ET 1Document147 pagesFujifilm Finepix s9000 s9500 SM ET 1newionNo ratings yet

- DF11serie Eng Tds PDFDocument14 pagesDF11serie Eng Tds PDFviaxaNo ratings yet

- Electronic Discharge MachineDocument28 pagesElectronic Discharge MachineShivanshu SinghNo ratings yet

- What Is A Socket PCBDocument8 pagesWhat Is A Socket PCBjackNo ratings yet

- ESMDocument10 pagesESM47 Bhushan BariNo ratings yet

- What Wattage Soldering Iron For ElectronicsDocument10 pagesWhat Wattage Soldering Iron For ElectronicsjackNo ratings yet

- Finger Safe/Power Distribution BlocksDocument2 pagesFinger Safe/Power Distribution Blocksangeljavier9No ratings yet

- Canusa GTS 65 2 Layer Installation GuideDocument2 pagesCanusa GTS 65 2 Layer Installation GuideleoNo ratings yet

- Connector: Disconnectable Crimp Style ConnectorsDocument3 pagesConnector: Disconnectable Crimp Style ConnectorsDaniel Gustavo Martinez MartinezNo ratings yet

- DSA pressure switch 2022Document4 pagesDSA pressure switch 2022gxn21177No ratings yet

- uSDX Building Manual DL2MANDocument17 pagesuSDX Building Manual DL2MANoscar tebarNo ratings yet

- Rofuse Turbo 400 + AccesoriesDocument1 pageRofuse Turbo 400 + AccesoriesMusic NetNo ratings yet

- 5SL Miniature Circuit BreakersDocument8 pages5SL Miniature Circuit BreakersSandeep ChandranNo ratings yet

- 5SL Miniature Circuit Breakers: BETA Low-Voltage Circuit ProtectionDocument8 pages5SL Miniature Circuit Breakers: BETA Low-Voltage Circuit Protectionashish sahaNo ratings yet

- A Complete Guide On How To Solder ElectronicsDocument8 pagesA Complete Guide On How To Solder ElectronicsjackNo ratings yet

- Basic Thing You Should Know About PCB Assembly ProcessDocument29 pagesBasic Thing You Should Know About PCB Assembly ProcessjackNo ratings yet

- What Is A Low Temperature Solder PasteDocument10 pagesWhat Is A Low Temperature Solder PastejackNo ratings yet

- 5SL Miniature Circuit Breakers - E10003-E38-9T-B2051-7600Document8 pages5SL Miniature Circuit Breakers - E10003-E38-9T-B2051-7600Ryan TorresNo ratings yet

- Datasheet 2site New 664 en 16-03-2023 PDFDocument2 pagesDatasheet 2site New 664 en 16-03-2023 PDFAnna BarazsulyNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Administrator & Helpdesk Interview Questions You'll Most Likely Be AskedFrom EverandAdministrator & Helpdesk Interview Questions You'll Most Likely Be AskedNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Sleep: Are You A Lark or An Owl?Document3 pagesSleep: Are You A Lark or An Owl?ხათუნა ტრაპაიძეNo ratings yet

- Masters of Sex 1x01 - PilotDocument66 pagesMasters of Sex 1x01 - PilotettaworNo ratings yet

- Transportation in Metro ManilaDocument3 pagesTransportation in Metro ManilaBichi BilayonNo ratings yet

- WORKSHEET 13.2 Formation of Male Gametes (Spermatogenesis)Document2 pagesWORKSHEET 13.2 Formation of Male Gametes (Spermatogenesis)HUSNA 83100% (1)

- Cutting Tool Material PDFDocument43 pagesCutting Tool Material PDFsandeepNo ratings yet

- Science and Technology Research Partnership For Sustainable Development (Satreps) Proposal On Iot X SDG X IndonesiaDocument6 pagesScience and Technology Research Partnership For Sustainable Development (Satreps) Proposal On Iot X SDG X IndonesiaelektroftuhNo ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- Maintenance Technician Electrical L4 PDFDocument37 pagesMaintenance Technician Electrical L4 PDFArun PrasathNo ratings yet

- Seasonal Variations in Kangra Tea QualityDocument6 pagesSeasonal Variations in Kangra Tea QualityashugulatiNo ratings yet

- Tempra VP EectValve PositionerDocument1 pageTempra VP EectValve PositionerNeeraj JangidNo ratings yet

- Sharp Productivity: Information Technology Reference GuideDocument71 pagesSharp Productivity: Information Technology Reference GuideIticien HitechingNo ratings yet

- Ostrich RacingDocument4 pagesOstrich RacingalexmadoareNo ratings yet

- Data Book de BombaDocument7 pagesData Book de BombaSharon Botiny100% (1)

- Manual de Calidad de Cerveza de Barril-2019 PDFDocument122 pagesManual de Calidad de Cerveza de Barril-2019 PDFAndrey Giovanny Riveros MerchanNo ratings yet

- The Origin of The CosmosDocument508 pagesThe Origin of The CosmosAntonio Pinto RenedoNo ratings yet

- Parallel FeederDocument3 pagesParallel FeederBhavik PrajapatiNo ratings yet

- Agar Content of Estuarine Seaweed Gracilaria Using Diffe - 2022 - Applied Food RDocument7 pagesAgar Content of Estuarine Seaweed Gracilaria Using Diffe - 2022 - Applied Food RLê Quốc Đăng KhoaNo ratings yet

- Bachelor of EngineeringDocument30 pagesBachelor of Engineeringmehul10941100% (1)

- Grammar Test CommasDocument2 pagesGrammar Test CommasAbeer Mohammed HamhoumNo ratings yet

- K68i PC ManualDocument101 pagesK68i PC ManualjjcanoolivaresNo ratings yet

- L A Level Physics A MS Jun 07 Old g481Document88 pagesL A Level Physics A MS Jun 07 Old g481dasha962No ratings yet

- Zgo-04!05!007 Mute Saic Detection Feature Guide Zxg10-Ibsc (v12.2.0) 20130425Document20 pagesZgo-04!05!007 Mute Saic Detection Feature Guide Zxg10-Ibsc (v12.2.0) 20130425Praveen DubeyNo ratings yet

- Thermolysis of Medical Waste (Waste Syringe) To Liquid Fuel Using Semi Batch ReactorDocument8 pagesThermolysis of Medical Waste (Waste Syringe) To Liquid Fuel Using Semi Batch ReactorTheJokerNo ratings yet

- L202 AU511 Technical DrawingDocument2 pagesL202 AU511 Technical DrawingghmoralesfNo ratings yet

- Vegan Mayonnaise - Simple Vegan Blog PDFDocument2 pagesVegan Mayonnaise - Simple Vegan Blog PDFjkoiluNo ratings yet

- PETE 628: Lesson 6Document54 pagesPETE 628: Lesson 6EdwinNo ratings yet