Professional Documents

Culture Documents

Cleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - Engneering

Cleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - Engneering

Uploaded by

Vasilica BarbarasaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - Engneering

Cleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - Engneering

Uploaded by

Vasilica BarbarasaCopyright:

Available Formats

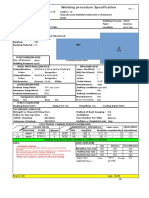

WELDING PROCEDURE SPECFICATION

11 46-CS-004

MINA ABDULLAH REFINERY

Note: This WPS is applicable for structural work

/

/ !'i ,/'

/" s .'=

,'i /f:

OA 19-07-2015 lssued for Review /MZ a} ,:,I {

" } ! '<X V l

' ai': I MU

s{

Rev. Date Description Originator Checked By App,roved By

CleanFuelsProject (-,.-y):5611;5JlJlffl; &

Kuwait National Petroleum Company (K.S.C.)

Kuwait :-:::;=.:.a:.-.::.- KNPC

Petrofac

PSCJ Job No. Jl-2025 / Samsung / CB&l i Pe'OfaC - ENGNEERING

soususc b

CONTRACT NO. CONTRACTOR JOB NO. DOCUMENT NO. REV

I

CFP/EPC/0054-MAB1 Jl-2025 P601 2MAB.000. 10.03.303 OA

I

Kuwait National Petroleum Company

(K.S.C) Welding Procedure P601 2MAB.000.10.03.302

Clean Fuels Project Specification REV. 04,19-7-2015

KNPC Contract No. CFP/EPC/0054-MAB1 i1 46-CS-004 Page 2 of 2

PSCJ Job No. Jl-2025

Record of Revisions

Rev. No. Page/Section Description

OA lssued for Review

A Petrofac -,i ? SAMSUNG

ENGINEER?NG M

MINA ABDULLAH (MAB) EPC PACKAGE 1 0F

CLEAN FUELS PROJECT (CFP) OF KUWAIT

Petrofae ,'..€aP'SAMSUNG

ihaihtaiiha 4h

PETROFAC / SAMSUNG / CB&l

A NATIONAL PETROLEUM COMPANY (K.S.C)

WELDING PROCEDURE SPECIFICATION

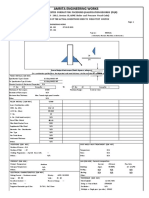

Based on AWS D1.1 & Proect Specs.

PREQUALFIED Yes J!L QUALIFIED sy (WPS)

WELDING

or PROCECURE PROCED RECORDS

QUALIFICATION

resriwaYes [,

SPECFICATION

(PQR)

ldentification 41 WPS-1146-004

Revision OA Date 19-Jul-15 By M.A.ZEAIR

CompanyName ConsolidatedContracorsCompa

WeldingProcess(es)

SupportingPQRNo.(s)SMAW Type-Manual

Prequalified X Semi-Automatic

Machine [Il Automatic 0

JOlNToesrahUSED FOR JOINT DESIGN AND DETAIL SEE PAGE 2&3

POSITION

Single [x DoubleWeld [] Vertical

Type: B-U2,C-U2&TC-U4b Progression :up[x Dowr0

PO8}ti0nOfGrO(Ne:ALL Fillel NA

Backing: ves [X NO €

BackingMaterial: weldmetal ELECTRICALCHARACTERISTICS

Root Opening AS PER SKETCH Root face DimAS PER SKETCH

Groove Angle: AS PER SKETCH Radius (J-U) NA Transler Mode (GMAW) Short-Circuiting

BackGouging: Yes Ga NO z Method Grinding Globular€ Spray g

Current:AC €ocep[p oces€puiseo€

BASEMETALS Other

Material Spec. ASTM A 36 0r equivalent Tungsten Elec

GROUPl &ll

TypeorGrade Size: NA

PlateThickness:

Diameter(Pipe) Groove: N/A Fillet: N/A Groove: 38mmmm Fillet: All Type NA

TECHNIQUE

FILLER METALS Stringer or Weave Bead: Both

AWS Specification AWS A5.1 Multi-pass or Single Pa

AWSClassificmion E7018-1 NumberofEledrodes Sin Ie

ConsumableManufacturer ESAB EledrodeSpacing LonJtudinal NA

Brand&Designation OK55.00 lateral NA

Angle NA

SHIELDING

Flux NA Gas NA

Composition NA Contact Tube to work distance NA

Eledrode-Flux(Class) N/A FlowRate NA Peening NA

GasCupSize NA Interpasscleanin : Grindin and/orBrushin

PREHEAT POSTWELDHEATTREATMENT

preheatTemp.Min Ts38mm,IFC Temp. ?lJl

InterpassTemp.Min 10"C Max 30(PC NA

Time

WELDING PROCEDuRE FillerMetals Current

Volts

Travel speed

APPROVED BY

'-aa "-fflr -,,,=....,....,.

Filler Metals

FLLING Current

SMAW

CAP SMAW

ROOT&HOT E7018-1

E7018-1

SMAW

Volts

3.2

E7018-l 4

Travel speed

DCEP

DCEP

2.5 DCEP140-200

110-140 24 NA

80-110 23

23 NA

NA

Process mmlmin

l

(Cl) Polarityi Amps JOINT DETAIL SEE PAGE 2&3

CCC SMAW E7018-1 2.5 DCEP 80-110 23 NA

Name:- SMAW E7018-1 4 DCEP 140-200 24 NA

SMAW E701 8-1 3.2 DCEP 110-140 23 NA

CCC

A crr

CCC

&. W:dp E,-=-

:.. A,.:=,===.=E,::r,:.,

4[kci-';:,;:,,::",7:;ec,

r

?

MINA ABDULLAH (M-AB) EPC PACKAGE 1 oF

Petrofae ,=) dfi' SAMSUNG 4k

ihaihttgma ?

CLEAN FUELS PROJECT (CFP) OF KUWAIT

NATIONAL PETROLEUM COMPANY (K.S.C)

l F., N.. : FM-1146-1001

R.. N=. :

,QCP-1146100

OA

WELDING PROCEDURE SPECIFICATION l H,..,. C..,.. : R......

PETROFAC / SAMSUNG / CB&l

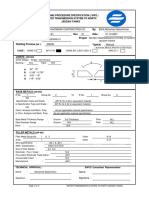

pased on AWS Di .1 & Project Specs. l PAGE 20F3

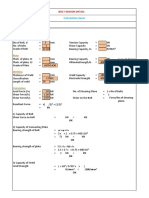

JOINT DESIGN AND DETAIL FOR GROOVE

? ffl

W

/-%

<BACKGOtjGE

r' 4

%

)'!'.1

(i?T'[T

R

.1 a4

Base metal Thk,kness Grgoye Pre aratlon l

Welding

Process Jolnt Des}gnation

LJiunl{mits

Tl 7 Growh

Root angl

Facee il

1?

Tolerencaa

I SMAW B-U2

20 mm

(max)

R=-Oto3.l8

f=Oto3.l8

....(X = 6Q,o o

+1.58.-0

-i-1 .r+s. -o

+1.58 ::3.18 l

not Umited

41f:9,-6Q

l

All dimension's-ffire-in rr+rn

? !?

;>,

r's

-a=

/',, (aacxaouat

1l i

ll,

l-+J-1.

-l .;!-

l'-"

Base rrH551 Thickness Groove Pre amtlon l

Waldlng LJ=unlirnitad Root opsning Tglerangas i

Root Facei

Procqps Jolnt Designation . j J 7 Groova mngm 2n

20 mm

R = O to 3.18 +1.58,-0 +1.58, -3.18

38 mm

(max)

f-Oto3.l8 +1 .sa, -o not Ilmited

SMAW (max)

lC-u2 as-60o .. +lp-(X) +ir9, -50

-All di-mensions are 'in mrn'

Flgurv i 01 ffl

1-S

l-

/"%

<'BACKGOUGE

?1@

N

k-,

l/

79.':R5'B(sey'

$

A'#?h-

j l-o" ' 7 -" "

'eN!:""A" 'a4' e-oai't:'i

Baae metal Thlckness .. Gro0e Preparation iiiiii ,,,,,,,,, t

Welding Uaunlimited Ptoot opsnlng

Root Faee Tolerenoss

Procass . Joint Demigr3ption Ti 7 Groove ang}e ' @s detai}ed g

20 mm R = O to 3.18 +1.5B,-O '+1.58, -3.18

SMAW TC-U4b 38 mm

rzo-toS.'tal +1.58,-0 not lirnitm i

(max) (rnax)

(w 45o ' +1:-Oo - +10€!-50

All dimensions are }n mm

Legent for flgurws

B-Butt joirit u-unHmJted thickness 1-Square groove

C-Corner Joint

2-Slrigle V-groove

T-T joint 4-S}ngle bevel Groove

MINA ABDULLAH (MAB) EPC PACKAGE 1 0F

CLEAN FUELS PROJECT (CFP) OF KUWAIT

A

PefrOra€: a @?' ihaihttpiha U!U

, sausuha4,i

PETROFAC / SAMSUNG / CB&I NATIONAL PETFIOLEUM COMPANY (K.S.C)

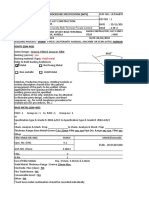

M! WELDING PROCEDURE SPECIFICATION

Based on AWS D1 .1 & ProJect Specs.

JOINT DESIGN AND DETAIL FOR FILLET

{

lff

f

5:1MIN!t-

(NOT LESS TH/)J% 1 irr, j25 rTr'na,:i

No':e: t = thick'er n*eml:i'e'r, t1 = thi'nner rneml:ier

I urel- ns 0 Loa ll

liil6in,

r:2 rpmJ

i+

BASE ME'TAL LESS T-IAN BASE METAL 1 ;4 in, ie rrm'.

*

',-44 ", [6 rairri', 'HICK OR MORE IN THICKNESS

(A) (B)

M.AXlML.JM DlETAll..ED SIZE' 0= '.FlLLE.'. '%N.t=L'D .A=...'Oj%G ED.GES

/

r

/'

Cse'B'C' n':."'>Fo9,CEC;Z31S,

a ,oS,e,oe<e3"81Ze

;ecx ln

You might also like

- ITP - Installation of Fiber Optic CablesDocument5 pagesITP - Installation of Fiber Optic CablesVasilica Barbarasa60% (5)

- ITP - Fencing and Gates Installation Works - MAB1Document24 pagesITP - Fencing and Gates Installation Works - MAB1Vasilica Barbarasa100% (2)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxDocument5 pagesWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- Ca6nm WPS/PQRDocument22 pagesCa6nm WPS/PQRDeepak0% (1)

- HOT Induction Bend MPS - CommentedDocument11 pagesHOT Induction Bend MPS - CommentedHASAN SHAHRIAR100% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Welder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document18 pagesWelder Performance Qualifications (WPQ) : (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)mahendraNo ratings yet

- HSE Front End Loading ProcedureDocument11 pagesHSE Front End Loading ProcedureVasilica BarbarasaNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxDocument4 pagesWelding Procedure Specification (WPS) : Code: Asme BPV Code Sec IxLipika GayenNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- WPS 002 ASME Section IXDocument4 pagesWPS 002 ASME Section IXIvan KawempyNo ratings yet

- PWPS 001Document2 pagesPWPS 001Mehrdad RezaeiNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- PT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Document16 pagesPT - SAE WPS PQR - MIGAS (PGDP) - Unlocked-2Batara SinagaNo ratings yet

- WPS 1aDocument2 pagesWPS 1aPrasenjit BhanjaNo ratings yet

- Wps PQR PDFDocument35 pagesWps PQR PDFquality unifab83% (6)

- 90-QD60-F-232 - PWPS 02Document2 pages90-QD60-F-232 - PWPS 02Mahmoud ElsayedNo ratings yet

- Welder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Document1 pageWelder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Ahmad Nabil ElsharkawyNo ratings yet

- Las Doc X 70 Hyundai MetDocument24 pagesLas Doc X 70 Hyundai MetdvsdNo ratings yet

- 2 - WQT KPRDocument27 pages2 - WQT KPRSuryadev singhNo ratings yet

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresNo ratings yet

- Toaz - Info Wps PQR Saw PRDocument6 pagesToaz - Info Wps PQR Saw PRMustafaNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- 3.ofis-W-39 - Ofis-Wps-02aDocument3 pages3.ofis-W-39 - Ofis-Wps-02aanandNo ratings yet

- Eversendai Offshore RMC Fze: Request For TestingDocument1 pageEversendai Offshore RMC Fze: Request For Testingbharani dharanNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- PQR (GMAW) - NotesDocument3 pagesPQR (GMAW) - Notesbibianamercado02No ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- Calificación Termotecnica CoindustrialDocument1 pageCalificación Termotecnica CoindustrialTato VargasNo ratings yet

- Wps 225Document29 pagesWps 225Muhammad firdaus rusliNo ratings yet

- Document No.: RevDocument2 pagesDocument No.: RevInaamNo ratings yet

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- WPS-PQR RepairDocument16 pagesWPS-PQR RepairmohammedetaNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- 02-Welding Procedure SpecificationDocument4 pages02-Welding Procedure Specificationveera Satya saiNo ratings yet

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- Fcaw Wps-001a PDFDocument3 pagesFcaw Wps-001a PDFirfan bari100% (1)

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Om-03 Hose Handling Crane PDFDocument126 pagesOm-03 Hose Handling Crane PDFcpîndaruNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- Welding Procedure Specification: JOINT (QW-402)Document10 pagesWelding Procedure Specification: JOINT (QW-402)Lipika GayenNo ratings yet

- Barracuda and Caratinga Crude Oil Fields Production Facilities ProjectDocument87 pagesBarracuda and Caratinga Crude Oil Fields Production Facilities ProjectneivaprojetosNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Wps 11Document2 pagesWps 11Avishek GuptaNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- WPS PQR Procedure PDFDocument31 pagesWPS PQR Procedure PDFsudeesh kumarNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- Equipment ListDocument11 pagesEquipment ListTunaNo ratings yet

- TSC-CCVT-WPS-28 Rev 00 (Welding Procedure Spec PVD)Document54 pagesTSC-CCVT-WPS-28 Rev 00 (Welding Procedure Spec PVD)Khôi ĐàoNo ratings yet

- WPS PDFDocument5 pagesWPS PDFHakanNo ratings yet

- Rahul Kumar W-010Document3 pagesRahul Kumar W-010veera Satya saiNo ratings yet

- W15 001S ASME Ahmad TermiziDocument1 pageW15 001S ASME Ahmad TermiziHoJienHauNo ratings yet

- J-22 Magnetic Particle Inspection Report No.59Document1 pageJ-22 Magnetic Particle Inspection Report No.59Yousab CreatorNo ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- Ii. 5 Tes - WPS Rebabbit Bearing Pltu TembilahanDocument4 pagesIi. 5 Tes - WPS Rebabbit Bearing Pltu TembilahanaddinulichsanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- VP-2025JV0P10083-000-O94-001 - 1 - (Installation Manuals)Document32 pagesVP-2025JV0P10083-000-O94-001 - 1 - (Installation Manuals)Vasilica BarbarasaNo ratings yet

- VP-2025JV0P10084-000-R96-001 - 4 - (Lifting Arrangement (Shipping & Erection) )Document38 pagesVP-2025JV0P10084-000-R96-001 - 4 - (Lifting Arrangement (Shipping & Erection) )Vasilica BarbarasaNo ratings yet

- P6003shu-129-30-Pg-082 - A3 - (Datasheet - Pressure Gauges - Unit 129)Document11 pagesP6003shu-129-30-Pg-082 - A3 - (Datasheet - Pressure Gauges - Unit 129)Vasilica BarbarasaNo ratings yet

- VP-2025JV0C40004-H-212-401-D20-005 - 4 - (Convection Coil H-212-401)Document2 pagesVP-2025JV0C40004-H-212-401-D20-005 - 4 - (Convection Coil H-212-401)Vasilica BarbarasaNo ratings yet

- P6012MAB.216.19.1.A416 VOA (Re Measurement Sheet For Unit 216 For Foundation D 216 107 MTO REF. MT)Document4 pagesP6012MAB.216.19.1.A416 VOA (Re Measurement Sheet For Unit 216 For Foundation D 216 107 MTO REF. MT)Vasilica BarbarasaNo ratings yet

- Cleanfuelsproject ( - ) %!I'4!Ffi!Ij!Lmffl4: Petrofac/Samsung/Cb&I Petrofac - E Esnamgsnuenerging BDocument5 pagesCleanfuelsproject ( - ) %!I'4!Ffi!Ij!Lmffl4: Petrofac/Samsung/Cb&I Petrofac - E Esnamgsnuenerging BVasilica BarbarasaNo ratings yet

- Re-Measurement Sheet FOR UNIT112 Foundation V 112 106 & V 112 206 Mto R F M O-C-112-V-106-206Document5 pagesRe-Measurement Sheet FOR UNIT112 Foundation V 112 106 & V 112 206 Mto R F M O-C-112-V-106-206Vasilica BarbarasaNo ratings yet

- Re-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Document6 pagesRe-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Vasilica BarbarasaNo ratings yet

- P6012MAB.112.19.1.A403 VOA (RE Measurement Sheet For Unit 112forFoundationV 112 0103 & V 112 0203 M)Document5 pagesP6012MAB.112.19.1.A403 VOA (RE Measurement Sheet For Unit 112forFoundationV 112 0103 & V 112 0203 M)Vasilica BarbarasaNo ratings yet

- General Assembly For Hot High Pressure SEPARATOR V-112-0202Document2 pagesGeneral Assembly For Hot High Pressure SEPARATOR V-112-0202Vasilica BarbarasaNo ratings yet

- Detail of Lifting Arrangement For Reactors and Separators V-112-0102 and V-2012-0110Document2 pagesDetail of Lifting Arrangement For Reactors and Separators V-112-0102 and V-2012-0110Vasilica BarbarasaNo ratings yet

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Document10 pagesQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNo ratings yet

- General Assembly For Fixed Reactor V-112-0110Document2 pagesGeneral Assembly For Fixed Reactor V-112-0110Vasilica BarbarasaNo ratings yet

- En 571-1 - Penetrent TestingDocument18 pagesEn 571-1 - Penetrent TestingVasilica Barbarasa100% (1)

- Mahboob Ms - t5 Flare Gas TransducerDocument8 pagesMahboob Ms - t5 Flare Gas TransducerVasilica BarbarasaNo ratings yet

- AMETank Product BrochureDocument6 pagesAMETank Product BrochureSYedZYnAleNo ratings yet

- ITP - Steel Tower For Water TankDocument4 pagesITP - Steel Tower For Water TankVasilica BarbarasaNo ratings yet

- HSE Front End Loading ProcedureDocument11 pagesHSE Front End Loading ProcedureVasilica BarbarasaNo ratings yet

- BOLTRIGHT Tightening ProcedureDocument2 pagesBOLTRIGHT Tightening ProcedureVasilica BarbarasaNo ratings yet

- Thermal Spray Coatings of Aluminium and 85 - 15 Zinc - Aluminium AlloyDocument27 pagesThermal Spray Coatings of Aluminium and 85 - 15 Zinc - Aluminium AlloyVasilica Barbarasa100% (1)

- Glass-Lined Steel Process EquipmentDocument21 pagesGlass-Lined Steel Process EquipmentVasilica Barbarasa100% (1)

- Example II.C-5 HSS Chevron Brace Connection: F F F FDocument5 pagesExample II.C-5 HSS Chevron Brace Connection: F F F FVasilica BarbarasaNo ratings yet

- AMETank Product BrochureDocument25 pagesAMETank Product BrochureVasilica BarbarasaNo ratings yet

- Cement Lining of PipesDocument26 pagesCement Lining of PipesVasilica BarbarasaNo ratings yet

- International Standard EN 898-1Document62 pagesInternational Standard EN 898-1Yasir AzmatNo ratings yet

- 50 Exercises - Extruded Boss - BaseDocument6 pages50 Exercises - Extruded Boss - BasengocNo ratings yet

- ECCS Recommendations For Fatigue Design of Steel StructuresDocument47 pagesECCS Recommendations For Fatigue Design of Steel StructuresCpm102No ratings yet

- Weld Procedure Summary: SR# Wps No. Process Aws No. P.No. Base Metal Thickness Range Diameter Range PWHTDocument5 pagesWeld Procedure Summary: SR# Wps No. Process Aws No. P.No. Base Metal Thickness Range Diameter Range PWHTshantilalNo ratings yet

- Ferrous Metals - Group 1Document40 pagesFerrous Metals - Group 1ELLIENo ratings yet

- Welding CodeDocument14 pagesWelding CodeKureiNo ratings yet

- Steel MakingDocument8 pagesSteel MakingCheeragNo ratings yet

- SAE Steel GradesDocument19 pagesSAE Steel GradesCarlos BustamanteNo ratings yet

- Ferrous Metallurgy: The Chemistry and Structure of Iron and SteelDocument30 pagesFerrous Metallurgy: The Chemistry and Structure of Iron and SteelKeith Tanaka MagakaNo ratings yet

- QW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Document1 pageQW-352 QW-353 QW-354 (Note (2) ) QW-355 QW-356 QW-357 (Note (1) )Deepanshu KhatriNo ratings yet

- FCAWDocument6 pagesFCAWmostafaNo ratings yet

- Ferro TungstenDocument9 pagesFerro TungstenTarun ChakrabortyNo ratings yet

- FCAW Consumables - Part 4 - TWIDocument6 pagesFCAW Consumables - Part 4 - TWIJlkKumarNo ratings yet

- Welding IntroDocument183 pagesWelding IntroDeepak KumarNo ratings yet

- 202302010-1 - Data Base Material QC IsoDocument78 pages202302010-1 - Data Base Material QC Isodimas pratamaNo ratings yet

- Invoice-WPQT Welder PTMDocument5 pagesInvoice-WPQT Welder PTMFerdie OSNo ratings yet

- ASME Material Numbers PDocument2 pagesASME Material Numbers PVivek S SurendranNo ratings yet

- Welding ConsumableDocument82 pagesWelding ConsumableAzmin BorkhanNo ratings yet

- ETABS Concrete Frame DesignDocument2 pagesETABS Concrete Frame DesignzulbahriNo ratings yet

- Engineering Materials-Chapter One-Ferrous Alloys HighlightedDocument32 pagesEngineering Materials-Chapter One-Ferrous Alloys HighlightedMohammed AssadNo ratings yet

- Calculation Sheet Connection DesignDocument1 pageCalculation Sheet Connection DesignJay SenjaliaNo ratings yet

- Print 1Document2 pagesPrint 1polman cad08No ratings yet

- Substitute MaterialDocument56 pagesSubstitute Materialzubair1951No ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- TG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationDocument1 pageTG-X308L TG-X309L TG-X316L TG-X347 TG-X2209: Description and ApplicationV U P RaoNo ratings yet

- NDT Request For Structure: PTSC Mechanical and ConstructionDocument5 pagesNDT Request For Structure: PTSC Mechanical and ConstructionTuấn ĐậuNo ratings yet

- Steel Cross ReferenceDocument4 pagesSteel Cross Referencecharles_boyle_3No ratings yet

- Ponton Drawing v6Document2 pagesPonton Drawing v6KrzysztofNo ratings yet

- Welding Consumables For Cast SteelDocument4 pagesWelding Consumables For Cast Steelmehul20110% (1)

- MATERIAL TECHNOLOGY - II - All ChaptersDocument51 pagesMATERIAL TECHNOLOGY - II - All ChaptersMohammed Aseer100% (1)