Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

29 viewsFault Diagnosis: Problems and Possible Causes: Problem

Fault Diagnosis: Problems and Possible Causes: Problem

Uploaded by

AhmedThe document provides a table listing common engine problems, possible causes checked by users, and possible causes checked by workshop personnel. It includes problems like the starter motor turning the engine too slowly, the engine not starting, the engine being difficult to start, not having enough power, misfiring, high fuel consumption, black exhaust smoke, blue or white exhaust smoke, low oil pressure, the engine knocking, and the engine running erratically. For each problem, it lists potential causes that could be checked by users or require more extensive checks by workshop personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Sebu9035-04-00 Omm C18 EnglishDocument172 pagesSebu9035-04-00 Omm C18 EnglishWilliam PierceNo ratings yet

- Husqvarna 444 Workshop ManualDocument55 pagesHusqvarna 444 Workshop ManualAndreea Muresan100% (2)

- Jenbacher: 1. General Conditions - Operating and Maintenance: - 1Document4 pagesJenbacher: 1. General Conditions - Operating and Maintenance: - 1Arîf100% (1)

- PQ1000 Operetion Manual-New PDFDocument4 pagesPQ1000 Operetion Manual-New PDFtong SaetungNo ratings yet

- Pump Goveror Class OneDocument38 pagesPump Goveror Class OneEolo RojasNo ratings yet

- Scuderia Topolino - Technical AdviceDocument130 pagesScuderia Topolino - Technical AdviceNikNo ratings yet

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- Diesel Engine Troubleshooting and MaintenanceDocument8 pagesDiesel Engine Troubleshooting and MaintenanceIhsan Ahmed100% (2)

- Tips For Troubleshooting EngineDocument22 pagesTips For Troubleshooting EngineSandeep NikhilNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- Engine Control SystemDocument26 pagesEngine Control SystemERMINSUL VICUÑA SALASNo ratings yet

- UNIT1L3S - Engine Performance TerminologyDocument10 pagesUNIT1L3S - Engine Performance TerminologyEbied Yousif AlyNo ratings yet

- Diesel Ingine TroubleshootingDocument7 pagesDiesel Ingine TroubleshootingCresente galendez100% (1)

- Cc200e h1 Cummins Mta11 G2a PDFDocument6 pagesCc200e h1 Cummins Mta11 G2a PDFnaruto akatcyNo ratings yet

- Sensors System, Advanced Fuel Injection System, Computer Control SystemDocument34 pagesSensors System, Advanced Fuel Injection System, Computer Control SystemAdil RandhawaNo ratings yet

- Operation and MaintenanceDocument13 pagesOperation and MaintenanceLe DuNo ratings yet

- (001-026) Cylinder BlockDocument30 pages(001-026) Cylinder Blockteknisi ABNo ratings yet

- Diesel Engine Trouble ShootingDocument3 pagesDiesel Engine Trouble ShootingAnonymous wxL9DSuYk100% (1)

- Excitation Loss Module: SpecificationDocument2 pagesExcitation Loss Module: SpecificationKenNaNo ratings yet

- 4087187Document2 pages4087187RasoolKhadibiNo ratings yet

- 12 Engine LubricationDocument47 pages12 Engine LubricationdudurezNo ratings yet

- Wastegate Turbocharger Operation DiagnosticDocument6 pagesWastegate Turbocharger Operation DiagnosticHamilton MirandaNo ratings yet

- Determining The Cause of Fuel Dilution of Engine Oil (1101, 1124, 1251, 1280, 1290)Document10 pagesDetermining The Cause of Fuel Dilution of Engine Oil (1101, 1124, 1251, 1280, 1290)Miguel GutierrezNo ratings yet

- SPB 25 Coolant Specification and MaintenanceDocument6 pagesSPB 25 Coolant Specification and Maintenancehuguer1No ratings yet

- Honda Karburator Gx100Document1 pageHonda Karburator Gx100cerimovicNo ratings yet

- Hdi DL06PDocument246 pagesHdi DL06Pq26n65hvfsNo ratings yet

- Stanadyne Pump Diagnostic Troubleshooting PDFDocument3 pagesStanadyne Pump Diagnostic Troubleshooting PDFOctavio RamosNo ratings yet

- 1606A-E93Tag4 Electropak: SeriesDocument10 pages1606A-E93Tag4 Electropak: Seriesubaldo caraballoNo ratings yet

- 3b. Powertrain Cont PDFDocument921 pages3b. Powertrain Cont PDFDejan StojanovskiNo ratings yet

- Compression and Fuel Pressure Testing Tools - Draft 19-12Document14 pagesCompression and Fuel Pressure Testing Tools - Draft 19-12Idia F OosthuizenNo ratings yet

- Model FA (Vacuum Servo)Document54 pagesModel FA (Vacuum Servo)Komatsu Perkins Hitachi100% (1)

- ss10560 PDFDocument78 pagesss10560 PDFWilson GuzmanNo ratings yet

- Compresor Sanden Service Guide Rev.2Document30 pagesCompresor Sanden Service Guide Rev.2adriantxeNo ratings yet

- Valve Stem ProjectionDocument2 pagesValve Stem Projectionjose luis rattiaNo ratings yet

- Lecture 4 Solar PV System DesignDocument6 pagesLecture 4 Solar PV System DesignDon Harvey MiraNo ratings yet

- The C.I. Fuel System: OutlineDocument51 pagesThe C.I. Fuel System: OutlineDanang Aji NugrohoNo ratings yet

- Disassembly:: W 0704 M0 Gas-MixerDocument4 pagesDisassembly:: W 0704 M0 Gas-MixerHelder PintoNo ratings yet

- Diesel Fuel System PDFDocument57 pagesDiesel Fuel System PDFDhil Piero100% (1)

- Diesel Injector Coding and Pilot LearningDocument3 pagesDiesel Injector Coding and Pilot LearningddaanniieellssaaNo ratings yet

- Industrial and Genset Engines Issue 9Document47 pagesIndustrial and Genset Engines Issue 9ramon hidalgoNo ratings yet

- Diesel Generator Set QSX15 Series Engine: Power GenerationDocument4 pagesDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdNo ratings yet

- Symptom: P0235-Boost Pressure Sensor PlausibilityDocument12 pagesSymptom: P0235-Boost Pressure Sensor PlausibilityJose Pozo RoblesNo ratings yet

- Drum Brake Adjustment PDFDocument2 pagesDrum Brake Adjustment PDFY. VásquezNo ratings yet

- 2013 Isuzu Truck: 2007-2013 Model YearsDocument10 pages2013 Isuzu Truck: 2007-2013 Model YearsDinukaDeshanNo ratings yet

- CH 11Document34 pagesCH 11Getachew TikueNo ratings yet

- 1103 & 1104 Operation & MaintenanceDocument72 pages1103 & 1104 Operation & MaintenanceJamyansuren TseveendorjNo ratings yet

- Garrett Cat 9 04 TurbosDocument49 pagesGarrett Cat 9 04 TurbosJorge Fernando H GNo ratings yet

- Journal BearingsDocument32 pagesJournal Bearingsa_salehiNo ratings yet

- Fuel Injector NozzlesDocument10 pagesFuel Injector NozzlesHenrik KunzkeNo ratings yet

- Engine Controls & SensorsDocument23 pagesEngine Controls & Sensorsrudey18No ratings yet

- Operator S Manual: Generating Set and Industrial EnginesDocument64 pagesOperator S Manual: Generating Set and Industrial EnginesAl Bima100% (1)

- Special Functions: Issue 1Document24 pagesSpecial Functions: Issue 1Musharraf KhanNo ratings yet

- Air Break System Presentation 2Document33 pagesAir Break System Presentation 2Ahmed ElzzaddenNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Lea Dardanos Efi-Controller eDocument6 pagesLea Dardanos Efi-Controller eadfumegaNo ratings yet

- Drive Train FINAL EXAM 47 of 70Document15 pagesDrive Train FINAL EXAM 47 of 70Sunny SNo ratings yet

- EFICAAKERJABAGUSDocument76 pagesEFICAAKERJABAGUSCim sastroNo ratings yet

- MSDS PAROIL S - GB - enDocument7 pagesMSDS PAROIL S - GB - enTeguh SNo ratings yet

- GIG-perkinis Generator Troubleshoting ProblemsDocument8 pagesGIG-perkinis Generator Troubleshoting Problemsalexberhane3No ratings yet

- Engine DiagnosticsDocument3 pagesEngine DiagnosticsSamir BoodanNo ratings yet

- Engine Trouble ShootingDocument6 pagesEngine Trouble Shootingcedro08No ratings yet

- Img 20220414 144432Document7 pagesImg 20220414 144432AlejandroPalenciaNo ratings yet

- Semperfi XR Cs ODBreg PDFDocument1 pageSemperfi XR Cs ODBreg PDFAhmedNo ratings yet

- 4354 PDFDocument19 pages4354 PDFAhmedNo ratings yet

- E-Marketing-A Global Perspective: Parminder Kaur, Dr. Ashutosh Pathak Karamjeet KaurDocument9 pagesE-Marketing-A Global Perspective: Parminder Kaur, Dr. Ashutosh Pathak Karamjeet KaurAhmedNo ratings yet

- Portable PDFDocument8 pagesPortable PDFAhmedNo ratings yet

- InterlockDocument3 pagesInterlockAhmedNo ratings yet

- Comparison Between Conventional Chilled Water System and VRF System PDFDocument9 pagesComparison Between Conventional Chilled Water System and VRF System PDFAhmed100% (1)

- Eaton 93pm Ups Brochure BR153033ENDocument6 pagesEaton 93pm Ups Brochure BR153033ENAhmedNo ratings yet

- Critical Power Power Management Systems Benefits Over PLCUKDocument12 pagesCritical Power Power Management Systems Benefits Over PLCUKAhmedNo ratings yet

- 182 03 - 629DDocument13 pages182 03 - 629DAhmedNo ratings yet

- MDGF Testing 80043-703-01Document37 pagesMDGF Testing 80043-703-01AhmedNo ratings yet

- Keep Your Emergency Power Systems FitDocument4 pagesKeep Your Emergency Power Systems FitAhmedNo ratings yet

- Is It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSDocument2 pagesIs It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSAhmedNo ratings yet

- Saso 2203 - DSDocument11 pagesSaso 2203 - DSAhmedNo ratings yet

- Dive Computer Owner's Manual I300: © Aqua Lung International, Inc. (2015) Doc. 12-7823-r07 (1/27/16)Document63 pagesDive Computer Owner's Manual I300: © Aqua Lung International, Inc. (2015) Doc. 12-7823-r07 (1/27/16)AhmedNo ratings yet

- The Ultimate UHD PVR: HardwareDocument17 pagesThe Ultimate UHD PVR: HardwareAhmedNo ratings yet

- Rocket 150ah SMF BatteryDocument2 pagesRocket 150ah SMF BatteryAhmedNo ratings yet

- Dec - Chris Marine PDFDocument2 pagesDec - Chris Marine PDFhugoheloNo ratings yet

- Chevrolet Parts CatalogueDocument35 pagesChevrolet Parts CatalogueChina auto parts wholesales75% (4)

- SSP 420 2.0L TDI Engine With Common Rail Injection SystemDocument64 pagesSSP 420 2.0L TDI Engine With Common Rail Injection SystemVictor Andres BombinNo ratings yet

- Engine Mechanical: Group 11ADocument76 pagesEngine Mechanical: Group 11AToponari MedveNo ratings yet

- 5f61488678b009a80d75574b - Development of The XMv3 High Efficiency Cycloidal EngineDocument13 pages5f61488678b009a80d75574b - Development of The XMv3 High Efficiency Cycloidal Engine임학진No ratings yet

- Brosur Perkins 60 150kvaDocument2 pagesBrosur Perkins 60 150kvaKanjeng Raden Aryo SaifuNo ratings yet

- Manual Mecanico Daelim s1 125Document226 pagesManual Mecanico Daelim s1 125nieblactualidad67% (3)

- Marine Engines ABATO WeichaiDocument14 pagesMarine Engines ABATO Weichaiarf89No ratings yet

- 1206a-E70ttag3 PN3184 - 4Document4 pages1206a-E70ttag3 PN3184 - 4MohamedJaberKutkutMjkNo ratings yet

- 05 - Rotor Remove and InstallDocument9 pages05 - Rotor Remove and InstallNimNo ratings yet

- 06.01.3 Engine Mechanical Component Model Series 457-500-900 - MasterDocument100 pages06.01.3 Engine Mechanical Component Model Series 457-500-900 - Masterkiki JZ10DQQNo ratings yet

- Ic EngineDocument17 pagesIc EngineRajeswar KumarNo ratings yet

- American MFG Aw1122 Parts BookDocument6 pagesAmerican MFG Aw1122 Parts BookMauricio Ariel H. OrellanaNo ratings yet

- 6.4L Diesel Talk LIVEDocument40 pages6.4L Diesel Talk LIVECHRISTIAN LOZANONo ratings yet

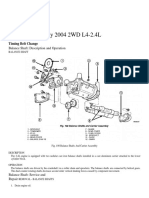

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDocument15 pagesJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNo ratings yet

- EGES240 CDocument50 pagesEGES240 CEdwin GilNo ratings yet

- Gas Turbine Power PlantDocument16 pagesGas Turbine Power PlantSathya Raj SimiNo ratings yet

- Hp3 Supply Pump Tightening Torque Change NotificationDocument2 pagesHp3 Supply Pump Tightening Torque Change NotificationDenisEcheverri100% (1)

- Final Year Technical Seminar: Department of Mechanical EngineeringDocument15 pagesFinal Year Technical Seminar: Department of Mechanical EngineeringNagabhushanaNo ratings yet

- Imarest Article1Document2 pagesImarest Article1Satyabrat GaanNo ratings yet

- Unit - IiiDocument19 pagesUnit - IiishirishNo ratings yet

- Er650 Fefw Lams Parts List PDFDocument105 pagesEr650 Fefw Lams Parts List PDFOliverNo ratings yet

- Moteur 400 500cc Geopolis - SatelisDocument72 pagesMoteur 400 500cc Geopolis - SatelisGeorge BaltzNo ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- V Force Wiring Pin Outs Part # 68030: Map/ Map/ TPS Wire TPS MAF Wire MAF Color Location Color LocationDocument3 pagesV Force Wiring Pin Outs Part # 68030: Map/ Map/ TPS Wire TPS MAF Wire MAF Color Location Color LocationMarcos Sepulveda UrrutiaNo ratings yet

- Ricardo SpecificationsDocument3 pagesRicardo Specificationsmihai.manolacheNo ratings yet

- d11t Track-Type Tractor Ama00001-Up (Machine) Powered by c32 Engine (Sebp5803 - 36) - Sistemas y Componentes2Document3 pagesd11t Track-Type Tractor Ama00001-Up (Machine) Powered by c32 Engine (Sebp5803 - 36) - Sistemas y Componentes2Juan Zangetsu UchihaNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument20 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNo ratings yet

Fault Diagnosis: Problems and Possible Causes: Problem

Fault Diagnosis: Problems and Possible Causes: Problem

Uploaded by

Ahmed0 ratings0% found this document useful (0 votes)

29 views4 pagesThe document provides a table listing common engine problems, possible causes checked by users, and possible causes checked by workshop personnel. It includes problems like the starter motor turning the engine too slowly, the engine not starting, the engine being difficult to start, not having enough power, misfiring, high fuel consumption, black exhaust smoke, blue or white exhaust smoke, low oil pressure, the engine knocking, and the engine running erratically. For each problem, it lists potential causes that could be checked by users or require more extensive checks by workshop personnel.

Original Description:

Fault Diagnosis for DGs

Original Title

Fault Diagnosis for DGs

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides a table listing common engine problems, possible causes checked by users, and possible causes checked by workshop personnel. It includes problems like the starter motor turning the engine too slowly, the engine not starting, the engine being difficult to start, not having enough power, misfiring, high fuel consumption, black exhaust smoke, blue or white exhaust smoke, low oil pressure, the engine knocking, and the engine running erratically. For each problem, it lists potential causes that could be checked by users or require more extensive checks by workshop personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

29 views4 pagesFault Diagnosis: Problems and Possible Causes: Problem

Fault Diagnosis: Problems and Possible Causes: Problem

Uploaded by

AhmedThe document provides a table listing common engine problems, possible causes checked by users, and possible causes checked by workshop personnel. It includes problems like the starter motor turning the engine too slowly, the engine not starting, the engine being difficult to start, not having enough power, misfiring, high fuel consumption, black exhaust smoke, blue or white exhaust smoke, low oil pressure, the engine knocking, and the engine running erratically. For each problem, it lists potential causes that could be checked by users or require more extensive checks by workshop personnel.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 4

Fault diagnosis

Problems and possible causes:

Problem Possible causes

Checks by the user Checks by the workshop personnel

The starter motor Battery capacity low.

turns the engine too Bad electrical connection.

slowly. Fault in starter motor.

Wrong grade of lubricating oil.

Starter motor turns engine too slowly Valve timing is incorrect

Fuel tank empty Bad compression

Spare Worn cylinder bores

Restriction in a fuel pipe Leakage between valves and seats

Fault in fuel lift pump Piston rings are not free or they are worn

The engine does not or broken

start . Dirty fuel filter element Faulty engine management system

Air in fuel system Broken drive on the high pressure pump

Fault in the fuel injector units Faulty injection control system

Cold start system used incorrectly Faulty sensor

Fault in cold start system

Wrong type or grade of fuel used

Starter motor turns engine too slowly Valve timing is incorrect

Spare Bad compression

Restriction in a fuel pipe Valves are not free

Fault in fuel lift pump Worn cylinder bores

Dirty fuel filter element Leakage between valves and seats

Restriction in air induction system Piston rings are not free or they are worn

The engine is or broken

difficult to start Air in fuel system Faulty engine management system

Fault in the fuel injector units

Cold start system used incorrectly

Fault in cold start system

Restriction in fuel tank vent

Wrong type or grade of fuel used

Restriction in exhaust pipe

Restriction in a fuel pipe Valve timing is incorrect

Fault in fuel lift pump Bad compression

Dirty fuel filter element Cylinder head gasket leaks

Restriction in air induction system Worn cylinder bores

Air in fuel system Leakage between valves and seats

Not enough power Fault in the fuel injector units Piston rings are not free or they are worn

or broken

Restriction in fuel tank vent Turbocharger impeller is damaged or dirty

Restricted movement of engine speed Induction system leaks

control

Restriction in exhaust pipe Turbocharger waste- gate does not work

correctly if one is fitted

Engine temperature is too high Faulty engine management system

Engine temperature is too low Faulty injection control system

Faulty sensor

Problem Possible causes

Checks by the user Checks by the workshop personnel

Restriction in a fuel pipe Valve timing is incorrect

Fault in fuel lift pump Bad compression

Dirty fuel filter element Cylinder head gasket leaks

Misfire Air in fuel system Valves are not free

Fault in the fuel injector units Leakage between valves and seats

Fault in cold start system Faulty engine management system

Engine temperature is too high Faulty sensor

Incorrect valve tip clearances

Restriction in air induction system Valve timing is incorrect

Fault in the fuel injector units Bad compression

Fault in cold start system Cylinder head gasket leaks

Wrong type or grade of fuel used Valves are not free

Restricted movement of engine Worn cylinder bores

High fuel speed control

consumption Restriction in exhaust pipe Leakage between valves and seats

Incorrect valve tip clearances Piston rings are not free or they are worn or

broken

Too much oil or oil of the wrong Induction system leaks

type is used in wet type air cleaner

if one is fitted

Faulty engine management system

Restriction in air induction system Valve timing is incorrect

Fault in the fuel injector units Bad compression

Fault in cold start system Cylinder head gasket leaks

Wrong type or grade of fuel used Valves are not free

Black exhaust Restriction in exhaust pipe Worn cylinder bores

smoke Engine temperature is too low Leakage between valves and seats

Incorrect valve tip clearances Piston rings are not free or they are worn or

broken

Turbocharger impeller is damaged or dirty

Induction system leaks

Faulty engine management

Wrong grade of lubricating oil. Valve timing is incorrect

Engine temperature is too low Bad compression

Fault in cold start system Cylinder head gasket leaks

Too much oil or oil of the wrong Worn cylinder bores

type is used in wet type air cleaner

if one is fitted

Blue or white Leakage between valves and seats

exhaust smoke Piston rings are not free or they are worn or

broken

Valve stems and /or guides are worn

Piston is damaged

Valve stem seal is damaged

Lubricating oil seal of turbocharger leaks

Faulty engine management system

Faulty injection control system

Problem Possible causes

Checks by the user Checks by the workshop personnel

The pressure of Wrong grade of lubricating oil. Crankshaft bearings are worn or damaged

the low oil Not enough lubricating oil in sump Lubricating oil pump is worn

pressure Defective gauge Relief valve does not close

lubricating oil Dirty lubricating oil filter element Relief valve spring is broken

system is too Fault in suction pipe of lubricating oil pump

low Restriction in sump strainer

Fault in fuel lift pump Valve timing is incorrect

Fault in the fuel injector units Valves are not free

The engine Fault in cold start system Worn cylinder bores

knocks Wrong type or grade of fuel used Piston rings are not free or they are worn

or broken

Engine temperature is too high Crankshaft bearings are worn or damaged

Incorrect valve tip clearances Piston is damaged

Too much oil or oil of the wrong type is Piston height is incorrect

used in wet type air cleaner if one is fitted

Valve spring is broken

Faulty engine management system

Faulty injection control system

Restriction in a fuel pipe Bad compression

Fault in fuel lift pump Valves are not free

Dirty fuel filter element Piston rings are not free or they are worn

The engine run or broken

erratically Restriction in air induction system

Air in fuel system Piston is damaged

Fault in the fuel injector units Valve spring is broken

Fault in cold start system Faulty engine management system

Restriction in fuel tank vent Faulty injection control system

Restricted movement of engine speed Faulty sensor

control

Engine temperature is too high

Incorrect valve tip clearances

Too much oil or oil of the wrong type is

used in wet type air cleaner if one is fitted

Fault in the fuel injector units Bad compression

Restricted movement of engine speed Cylinder head gasket leaks

control

Engine temperature is too high Valves are not free

Fan damaged Piston rings are not free or they are worn

or broken

Vibration Fault in engine mounting or flywheel Piston is damaged

housing

Flywheel housing or flywheel is not aligned

correctly

Faulty engine management system

Faulty injection control system

Faulty sensor

Problem Possible causes

Checks by the user Checks by the workshop personnel

The pressure of the Wrong grade of lubricating oil. Relief valve does not open

low pressure Defective gauge

lubricating oil

system is too high

Restriction in air induction system Valve timing is incorrect

Fault in the fuel injector units Cylinder head gasket leaks

Fault in cold start system Piston is damaged

Restriction in exhaust pipe Fault in thermostat or thermostat is of an

The engine oil incorrect type

temperature is too Fan damaged Restriction in coolant passages

high Too much lubricating oil in sump Fault in water pump

Restriction in air or water passages Turbocharger waste-gate does not work

of raditor correctly if one is fitted

Insufficient coolant in system Faulty sensor

Drive belt for water pump is loose

Restriction in breather pipe Cylinder head gasket leaks

Fault in exhauster Worn cylinder bores

Crankcase pressure Piston rings are not free or they are worn or

broken

Valve stems and /or guides are worn

Piston is damaged

Restriction in air induction system Valve timing is incorrect

Incorrect valve tip clearances Cylinder head gasket leaks

Valves are not free

Worn cylinder bores

Bad compression Leakage between valves and seats

Piston rings are not free or they are worn or

broken

Valve stems and /or guides are worn

Piston height is incorrect

Valve spring is broken

The engine starts Dirty fuel filter element Faulty engine management system

and stops Restriction in air induction system Faulty injection control system

Air in fuel system Faulty sensor

The pressure of the Wrong grade of lubricating oil. Faulty engine management system

high pressure Not enough lubricating oil in sump Faulty injection control system

lubricating oil Defective gauge Faulty sensor

system is too low Dirty lubricating oil filter element

You might also like

- Sebu9035-04-00 Omm C18 EnglishDocument172 pagesSebu9035-04-00 Omm C18 EnglishWilliam PierceNo ratings yet

- Husqvarna 444 Workshop ManualDocument55 pagesHusqvarna 444 Workshop ManualAndreea Muresan100% (2)

- Jenbacher: 1. General Conditions - Operating and Maintenance: - 1Document4 pagesJenbacher: 1. General Conditions - Operating and Maintenance: - 1Arîf100% (1)

- PQ1000 Operetion Manual-New PDFDocument4 pagesPQ1000 Operetion Manual-New PDFtong SaetungNo ratings yet

- Pump Goveror Class OneDocument38 pagesPump Goveror Class OneEolo RojasNo ratings yet

- Scuderia Topolino - Technical AdviceDocument130 pagesScuderia Topolino - Technical AdviceNikNo ratings yet

- General Diesel Engine Diagnostic Guide PDFDocument3 pagesGeneral Diesel Engine Diagnostic Guide PDFan0th3r_0n3No ratings yet

- Diesel Engine Troubleshooting and MaintenanceDocument8 pagesDiesel Engine Troubleshooting and MaintenanceIhsan Ahmed100% (2)

- Tips For Troubleshooting EngineDocument22 pagesTips For Troubleshooting EngineSandeep NikhilNo ratings yet

- Inline S3.8 TroubleshootingDocument32 pagesInline S3.8 TroubleshootingKrishna PardeshiNo ratings yet

- Engine Control SystemDocument26 pagesEngine Control SystemERMINSUL VICUÑA SALASNo ratings yet

- UNIT1L3S - Engine Performance TerminologyDocument10 pagesUNIT1L3S - Engine Performance TerminologyEbied Yousif AlyNo ratings yet

- Diesel Ingine TroubleshootingDocument7 pagesDiesel Ingine TroubleshootingCresente galendez100% (1)

- Cc200e h1 Cummins Mta11 G2a PDFDocument6 pagesCc200e h1 Cummins Mta11 G2a PDFnaruto akatcyNo ratings yet

- Sensors System, Advanced Fuel Injection System, Computer Control SystemDocument34 pagesSensors System, Advanced Fuel Injection System, Computer Control SystemAdil RandhawaNo ratings yet

- Operation and MaintenanceDocument13 pagesOperation and MaintenanceLe DuNo ratings yet

- (001-026) Cylinder BlockDocument30 pages(001-026) Cylinder Blockteknisi ABNo ratings yet

- Diesel Engine Trouble ShootingDocument3 pagesDiesel Engine Trouble ShootingAnonymous wxL9DSuYk100% (1)

- Excitation Loss Module: SpecificationDocument2 pagesExcitation Loss Module: SpecificationKenNaNo ratings yet

- 4087187Document2 pages4087187RasoolKhadibiNo ratings yet

- 12 Engine LubricationDocument47 pages12 Engine LubricationdudurezNo ratings yet

- Wastegate Turbocharger Operation DiagnosticDocument6 pagesWastegate Turbocharger Operation DiagnosticHamilton MirandaNo ratings yet

- Determining The Cause of Fuel Dilution of Engine Oil (1101, 1124, 1251, 1280, 1290)Document10 pagesDetermining The Cause of Fuel Dilution of Engine Oil (1101, 1124, 1251, 1280, 1290)Miguel GutierrezNo ratings yet

- SPB 25 Coolant Specification and MaintenanceDocument6 pagesSPB 25 Coolant Specification and Maintenancehuguer1No ratings yet

- Honda Karburator Gx100Document1 pageHonda Karburator Gx100cerimovicNo ratings yet

- Hdi DL06PDocument246 pagesHdi DL06Pq26n65hvfsNo ratings yet

- Stanadyne Pump Diagnostic Troubleshooting PDFDocument3 pagesStanadyne Pump Diagnostic Troubleshooting PDFOctavio RamosNo ratings yet

- 1606A-E93Tag4 Electropak: SeriesDocument10 pages1606A-E93Tag4 Electropak: Seriesubaldo caraballoNo ratings yet

- 3b. Powertrain Cont PDFDocument921 pages3b. Powertrain Cont PDFDejan StojanovskiNo ratings yet

- Compression and Fuel Pressure Testing Tools - Draft 19-12Document14 pagesCompression and Fuel Pressure Testing Tools - Draft 19-12Idia F OosthuizenNo ratings yet

- Model FA (Vacuum Servo)Document54 pagesModel FA (Vacuum Servo)Komatsu Perkins Hitachi100% (1)

- ss10560 PDFDocument78 pagesss10560 PDFWilson GuzmanNo ratings yet

- Compresor Sanden Service Guide Rev.2Document30 pagesCompresor Sanden Service Guide Rev.2adriantxeNo ratings yet

- Valve Stem ProjectionDocument2 pagesValve Stem Projectionjose luis rattiaNo ratings yet

- Lecture 4 Solar PV System DesignDocument6 pagesLecture 4 Solar PV System DesignDon Harvey MiraNo ratings yet

- The C.I. Fuel System: OutlineDocument51 pagesThe C.I. Fuel System: OutlineDanang Aji NugrohoNo ratings yet

- Disassembly:: W 0704 M0 Gas-MixerDocument4 pagesDisassembly:: W 0704 M0 Gas-MixerHelder PintoNo ratings yet

- Diesel Fuel System PDFDocument57 pagesDiesel Fuel System PDFDhil Piero100% (1)

- Diesel Injector Coding and Pilot LearningDocument3 pagesDiesel Injector Coding and Pilot LearningddaanniieellssaaNo ratings yet

- Industrial and Genset Engines Issue 9Document47 pagesIndustrial and Genset Engines Issue 9ramon hidalgoNo ratings yet

- Diesel Generator Set QSX15 Series Engine: Power GenerationDocument4 pagesDiesel Generator Set QSX15 Series Engine: Power GenerationsdasdNo ratings yet

- Symptom: P0235-Boost Pressure Sensor PlausibilityDocument12 pagesSymptom: P0235-Boost Pressure Sensor PlausibilityJose Pozo RoblesNo ratings yet

- Drum Brake Adjustment PDFDocument2 pagesDrum Brake Adjustment PDFY. VásquezNo ratings yet

- 2013 Isuzu Truck: 2007-2013 Model YearsDocument10 pages2013 Isuzu Truck: 2007-2013 Model YearsDinukaDeshanNo ratings yet

- CH 11Document34 pagesCH 11Getachew TikueNo ratings yet

- 1103 & 1104 Operation & MaintenanceDocument72 pages1103 & 1104 Operation & MaintenanceJamyansuren TseveendorjNo ratings yet

- Garrett Cat 9 04 TurbosDocument49 pagesGarrett Cat 9 04 TurbosJorge Fernando H GNo ratings yet

- Journal BearingsDocument32 pagesJournal Bearingsa_salehiNo ratings yet

- Fuel Injector NozzlesDocument10 pagesFuel Injector NozzlesHenrik KunzkeNo ratings yet

- Engine Controls & SensorsDocument23 pagesEngine Controls & Sensorsrudey18No ratings yet

- Operator S Manual: Generating Set and Industrial EnginesDocument64 pagesOperator S Manual: Generating Set and Industrial EnginesAl Bima100% (1)

- Special Functions: Issue 1Document24 pagesSpecial Functions: Issue 1Musharraf KhanNo ratings yet

- Air Break System Presentation 2Document33 pagesAir Break System Presentation 2Ahmed ElzzaddenNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Lea Dardanos Efi-Controller eDocument6 pagesLea Dardanos Efi-Controller eadfumegaNo ratings yet

- Drive Train FINAL EXAM 47 of 70Document15 pagesDrive Train FINAL EXAM 47 of 70Sunny SNo ratings yet

- EFICAAKERJABAGUSDocument76 pagesEFICAAKERJABAGUSCim sastroNo ratings yet

- MSDS PAROIL S - GB - enDocument7 pagesMSDS PAROIL S - GB - enTeguh SNo ratings yet

- GIG-perkinis Generator Troubleshoting ProblemsDocument8 pagesGIG-perkinis Generator Troubleshoting Problemsalexberhane3No ratings yet

- Engine DiagnosticsDocument3 pagesEngine DiagnosticsSamir BoodanNo ratings yet

- Engine Trouble ShootingDocument6 pagesEngine Trouble Shootingcedro08No ratings yet

- Img 20220414 144432Document7 pagesImg 20220414 144432AlejandroPalenciaNo ratings yet

- Semperfi XR Cs ODBreg PDFDocument1 pageSemperfi XR Cs ODBreg PDFAhmedNo ratings yet

- 4354 PDFDocument19 pages4354 PDFAhmedNo ratings yet

- E-Marketing-A Global Perspective: Parminder Kaur, Dr. Ashutosh Pathak Karamjeet KaurDocument9 pagesE-Marketing-A Global Perspective: Parminder Kaur, Dr. Ashutosh Pathak Karamjeet KaurAhmedNo ratings yet

- Portable PDFDocument8 pagesPortable PDFAhmedNo ratings yet

- InterlockDocument3 pagesInterlockAhmedNo ratings yet

- Comparison Between Conventional Chilled Water System and VRF System PDFDocument9 pagesComparison Between Conventional Chilled Water System and VRF System PDFAhmed100% (1)

- Eaton 93pm Ups Brochure BR153033ENDocument6 pagesEaton 93pm Ups Brochure BR153033ENAhmedNo ratings yet

- Critical Power Power Management Systems Benefits Over PLCUKDocument12 pagesCritical Power Power Management Systems Benefits Over PLCUKAhmedNo ratings yet

- 182 03 - 629DDocument13 pages182 03 - 629DAhmedNo ratings yet

- MDGF Testing 80043-703-01Document37 pagesMDGF Testing 80043-703-01AhmedNo ratings yet

- Keep Your Emergency Power Systems FitDocument4 pagesKeep Your Emergency Power Systems FitAhmedNo ratings yet

- Is It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSDocument2 pagesIs It Time For Industrial UPS Systems in Data Centers?: White Paper PCS100 UPSAhmedNo ratings yet

- Saso 2203 - DSDocument11 pagesSaso 2203 - DSAhmedNo ratings yet

- Dive Computer Owner's Manual I300: © Aqua Lung International, Inc. (2015) Doc. 12-7823-r07 (1/27/16)Document63 pagesDive Computer Owner's Manual I300: © Aqua Lung International, Inc. (2015) Doc. 12-7823-r07 (1/27/16)AhmedNo ratings yet

- The Ultimate UHD PVR: HardwareDocument17 pagesThe Ultimate UHD PVR: HardwareAhmedNo ratings yet

- Rocket 150ah SMF BatteryDocument2 pagesRocket 150ah SMF BatteryAhmedNo ratings yet

- Dec - Chris Marine PDFDocument2 pagesDec - Chris Marine PDFhugoheloNo ratings yet

- Chevrolet Parts CatalogueDocument35 pagesChevrolet Parts CatalogueChina auto parts wholesales75% (4)

- SSP 420 2.0L TDI Engine With Common Rail Injection SystemDocument64 pagesSSP 420 2.0L TDI Engine With Common Rail Injection SystemVictor Andres BombinNo ratings yet

- Engine Mechanical: Group 11ADocument76 pagesEngine Mechanical: Group 11AToponari MedveNo ratings yet

- 5f61488678b009a80d75574b - Development of The XMv3 High Efficiency Cycloidal EngineDocument13 pages5f61488678b009a80d75574b - Development of The XMv3 High Efficiency Cycloidal Engine임학진No ratings yet

- Brosur Perkins 60 150kvaDocument2 pagesBrosur Perkins 60 150kvaKanjeng Raden Aryo SaifuNo ratings yet

- Manual Mecanico Daelim s1 125Document226 pagesManual Mecanico Daelim s1 125nieblactualidad67% (3)

- Marine Engines ABATO WeichaiDocument14 pagesMarine Engines ABATO Weichaiarf89No ratings yet

- 1206a-E70ttag3 PN3184 - 4Document4 pages1206a-E70ttag3 PN3184 - 4MohamedJaberKutkutMjkNo ratings yet

- 05 - Rotor Remove and InstallDocument9 pages05 - Rotor Remove and InstallNimNo ratings yet

- 06.01.3 Engine Mechanical Component Model Series 457-500-900 - MasterDocument100 pages06.01.3 Engine Mechanical Component Model Series 457-500-900 - Masterkiki JZ10DQQNo ratings yet

- Ic EngineDocument17 pagesIc EngineRajeswar KumarNo ratings yet

- American MFG Aw1122 Parts BookDocument6 pagesAmerican MFG Aw1122 Parts BookMauricio Ariel H. OrellanaNo ratings yet

- 6.4L Diesel Talk LIVEDocument40 pages6.4L Diesel Talk LIVECHRISTIAN LOZANONo ratings yet

- Jeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeDocument15 pagesJeep Truck Liberty 2004 2WD L4-2.4L: Timing Belt ChangeJuan vaizNo ratings yet

- EGES240 CDocument50 pagesEGES240 CEdwin GilNo ratings yet

- Gas Turbine Power PlantDocument16 pagesGas Turbine Power PlantSathya Raj SimiNo ratings yet

- Hp3 Supply Pump Tightening Torque Change NotificationDocument2 pagesHp3 Supply Pump Tightening Torque Change NotificationDenisEcheverri100% (1)

- Final Year Technical Seminar: Department of Mechanical EngineeringDocument15 pagesFinal Year Technical Seminar: Department of Mechanical EngineeringNagabhushanaNo ratings yet

- Imarest Article1Document2 pagesImarest Article1Satyabrat GaanNo ratings yet

- Unit - IiiDocument19 pagesUnit - IiishirishNo ratings yet

- Er650 Fefw Lams Parts List PDFDocument105 pagesEr650 Fefw Lams Parts List PDFOliverNo ratings yet

- Moteur 400 500cc Geopolis - SatelisDocument72 pagesMoteur 400 500cc Geopolis - SatelisGeorge BaltzNo ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- V Force Wiring Pin Outs Part # 68030: Map/ Map/ TPS Wire TPS MAF Wire MAF Color Location Color LocationDocument3 pagesV Force Wiring Pin Outs Part # 68030: Map/ Map/ TPS Wire TPS MAF Wire MAF Color Location Color LocationMarcos Sepulveda UrrutiaNo ratings yet

- Ricardo SpecificationsDocument3 pagesRicardo Specificationsmihai.manolacheNo ratings yet

- d11t Track-Type Tractor Ama00001-Up (Machine) Powered by c32 Engine (Sebp5803 - 36) - Sistemas y Componentes2Document3 pagesd11t Track-Type Tractor Ama00001-Up (Machine) Powered by c32 Engine (Sebp5803 - 36) - Sistemas y Componentes2Juan Zangetsu UchihaNo ratings yet

- VAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualDocument20 pagesVAR Part 7 - Aircraft Maintenance Basic Cat A: Training ManualPhạm Đức HuyNo ratings yet