Professional Documents

Culture Documents

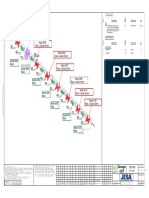

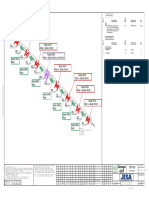

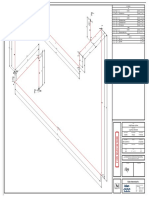

For Construction: 1 383-L-ISO-18003-00

For Construction: 1 383-L-ISO-18003-00

Uploaded by

Ranish P. KurianOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Construction: 1 383-L-ISO-18003-00

For Construction: 1 383-L-ISO-18003-00

Uploaded by

Ranish P. KurianCopyright:

Available Formats

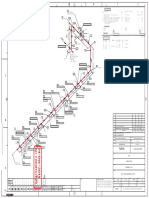

N+38°W FIELD MATERIALS

PT DESCRIPTION SIZE JGC SYMBOL SHRT OPT HOLD QTY

NO (IN) CODE

PIPE

1 Pipe D2996-Tp.1-Gr.1-Cl.F Seamless 1 P01N-003KR P 1 0.7 M

AWWA C950 ID Series Table-1

Adhesive joint Bell and spigot

ends Schedule MFR_STD

FITTINGS/SPECIALTIES

2 90 deg elbow D5685-Tp.1-Gr.1-Cl.F 1 P02N-0029C 9L 1 1

CONN. TO Seamless Manufacturer-standard

383P0014B/N3

Adhesive joint Bell ends Long

1 in FFFE 150

E 2892050 radius Schedule MFR_STDxMFR_STD

44 0 N 127951

112 EL +102617 FLANGES

32 8

3 Flange Adhs Bell 1 P61N-003CH F 1 1

2 <1 > 1 D4024-Tp.1-Gr.1-Cl.3 CL150 ASME

B16.5 FF

112 1"

GASKETS

F3 G4 B5 4 Sheet gasket EPDM CL150 ASME 1 P74U-003EN G 1 1

B16.21 Flange ASME B16.5 FF

9 3.2mm-T

27 34

3

BOLTS

5 Bolt and Nut A193-B7 / A194-2H 1/2 P80S-0595V B 24003 4

ASME B1.1 PTFE coated UNC

Stud-bolt with two Heavy HEX nuts

with two TFE coated CS washers ,

90.00 mm

CUT PIPE LENGTH

PIECE LENGTH SIZE REMARKS PIECE LENGTH SIZE REMARKS

NO (MM) (IN) NO (MM) (IN)

<1> 293 1 <2> 405 1

517

405

<2> 1

1"

TO OWS

E 2891607

N 127951

EL +102100

FOR CONSTRUCTION

1. PIPE WELDING TO CALTEX SPEC. NYS B9.1 10. ALL DIMENSIONS, CO-ORDINATES & ELEVATIONS ARE IN

2. BUTT WELD FOR CS PIPING, 3" & SMALLER USE WELD ROD AWS E6010 (WPS CS1). MILLIMETERS UNLESS OTHERWISE SPECIFIED. FIRM UP NO. 3 API OIL SEPARATOR PROJECT THE BAHRAIN PETROLEUM CO. BSC (CLOSED)

3. BUTT WELD FOR CS PIPING, 4" & LARGER USE WELD ROD AWS E601 11. CONTRACTOR TO FIELD VERIFY DIMENSIONS AND F.W. LOCATIONS

FOR ROOT RUN & AWS E7018 FOR FILL & CAP (WPS CS9). PRIOR TO THE START OF WORK AND ADVISE BAPCO OF ANY DRAWING TITLE

4. ALL FILLET & SOCKET WELD FOR CS PIPING, USE WELD ROD AWS E7018 (WPS CS7). INTERFERENCE PROBLEMS OR CHANGES REQUIRED. 0 0 G K0 9 7 0 0 0 0 0 0 ISOMETRIC PIPING DETAIL SHEET FOR LINE NO.

5. FOR STAINLESS STEEL PIPING USE WELD ROD AWS ER316 12. COORDINATES AND ELEVATIONS SHOWN IN ISOMETRIC DRAWING

FOR ROOT RUN & AWS E318-15 FOR FILL & CAP (WPS SS3). ARE FOR REFERENCE ONLY, ACTUAL COORDINATES AND DWG No. SIZE REV. 383-1"-WW-0350-RXB32

6. FOR SUPER DUPLEX PIPING, USE WELD ROD AWS SANDVIK 25.10.4L (WPS 839-DPS-001).

7. INSULATION AS PER BAPCO DOC. NO. 383-N-TSP-17501-001.

ELEVATION FOR PIPING ERECTION TO BE FOLLOWED AS PER

PIPING GA DRAWINGS.

B000-383-WW-0350 D C0 PIPING SPEC. PER SPEC.

13. SUPPORT HEIGHT TO BE CONFIRMED PRIOR TO FABRICATION & RXB32 NA

8. FIELD WELDS ARE INDICATED

INSTALLATION AS PER ACTUAL SITE CONDITION. REF. PLAN DRG. NO REF. P&ID DRG. NO

9. F.C. INDICATES FIELD CHECK DIMENSION.

383-L-GAD-17506-001 383-A-PID-17501-016

E.X. DESIGN PRESSURE 170.0 PSIG DESIGN TEMP 180.0 0

F DATE PREPARED CHECKED APPROVED

P.N. R. RAZALAN M. ESPINOSA M. NUNAG

E.X. OPRG. PRESSURE 130.0 PSIG OPRG. TEMP 155.0 0

F

05-JUL-'19

P.N. E.X. DRAWING NO SCALE SIZE

HYDROTEST PRESS 0.0 PSIG SERVICE TEST V

C0 05-JUL-'19 ISSUED FOR CONSTRUCTION

E.X. 62314

RR MN 62314 NTS A3

P.N. EN0894 RADIOGRAPHY - % PAINTING SPEC - P.N. TOT SHT REV

REV

NO

DATE REVISION DRAWN CHKD

STRESS

ANALYS

ENGR OWNER MAINT RED OTHER

ENG

DEPT PROCESS FLUID WASTEWATER STRESS RELIEVED NO EN0894

383-L-ISO-18003-00 1 1 1 C0

IN DR01A

P-2

9 EXTRACTION DATE:7/2/2019 10:29:52 AM

01-SE INTED

H EN PR

LED W

TROL

NCON

You might also like

- A330-200 Panel Pylong2zDocument1 pageA330-200 Panel Pylong2zpontoo100% (5)

- NEBOSH International Technical Certificate in Oil & Gas Operational Safety Question BankDocument11 pagesNEBOSH International Technical Certificate in Oil & Gas Operational Safety Question BankRanish P. KurianNo ratings yet

- TIPS - 0420-12 Guidelines For Measure of Vacuum Pump Air FlowDocument17 pagesTIPS - 0420-12 Guidelines For Measure of Vacuum Pump Air FlowArturo Manuel Vizcarra100% (1)

- IFI 2018 Book of Fastener Standards - TOCDocument7 pagesIFI 2018 Book of Fastener Standards - TOCMahmoud Al Homran0% (2)

- Square and Rectangular Louvre Face Ceiling Diffuser: Model SADocument24 pagesSquare and Rectangular Louvre Face Ceiling Diffuser: Model SARifa MuzakkiaNo ratings yet

- B000 386 WW 0500Document3 pagesB000 386 WW 0500Ranish P. KurianNo ratings yet

- South Refineries Company: Basrah Refinery Upgrading Project ProjectDocument5 pagesSouth Refineries Company: Basrah Refinery Upgrading Project ProjectBasem AlsaftliNo ratings yet

- Fy 1Document6 pagesFy 1Arie Akhmad FaizalNo ratings yet

- For Construction: 1 383-L-ISO-17870-00Document3 pagesFor Construction: 1 383-L-ISO-17870-00Ranish P. KurianNo ratings yet

- Pylon 330 TEST PDFDocument1 pagePylon 330 TEST PDFBRAHYAM DAVILANo ratings yet

- CD436497.001Document1 pageCD436497.001ahmadNo ratings yet

- CD436495.001Document1 pageCD436495.001ahmadNo ratings yet

- CLASSIMAT Formet - USTER - QCD-Format-No-64Document1 pageCLASSIMAT Formet - USTER - QCD-Format-No-64Md. Mamunur RashidNo ratings yet

- Piping IsometricDocument1 pagePiping IsometricAshish JagtapNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- Manual Valve List - FS-554!18!19Document1 pageManual Valve List - FS-554!18!19Ajay PrajapatiNo ratings yet

- 0127 R8B 04 WP 311 01Document1 page0127 R8B 04 WP 311 01ABDERRAZZAKNo ratings yet

- Valve List - F-5001Document3 pagesValve List - F-5001Ajay PrajapatiNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- 0127 R8B 06 WP 311 01Document1 page0127 R8B 06 WP 311 01ABDERRAZZAKNo ratings yet

- 001Document2 pages001Robles DreschNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNo ratings yet

- 01Document1 page01Reno Reza GumilangNo ratings yet

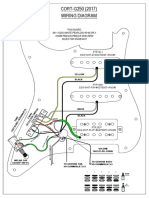

- Cort G250DX WiringDocument1 pageCort G250DX WiringMuhammad Irvan FardaniNo ratings yet

- Drawing (p15 Ace 857)Document14 pagesDrawing (p15 Ace 857)ritoh8657No ratings yet

- 4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Document1 page4103 TOYO20 92DJ 1300 052 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Thread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectDocument1 pageThread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectKuwait Gulf CircleNo ratings yet

- 1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Document1 page1/1 P055AZOR-05P00-1353-51 A A-2: 3c 248 HV 10 Shop ASME B31.3Deshwa SaravananNo ratings yet

- Iht12df+280sm NewDocument1 pageIht12df+280sm Newkeeprocking9777No ratings yet

- 4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Document2 pages4103 TOYO20 92DJ 1300 036 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Piping DetailsDocument16 pagesPiping DetailsSasi MesthiriNo ratings yet

- Wps P 005ltcsr PTT Rev. 0 - DNV SignedDocument1 pageWps P 005ltcsr PTT Rev. 0 - DNV SignedPrapas PhengprakhonNo ratings yet

- 300 WW 14T2 1 009 Bk1.shaDocument1 page300 WW 14T2 1 009 Bk1.shaABDERRAZZAKNo ratings yet

- Onkyo+Txsr 805+schematicsDocument36 pagesOnkyo+Txsr 805+schematicsJuarez Mesquita Leite JuniorNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- For ConstructionDocument5 pagesFor ConstructionBasem AlsaftliNo ratings yet

- E-03 Main Switch BoardDocument116 pagesE-03 Main Switch BoardJay TandelNo ratings yet

- 3M0053 Y10 000 01 - Manual Hoist - DRAWINGDocument7 pages3M0053 Y10 000 01 - Manual Hoist - DRAWINGCaspian DattaNo ratings yet

- 100 A 32421PE-2 - Layout1Document1 page100 A 32421PE-2 - Layout1Frederique VerhulstNo ratings yet

- TP 09Document6 pagesTP 09Karunanithi NagarajanNo ratings yet

- Fiberc M: SEE SHEET 7/135Document1 pageFiberc M: SEE SHEET 7/135Jao BaluyutNo ratings yet

- Welder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122Document4 pagesWelder Qualification Register SENBAL UPDATE (FCAW, SMAW & STRUCTURE) 261122R.A. AbriantoNo ratings yet

- Torqur ValveDocument1 pageTorqur ValvesutomoNo ratings yet

- Af 6atsp0h Iso PL 240019 01 001 C06Document1 pageAf 6atsp0h Iso PL 240019 01 001 C06Rashad AlasgarovNo ratings yet

- RT Request 87Document1 pageRT Request 87Somnath MandalNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- DRG 2400392.00025042024142358360387Document1 pageDRG 2400392.00025042024142358360387Milind KhandaveNo ratings yet

- 13-PRCBD-INS-FS-200 - PRESSURE GAUGE (PRC-Biodiesel-022)Document2 pages13-PRCBD-INS-FS-200 - PRESSURE GAUGE (PRC-Biodiesel-022)firman harianjaNo ratings yet

- Prohibited Outside of Their Purpose Information in This Document Is Property of Petrobras, BeingDocument5 pagesProhibited Outside of Their Purpose Information in This Document Is Property of Petrobras, BeingRobles DreschNo ratings yet

- S15720 (A) Front Guard Fitting GuideDocument2 pagesS15720 (A) Front Guard Fitting GuideKarikalan JayNo ratings yet

- Welding and Inspection Plan (Wip) Part 1: Design: Issued By: DateDocument4 pagesWelding and Inspection Plan (Wip) Part 1: Design: Issued By: DateJorgeAgustínSalgadoMirandaNo ratings yet

- SP 01Document1 pageSP 01Giang Vuong KhaiNo ratings yet

- FYH ZK - EnglishDocument17 pagesFYH ZK - EnglishRicardo TurlaNo ratings yet

- RT Request For Sivert Date 13-Apr-17: Hail Surface FacilitiesDocument1 pageRT Request For Sivert Date 13-Apr-17: Hail Surface FacilitiesAnonymous AdofXEYAgENo ratings yet

- Commercial Bid FormDocument68 pagesCommercial Bid FormKasarachi AmadiNo ratings yet

- I-II Create-Part-NumberDocument5 pagesI-II Create-Part-NumberKemal YıldırımNo ratings yet

- Profile RT 21-060-004Document4 pagesProfile RT 21-060-004Marcus AntoniusNo ratings yet

- Lt-D37 & Lt-D38 Limits, Note Change:: (L) (L) - (L) - (L) - (R) - (L) - (R) - GinliDocument2 pagesLt-D37 & Lt-D38 Limits, Note Change:: (L) (L) - (L) - (L) - (R) - (L) - (R) - GinliRicardo Aguilera T.No ratings yet

- List Applicable WPS Piping & PipelineDocument6 pagesList Applicable WPS Piping & PipelineFerdie OSNo ratings yet

- 1. Mạch điện đồng hồ santafe 2014-2018Document5 pages1. Mạch điện đồng hồ santafe 2014-2018PRO ECUNo ratings yet

- HD431910029X00Document1 pageHD431910029X00Malik MalikNo ratings yet

- Apis PJ MSR As of 12-Mar-2020Document324 pagesApis PJ MSR As of 12-Mar-2020Ranish P. KurianNo ratings yet

- E32 P R340 2136Document5 pagesE32 P R340 2136Ranish P. KurianNo ratings yet

- Vendor As Built StatusDocument199 pagesVendor As Built StatusRanish P. KurianNo ratings yet

- B000 386 WW 0500Document3 pagesB000 386 WW 0500Ranish P. KurianNo ratings yet

- J-DMS: Uncontrolled When PrintedDocument1 pageJ-DMS: Uncontrolled When PrintedRanish P. KurianNo ratings yet

- PL AN T OR TH: Line Condition (Press. Unit: Kg/Cm2 G Temp. Unit: Degc) FabricationDocument1 pagePL AN T OR TH: Line Condition (Press. Unit: Kg/Cm2 G Temp. Unit: Degc) FabricationRanish P. KurianNo ratings yet

- For Construction: 1 383-L-ISO-17870-00Document3 pagesFor Construction: 1 383-L-ISO-17870-00Ranish P. KurianNo ratings yet

- NEBOSH International Technical Certificate in Oil & Gas Operational SafetyDocument26 pagesNEBOSH International Technical Certificate in Oil & Gas Operational SafetyRanish P. Kurian100% (2)

- Vendor As Built StatusDocument199 pagesVendor As Built StatusRanish P. KurianNo ratings yet

- DCR Report With Complete Document History: Page 1 of 1Document1 pageDCR Report With Complete Document History: Page 1 of 1Ranish P. KurianNo ratings yet

- West Qurna I Section 2: Rev. Date Description Prepared by Reviewed byDocument5 pagesWest Qurna I Section 2: Rev. Date Description Prepared by Reviewed byRanish P. KurianNo ratings yet

- PMP 1000 Question PDFDocument190 pagesPMP 1000 Question PDFRanish P. Kurian100% (2)

- Aide Memoire: Subject: DEL EGC Project, QatarDocument5 pagesAide Memoire: Subject: DEL EGC Project, QatarRanish P. KurianNo ratings yet

- Export Gas Compression Facility Upgrade ProjectDocument3 pagesExport Gas Compression Facility Upgrade ProjectRanish P. KurianNo ratings yet

- Product Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Document12 pagesProduct Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Vilas m ChinkeNo ratings yet

- FN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeDocument1 pageFN400 H# Series Long Radius Flow Nozzles - Holding Ring TypeAjay ChodankarNo ratings yet

- Medidor Caudal Kobold DpuDocument4 pagesMedidor Caudal Kobold DpuBase SistemasNo ratings yet

- Butterfly Valve DatasheetDocument2 pagesButterfly Valve DatasheetKanthan DevanNo ratings yet

- BD 94 - 17 Minor StructuresDocument69 pagesBD 94 - 17 Minor StructuresAnil KumarNo ratings yet

- Spare Parts Catalogue: Bajaj Auto LimitedDocument44 pagesSpare Parts Catalogue: Bajaj Auto LimitedAbdulhaq Sayed0% (1)

- Case Study 04Document14 pagesCase Study 04HugoNo ratings yet

- M PM 170Document34 pagesM PM 170mahesh_eilNo ratings yet

- Tightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsDocument184 pagesTightening Torques Lubricants Tools: AB 0100 EN Servicing SAMSON ProductsROSNo ratings yet

- 22-V-0101-Transportation CaseDocument33 pages22-V-0101-Transportation CasesanjayNo ratings yet

- Katalog 2 enDocument1,060 pagesKatalog 2 enmunhNo ratings yet

- Technical Information PSVDocument30 pagesTechnical Information PSVVinicius De Holanda PasoliniNo ratings yet

- Low Gas Pressure Regulator: Product HandbookDocument31 pagesLow Gas Pressure Regulator: Product HandbookmanishaliveNo ratings yet

- Brochure - Flange Insulation ProductsDocument4 pagesBrochure - Flange Insulation ProductsnidhinNo ratings yet

- 3p531-Api 617-C505u-Re C505 - LPCDocument8 pages3p531-Api 617-C505u-Re C505 - LPCYusri FakhrizalNo ratings yet

- Valves PDFDocument12 pagesValves PDFAnonymous HFIQgANMQNo ratings yet

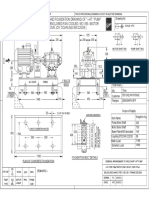

- Turbo Submittal At200-0.8s g5p Cargill (1) (2) - 1Document2 pagesTurbo Submittal At200-0.8s g5p Cargill (1) (2) - 1ivantellez-famNo ratings yet

- Piping Class - GS70Document1 pagePiping Class - GS70Dmitriy RybakovNo ratings yet

- Specification For LP & HP Dosing System-PC - AUX-BLR - DOS-R00-3Document11 pagesSpecification For LP & HP Dosing System-PC - AUX-BLR - DOS-R00-3Manoj NirgudeNo ratings yet

- Gas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTDocument36 pagesGas Flotation Package (Asbea-A-2703) 32294 Ponticelli - Al Shaheen PWTTĩnh Hồ TrungNo ratings yet

- Trueline Knife-Gate Valve CatalogueDocument12 pagesTrueline Knife-Gate Valve Cataloguetoto-gmbhNo ratings yet

- TOTO MRP Price List - 01-04-2019Document65 pagesTOTO MRP Price List - 01-04-2019Joshua Gnanaraj100% (1)

- ISO 1514-1 1997 Non - Metallic Flat Gasket With or Whithout InsertsDocument22 pagesISO 1514-1 1997 Non - Metallic Flat Gasket With or Whithout Insertsjosevil79No ratings yet

- GCBV2e V1Document11 pagesGCBV2e V1Kemal GokovicNo ratings yet

- Isuzu 4LE1Document46 pagesIsuzu 4LE1Максим Глущенко100% (1)

- Level Indicator Switch PDFDocument6 pagesLevel Indicator Switch PDFIbrahim Ben AmeurNo ratings yet

- Vogt Valves: Catalog and Application ManualDocument148 pagesVogt Valves: Catalog and Application ManualmaherNo ratings yet