Professional Documents

Culture Documents

Working Process Woven & Knit

Working Process Woven & Knit

Uploaded by

md. habibul islam0 ratings0% found this document useful (0 votes)

52 views2 pagesThis document outlines the production process for garment manufacturing, including 7 key steps: 1) Fabric process, 2) Cutting process, 3) Sewing process, 4) Washing process, 5) Finishing and packing process, 6) Inspection process, and 7) Packing process. Each step includes specific quality control checkpoints such as fabric inspection, marker preparation, inline quality checks, moisture testing, and multiple levels of inspection sampling. The end-to-end process is designed to ensure good quality at each stage of garment production.

Original Description:

Working process flow chart for woven & knot garments.

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the production process for garment manufacturing, including 7 key steps: 1) Fabric process, 2) Cutting process, 3) Sewing process, 4) Washing process, 5) Finishing and packing process, 6) Inspection process, and 7) Packing process. Each step includes specific quality control checkpoints such as fabric inspection, marker preparation, inline quality checks, moisture testing, and multiple levels of inspection sampling. The end-to-end process is designed to ensure good quality at each stage of garment production.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

52 views2 pagesWorking Process Woven & Knit

Working Process Woven & Knit

Uploaded by

md. habibul islamThis document outlines the production process for garment manufacturing, including 7 key steps: 1) Fabric process, 2) Cutting process, 3) Sewing process, 4) Washing process, 5) Finishing and packing process, 6) Inspection process, and 7) Packing process. Each step includes specific quality control checkpoints such as fabric inspection, marker preparation, inline quality checks, moisture testing, and multiple levels of inspection sampling. The end-to-end process is designed to ensure good quality at each stage of garment production.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

GPQ follow up work process.

Sample process: Production process:

1) Development Sample 1) Fabric process:

2) Lab dip submission 2) Cutting process:

3) Fit sample 3) Sewing process:

4) PP sample 4 ) Washing process:

5) Top Sample 5) Finishing process:

6) Packing process:

7) Inspection process:

1) Fabric Process:

A) Fabric & Fabric AC test.

B) Fabric inspection following 4 point system.

C) Shade blanket report with country plan or PO plan.

D) Shrinkage blanket report with grade pattern.

E) Keeping fabric style wise on pallet with bin card.

2) Cutting Process:

A) Fabric relaxation 24 hours and record.

B) Spreading inspection with record.

C) Marker prepared and checking as per fabric shade, grin line and way.

D) Precision cutting panel.

E) Cut panel inspection and replacement from same roll.

F) Bundling system with shade number.

3) Sewing process:

A) Pre-production QC inspection package. (all necessary things)

B) Self PP meeting and corrective action plan on critical points.

C) End line QC, critical process QC and line controller on every line.

D) Inline and measurement report daily basis before and after wash.

E) Additional technique apply to execute good quality.(traffic light system, using shade label,

special guide & folder Etc.)

F) Garment ( PROD & CPSIA test)

4) Washing process:

G) Inspection all dry process pc to pc.( whisker, tagging, grinding, destroy, hand sending, PP spray

tie Etc.)

H) Inspection wet process pc to pc before sending the goods to finishing.( shade variation, hand

feel and washing spot etc.)

5) Finishing & packing process:

A) Remove uncut & loose thread.

B) Pressing following care instruction or iron symbol.

C) Snap, rivet, button & bow Etc. attaching following pull test requirement.

D) Visual checking and measuring on key points.

E) Lot pass inspection on completed checking goods.

F) Passing the goods by metal detector machine.

G) Finishing accessories placement and folding method following PO instruction or manual.

H) Moisture ensure before packing.

I) Assortment and carton pack with shipping mark following PO instruction.

J) Top sample from actual bulk production.

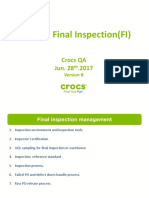

6) Inspection process:

A) Frist inline on 5% packed goods.

B) 2nd inline on 30% to 40% packed goods.

C) Pre final before offer final inspection to third party.

You might also like

- Quality 101Document9 pagesQuality 101Decoay40% (15)

- ANSYS Mechanical APDL for Finite Element AnalysisFrom EverandANSYS Mechanical APDL for Finite Element AnalysisRating: 4.5 out of 5 stars4.5/5 (8)

- ISTQB Sample Question Papers-Part 1Document55 pagesISTQB Sample Question Papers-Part 1chall98% (41)

- JSA For Electrical TestingDocument5 pagesJSA For Electrical TestingAchmad Djadjang0% (1)

- Method Statement For Ultrasonic Testing: DCSM Project 2019Document5 pagesMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenNo ratings yet

- ATSTC7 Level 0 ISTQB Info SummaryDocument3 pagesATSTC7 Level 0 ISTQB Info SummaryrishabraneNo ratings yet

- Site Control of Materials: Handling, Storage and ProtectionFrom EverandSite Control of Materials: Handling, Storage and ProtectionNo ratings yet

- Digital Circuit Testing: A Guide to DFT and Other TechniquesFrom EverandDigital Circuit Testing: A Guide to DFT and Other TechniquesNo ratings yet

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityFrom EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityRating: 5 out of 5 stars5/5 (2)

- Woven Garments Quality Control ProcedureDocument47 pagesWoven Garments Quality Control ProcedureJobaer100% (1)

- QA ManualDocument11 pagesQA ManualFazle Riaz Khan100% (1)

- Quality Control Program For An Apparel Manufacturing Unit: Assignment 2Document12 pagesQuality Control Program For An Apparel Manufacturing Unit: Assignment 2Amrita MitraNo ratings yet

- Amaan Work. 01Document21 pagesAmaan Work. 01Izhan ANo ratings yet

- QMS 2Document89 pagesQMS 2Oki SyahrialNo ratings yet

- Pre-Productionactivities: Cutting QualityDocument3 pagesPre-Productionactivities: Cutting QualityPuja PrasadNo ratings yet

- Cutting Procedure WorkingDocument3 pagesCutting Procedure Workingrial100% (1)

- AG-TCF-2-04. Manufacturing of Products 10.11 ClauseDocument26 pagesAG-TCF-2-04. Manufacturing of Products 10.11 ClauseKarina GorisNo ratings yet

- For Line QC GPQ Training 1682907711Document9 pagesFor Line QC GPQ Training 1682907711ABDULNo ratings yet

- Best Practices For Final Inspection PDFDocument20 pagesBest Practices For Final Inspection PDFManmohan KumarNo ratings yet

- Fi TTQC3 OkDocument12 pagesFi TTQC3 OkMoklesur Rahman100% (1)

- Department of Industrial and Management Engineering: Arab Academy For Science, Technology, and Maritime TransportDocument10 pagesDepartment of Industrial and Management Engineering: Arab Academy For Science, Technology, and Maritime Transporthazem deifallahNo ratings yet

- Quality Control DepartmentDocument4 pagesQuality Control DepartmentYogaLakshimi JNo ratings yet

- List Document To Be Prepare Rev 1Document1 pageList Document To Be Prepare Rev 1ali imronNo ratings yet

- Quality Assurance SOP TemplateDocument3 pagesQuality Assurance SOP TemplateGAURAV SHARMANo ratings yet

- Cutting Room PlanningDocument28 pagesCutting Room Planningsameer_mishra_589% (27)

- Qualitycontrol 140803081747 Phpapp01Document72 pagesQualitycontrol 140803081747 Phpapp01ShivamNo ratings yet

- Sample Exam 2Document13 pagesSample Exam 2khaledsaadouni18No ratings yet

- Factory SOP Training Content - MASTDocument61 pagesFactory SOP Training Content - MASTIndika DissanayakeNo ratings yet

- SAP - QM ModuleDocument5 pagesSAP - QM Modulemaroli_yogeshNo ratings yet

- Test Report PVC Cassette (SYG) : ObjectiveDocument5 pagesTest Report PVC Cassette (SYG) : Objectiveikmal rashidNo ratings yet

- BGMEA University of Fashion & Technology Department of Textile EngineeringDocument52 pagesBGMEA University of Fashion & Technology Department of Textile EngineeringNafis MahmudNo ratings yet

- Apparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshDocument11 pagesApparel Quality Management: Assignment Ii Total Quality Management Practices in Opex Group, BangladeshShivani JayanthNo ratings yet

- Fabric InspectionDocument6 pagesFabric InspectionJothi Vel Murugan100% (7)

- Fabric InspectionDocument5 pagesFabric InspectionpravinthombreNo ratings yet

- Cau Hoi On TapDocument9 pagesCau Hoi On TaplananhITNo ratings yet

- Wet - Processing - Guidelines - PDF Filename UTF-8''Wet Processing GuidelinesDocument3 pagesWet - Processing - Guidelines - PDF Filename UTF-8''Wet Processing GuidelinesEbnul KarimNo ratings yet

- Assignment Tutorial Casting 2020Document3 pagesAssignment Tutorial Casting 2020Pdijk 007No ratings yet

- Food Manufacturer Inspection GuideDocument4 pagesFood Manufacturer Inspection GuideRheamel RhamzNo ratings yet

- Factory Tour ExplainDocument8 pagesFactory Tour ExplainLâmViênNo ratings yet

- Annex 6: Guidance On Good Manufacturing Practices (GMP) : Inspection ReportDocument5 pagesAnnex 6: Guidance On Good Manufacturing Practices (GMP) : Inspection Reportumarn1582No ratings yet

- Internship Project ReportDocument3 pagesInternship Project Reportazizah kamaruddin lowNo ratings yet

- 4 Point SystemDocument3 pages4 Point Systemtex_hasan_014No ratings yet

- Statistical Approach To Quality ManagementDocument46 pagesStatistical Approach To Quality Managementmsj fall2021No ratings yet

- 10 5923 J Materials 20150503 01Document9 pages10 5923 J Materials 20150503 01Martin Eduardo Prieto BenitesNo ratings yet

- Bhartiya International LTD.: Learnings, Observations and AnalysisDocument16 pagesBhartiya International LTD.: Learnings, Observations and AnalysisAshish KumarNo ratings yet

- Quality Engineering - Process Control Plan For PVC Power Moisture Content ControlDocument8 pagesQuality Engineering - Process Control Plan For PVC Power Moisture Content ControlThanh Tốc ĐộNo ratings yet

- Total Quality Process Control for Injection MoldingFrom EverandTotal Quality Process Control for Injection MoldingRating: 5 out of 5 stars5/5 (1)

- Handbook of Quality Integrated Circuit ManufacturingFrom EverandHandbook of Quality Integrated Circuit ManufacturingRating: 5 out of 5 stars5/5 (1)

- Cleanroom Technology: Fundamentals of Design, Testing and OperationFrom EverandCleanroom Technology: Fundamentals of Design, Testing and OperationNo ratings yet

- Development of Sustainable Bioprocesses: Modeling and AssessmentFrom EverandDevelopment of Sustainable Bioprocesses: Modeling and AssessmentNo ratings yet

- Final DocDocument97 pagesFinal DocRishi50% (2)

- PW Nelson July 5Document56 pagesPW Nelson July 5Pennywise PublishingNo ratings yet

- Last Mile 5category LayoutsDocument24 pagesLast Mile 5category LayoutsManoj NakraNo ratings yet

- Rosalie DollDocument5 pagesRosalie DollLoredana100% (1)

- A Power Point Presentation On HUL's Marketing Strategy in Rural India - FinalDocument26 pagesA Power Point Presentation On HUL's Marketing Strategy in Rural India - FinalGuddu Kumar100% (2)

- SAP ProcurementDocument6 pagesSAP ProcurementyusufzainasirNo ratings yet

- MM 5 - Advertising and Sales Promotion 1Document7 pagesMM 5 - Advertising and Sales Promotion 1yang_1925No ratings yet

- Pitch Diameter and Ovality Gages Tapered Threads MRP-1000 Series MRP-2000 Series MRP-3000 SeriesDocument2 pagesPitch Diameter and Ovality Gages Tapered Threads MRP-1000 Series MRP-2000 Series MRP-3000 Seriessajithv78No ratings yet

- Assignment On Consumer Buying ProcessDocument3 pagesAssignment On Consumer Buying ProcessWaqaarNo ratings yet

- Klean KanteenDocument28 pagesKlean Kanteenapi-30047374875% (4)

- Crafts Beautiful March 2017Document130 pagesCrafts Beautiful March 2017EdgarGarcia100% (2)

- Cheers Coorg 19102012Document1 pageCheers Coorg 19102012manuscryptsNo ratings yet

- Benson Beltings: Product InformationDocument2 pagesBenson Beltings: Product InformationbbulutmmNo ratings yet

- Market ResearchDocument89 pagesMarket ResearchSankeitha SinhaNo ratings yet

- Lenovo G460 Hardware Maintenance Manual V4.0 PDFDocument91 pagesLenovo G460 Hardware Maintenance Manual V4.0 PDFhefersonNo ratings yet

- Apple Inc.: Managing Global Supply Chain: Case AnalysisDocument9 pagesApple Inc.: Managing Global Supply Chain: Case AnalysisPrateek GuptaNo ratings yet

- Textiles SN Company NameDocument18 pagesTextiles SN Company NameBusiness PartnerzNo ratings yet

- Kukri Athlete 2021Document11 pagesKukri Athlete 2021barry stoneNo ratings yet

- CH 1 MarketingDocument68 pagesCH 1 Marketinganwar muhammedNo ratings yet

- Aditya Birla MoreDocument11 pagesAditya Birla Morearunabh3245No ratings yet

- Feasibility Study: Identification and Exploration of Business ScenariosDocument12 pagesFeasibility Study: Identification and Exploration of Business ScenariosAngelica Valdez BautoNo ratings yet

- 48 Linen - 2Document21 pages48 Linen - 2ponavnitNo ratings yet

- Caterers IndexDocument38 pagesCaterers IndexFleursdeCerisierNo ratings yet

- Campey - TIP - Brush It - Operators Manual - 2010Document20 pagesCampey - TIP - Brush It - Operators Manual - 2010Campey Turf Care SystemsNo ratings yet

- ALCOSCANDocument2 pagesALCOSCANMohammadNo ratings yet

- Seam Puckering and Its Types: Submitted By: Prakriti Gorai (B F T / 1 9 / 7 5) Semester 4Document9 pagesSeam Puckering and Its Types: Submitted By: Prakriti Gorai (B F T / 1 9 / 7 5) Semester 4PrakritiNo ratings yet

- Kitchen Bath News 042017 2Document68 pagesKitchen Bath News 042017 2haji5No ratings yet

- Safety: A Full Time JOB Not A Part-Time PracticeDocument113 pagesSafety: A Full Time JOB Not A Part-Time PracticeEricson ValenzuelaNo ratings yet