Professional Documents

Culture Documents

Tutorial: Valve Closure and Transient Pressure Wave (Part 1)

Tutorial: Valve Closure and Transient Pressure Wave (Part 1)

Uploaded by

Anonymous I4CTAwUCopyright:

Available Formats

You might also like

- Linde E20 25 30 Forklift Trucks Service Manual PDFDocument62 pagesLinde E20 25 30 Forklift Trucks Service Manual PDFmike peters100% (3)

- Lab 1 Measurement of Airflow Lab Manual-1Document10 pagesLab 1 Measurement of Airflow Lab Manual-1Nadeem Rehman100% (1)

- File Handling in C LanguageDocument5 pagesFile Handling in C Languagesudhakar kethanaNo ratings yet

- Caviter PDFDocument12 pagesCaviter PDFstphn_maturinNo ratings yet

- Std. Test Methods For Metal Powders & PM ProductsDocument12 pagesStd. Test Methods For Metal Powders & PM ProductschandiniNo ratings yet

- 4.3-Euler's Equation PDFDocument6 pages4.3-Euler's Equation PDFRonald Cario SeguinNo ratings yet

- Tutorial: Valve Closure and Transient Pressure Wave (Part 2)Document8 pagesTutorial: Valve Closure and Transient Pressure Wave (Part 2)Anonymous I4CTAwUNo ratings yet

- Tutorial: Valve Closure and Transient Pressure Wave (Part 3)Document4 pagesTutorial: Valve Closure and Transient Pressure Wave (Part 3)Anonymous I4CTAwUNo ratings yet

- Water Hammer 1Document11 pagesWater Hammer 1shaffetiNo ratings yet

- REPORTpp 1Document16 pagesREPORTpp 1gajulavamshikrishna02No ratings yet

- Demonstration of Bernoulli's TheoremDocument22 pagesDemonstration of Bernoulli's TheoremEason OngNo ratings yet

- FM 24 ManualDocument18 pagesFM 24 ManualMohd Nor SollehanNo ratings yet

- Answer No 3Document15 pagesAnswer No 3Politik Itu KejamNo ratings yet

- Spool Valves and Hydraulic CircuitsDocument7 pagesSpool Valves and Hydraulic CircuitsDINESHASHOKNo ratings yet

- Vcone To Orifice Plate Noise ComparisonDocument8 pagesVcone To Orifice Plate Noise ComparisonDavid P. MonjureNo ratings yet

- Formal ReportxDocument7 pagesFormal ReportxDarshan ShaarmaNo ratings yet

- A Nodal Approach For Applying Systems Analysis To The Flowing and Artificial Lift Oil or Gas WellDocument2 pagesA Nodal Approach For Applying Systems Analysis To The Flowing and Artificial Lift Oil or Gas WellKaro MárquezNo ratings yet

- Flowmeter Installation EffectsDocument12 pagesFlowmeter Installation EffectsgykataiNo ratings yet

- Line BreakDocument16 pagesLine BreakFlorencia BalseiroNo ratings yet

- Experiment 2 - Flow Measurement: Page 1 of 6Document6 pagesExperiment 2 - Flow Measurement: Page 1 of 6fadyaNo ratings yet

- Surge Pressure Prediction For Running LinersDocument13 pagesSurge Pressure Prediction For Running LinersPegasus Vertex, Inc.100% (1)

- Compressible Flow in A Convergent - Divergent NozzleDocument10 pagesCompressible Flow in A Convergent - Divergent NozzleNeville Lawless75% (8)

- FLOW MEASUREMENT - Course NotesDocument38 pagesFLOW MEASUREMENT - Course Notespawan deepNo ratings yet

- VPT-Kalatjari (Sazeh Engineering Consultants)Document16 pagesVPT-Kalatjari (Sazeh Engineering Consultants)cristianNo ratings yet

- VALTEK Valve Size PDFDocument16 pagesVALTEK Valve Size PDFalbahbahaneeNo ratings yet

- Petroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesDocument14 pagesPetroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesUnknown Gamer467No ratings yet

- Computational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveDocument4 pagesComputational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveMax KocourNo ratings yet

- Calculating Pump HeadDocument8 pagesCalculating Pump HeadPascal SayahNo ratings yet

- Fluid FrictionDocument18 pagesFluid Frictioncakhoa100% (2)

- NO. Title Allocated MARKS (%) MarksDocument22 pagesNO. Title Allocated MARKS (%) MarksjufferyNo ratings yet

- Compressible Flow Across A Varying Area PassageDocument4 pagesCompressible Flow Across A Varying Area PassageGaurav VaibhavNo ratings yet

- Flow - and - Pressure Measurement by ManometerDocument23 pagesFlow - and - Pressure Measurement by ManometerDhanraj Patil100% (1)

- Control Valves Interview QuestionsDocument7 pagesControl Valves Interview QuestionsDerbel WalidNo ratings yet

- Pipe Friction LossDocument6 pagesPipe Friction LossHoongNo ratings yet

- Laminar & Turbulent Flow in PipesDocument5 pagesLaminar & Turbulent Flow in PipesDhananjay KadamNo ratings yet

- Addis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringEskiasNo ratings yet

- Single PDFDocument16 pagesSingle PDFVignesh WaranNo ratings yet

- Ece135p Exp. 4 Pressure Flow and Level Process ControlDocument8 pagesEce135p Exp. 4 Pressure Flow and Level Process ControlPao CastillonNo ratings yet

- HydraulicsDocument65 pagesHydraulicsMohsin Ehsan100% (1)

- Pump Head CalculationDocument15 pagesPump Head CalculationYashapuja100% (2)

- NEL Best Practice - Impulse Lines For DP FTs PDFDocument8 pagesNEL Best Practice - Impulse Lines For DP FTs PDFnasirmuzaffar0% (1)

- CVS 4150 & 4160 Pressure Controller July 2012 PDFDocument12 pagesCVS 4150 & 4160 Pressure Controller July 2012 PDFOghale B. E. OmuaborNo ratings yet

- Cavitation in Valves 7-22-08Document6 pagesCavitation in Valves 7-22-08Keivn SimiyuNo ratings yet

- Control Valve SizingDocument16 pagesControl Valve SizingmsNo ratings yet

- Interview Questions For Instrument EngineersDocument4 pagesInterview Questions For Instrument EngineerszhangyiliNo ratings yet

- E3 BernoulliDocument16 pagesE3 BernoullikishoreNo ratings yet

- Nozzle Press Lab Online 1Document11 pagesNozzle Press Lab Online 1Ahmad NaeemNo ratings yet

- Advantages of Bladder Surge TanksDocument8 pagesAdvantages of Bladder Surge TanksChrisHogbenNo ratings yet

- Pipe NetworkDocument9 pagesPipe Networkfireorion7No ratings yet

- Pipe Friction ExperimentDocument10 pagesPipe Friction ExperimentCstiosen50% (2)

- Flow Measurement in Closed ConduitDocument65 pagesFlow Measurement in Closed ConduitjohnmayardNo ratings yet

- Pressure Transient in Liquid PipingDocument40 pagesPressure Transient in Liquid PipingMustafa AhsanNo ratings yet

- Spe 8025 MS PDFDocument36 pagesSpe 8025 MS PDFvictory cvsgNo ratings yet

- Controlador 4160Document12 pagesControlador 4160Antonio Castillo GNo ratings yet

- Comsol Report FinalDocument12 pagesComsol Report FinalEsraaNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Texto 1: The Digital AgeDocument6 pagesTexto 1: The Digital AgeMaria Cristina LourenconiNo ratings yet

- WB SpcxbarandrintroDocument4 pagesWB SpcxbarandrintromitiwanaNo ratings yet

- 73 Dit Power StrokeDocument78 pages73 Dit Power StrokeNic Price100% (1)

- Physics 20 21Document23 pagesPhysics 20 21CarolusBorromeusWisnuNo ratings yet

- Angles in Special QuadrilateralsDocument3 pagesAngles in Special QuadrilateralsSanad AhmadNo ratings yet

- Dynamics of Ma-ChineryDocument1 pageDynamics of Ma-Chineryvenkat krishnanNo ratings yet

- Ra7-018 - EpmDocument4 pagesRa7-018 - EpmivanNo ratings yet

- Gradient Descent For Linear Regression - CourseraDocument1 pageGradient Descent For Linear Regression - CourseraVishnuNo ratings yet

- State Space Solutions and Realizations: EE-601: Linear System TheoryDocument29 pagesState Space Solutions and Realizations: EE-601: Linear System TheorysunilsahadevanNo ratings yet

- Adenosine Triphosphate - WikipediaDocument65 pagesAdenosine Triphosphate - WikipediaBashiir NuurNo ratings yet

- THAI COATER Spec PDFDocument4 pagesTHAI COATER Spec PDFConfundo Paa DuroNo ratings yet

- Silicon PNP Transistor in A SOT-89 Plastic Package.: DescriptionsDocument7 pagesSilicon PNP Transistor in A SOT-89 Plastic Package.: DescriptionsAbdallah EstambelliNo ratings yet

- Relay CatalogueDocument38 pagesRelay CatalogueИгорьNo ratings yet

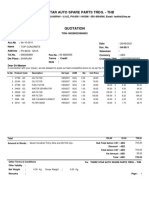

- Three Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055Document1 pageThree Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055syed ahmedNo ratings yet

- Quad 405 Current Dumping Audio Amplifer DCDDocument3 pagesQuad 405 Current Dumping Audio Amplifer DCDmetinprivat01100% (1)

- Iso 1977 2006 en PDFDocument8 pagesIso 1977 2006 en PDFRainer Ricardo MacielNo ratings yet

- DSAD Regular HODocument6 pagesDSAD Regular HODavidNo ratings yet

- MCQ Engineering Mechanics Part VDocument17 pagesMCQ Engineering Mechanics Part VDominic LanticseNo ratings yet

- Report - Welding and Types of WeldingDocument13 pagesReport - Welding and Types of WeldingИгорь ПетраковNo ratings yet

- Effect of Backward Walking Training On Postural Balance in Children With Hemiparetic Cerebral Palsy A Randomized Controlled StudyDocument12 pagesEffect of Backward Walking Training On Postural Balance in Children With Hemiparetic Cerebral Palsy A Randomized Controlled Studyprawira arthawanNo ratings yet

- Figure of SpeechDocument9 pagesFigure of SpeechReymar PalamiNo ratings yet

- Replace Capacitors On EcuDocument9 pagesReplace Capacitors On EcuHomar Mur100% (3)

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- 1 PBDocument20 pages1 PBYou IfkirnNo ratings yet

- As400 QuestionsDocument6 pagesAs400 QuestionslakshmiNo ratings yet

- Design and Simulation of InGaAs/GaAsSb Single Quantum Well Structure For Optical Fiber Application: Electronic Band Structure, Carrier Transport, and Optical Gain AnalysisDocument4 pagesDesign and Simulation of InGaAs/GaAsSb Single Quantum Well Structure For Optical Fiber Application: Electronic Band Structure, Carrier Transport, and Optical Gain AnalysisPriyanka KilaniyaNo ratings yet

Tutorial: Valve Closure and Transient Pressure Wave (Part 1)

Tutorial: Valve Closure and Transient Pressure Wave (Part 1)

Uploaded by

Anonymous I4CTAwUOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial: Valve Closure and Transient Pressure Wave (Part 1)

Tutorial: Valve Closure and Transient Pressure Wave (Part 1)

Uploaded by

Anonymous I4CTAwUCopyright:

Available Formats

BOSfluids

Tutorial

Valve closure and transient

pressure wave (part 1)

The “Valve closure and transient pressure wave” is a 3 part tutorial.

Part 1 describes the pressure wave and reflection and transmission

due to varying diameter piping.

BOSfluids Valve Closure and Transient Pressure Waves Part 1

1. CONSTRUCTING THE MODEL

1.1. Introduction

This basic gas-hammer simulation is intended to demonstrate a number of the different

options in BOSfluids® regarding pressure wave analysis. These options are used and

discussed to help the user understand the program and the basic physical phenomena of

pressure waves and interaction with boundary types.

The system shown in Figure 1 will be used to demonstrate the analysis of pressure waves in

a pipe with diameter variations. The system consists of a gate valve and three sections of

piping, of which the mid-section is of a larger diameter. In the gas-filled system, pressure

waves are created after the rapid closure of the valve.

In this first part of the tutorial the model is build, analyzed and the results are discussed. For

information on the basic inputs of the BOSfluids interface, please refer to the Get Started

tutorial.

20 ft

6” 20 ft

Valve

10” 20 ft

6”

Figure 1 | Model of the piping system used to illustrate pressure waves due to pipe diameter variations

1.2. Building the Model

Start BOSfluids and create a new model with the title ValveClosure1. Select English measuring

units. Begin to create the piping model by selecting the + button. Use the information

provided in Table 1 to define all the elements in the system. All elements are aligned parallel

to the X-axis. The roughness and temperature parameters of the piping element can be left as

default.

Copyright © Dynaflow Research Group. Page 1 of 11

BOSfluids Valve Closure and Transient Pressure Waves Part 1

Table 1 | Element Parameters

Length

Element Type Parameters

(inch)

5 – 10 15 Pipe Diameter = 6”, Thickness = 0.280”

Diameter = 6”, Valve Bore = 2.93”,

10 – 12 9 Valve

Discharge Coefficient = 0.5

12 – 18 192 Pipe Diameter = 6”, Thickness = 0.280”

18 – 20 24 Pipe Diameter = 6”, Thickness = 0.280”

20 – 22 24 Pipe Diameter = 10”, Thickness = 0.365”

22 – 28 192 Pipe Diameter = 10”, Thickness = 0.365”

28 – 30 24 Pipe Diameter = 10”, Thickness = 0.365”

30 – 32 24 Pipe Diameter = 6”, Thickness = 0.280”

32 – 38 192 Pipe Diameter = 6”, Thickness = 0.280”

38 – 40 24 Pipe Diameter = 6”, Thickness = 0.280”

For the steady state analysis, the valve position will be fully open. Set the valve opening

position to 100%.

During the transient analysis, the valve will almost instantly close, with a closing time of

5ms. Set the Valve Actions of the valve to be initially 100% open and fully closed at t = 0.005

seconds, as seen in Figure 2.

Figure 2 | Valve closing action

Page 2 of 11 Copyright © Dynaflow Research Group.

BOSfluids Valve Closure and Transient Pressure Waves Part 1

1.3. Model Boundary Conditions

1.3.1. Pressure Waves: Theoretical Background

Pressure waves can produce standing wave patterns and “resonances” in piping systems.

The type of pattern is typically associated with the two basic boundary conditions and

resonant period shown in Figure 3.

Figure 3 | Standing wave patterns for various end type boundary conditions

At open ends the pressure is fixed at a single, or controlled value, and the velocity (or flow

rate) is adjusted by the solution of the flow equations to satisfy the continuity and energy

equations. These boundary conditions are typically found at the entrance to large volumes,

i.e. tanks or pressure vessels.

At closed ends the velocity (or flow rate) is fixed at a single, or controlled value, and the

pressure is adjusted by the solution of the flow equations to satisfy the continuity and

energy equations. These boundary conditions are typically found at end caps, pistons,

closed valves, or the discharges of positive displacement machines.

The type of end modeled in BOSfluids depends on the type of boundary condition specified

at the node. By default BOSfluids assumes that each pipe end, if not explicitly defined to be

otherwise, contains an end cap, i.e. is a dead end. If the end of a particular system is not a

closed end, but rather opens into a larger container or to the atmosphere, the user should

place a boundary condition at that end node. Fixed pressure boundary conditions simulate

an “open end” and allow high pressure waves to pass. Fixed flow boundary conditions

simulate a “closed end” for the pressure waves and reflect pressure waves that encroach

upon it, with the velocity remaining constant at all times.

In actual systems, fixed flow boundary conditions are usually only dealt with in letdown-

stations where sonic conditions exist at the pressure let down valve, and at the discharge of

positive displacement machines. Fixed pressure boundary conditions are more common,

and exist at the entrances and exits of vessels, and at the entrances and exits of centrifugal

equipment.

In steady state simulations, a fixed flow boundary condition is often used to determine the

steady state pressure drop required to maintain a certain flow rate. Once the pressure drop

Copyright © Dynaflow Research Group. Page 3 of 11

BOSfluids Valve Closure and Transient Pressure Waves Part 1

to support the flow rate is determined, the fixed flow boundary condition is replaced with a

fixed head (pressure) boundary condition to more accurately simulate the open ended

condition at the source, (or discharge).

Figure 4 | Schematic overview of a heat exchanger used to illustrate a typical resonator

This is demonstrated by the following example. The heat exchanger in Figure 4 discharges a

hot liquid through the cutoff valve and into the process tower. If the process experiences

overheating problems the cutoff valve is closed in 0.5 seconds. This is a rapid closure and we

want to investigate the system for a possible water hammer event. The steady state flow

discharge from the heat exchanger is at 150 psi and 0.3 ft3/s. We know the elevation

difference between 5 and 45, but there will also be some friction losses. How can the system

be modeled?

Both the nodes 5 and 45 exist at open ends on the piping system and should be modeled as

fixed pressure boundary conditions. We only know the flow rate and the pressure at one

node however.

In this case, BOSfluids can be used to find exactly the pressure at the opposite node to

support the design flow rate. This is important because the velocity is proportional to the

flow rate and the water hammer pressure rise is proportional to the velocity. The procedure

could be as follows: Run a steady state analysis first with a fixed pressure boundary

condition of 150 psi at node 5, and a fixed flow boundary condition of 0.3 ft 3/s at node 45.

The steady state solution will calculate exactly what pressure will exist at node 45 to support

the 0.3 ft3/s flow. This pressure will then be used in a transient analysis of the system. This

will ensure a proper simulation of the boundary conditions as open ends when a transient

valve closure occurs.

Page 4 of 11 Copyright © Dynaflow Research Group.

BOSfluids Valve Closure and Transient Pressure Waves Part 1

1.3.2. Defining the Boundary Conditions

Now we return back to our model and define the boundary conditions. As discussed,

boundary conditions need to be specified in the system for the program to establish steady

state and transient flow conditions. The boundary conditions are usually specified at the

inlet and outlet of a system and can either be a specified as a pressure or flow rate. At least

one pressure must be defined somewhere in the system. This can be illustrated by referring

to a flow through a straight horizontal pipe. For the steady state case, the flow at both ends

can be entered, but this does not tell anything about the pressure to produce the flow. If the

pressure is specified, the program calculates the flow at the point. If the flow is specified,

then the program calculates the pressure to support it.

In our model, both the inlet and outlet pressures are specified. In the sub-tab BCs & Nodes of

the Piping tab define the following boundary conditions for Node 5 and 40.

Table 2 | Element parameters

Node Boundary Condition Details

5 Fixed Pressure P = 20 psi

40 Fixed Pressure P = 23 psi

1.4. Setting up the Analysis

The type of analysis to simulate is defined in the Analysis sub-tab. The analysis tab should

appear as shown in Figure 5. In order to investigate the pressure wave through the system a

Transient analysis type is used. All analysis options can remain as default.

Figure 5 | Defining the Analysis type

Copyright © Dynaflow Research Group. Page 5 of 11

BOSfluids Valve Closure and Transient Pressure Waves Part 1

Next the fluid type is specified. For the predefined fluid types the fluid properties will

include a temperature dependency. When entering user defined fluid properties, the

program will assume these are constant.

For the current example, a User Defined fluid property is selected. The transported fluid in

the piping system is a gas, so the fluid type is set to Gas, with the properties as shown in

Figure 6.

Figure 6 | Fluid properties

Note that the calculated speed of sound is overridden since the speed of sound is explicitly

specified. If not specified it is calculated from the mean pressure and specific heat ratio.

The “used” speed of sound as found in the results may differ slightly from the specified

speed of sound, since small adjustments might be necessary during the calculation to

establish the correct grid for the characteristic equations. This can be controlled by adjusting

the Wave Speed Tolerance in the Analysis settings screen.

2. RUNNING THE SIMULATION

Select the tab Run and ensure that the main scenario is selected in the Scenario List. Run the

analysis and check the Messages section to make sure that no errors have occurred during the

simulation. Proceed to the Results tab after a successful run is completed.

Page 6 of 11 Copyright © Dynaflow Research Group.

BOSfluids Valve Closure and Transient Pressure Waves Part 1

3. REVIEWING THE RESULTS

3.1. Initial Pressure Results

For the current case, we are interested in the pressure versus time profile at node 18. Using

the 2-D Output section, select Node, enter node 18, select the Main scenario, and select

Pressure in the Data Sets list and click Plot. BOSfluids produces the Time Plot shown in Figure

7.

Figure 7 | Pressure output at node 18 with default settings

Two things can be noticed about this plot:

1) There are not too many points on the curve. We’d probably like a few more data

points.

2) The total simulation time is 0.14 seconds. At a sound speed of 1200 feet per second,

and a total length of 60 feet, a wave travels from one end to the other and back again

in: 2·L/c = 2·60/1200 = 0.1 seconds. BOSfluids produced results for a total simulation

time that is 40% longer than the wave travel time. If the output from this calculation

was to be used in a pipe stress program it is usually desirable to produce at least five

peaks of the lowest resonance. In this case that would mean extending the time to 0.5

seconds.

To improve the results, return to the analysis settings, Scenarios Analysis. The total

Simulation Time is found under Transient settings. If left unspecified BOSfluids will

automatically choose a simulation time based on the transient actions specified in the

problem, the length of the system and lowest occurring frequencies (if specified). In general

the simulation time is sufficient, but the user is encouraged to always check the results if all

Copyright © Dynaflow Research Group. Page 7 of 11

BOSfluids Valve Closure and Transient Pressure Waves Part 1

of the expected transient effects are within the reported time frame. In this case due to the

rapid closure of the valve (time required for the transient actions is very short) and the

limited length of the piping system, the simulation time is relatively short. Increase the

simulation time to 0.2 seconds, see Figure 8.

The time step during the transient analysis is usually very short. To reduce the amount of

output data, BOSfluids only reports at a multiple of this internally used time step. The

options for the output data are found under Output settings. The Output Interval can be

specified and also the start and end time of the output data can be specified to further

reduce the amount of output data when necessary. Specify the output interval to be 1 ms

(=0.001 s), see Figure 8.

Figure 8 | Change the fields in the analysis input screen

Proceed to the Run tab and re-run the simulation.

Page 8 of 11 Copyright © Dynaflow Research Group.

BOSfluids Valve Closure and Transient Pressure Waves Part 1

3.2. Improved Results

In the Results tab we can check how our new settings were used during the simulation. In

the toolbar click “view simulation reports” and open the Transient Warning & Messages

report, see Figure 9.

Figure 9 | The Transient Warnings & Messages simulation report

In this simulation report it can be seen that the internally used calculation time step is 0.4 ms

and the requested output time step is 1 ms. This means every 3 time steps data is reported to

the results file so the effective output time step is 1.2 ms.

When the pressure plot at node 18 is again produced it looks much better, see Figure 10.

Figure 10 | Pressure output at node 18 with the new output settings

Copyright © Dynaflow Research Group. Page 9 of 11

BOSfluids Valve Closure and Transient Pressure Waves Part 1

Several pressure peaks are seen. The first pressure wave increases the pressure, due to the

valve closure. The second (negative) pressure peak is produced by the initial pressure wave

reflecting at the diameter change at node 30. The third pressure peak is from the pressure

wave reflecting at the boundary condition at node 40 and decreases the pressure at node 18.

From Figure 10 it can be seen that the time between the first pass of the pressure wave and

the reflection from the boundary condition is 0.084 - 0.019 = 0.065 seconds. The distance

covered by the pressure wave is twice the distance between node 18 and node 40 (= 84 ft).

With the specified wave speed of 1200 ft/s, the theoretical time to cover 84 ft is 84/1200 = 0.07

seconds, so this agrees with the results from the simulation.

The first three pressure peaks are explained in Figure 11.

Figure 11 | Description of the different type of wave interaction occurring in the pipeline

To compare the results at multiple nodes in the same plot, a node group needs to be created.

Node groups can be made in the BCs & Nodes tab. Select All in the Node Groups list, and

select 18, 22, and 32 while holding the ctrl button in the Nodes list. Click the create group

icon . Click the add group button + and create a new node group called Node 18, 22 and 32.

Without running the simulation return to the Results tab. At the 2-D Output, select Node

Group Node 18, 22 and 32. Select the Main scenario and Pressure from the data set and plot

the results, see Figure 12.

Page 10 of 11 Copyright © Dynaflow Research Group.

BOSfluids Valve Closure and Transient Pressure Waves Part 1

Figure 12 | Comparison of pressure waves in 6” and 10” pipeline at node 18, 22 and 32

The diameter of the pipe has a significant effect on the line pressure, as can be seen by

comparing the pressure wave at nodes 18 and 22 in Figure 12. These nodes are four feet

apart, but have different diameters. Node 18 is in the 6” pipe section and node 22 is in the

10” pipe section. Compare these with node 32 which is in the 6” pipe section just

downstream of the diameter change from 10” to 6”.

The pressure peaks are smaller in the larger diameter system. The pressure waves

originating from the valve closure increase the local pressure, while pressure waves

reflecting information from the fixed pressure boundary condition decrease the local

pressure. Eventually the pressure downstream of the valve will reach a steady state pressure

of 23 psi.

4. CONCLUDING REMARKS

This example demonstrates the interaction of pressure waves reflecting from diameter

changes and open and closed end boundary conditions. It is important the user develops an

intuitive feel for how a physical system behaves, so the results of a simulation can be

compared to what would be physically expected. By adjusting the output interval and

simulation time it can be confirmed that the transient behaviour is properly captured in the

output. It is also wise to make it common practice to check the prescribed values, like the

pressure at the boundary conditions and the valve opening transient.

Copyright © Dynaflow Research Group. Page 11 of 11

You might also like

- Linde E20 25 30 Forklift Trucks Service Manual PDFDocument62 pagesLinde E20 25 30 Forklift Trucks Service Manual PDFmike peters100% (3)

- Lab 1 Measurement of Airflow Lab Manual-1Document10 pagesLab 1 Measurement of Airflow Lab Manual-1Nadeem Rehman100% (1)

- File Handling in C LanguageDocument5 pagesFile Handling in C Languagesudhakar kethanaNo ratings yet

- Caviter PDFDocument12 pagesCaviter PDFstphn_maturinNo ratings yet

- Std. Test Methods For Metal Powders & PM ProductsDocument12 pagesStd. Test Methods For Metal Powders & PM ProductschandiniNo ratings yet

- 4.3-Euler's Equation PDFDocument6 pages4.3-Euler's Equation PDFRonald Cario SeguinNo ratings yet

- Tutorial: Valve Closure and Transient Pressure Wave (Part 2)Document8 pagesTutorial: Valve Closure and Transient Pressure Wave (Part 2)Anonymous I4CTAwUNo ratings yet

- Tutorial: Valve Closure and Transient Pressure Wave (Part 3)Document4 pagesTutorial: Valve Closure and Transient Pressure Wave (Part 3)Anonymous I4CTAwUNo ratings yet

- Water Hammer 1Document11 pagesWater Hammer 1shaffetiNo ratings yet

- REPORTpp 1Document16 pagesREPORTpp 1gajulavamshikrishna02No ratings yet

- Demonstration of Bernoulli's TheoremDocument22 pagesDemonstration of Bernoulli's TheoremEason OngNo ratings yet

- FM 24 ManualDocument18 pagesFM 24 ManualMohd Nor SollehanNo ratings yet

- Answer No 3Document15 pagesAnswer No 3Politik Itu KejamNo ratings yet

- Spool Valves and Hydraulic CircuitsDocument7 pagesSpool Valves and Hydraulic CircuitsDINESHASHOKNo ratings yet

- Vcone To Orifice Plate Noise ComparisonDocument8 pagesVcone To Orifice Plate Noise ComparisonDavid P. MonjureNo ratings yet

- Formal ReportxDocument7 pagesFormal ReportxDarshan ShaarmaNo ratings yet

- A Nodal Approach For Applying Systems Analysis To The Flowing and Artificial Lift Oil or Gas WellDocument2 pagesA Nodal Approach For Applying Systems Analysis To The Flowing and Artificial Lift Oil or Gas WellKaro MárquezNo ratings yet

- Flowmeter Installation EffectsDocument12 pagesFlowmeter Installation EffectsgykataiNo ratings yet

- Line BreakDocument16 pagesLine BreakFlorencia BalseiroNo ratings yet

- Experiment 2 - Flow Measurement: Page 1 of 6Document6 pagesExperiment 2 - Flow Measurement: Page 1 of 6fadyaNo ratings yet

- Surge Pressure Prediction For Running LinersDocument13 pagesSurge Pressure Prediction For Running LinersPegasus Vertex, Inc.100% (1)

- Compressible Flow in A Convergent - Divergent NozzleDocument10 pagesCompressible Flow in A Convergent - Divergent NozzleNeville Lawless75% (8)

- FLOW MEASUREMENT - Course NotesDocument38 pagesFLOW MEASUREMENT - Course Notespawan deepNo ratings yet

- VPT-Kalatjari (Sazeh Engineering Consultants)Document16 pagesVPT-Kalatjari (Sazeh Engineering Consultants)cristianNo ratings yet

- VALTEK Valve Size PDFDocument16 pagesVALTEK Valve Size PDFalbahbahaneeNo ratings yet

- Petroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesDocument14 pagesPetroleum Engineering 325 Petroleum Production System Fluid Friction and Pressure Drop in Pipes, Couplings and ValvesUnknown Gamer467No ratings yet

- Computational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveDocument4 pagesComputational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveMax KocourNo ratings yet

- Calculating Pump HeadDocument8 pagesCalculating Pump HeadPascal SayahNo ratings yet

- Fluid FrictionDocument18 pagesFluid Frictioncakhoa100% (2)

- NO. Title Allocated MARKS (%) MarksDocument22 pagesNO. Title Allocated MARKS (%) MarksjufferyNo ratings yet

- Compressible Flow Across A Varying Area PassageDocument4 pagesCompressible Flow Across A Varying Area PassageGaurav VaibhavNo ratings yet

- Flow - and - Pressure Measurement by ManometerDocument23 pagesFlow - and - Pressure Measurement by ManometerDhanraj Patil100% (1)

- Control Valves Interview QuestionsDocument7 pagesControl Valves Interview QuestionsDerbel WalidNo ratings yet

- Pipe Friction LossDocument6 pagesPipe Friction LossHoongNo ratings yet

- Laminar & Turbulent Flow in PipesDocument5 pagesLaminar & Turbulent Flow in PipesDhananjay KadamNo ratings yet

- Addis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringDocument10 pagesAddis Ababa Science and Technology University: College of Electrical and Mechanical EngineeringEskiasNo ratings yet

- Single PDFDocument16 pagesSingle PDFVignesh WaranNo ratings yet

- Ece135p Exp. 4 Pressure Flow and Level Process ControlDocument8 pagesEce135p Exp. 4 Pressure Flow and Level Process ControlPao CastillonNo ratings yet

- HydraulicsDocument65 pagesHydraulicsMohsin Ehsan100% (1)

- Pump Head CalculationDocument15 pagesPump Head CalculationYashapuja100% (2)

- NEL Best Practice - Impulse Lines For DP FTs PDFDocument8 pagesNEL Best Practice - Impulse Lines For DP FTs PDFnasirmuzaffar0% (1)

- CVS 4150 & 4160 Pressure Controller July 2012 PDFDocument12 pagesCVS 4150 & 4160 Pressure Controller July 2012 PDFOghale B. E. OmuaborNo ratings yet

- Cavitation in Valves 7-22-08Document6 pagesCavitation in Valves 7-22-08Keivn SimiyuNo ratings yet

- Control Valve SizingDocument16 pagesControl Valve SizingmsNo ratings yet

- Interview Questions For Instrument EngineersDocument4 pagesInterview Questions For Instrument EngineerszhangyiliNo ratings yet

- E3 BernoulliDocument16 pagesE3 BernoullikishoreNo ratings yet

- Nozzle Press Lab Online 1Document11 pagesNozzle Press Lab Online 1Ahmad NaeemNo ratings yet

- Advantages of Bladder Surge TanksDocument8 pagesAdvantages of Bladder Surge TanksChrisHogbenNo ratings yet

- Pipe NetworkDocument9 pagesPipe Networkfireorion7No ratings yet

- Pipe Friction ExperimentDocument10 pagesPipe Friction ExperimentCstiosen50% (2)

- Flow Measurement in Closed ConduitDocument65 pagesFlow Measurement in Closed ConduitjohnmayardNo ratings yet

- Pressure Transient in Liquid PipingDocument40 pagesPressure Transient in Liquid PipingMustafa AhsanNo ratings yet

- Spe 8025 MS PDFDocument36 pagesSpe 8025 MS PDFvictory cvsgNo ratings yet

- Controlador 4160Document12 pagesControlador 4160Antonio Castillo GNo ratings yet

- Comsol Report FinalDocument12 pagesComsol Report FinalEsraaNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedFrom EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNo ratings yet

- Texto 1: The Digital AgeDocument6 pagesTexto 1: The Digital AgeMaria Cristina LourenconiNo ratings yet

- WB SpcxbarandrintroDocument4 pagesWB SpcxbarandrintromitiwanaNo ratings yet

- 73 Dit Power StrokeDocument78 pages73 Dit Power StrokeNic Price100% (1)

- Physics 20 21Document23 pagesPhysics 20 21CarolusBorromeusWisnuNo ratings yet

- Angles in Special QuadrilateralsDocument3 pagesAngles in Special QuadrilateralsSanad AhmadNo ratings yet

- Dynamics of Ma-ChineryDocument1 pageDynamics of Ma-Chineryvenkat krishnanNo ratings yet

- Ra7-018 - EpmDocument4 pagesRa7-018 - EpmivanNo ratings yet

- Gradient Descent For Linear Regression - CourseraDocument1 pageGradient Descent For Linear Regression - CourseraVishnuNo ratings yet

- State Space Solutions and Realizations: EE-601: Linear System TheoryDocument29 pagesState Space Solutions and Realizations: EE-601: Linear System TheorysunilsahadevanNo ratings yet

- Adenosine Triphosphate - WikipediaDocument65 pagesAdenosine Triphosphate - WikipediaBashiir NuurNo ratings yet

- THAI COATER Spec PDFDocument4 pagesTHAI COATER Spec PDFConfundo Paa DuroNo ratings yet

- Silicon PNP Transistor in A SOT-89 Plastic Package.: DescriptionsDocument7 pagesSilicon PNP Transistor in A SOT-89 Plastic Package.: DescriptionsAbdallah EstambelliNo ratings yet

- Relay CatalogueDocument38 pagesRelay CatalogueИгорьNo ratings yet

- Three Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055Document1 pageThree Star Auto Spare Parts Trdg. - THB: 04-10-0011 26/08/2021 Top Concrete PO - BOX: 12515 050305999 06 8823055syed ahmedNo ratings yet

- Quad 405 Current Dumping Audio Amplifer DCDDocument3 pagesQuad 405 Current Dumping Audio Amplifer DCDmetinprivat01100% (1)

- Iso 1977 2006 en PDFDocument8 pagesIso 1977 2006 en PDFRainer Ricardo MacielNo ratings yet

- DSAD Regular HODocument6 pagesDSAD Regular HODavidNo ratings yet

- MCQ Engineering Mechanics Part VDocument17 pagesMCQ Engineering Mechanics Part VDominic LanticseNo ratings yet

- Report - Welding and Types of WeldingDocument13 pagesReport - Welding and Types of WeldingИгорь ПетраковNo ratings yet

- Effect of Backward Walking Training On Postural Balance in Children With Hemiparetic Cerebral Palsy A Randomized Controlled StudyDocument12 pagesEffect of Backward Walking Training On Postural Balance in Children With Hemiparetic Cerebral Palsy A Randomized Controlled Studyprawira arthawanNo ratings yet

- Figure of SpeechDocument9 pagesFigure of SpeechReymar PalamiNo ratings yet

- Replace Capacitors On EcuDocument9 pagesReplace Capacitors On EcuHomar Mur100% (3)

- TF100-53B 3900 Series QD CouplingsDocument6 pagesTF100-53B 3900 Series QD CouplingsrrrrNo ratings yet

- 1 PBDocument20 pages1 PBYou IfkirnNo ratings yet

- As400 QuestionsDocument6 pagesAs400 QuestionslakshmiNo ratings yet

- Design and Simulation of InGaAs/GaAsSb Single Quantum Well Structure For Optical Fiber Application: Electronic Band Structure, Carrier Transport, and Optical Gain AnalysisDocument4 pagesDesign and Simulation of InGaAs/GaAsSb Single Quantum Well Structure For Optical Fiber Application: Electronic Band Structure, Carrier Transport, and Optical Gain AnalysisPriyanka KilaniyaNo ratings yet