Professional Documents

Culture Documents

General Construction Notes

General Construction Notes

Uploaded by

chrisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Construction Notes

General Construction Notes

Uploaded by

chrisCopyright:

Available Formats

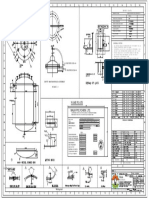

GENERAL CONSTRUCTION NOTES

GENERAL NOTES NOTES ON CONCRETE MIXES & PLACING

1. ALL CONCRETE SHALL DEVELOP A MIN. COMPRESSIVE STRENGTH AT THE END OF TWENTY EIGHT 3. IF SLABS ARE REINFORCED BOTH WAYS BARS ALONG THE SHORTER SPAN SHALL BE PLACED

1.0 STANDARDS AND REFERENCES BELOW THOSE ALONG THE LONG SPAN AT THE CENTER AND OVER THE LONGER SPAN FOR

(28) DAYS W/ CORRESPONDING MAXIMUM SIZE AGGREGATE & SLUMP AS FOLLOWS.

THE FOLLOWING SHALL GOVERN THE DESIGN FABRICATION AND CONSTRUCTION OF THE PROJECT. REINFORCING BARS NEAR THE SUPPORTS. THE SPACING OF THE BARS AT THE COLUMN STRIPS

1.1 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES (N.S.C.P 2015) VOL.1, SEVENTH EDITION. MAX. SIZE OF SHALL NOT BE MORE THAN ONE AND A HALF (1 21 ) SLAB THICKNESS.

LOCATION 28 DAYS STRENGTH AGGREGATE MAX SLUMP

2.0 DESIGN CRITERIA ALL OTHERS, INCLUDING 20mm 100mm 4. TEMPERATURE BARS FOR SLAB SHALL BE GENERALLY PLACED NEAR THE FACE IN TENSION AND

4000 PSI(27.6 MPa)

2.1 LOADINGS SHALL NOT BE LESS THAN 0.0025 X GROSS-SECTIONAL AREA (Ag) OF THE SLAB.

CONF.REINF.

SUSPENDED SLABS JOINT HOOP SPACE @ "2Sh" WHEN

COLUMNS 4000 PSI(27.6 MPa) 20mm 100mm (SEE SCHEDULE BELOW)

A. DEAD LOAD THERE ARE BEAMS HAVING WIDTH OF

BEAMS 4000 PSI(27.6 MPa) 20mm 100mm

D JOINTREINF. D PER SCHEDULE D JOINT REINF. D

CONCRETE 23.56kNm 3 AT LEAST ONE-HALF THE COLUMN

SLABONFILL 2500 PSI(17.5 MPa) 20mm 100mm SCHEDULE OF MINIMUM SLAB REINFORCEMENT WIDTH & DEPTHS NOT LESS THAN

STEEL 76.93kNm 3 THREE QUARTERS OF THE DEEPEST

150mmTHK.CHBWALL 2.73kPa 2. MAINTAIN MINIMUM CONCRETE COVER FOR REINFORCING STEEL AS FOLLOWS. MINIMUMTEMPERATUREBARS BEAM THAT FRAME INTO FOUR

CONF.REINF.

100mmTHK.CHBWALL 2.11kPa SUSPENDED SLABS 20mm 100mm 10mmØ @250mm EACH WAY SIDES OF THE COLUMN. ALL OTHER

B. LIVE LOAD SLAB ON GRADE 40mm 125mm 10mmØ @250mm EACH WAY CONDITIONS USE HOOPS @ "Sh" CENTERS.

Sh

WALLS ABOVE THE GRADE 25mm

ROOF 1.00kPa 150mm 10mmØ @250mm EACH WAY

BEAM STIRRUPS AND COLUMN TIES 40mm

COLUMN TIES AS

CLASSROOMS 1.90kPa 175mm 10mmØ @250mm EACH WAY

WHERE CONCRETE IS EXPOSED TO FOR COL. BAR SPLICES SEE TABLE

TOILETS 1.90kPa 200mm 10mmØ @250mm EACH WAY

CORRIDORS ABOVE, STAIRS 3.80kPa EARTH BUT POURED AGAINST FORMS 50mm OF MIN. LAP SPLICE LENGTH OF

WHERE CONCRETE IS DEPOSITED COLUMN REINFORCEMENT

CORRIDORS ON GROUND 4.80kPa 75mm 5. UNLESS OTHERWISE NOTED IN THE PLANS ALL BEDDED SLABS SHALL BE REINFORCED WITH 10mmØ

DIRECTLY AGAINST EARTH

AT 250mm O.C. EACH WAY TO CENTER OF SLAB AND CONSTRUCTION JOINTS FOR SAME SHALL

CONF.REINF.

C. WIND LOAD

BUILDING CATEGORY = 1 (ESSENTIAL FACILITIES) NOT BE LESS THAN 3.65 METER APART.

Sh

3. CONCRETE SHALL BE DEPOSITED IN ITS FINAL POSITION WITHOUT SEGREGATION. RE-HANDLING

OR PLACING SHALL BE DONE PREFERABLY WITH BUGGIES, BUCKETS OR WHEEL BARROWS, 6. PROVIDE EXTRA REINFORCEMENTS FOR CORNER SLAB (TWO ADJACENT DISCONTINUES EDGES) NOTE:

OPTION 1

NO CHUTES WILL BE ALLOWED EXCEPT TO TRANSFER CONCRETE FROM HOPPERS TO BUIGGIES, AS SHOWN BELOW. ALL CONCRETE REINF. DETAIL SHOULD

EXPOSURE CAT. D (FLAT UNOBSTRUCTED AREAS AND/OR NEAR BODIES OF WATER) WHEEL BARROWS OR BUCKETS IN WHICH CASE THEY SHALL NOT EXCEED SIX (6) METERS BE DONE IN ACCORDANCE WITH ACI

7. CONCRETE SLAB REINFORCEMENT SHALL BE PROPERLY SUPPORTED WITH 10mm STEEL CHAIR DETAILING MANUAL (LATEST EDITION)

WIND VELOCITY V = 340 KPH

CONF.REINF.

IN AGGREGATE LENGTH. OR APPROVED EQUIVALENT SPACED AT 1.0 METER ON CENTER BOTH WAYS.

P = qh (GCpf) - (GCpi) (DESIGN WIND PRESSURE)

4. NO DEPOSITING OF CONCRETE SHALL BE ALLOWED WITHOUT THE USE OF VIBRATORS UNLESS

WHERE: qh = VELOCITY PRESSURE (kPa)

AUTHORIZED IN WRITING BY DESIGNER AND ONLY FOR UNUSUAL CONDITIONS WHERE VIBRATIONS

GCpf = EXTERNAL PRESSURE COFFECIENT Ø12x1000 LONG AT

ARE EXTREMELY DIFFICULT TO ACCOMPLISH. MID-DEPTH OF SLAB

GCpf = INTERNAL PRESSURE COFFECIENT

5. ALL ANCHOR BOLTS, DOWELS, AND OTHER INSERTS SHALL BE PROPERLY POSITIONED & SECURED TYPICALCOLUMNELEV.SHOWING

D. SEISMIC LOAD IN PLACE PRIOR TO PLACING OF CONCRETE. DOWN INTO EDGE BEAM. EXTENDED AT EACH CORNER DOWELSANDTIESSPACING

4-Ø 12@1800 LONG TOP BARS BEND 1-Ø12 TOP &

Cvl W (DESIGN BASE SHEAR) 6. ALL CONCRETE SHALL BE KEPT MOST FOR A MINIMUM OF SEVEN CONSECUTIVE DAYS IMMEDIATELY BARS MIN. OF1,200 (4'-0") INTO BARS. BOTT.BARS

V= AFTER POURING BY THE USE OF WET BURLAP, FOG SPRAYING, CURING COMPOUNDS OR OTHER

RT

APPROVED METHODS. 4-Ø12 BOTT. BARS

Vmax= 2.50CaI W

400

Vmin= 0.11CalW

RT 7. STRIPPING OF FORMS AND SHORES: LAP SPLICE LENGTH:

Vmin= 0.80ZNvI W (ZONE4) FOUNDATION 24 HOURS AT ANY LEVEL NO MORE THAN

R

0

ALTERNATE BARS SHOULD BE

60

SUSPENDED SLAB EXCEPT WHEN 8 DAYS 0 SLAB 38mm

WHERE: W = TOTAL DEAD LOAD 60 OPENING CLEAR SPLICED. MIN .DISTANCE BET.

ADDITIONAL LOADS ARE IMPOSED

T = NATURAL PERIOD = Ct(h) WALLS 21 DAYS TWO ADJACENT BARS SPLICES

SHALL BE 600mm.

WHERE: C = NUMERICAL COEFFICIENT

400

BEAMS 14 DAYS

CONF.REINF.TIESLAT.TIES H(CLEARHEIGHTOFCOL.)

h = BUILDING HEIGHT 21 DAYS L

COLUMNS

I = IMPORTANCE FACTOR = 1.50

WITHIN CENTER

IN TWO WAY SLAB EXTEND

HALF OF "H"

R= NUMERICAL FACTOR = 8.50 8. THE CONTRACTOR SHALL SUBMITT HIS SCHEDULE OF POURING AND THE LOCATION OF THE BARS UP TO BEAM SUPPORT

60

CONSTRUCTION JOINTS TO THE STRUCTURAL ENGINEER AT LEAST (4) DAYS PRIOR TO THE

0

SEISMIC COEFFICIENT Cv = 0.44Nv 0.25L

POURING FOR APPROVAL. OMIT TRIMMER BARS WHERE

Ca = 0.64Nv OPENING IS FRAMED BY BEAM TOP BARS @ SUPPORT (CONT.)

NEAR SOURCE FACTOR (5km) Nv = 1.6 9. THE CONTRACTOR SHALL FURNISH AND MAINTAIN ADEQUATE FORMS AND SHORING UNTIL THE TYPICAL CORNER SLAB DETAIL REQ'D. BOTT. BARS @ SUPPORT

Na = 1.2 CONCRETE MEMBERS HAVE ATTAINED THEIR WORKING CONDITION AND STRENGTH. TYPICAL SLAB

JT. REINF.

Z = SEISMIC ZONE = 0.40 (ZONE 4) OPENING DET.

S = SOIL TYPE = D

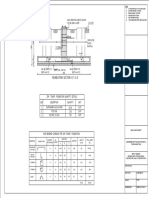

NOTES ON FOOTINGS

2.2 DESIGN STRESSES 1. FOOTINGS ARE DESIGNED FOR AN ALLOWANCE SOIL BEARING PRESSURE OF 96 KPa(2000 psf).

A. CONCRETE COMPRESSIVE STRENGTH @ 28 DAYS: CONTRACTOR SHALL REPORT TO THE ENGINEER, IN WRITING, THE ACTUAL SOIL CONDITIONS NOTES ON COLUMNS 0.165L SPLICE BOTTOM BARS

AT MIDSPAN

a. FOOTINGS, COLUMNS, BEAMS AND SLABS f'c = 27.6 MPa(4,000 psi) UNCOVERED AND CONFIRM ACTUAL BEARING CAPACITY OF SOIL BEFORE DEPOSITING CONCRETE. 1. PROVIDE EXTRA SETS OF TIES AT 100 O.C. FOR TIED COLUMN REINFORCEMENT ABOVE 0.22L EXTRA TOP BARS

b. SLAB ON FILL f'c = 17.5 MPa(2,500 psi) 2. FOOTING SHALL REST AT LEAST 1500mm BELOW NATURAL GRADE LINE UNLESS OTHERWISE AND BELOW BEAM-COLUMN CONNECTIONS FOR A DISTANCE FROM FACE OF CONNECTION @ SUPPORT

C. SLAB f'c = 27.6 MPa(4,000 psi) INDICATED IN PLANS. NO FOOTING SHALL REST ON FILL EQUAL TO GREATER OF THE OVERALL THICKNESS OF COLUMN, 16 TIMES THE CLEAR HEIGHT OF

3. MINIMUM CONCRETE PROTECTION FOR REINFORCEMENT SHALL BE 75mm CLEAR FOR CONCRETE COLUMN OR 450mm.

B. REINFORCING STEEL BARS

a. FOR BARS 16mm AND GREATER (INTERMEDIATE GRADE DEFORMED BAR) fy = 414 MPa(60,000 psi) DEPOSITED THE GROUND AND 50mm FOR CONCRETE DEPOSITED AGAINST A FORM WORK.

b. FOR BARS LESS THAN 16mm (STRUCTURAL GRADE DEFORMED BAR) fy = 275 MPa(40,000 psi) 4. IN CASES WHERE THE SOIL CONDITION IS SUCH THAT THE MINIMUM ALLOWABLE SOIL PRESSURE

2. COLUMN TIES SHALL BE PROTECTED EVERY WHERE BY A COVERING OF CONCRETE CAST

MONOLITHICALLY WITH THE CORE WITH A MINIMUM THICKNESS OF 40mm AND NOT LESS

TYP. DETAIL OF COL. LAP SPLICE

OF 96 KPa(2000 psf) CANNOT BE ATTAINED AT A PRACTICAL DEPTHS THE USE OF MICROPILES,

C. STRUCTURAL STEEL ASTM-A36 BORED PILES, OR DRIVEN PILES MAY BE ADOPTED IN LIEU OF STANDARD ISOLATED FOOTINGS. THAN 40 TIMES THE MAXIMUM SIZE OF COARSE AGGREGATE IN MILLIMETERS. & EXT. GIRDER TO COL. CONNECT.

FOR TRUSSES, BRACING ,& STRUTS fy = 248 MPa(36,000 psi) 3. WHERE COLUMNS CHANGE IN SIZE, VERTICAL REINFORCEMENT SHALL BE OFF SET AT A

D. PURLINS SLOPE MONOLITHICALLY WITH THE CORE WITH MINIMUM THICKNESS OF 40mm AND

COLD FORMED LIGHT fy = 248 MPa(36,000 psi) NOTES ON REINFORCEMENT

E. MASONRY UNIT (CHB) NOT LESS THAN 40 TIMES THE MAXIMUM SIZE COARSE AGGREGATE IN MILLIMETERS

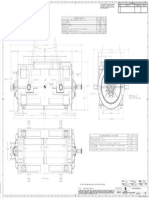

1. UNLESS OTHERWISE NOTED IN PLANS, THE YIELD STRENGTH OF REINFORCING BARS SHALL BE: 4. UNLESS OTHERWISE INDICATED IN THE PLANS, LAP SPLICES FOR VERTICAL COLUMN NOTES ON BEAMS AND GIRDERS

NON-LOADING BEARING CHB WALLS fm' = 3.45 MPa(500 psi) fy = 414 MPa(60,000 psi)

A. FOOTINGS, FOOTING BEAMS AND GIRDERS REINFORCEMENT SHALL BE MADE WITHIN THE CENTER HALF OF COLUMN HEIGHT, AND

F. WELDS E - 60XX ELECTRODE fy = 414 MPa(60,000 psi) 1. UNLESS, OTHERWISE NOTED IN PLANS, CAMBER ALL BEAMS AND GIRDER AT

a. Ft = 96.60MPa(14,000 psi) B. COLUMNS AND SHEAR WALLS THE SPLICE LENGTH SHALL BE LESS THAN 40 BAR DIAMETERS. WELDING OR APPROVED

G. STRUCTURAL BOLTS ASTM-A307 fy = 414 MPa(60,000 psi) LEAST 6mmØ FOR EVERY 4.50m OF SPAN, EXCEPT CANTILEVERS FOR WHICH

b. Fv=69.00 MPa(10,000 psi) C. BEAMS AND GIRDER MECHANICAL DEVICES MAYBE USED PROVIDED THAT NOT MORE THAN ALTERNATE BARS

3.0 IN THE INTERPRETATION OF THE DRAWING, INDICATED DIMENSIONS SHALL GOVERN. D. NON-LOAD BEARING WALL PARTITIONS, BEDDED SLABS, FLOOR & ROOF SLABS, THE CAMBER SHALL BE AS NOTED IN PLANS OR AS ORDERED BY THE ENGINEER

PARAPETS, CATCH BASIN, SIDEWALK fy = 275 MPa(40,000 psi) ARE WELDED OR MECHANICALLY SPLICED AT ANY LEVEL AND THE VERTICAL DISTANCES

DISTANCES AND SIZES SHALL NOT BE SCALED FOR CONSTRUCTION PURPOSES BETWEEN THESE WELDS OR SPLICES OF ADJACENT BARS IS NOT LESS THAN 600mm. BUT IN NO CASE LESS THAN 20mm FOR EVERY 3.0M OF FREE SPAN.

2. ALL REINFORCING BARS SIZE 10mm OR LARGER SHALL BE DEFORMED IN ACCORDANCE WITH THE ASTM A-706

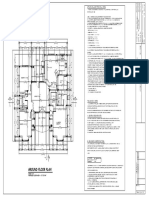

4.0 IN REFERENCES TO OTHER DRAWINGS, SEE ARCHITECTURAL DRAWINGS FOR DEPRESSIONS IN FLOOR 2. TYPICAL BARS BENDING AND CUTTING DETAILS FOR BEAMS SHALL BE AS

BARS SMALLER THAN 10mm MAY BE PLAIN.

SLABS, OPENINGS IN THE WALLS AND SLABS,INTERIOR PARTITIONS, LOCATIONS OF DRAINS ETC. 3. SPLICES SHALL BE SECURELY WIRED TOGETHER & SHALL LAP OR EXTEND IN ACCORDANCE w/ TABLE B SHOWN IN FIG.B-1

5.0 IN CASE OF DISCREPANCIES AS TO THE LAYOUT, DIMENSIONS AND ELEVATIONS BETWEEN THE (TABLE OF LAP SPLICE & ANCHORAGE LENGTH) UNLESS OTHERWISE SHOWN ON DRAWINGS, SPLICES SHALL BE H

STRUCTURAL PLANS AND ARCHITECTURAL DRAWINGS, THE CONTRACTORS SHALL NOTIFY BOTH THE STAGGERED WHEN EVER POSSIBLE.

STRUCTURAL ENGINEER AND ARCHITECT. CROSS-TIE

NOTES ON CONCRETE SLABS

350mm.MAX.

6.0 ALL CONCRETE WORKS AND CONCRETE REINFORCEMENTS SHALL BE DONE IN ACCORDANCE WITH THE L1 L2

ACI.318-14M BUILDING CODE REQUIREMENT AND ALL STRUCTURAL STEEL WORKS ACCORDING WITH THE 1. ALL SLAB REINFORCEMENTS SHALL BE 20mm CLEAR MINIMUM FROM BOTTOM AND FROM THE TOP OF SLAB. L1 3

1

L13 L23 L23

AISC-05 IN SO FAR AS THEY DO NOT CONFLICT WITH THE LOCAL BUILDING CODE REQUIREMENT. 2. UNLESS OTHERWISE SHOWN, REINFORCEMENT IN CONTINUOUS ELEVATED SLAB SHALL BE CUT AS FOLLOWS:

10

H

dm

7.0 ACI REFERS TO AMERICAN CONCRETE INSTITUTE, AISC REFERS TO AMERICAN INSTITUTE OF STEEL

in.

CONSTRUCTION AND ASTM REFERS TO AMERICAN SOCIETY FOR TESTING MATERIALS.

BENTBAR

8.0 CONSTURCTION NOTES AND TYPICAL DETAILS APPLY TO ALL DRAWINGS UNLESS OTHERWISE SHOWN OR

NOTED. MODIFY TYPICAL DETAILS AS DIRECTED TO MEET SPECIAL CONDITIONS. L1 L2 1

L1 5 L15 L25 L25

L14 L14 L24 TOPBARS

9.0 SHOP DRAWING WITH ERECTION AND PLACING DIAGRAMS OF ALL STRUCTURAL STEELS, MISCELLANEOUS TOPBAR 2 Ø 12mm SIDE BARS WEBBARS

IRON, PRE-CAST CONCRETE, ETC. SHALL BE SUBMITTED FOR ENGINEERS APPROVAL BEFORE FABRICATION. BOTTOMBARS

10. CONTRACTOR SHAL LNOTE AND PROVIDE ALL MISCELLANEOUS CURBS,SILLS, STOOLS EQUIPMENT AND

MECHANICAL BASES THAT ARE REQUIRED BYTHEARCHITECTURAL, ELECTRICAL AND MECHANICAL DRAWINGS.

FIGUREB-1

11. ALL RESULTS OF THE MATERIAL TESTING FOR CONCRETE, REINFORCING BARS & STRUCTURAL STEEL MUST

BOTTOMBAR

BE NOTED & APPROVED BY THE MATERIALS ENGINEER OR STRUCTURAL DESIGNER.

NO. DATE REVISIONS/COMMENTS SHEET CONTENTS : SHEET NO. :

JOB NO. :

CHRISTIAN G. GODINO PROPOSED 2 STOREY RESIDENTIAL GENERAL CONSTRUCTION NOTES

DATE : -

STRCUTURAL ANALYSIS AND CONSTRUCTION

CIVIL ENGINEER WITH DECK RESIDENCE MR. AND MRS. CARLITO MENESES SCALE :

BORONGAN CITY, EASTERN SAMAR CADD BY :

MOBILE #:09263791625

EMAIL: chrisgodino@yahoo.com 0117452 9186683 LOCATION :

BRGY. 02, POBLACION, MAYDOLONG, EASTERN SAMAR

PROJECT OWNER CHECKED BY : S-1

MAY 2019 BORONGAN CITY DATE :

You might also like

- Structural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1Document1 pageStructural Plan 3 Storey Building Balamban Cebu (2) Model - PDF 1roger100% (2)

- Test Exer 6Document3 pagesTest Exer 6Uratile PatriciaNo ratings yet

- Clinical Establishment ActDocument44 pagesClinical Establishment ActNeelesh Bhandari100% (1)

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- Camel Power (Done Excel, Pending CC)Document40 pagesCamel Power (Done Excel, Pending CC)CK AngNo ratings yet

- Iso 10003 - 2018 (Eng)Document44 pagesIso 10003 - 2018 (Eng)mblancol75% (4)

- Online Voting System SRSDocument7 pagesOnline Voting System SRSSanthosh KumarNo ratings yet

- Structural 2storeyDocument11 pagesStructural 2storeyMark James Mateo100% (1)

- StructuralDocument15 pagesStructuralMark James MateoNo ratings yet

- Plan 20ld0130 - Part 3Document11 pagesPlan 20ld0130 - Part 3MarjanNo ratings yet

- 23kk0043 Set BDocument30 pages23kk0043 Set BcemirasmpcNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- Revised Structural PlansDocument46 pagesRevised Structural Plansangelandlucifergabriel009No ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesCarlo M. FloresNo ratings yet

- Genral NotesDocument1 pageGenral NotesArjay AletaNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesLon OdiNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- General Construction Notes: FC Engineering ServicesDocument1 pageGeneral Construction Notes: FC Engineering ServicesMac KYNo ratings yet

- General Notes BridgeDocument6 pagesGeneral Notes BridgeEnglish for KidsNo ratings yet

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- General Notes:: Fillet Weld TableDocument1 pageGeneral Notes:: Fillet Weld Tablefrancis sebastian lagamayoNo ratings yet

- Ska 51 06 - R0 - Second Floor Slab Beam Details - Siolim Villa - 2023.12.18Document1 pageSka 51 06 - R0 - Second Floor Slab Beam Details - Siolim Villa - 2023.12.18TrishanjitNo ratings yet

- DPWH Building PlansDocument5 pagesDPWH Building PlansHelp DACNo ratings yet

- Structurals 2Document1 pageStructurals 2seulipark2629No ratings yet

- QAHD Office Building 30 M Structural Plans-S100.0Document1 pageQAHD Office Building 30 M Structural Plans-S100.0Adrian PachecoNo ratings yet

- GA Stang Fire MonitorDocument1 pageGA Stang Fire MonitorDAN DANINo ratings yet

- Ce - 07Document1 pageCe - 07Arnulfo Jose Pi DiNo ratings yet

- General Construction Notes: Typical Connection Detail of Masonry WallDocument1 pageGeneral Construction Notes: Typical Connection Detail of Masonry WallMItchNo ratings yet

- General Notes: Beginning of Project (End of Diaphragm) End of Project (End of Diaphragm)Document8 pagesGeneral Notes: Beginning of Project (End of Diaphragm) End of Project (End of Diaphragm)SannyBombeoJomocNo ratings yet

- Potable Water OHT Near GLSR - Zone 4Document1 pagePotable Water OHT Near GLSR - Zone 4Mohit AgarwalNo ratings yet

- Architecture: Construction Notes Design and Management ServicesDocument1 pageArchitecture: Construction Notes Design and Management ServicesChristian ReyesNo ratings yet

- Main Fire Station-1Document1 pageMain Fire Station-1Jhon CenaNo ratings yet

- General Notes-1: Table 1: Lap Splices For RebarsDocument1 pageGeneral Notes-1: Table 1: Lap Splices For RebarsTanvir IslamNo ratings yet

- Structural Notes: Typ. CHB Partition On Suspended Slab 7Document1 pageStructural Notes: Typ. CHB Partition On Suspended Slab 7Joshua VacaroNo ratings yet

- Civil / Structural Construction Notes: Nearest Faultline Site Location FromDocument1 pageCivil / Structural Construction Notes: Nearest Faultline Site Location FromVince Bagsit PolicarpioNo ratings yet

- General Notes:: Typical Section of R.C.C. Storm Water DrainDocument2 pagesGeneral Notes:: Typical Section of R.C.C. Storm Water Drainbijnor officeNo ratings yet

- General NotesDocument1 pageGeneral NotesDesign explorer olomizanaNo ratings yet

- 800 MMDocument1 page800 MMPRAMODH CHELLURUNo ratings yet

- 3616A, B ModelDocument1 page3616A, B ModelVarun MalhotraNo ratings yet

- 25M Tower FDN - 2Document1 page25M Tower FDN - 2Hikmat B. Ayer - हिक्मत ब. ऐरNo ratings yet

- Transportation Idaho Department: NotesDocument1 pageTransportation Idaho Department: NotesBikash SigdelNo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- BoDPP Transformer Pad Foundation PlanDocument1 pageBoDPP Transformer Pad Foundation PlanAnonymous YNAVSfXNo ratings yet

- Drawing3 Layout1Document1 pageDrawing3 Layout1mohamedsshNo ratings yet

- Max Pulling TensionsDocument1 pageMax Pulling TensionssatheeskrsnaNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Anchor Bolt Plan: A B C D E FDocument1 pageAnchor Bolt Plan: A B C D E FElancheliyanNo ratings yet

- Typical Application For Painting Centre Line in City Area (Less Than 24 HRS)Document2 pagesTypical Application For Painting Centre Line in City Area (Less Than 24 HRS)Ummi SurayaNo ratings yet

- Gen NotesDocument1 pageGen NotesGian OrillosaNo ratings yet

- Proposed Three Bedroom-P2Document1 pageProposed Three Bedroom-P2MatthewNo ratings yet

- ORISSA SCHOOL (STR-ARCH) - Model - pdf73Document1 pageORISSA SCHOOL (STR-ARCH) - Model - pdf73NISHIKANTA MONDALNo ratings yet

- General Notes Symbol List Abbreviations: Reference Sheet - SprinklerDocument64 pagesGeneral Notes Symbol List Abbreviations: Reference Sheet - SprinklerAnonymous qOBFvINo ratings yet

- Basis of DesignDocument1 pageBasis of DesignRajaImranNo ratings yet

- R A S L I M S-01 Proposed 3-Storey Mix-Used Commercial BuildingDocument1 pageR A S L I M S-01 Proposed 3-Storey Mix-Used Commercial BuildingShariah MelonNo ratings yet

- Standard Drawings PDFDocument42 pagesStandard Drawings PDFOpendi CharlesNo ratings yet

- General Notes Concrete Works and Reinforcing Bars: Project TitleDocument5 pagesGeneral Notes Concrete Works and Reinforcing Bars: Project TitleCamille Ariel100% (1)

- A LiftDocument1 pageA LiftAPS DESIGN INFRA PVT.LTD.No ratings yet

- Typical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsDocument1 pageTypical Beam Details Typical Footing Details: Schedule of Footings Schedule of BeamsRenel GarciaNo ratings yet

- QP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficDocument1 pageQP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficnawajhaNo ratings yet

- Foundation Plan 2Nd Floor Framing Plan: B C D A B C D ADocument1 pageFoundation Plan 2Nd Floor Framing Plan: B C D A B C D AMark Ruby OpawonNo ratings yet

- Plinth Slab LVL (Rev.4) 10-08-2017 Sh.2Document1 pagePlinth Slab LVL (Rev.4) 10-08-2017 Sh.2Monali VarpeNo ratings yet

- COMP WALL WITH RETAINING WALL ModelDocument1 pageCOMP WALL WITH RETAINING WALL ModelAmarjit KulkarniNo ratings yet

- 35dd64a7e13ce8dd0f9b964059610d53 (2)Document1 page35dd64a7e13ce8dd0f9b964059610d53 (2)chrisNo ratings yet

- 1645085909875702Document1 page1645085909875702chrisNo ratings yet

- 2005z 0116 Steepslope MassgrdDocument9 pages2005z 0116 Steepslope MassgrdchrisNo ratings yet

- Balmoral Survey1Document1 pageBalmoral Survey1chrisNo ratings yet

- Overall Site Plan 10-11-22Document1 pageOverall Site Plan 10-11-22chrisNo ratings yet

- 400 - 53 - 016 Alta R1Document2 pages400 - 53 - 016 Alta R1chrisNo ratings yet

- Apr 2551paul Ave v7 RevisionDocument1 pageApr 2551paul Ave v7 RevisionchrisNo ratings yet

- 3100 Drexel Drive - Floor PlansDocument1 page3100 Drexel Drive - Floor PlanschrisNo ratings yet

- Swiftwater - Lane-Drainage Plan1Document1 pageSwiftwater - Lane-Drainage Plan1chrisNo ratings yet

- CA Boonville 20120224 TM GeoDocument1 pageCA Boonville 20120224 TM GeochrisNo ratings yet

- B C D E: Roof PlanDocument1 pageB C D E: Roof PlanchrisNo ratings yet

- Roof Pitch-Shutters-Stack Windows ExamplesDocument2 pagesRoof Pitch-Shutters-Stack Windows ExampleschrisNo ratings yet

- Scan Jun 15, 2022Document1 pageScan Jun 15, 2022chrisNo ratings yet

- Velocity Pressure Calculation - Perimeter WallDocument3 pagesVelocity Pressure Calculation - Perimeter WallchrisNo ratings yet

- 2 PDFDocument1 page2 PDFchrisNo ratings yet

- 4 PDFDocument1 page4 PDFchrisNo ratings yet

- 4 PDFDocument1 page4 PDFchrisNo ratings yet

- Down Spout Computation PDFDocument1 pageDown Spout Computation PDFchrisNo ratings yet

- Ground Floor Plan: A B C D F EDocument1 pageGround Floor Plan: A B C D F EchrisNo ratings yet

- 8 PDFDocument1 page8 PDFchrisNo ratings yet

- Tagoloan Bridge Water Level (M)Document4 pagesTagoloan Bridge Water Level (M)chrisNo ratings yet

- Step 1 Compute Capacity of Selected Gutter Size Using "Manning's Equation"Document1 pageStep 1 Compute Capacity of Selected Gutter Size Using "Manning's Equation"chrisNo ratings yet

- Foundation Plan: A B C D F EDocument1 pageFoundation Plan: A B C D F EchrisNo ratings yet

- Hydraulic Simulation Q and RainfallDocument23 pagesHydraulic Simulation Q and RainfallchrisNo ratings yet

- Basics of News WritingDocument31 pagesBasics of News WritingAngela Mae VillalunaNo ratings yet

- Eval Manual V5.1Document14 pagesEval Manual V5.1M Ahmed LatifNo ratings yet

- Chapter Add On 1Document18 pagesChapter Add On 1Escada BebeyNo ratings yet

- Composing A Melody PDFDocument29 pagesComposing A Melody PDFfrank orozco100% (1)

- Br2e Adv Readingfile03Document2 pagesBr2e Adv Readingfile03PressCall AcademyNo ratings yet

- The State of Structural Engineering in The US - IDEA StatiCaDocument6 pagesThe State of Structural Engineering in The US - IDEA StatiCaluisNo ratings yet

- Solucionario Ingenieria en Control Moderna OGATADocument240 pagesSolucionario Ingenieria en Control Moderna OGATAanandpj444471% (7)

- The Current WarDocument1 pageThe Current WarkanuvietNo ratings yet

- ICC 70 AdministratorsGuide en PDFDocument92 pagesICC 70 AdministratorsGuide en PDFMarie ManuelNo ratings yet

- Name of Customer - Name of Project - TE-112045 - WFC - Print - OutDocument1 pageName of Customer - Name of Project - TE-112045 - WFC - Print - OutJavier EspinosaNo ratings yet

- Fundamentals of Thermal Sensors: Thu HuynhDocument39 pagesFundamentals of Thermal Sensors: Thu HuynhsamcaridoNo ratings yet

- Dwnload Full Intermediate Accounting 8th Edition Spiceland Solutions Manual PDFDocument12 pagesDwnload Full Intermediate Accounting 8th Edition Spiceland Solutions Manual PDFsorbite.bebloodu2hh0j100% (15)

- Using Emtp RVDocument263 pagesUsing Emtp RVshotorbari100% (1)

- CBLM Smaw 1Document24 pagesCBLM Smaw 1Charis AbadNo ratings yet

- Establishing An FFSDocument2 pagesEstablishing An FFSAndrew George ADEMNo ratings yet

- Bridget Wisnewski ResumeDocument2 pagesBridget Wisnewski Resumeapi-425692010No ratings yet

- Philippine Notices To MarinersDocument42 pagesPhilippine Notices To MarinersTaneo Prince CalebNo ratings yet

- How To Calculate Quantity of Bricks in WallDocument5 pagesHow To Calculate Quantity of Bricks in Wallواثق كريم نعيمNo ratings yet

- BC 640Document5 pagesBC 640Miguel AngelNo ratings yet

- R1600H Sistema ImplementosDocument31 pagesR1600H Sistema ImplementosLuis Angel Pablo Juan de Dios100% (1)

- CT CalculationDocument2 pagesCT CalculationTheresia AndinaNo ratings yet

- ThinkPad X1 Carbon 6th Gen Datasheet enDocument3 pagesThinkPad X1 Carbon 6th Gen Datasheet enAnushree SalviNo ratings yet

- ANH 8D OnlineDocument6 pagesANH 8D OnlineisserHsl 'v'No ratings yet

- AI in Foreign Language Learning and Teaching - Theory and PracticeDocument160 pagesAI in Foreign Language Learning and Teaching - Theory and PracticeFabi Rodríguez CházaroNo ratings yet

- How To Read Wiring DiagramsDocument24 pagesHow To Read Wiring Diagramsagoudimies100% (7)