Professional Documents

Culture Documents

Shafqat Farooq

Shafqat Farooq

Uploaded by

shafqat12345678Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shafqat Farooq

Shafqat Farooq

Uploaded by

shafqat12345678Copyright:

Available Formats

SHAFQAT FAROOQ, EIT

Cell No: 713-344-7664, Email: shafqat.farooq91@gmail.com, www.linkedin.com/in/shafqat-381

_____________________________________________________________________________________________________

SUMMARY: Mechanical Engineer with 3+ years of experience in Engineering Design, Agile Methodology, BIM (MicroStation),

Team Center, Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), GD&T, ASME Y14.5, DFMA, Product

Verification and Validation, Data Analytics, ASME Codes, and P&ID. Team leader and Changing Agent seeking for a full-time

position where I can utilize my technical and managerial skills.

_____________________________________________________________________________________________________

EDUCATION

M.Sc. Mechanical Engineering Dec-2018

University of Houston- Main Campus, CGPA 4.0

Publications: “Large-scale structures in high Reynolds number rotating Waleffe flow” – Journal of Fluid Mechanics

Relevant Key Courses: Data Analysis, Design & Prototyping, Modelling & Optimization, CFD, Computational Mechanics

B.Sc. Mechanical Engineering July-2014

National University of Sciences and Technology (NUST), CGPA 3.7

Relevant Key Courses: Numerical Analysis, Mechanics of Materials, Design of Machine, Manufacturing Processes, Control

Systems, Instrumentation & Measurement, Computer Aided Design, Planning Engineering/Project Management

CERTIFICATION

Texas Board of Professional Engineers Mar-2019

Engineer in Training (FE Mechanical), ID # 66042

AUTODESK Feb-2019

CAD for Engineers, ID # 1029000-108871

Management and Strategy Institute Nov-2018

Six Sigma Green Belt, ID # 17754952

__________________________________________________________________________________________________

TECHNICAL SKILLS CNC, G & M Codes, Injection Molding, ASHRAE, REVIT, SolidWorks, Pro-E/Creo, AutoCAD, MATLAB, ANSYS

(Fluent), COMSOLE, Python, Linux, Microsoft Office (Word, Excel, PowerPoint)

_____________________________________________________________________________________________________

WORK EXPERIENCE

Gardner Denver- Oberdorfer Pumps

Design Engineer- LTTS May 2019 to present

Designing 2D and 3D models of Helical Gear, Flexible Impellers, and Centrifugal Pumps using AutoDesk Inventor and

AutoCAD as per ASME 14.5-2009 (GD&T) and Gardner Denver Standards

Managing 3D models, drawings, and assemblies in AutoDesk Vault and Team Center

Creating Material Specifications and Purchase Specifications for Vendors and Suppliers

Utilizing SAP-ERP for managing documents and drawings changes through ECN Process and SAP Materials Management

GRIND, LLC, USA Mar 2019 to Apr 2019

Mechanical Design\Manufacturing Engineer

Designing 2D and 3D modelling of Electro-Mechanical assemblies, Enclosures and Sheet Metal components using

SolidWorks and Inventor for GRIND’s pneumatic operated automatic machine technology

Coordinating New Product Introduction (NPI) programs for enhancing GRIND’s technology products experience

Manufacturing parts and components using Welding, Injection Molding, CNC Plasma Cutter and 3D Printers

Performing DFMA and VAVE Principles for improving manufacturing processes and material cost

Developing alternative prototype concepts, testing, verifying, and validating product functional performance

Applying DFMEA for root cause problems in the product design and suggesting improvements

Developing Corrective Action Preventive Action (CAPA) for eliminating non-conformities in product design

Managing Bills of materials (BOMS) for product manufacturing using Team Center

University of Houston, USA Feb 2018 to Feb 2019

Research Assistant

Performed CFD simulations in ANSYS to understand fluid phenomenon in wall bounded system

Utilized Python and Linux for data processing and data visualizations of turbulent velocity and pressure fields

Bentley Systems June 2014 to July 2017

Mechanical Design\Quality Engineer

Designed and developed mechanical systems and drawings using Product Lifecycle Management (PLM) system (Team

Center & Bentley ProjectWise), Bentley Modeling Software, AutoCAD, AUTODESK Inventor and SolidWorks

Utilized Agile Product Development for iterative product delivery and collaborative decision making

Conducted design reviews related to DFM&A, GD&T, Statistical Tolerance Stack Up Analysis and Material Selection

Performed Root Cause Analysis and DFMEA to reduce high stress points in design layout

Designed Piping & Instrumentation diagrams (P&ID’S) using Bentley OpenPlant PID and performed Finite Element

Analysis and Stress Analysis as per ASME Codes (B31.1, B31.3, B31.4) using AutoPIPE

Designed and developed heat exchanger, pressure vessels and performed mechanical stress and thermal-fluid analysis

as per TEMA and ASME Section VIII standards in AutoPIPE Vessel

Attock Oil Refinery Limited June 2013 to July 2013

Maintenance Engineer (Intern)

Assisted the overhauling with hands on experience on Heavy Duty V12 Diesel Engines for power production

Coordinated maintenance activities of Centrifugal Pumps, Heat Exchangers and Screw Type Pumps

Assisted maintenance team in Major Shutdowns of Distillation plants (How Baker Unit-II & Heavy Crude Unit)

British American Tobacco July 2012 to Aug 2012

Manufacturing\Quality Engineer (Intern)

Monitored and maintained cutting and packaging machinery, and assembly lines in Manufacturing Department

Directed a team of 5 members for verification of engineering items in inventory store using SAP software

Improved Manufacturing Quality Index by 2 % by training machine operators with Statistical Process Control and CMM

_____________________________________________________________________________________________________

INDUSTRIAL & ACADEMIC PROJECTS

Research and Development of Piping Metallic Joints

Led a team of six people in developing flexibility model for Metallics joints used widely in Petrochemical industry

increasing accuracy of structural, hydraulic and thermal stresses by 30 % and sales of Bentley product by 12 %

Design and Analysis of Door Lock Mechanism and Air Pressure Plug

Designed Door Lock Mechanism and Air Pressure Plug in SolidWorks using Design for Manufacturing & Assembly

Analysis (DFMA) and Process Planning using Geometric Dimensioning &Tolerancing (GD&T, ASME Y14.5)

Maximized design efficiency by 3 %, reduced 25 % Manufacturing index and improved 100 % process planning

Design, Analysis and Fabrication of Hybrid Vertical Axis Wind Turbine

Designed 2D and 3D HVAWT in SolidWorks and analyzed turbine performance through CFD analysis in ANSYS (Fluent)

and optimized the HVAWT turbine using one way bearing clutch increasing power efficiency by 4 %

Design, Modelling and Analysis of Split Solenoid Electromagnet

Designed Split Solenoid Electromagnet and cooling system in Multiphysics COMSOL utilizing electromagnetic, thermal

and structural analysis and optimized the magnetic field using Monte Carlo simulation

Design of Face Recognition Program in MATLAB

Developed Face Recognition Program using Data analytics and Machine learning tools (PCA, SVD and LDA)

___________________________________________________________________________________________________

HONORS AND AWARDS

Currently stand in top 1/5th of entire engineering class at University of Houston

Honored with the membership of Tau Beta Pi Engineering Honors Society for academic excellence

You might also like

- Mahesh Thalkar-Design & Manufacturing Engineer-July-22 PDFDocument3 pagesMahesh Thalkar-Design & Manufacturing Engineer-July-22 PDFrahulpillai91No ratings yet

- Michael Zhiguo Shen: Troy, MIDocument2 pagesMichael Zhiguo Shen: Troy, MIShiraz KhanNo ratings yet

- SD ResumeDocument2 pagesSD ResumeShashanka DuttaNo ratings yet

- LCI Report Config - EnglDocument19 pagesLCI Report Config - EnglMihai Cristian LascuNo ratings yet

- Venkatesh - Manavaddar (Technical Writting) - 2014Document4 pagesVenkatesh - Manavaddar (Technical Writting) - 2014Venkatesh ManavaddarNo ratings yet

- Karthic SengottaiyanDocument5 pagesKarthic SengottaiyanKarthic MannarNo ratings yet

- Abdurrahman M Syed: Professional SummaryDocument3 pagesAbdurrahman M Syed: Professional SummaryRamesh AmuluruNo ratings yet

- Akshay Pawar CV2Document3 pagesAkshay Pawar CV2Akshay pawarNo ratings yet

- Resume 2Document2 pagesResume 2anvitistiwariNo ratings yet

- Gurpreet Banhal1Document5 pagesGurpreet Banhal1aditya_pandey_77No ratings yet

- Anil CV 20170101Document4 pagesAnil CV 20170101ANILNo ratings yet

- Miriam Glickman - Resume 2024Document2 pagesMiriam Glickman - Resume 2024api-483695163No ratings yet

- Ravi Kaninde ResumeDocument2 pagesRavi Kaninde Resumeapi-357519222No ratings yet

- Achieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivateDocument12 pagesAchieved 20% Greater Efficiency: Manage Facilitate Consult Organize Resolve Assist MotivatestrganeshkumarNo ratings yet

- Role of Cad/Cam in Designing, Developing and Manufacturing of New ProductsDocument4 pagesRole of Cad/Cam in Designing, Developing and Manufacturing of New ProductsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Senior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerDocument2 pagesSenior Mechanical Design Engineer in Minneapolis ST Paul MN Resume Steven FischerSteven FischerNo ratings yet

- Sample Resume 1Document3 pagesSample Resume 1ashok_SnehaNo ratings yet

- Catia V5: Role in The IndustryDocument30 pagesCatia V5: Role in The Industrycadd puthurNo ratings yet

- PARTHIV TRIVEDI 2009 1bDocument3 pagesPARTHIV TRIVEDI 2009 1bParthivNo ratings yet

- CV Nirav Patel (BE Mechanical) - 4Document5 pagesCV Nirav Patel (BE Mechanical) - 4Nirav PatelNo ratings yet

- Project Engineering Manager in Dayton OH Resume Rick PelfreyDocument2 pagesProject Engineering Manager in Dayton OH Resume Rick PelfreyRickPelfreyNo ratings yet

- 1527854274515resume MANOJKUMAR PDFDocument2 pages1527854274515resume MANOJKUMAR PDFManoj KumarNo ratings yet

- Ppce Unit - I Process Planning and Cost EstimationDocument14 pagesPpce Unit - I Process Planning and Cost EstimationJacob RubasinghNo ratings yet

- The Value of Early Analysis (Part 1) : by Gregory RothDocument4 pagesThe Value of Early Analysis (Part 1) : by Gregory RothanandakoeNo ratings yet

- Daine BrownDocument3 pagesDaine BrownAbdul samiNo ratings yet

- Cad Cam CaeDocument60 pagesCad Cam CaeKishor PatilNo ratings yet

- Yuchuantiffanylin ResumeDocument1 pageYuchuantiffanylin Resumeapi-376935976No ratings yet

- Nazia Ansari CV New - MDocument4 pagesNazia Ansari CV New - MNazia AnsariNo ratings yet

- Cad 20S3 2023 72-83Document13 pagesCad 20S3 2023 72-83vipinNo ratings yet

- MB0044 Set-1Document19 pagesMB0044 Set-1haderayesfayNo ratings yet

- The Application of Pro Engineer in CADCAMDocument9 pagesThe Application of Pro Engineer in CADCAMHafiezul HassanNo ratings yet

- Reverse Engineering NotesDocument4 pagesReverse Engineering Notesapi-379303652100% (3)

- Smart Design Solutions PDFDocument6 pagesSmart Design Solutions PDFDeepak Raj ChauhanNo ratings yet

- Me8793 Qb.Document38 pagesMe8793 Qb.YUVA RAJA BNo ratings yet

- Venkadachalapathy Thangavel: LinkedinDocument4 pagesVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thNo ratings yet

- Pratiksh Patel's ResumeDocument2 pagesPratiksh Patel's ResumePratiksh PatelNo ratings yet

- Resume-Chetan-Dhuri-Mechanical Design FEADocument4 pagesResume-Chetan-Dhuri-Mechanical Design FEAChetan DhuriNo ratings yet

- Vanross Jn. Thiruvananthapuram: (Racing Hart)Document11 pagesVanross Jn. Thiruvananthapuram: (Racing Hart)RaUlKishanNo ratings yet

- On Case Studies For Concurrent Engineering Concept in Shipbuilding IndustryDocument16 pagesOn Case Studies For Concurrent Engineering Concept in Shipbuilding IndustryAman BaghelNo ratings yet

- Dibello Resume 1pg 2016Document1 pageDibello Resume 1pg 2016api-251134706No ratings yet

- Monster Resume FormatDocument3 pagesMonster Resume FormatMSKumarNo ratings yet

- Annexure 1Document2 pagesAnnexure 1Pandi RajNo ratings yet

- Nagaraj HNDocument3 pagesNagaraj HNmukesh.33No ratings yet

- Cad 20 (S3) 2023 72-83Document12 pagesCad 20 (S3) 2023 72-83vipinNo ratings yet

- Autocad Project Report (Without Notes)Document13 pagesAutocad Project Report (Without Notes)Harpreet Harry0% (1)

- Kalyani Pramod Management Technical ConsultingDocument3 pagesKalyani Pramod Management Technical ConsultingPramod Shalivahan KalyaniNo ratings yet

- CAD/CAM Means Computer-Aided Design and Computer-Aided Manufacturing. It Is The TechnologyDocument10 pagesCAD/CAM Means Computer-Aided Design and Computer-Aided Manufacturing. It Is The TechnologyRavi SekharNo ratings yet

- Jilu Easow Raju: Assistant Manager - CAD AutomationDocument3 pagesJilu Easow Raju: Assistant Manager - CAD Automationjilukv2No ratings yet

- TeresDocument1 pageTeresvibush VarshanNo ratings yet

- Vishnu Priya RamakrishnanDocument2 pagesVishnu Priya RamakrishnanarunashireenNo ratings yet

- UNIT 1 Lecture 1 CAD AutoDocument21 pagesUNIT 1 Lecture 1 CAD AutoMohd InayathNo ratings yet

- A Dimensional Engineering Process For ShipbuildingDocument11 pagesA Dimensional Engineering Process For ShipbuildingWJccnNo ratings yet

- Facilities Industrial Engineering 1659611573Document25 pagesFacilities Industrial Engineering 1659611573bvphimanshuNo ratings yet

- Cad BookDocument86 pagesCad BookGopi RaguNo ratings yet

- Introduction To Cad/Cam: Arvind DeshpandeDocument38 pagesIntroduction To Cad/Cam: Arvind DeshpandeKarthi KeyanNo ratings yet

- Monster CV Template Graduate - Mechanical - EngineeringDocument2 pagesMonster CV Template Graduate - Mechanical - EngineeringZaid Bin AkberNo ratings yet

- 1 Cad Cam Intro PDFDocument40 pages1 Cad Cam Intro PDFWesleyNo ratings yet

- Abhay Pratap Singh Sengar: Phone: - +91-9329883200Document4 pagesAbhay Pratap Singh Sengar: Phone: - +91-9329883200fiemsabyasachiNo ratings yet

- Abhishek Singh Rathore2024.1Document4 pagesAbhishek Singh Rathore2024.1Rathore ABhishek singhNo ratings yet

- Kidney Disease, or Renal Disease, Also Known As Nephropathy, Is Damage To orDocument1 pageKidney Disease, or Renal Disease, Also Known As Nephropathy, Is Damage To orshafqat12345678No ratings yet

- Republic of IndiaDocument5 pagesRepublic of Indiashafqat12345678No ratings yet

- Photo Requirements For Ead ApplicationDocument1 pagePhoto Requirements For Ead Applicationshafqat12345678No ratings yet

- Kashmir 2Document1 pageKashmir 2shafqat12345678No ratings yet

- Jammu and Kashmir (Document1 pageJammu and Kashmir (shafqat12345678No ratings yet

- Torque ConverterDocument6 pagesTorque Convertershafqat12345678No ratings yet

- 4-S4p1-Stained Glass SymmetryDocument8 pages4-S4p1-Stained Glass Symmetryapi-325015040No ratings yet

- Lighting - Education - Science-ZumtobelDocument60 pagesLighting - Education - Science-ZumtobelManoj IllangasooriyaNo ratings yet

- Officejet Pro X476 X576 Troubleshooting ManualDocument156 pagesOfficejet Pro X476 X576 Troubleshooting ManualDiego Weber Aita100% (1)

- Stress-Strain Curve - WikipediaDocument3 pagesStress-Strain Curve - WikipediaTomy GeorgeNo ratings yet

- Presentationonnumericalmethodpowerpointfinal 141213041412 Conversion Gate02Document17 pagesPresentationonnumericalmethodpowerpointfinal 141213041412 Conversion Gate02rabiaNo ratings yet

- La-Borne CatalogueDocument10 pagesLa-Borne Catalogueronald.wongNo ratings yet

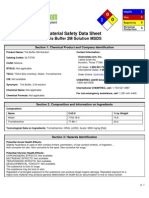

- MSDS Tris BufferDocument6 pagesMSDS Tris BuffervombyNo ratings yet

- Ebook Gravity S Fatal Attraction Black Holes in The Universe Third Edition Mitchell Begelman Online PDF All ChapterDocument69 pagesEbook Gravity S Fatal Attraction Black Holes in The Universe Third Edition Mitchell Begelman Online PDF All Chaptermary.bailey437100% (5)

- Proact™ Digital Speed Control System For Models I and Ii: Installation and Operation ManualDocument68 pagesProact™ Digital Speed Control System For Models I and Ii: Installation and Operation ManualKawarauNo ratings yet

- Chapter 5: ThermochemistryDocument22 pagesChapter 5: ThermochemistryHakimNo ratings yet

- Modern Missile AnalysisDocument37 pagesModern Missile AnalysisamenendezamNo ratings yet

- Lesson 5 Work and EnergyDocument18 pagesLesson 5 Work and EnergyanonymousNo ratings yet

- ACI 562 16 The ACI Concrete Repair CodeDocument7 pagesACI 562 16 The ACI Concrete Repair CodeDonny. B TampubolonNo ratings yet

- 2103-Abj - 2010 - Class Example 2 - Pathlines, Streamlines, StreaklinesDocument6 pages2103-Abj - 2010 - Class Example 2 - Pathlines, Streamlines, StreaklinesDitto R Desmar DikaNo ratings yet

- First Push 2024 Grade 12 Marking Guide March 2024Document12 pagesFirst Push 2024 Grade 12 Marking Guide March 2024lemonlululu1No ratings yet

- DUPLEX 500 - 11000 Multi EN - 2018 - 03Document8 pagesDUPLEX 500 - 11000 Multi EN - 2018 - 03Constantin CilibiuNo ratings yet

- PPT-Vector Calculus - Unit-2-Part-1Document34 pagesPPT-Vector Calculus - Unit-2-Part-1Arihant DebnathNo ratings yet

- Ellipse LabDocument4 pagesEllipse Labapi-251355123No ratings yet

- Sartorius Cata Integrated Lab Equipment S 0300 eDocument430 pagesSartorius Cata Integrated Lab Equipment S 0300 eedal_108No ratings yet

- Consultative Group On Sustainable Development Indicators (CGSDI) (R.O.C) PDFDocument1 pageConsultative Group On Sustainable Development Indicators (CGSDI) (R.O.C) PDFbrayanlomasNo ratings yet

- Bubbledeck Voided Flat Slab Solutions: June 2008Document91 pagesBubbledeck Voided Flat Slab Solutions: June 2008Gan Chin PhangNo ratings yet

- Seal Ball ValvesDocument45 pagesSeal Ball Valvesmetasoniko2014No ratings yet

- Application and Processing of Metal AlloysDocument44 pagesApplication and Processing of Metal AlloysShaira DaleNo ratings yet

- The Short Life of Evariste Galois: by Tony RothmanDocument14 pagesThe Short Life of Evariste Galois: by Tony RothmanisraeloNo ratings yet

- Compressive Properties of Rigid Plastics: Standard Test Method ForDocument7 pagesCompressive Properties of Rigid Plastics: Standard Test Method ForAsep Aby SaputraNo ratings yet

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocument4 pagesSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNo ratings yet

- Manometers Notes 1Document13 pagesManometers Notes 1Sri Kiran ThunuguntlaNo ratings yet

- GMW15185-GMP.E-P.133-Draft A-14MR08Document3 pagesGMW15185-GMP.E-P.133-Draft A-14MR08FERNANDO JOSE NOVAESNo ratings yet

- Hand Biometrics: Erdem Yo Ru K, Helin Dutag Aci, Bu Lent SankurDocument15 pagesHand Biometrics: Erdem Yo Ru K, Helin Dutag Aci, Bu Lent Sankurjit_72No ratings yet

- ElectricalEngineerigLabManual IIECE PDFDocument75 pagesElectricalEngineerigLabManual IIECE PDFUpender Rao SunkishalaNo ratings yet