Professional Documents

Culture Documents

Production of Emulsion House Paint Using Polyvinyl

Production of Emulsion House Paint Using Polyvinyl

Uploaded by

Otegba GiftOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Production of Emulsion House Paint Using Polyvinyl

Production of Emulsion House Paint Using Polyvinyl

Uploaded by

Otegba GiftCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/293012518

Production of Emulsion House Paint Using Polyvinyl Acetate and Gum Arabic

as Binder

Article · January 2015

DOI: 10.11648/j.ijmsa.20150405.20

CITATIONS READS

0 6,805

1 author:

Surajudeen Abdulsalam

Abubakar Tafawa Balewa University

34 PUBLICATIONS 206 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

water treatment using natural coagulants View project

Polluted soil bioremediation process View project

All content following this page was uploaded by Surajudeen Abdulsalam on 22 October 2016.

The user has requested enhancement of the downloaded file.

International Journal of Materials Science and Applications

2015; 4(5): 350-353

Published online October 30, 2015 (http://www.sciencepublishinggroup.com/j/ijmsa)

doi: 10.11648/j.ijmsa.20150405.20

ISSN: 2327-2635 (Print); ISSN: 2327-2643 (Online)

Production of Emulsion House Paint Using Polyvinyl

Acetate and Gum Arabic as Binder

Surajudeen Abdulsalam*, Zebulu Dauma Maiwada

Department of Chemical Engineering, Faculty of Engineering & Engineering Technology, Abubakar Tafawa Balewa University Bauchi,

Bauchi-Nigeria

Email address:

surajudeen_abdulsalam@yahoo.com (S. Abdulsalam), zebulunolimit@gmail.com (Z. D. Maiwada)

To cite this article:

Surajudeen Abdulsalam, Zebulu Dauma Maiwada. Production of Emulsion House Paint Using Polyvinyl Acetate and Gum Arabic as Binder.

International Journal of Materials Science and Applications. Vol. 4, No. 5, 2015, pp. 350-353. doi: 10.11648/j.ijmsa.20150405.20

Abstract: In view of the high cost of paints as a result of importation of raw materials and the need to use our locally available

raw materials for economic and industrial developments, a study was carried out for the production of emulsion house paint by

supplementing imported synthetic binder (polyvinyl acetate, PVA) with a locally available binder (gum Arabic, GA) in six different

proportions labelled; Sample A (100% PVA), Sample B (80% PVA: 20% GA), Sample C (60% PVA: 40% GA), Sample D (40%

PVA: 60% GA), Sample E (20% PVA: 80% GA) and Sample F (100% GA). Standard emulsion paint formulation and method of

production were employed. All the six samples gave high quality emulsion paints in terms of opacity, adhesion, ease of application

and coverage. However, it was observed that paint brightness diminished with increased gum Arabic composition; Sample F being

badly affected. Samples B to E thus resulted in quality paints without any blemish. Therefore, gum Arabic (Acacia Senegal) can be

used as a supplement to PVA in emulsion paint production in all proportions investigated except Sample F.

Keywords: High Cost, Supplement, Quality Parameters, Polyvinyl Acetate, Gum Arabic, Emulsion Paint

involved in paint production, quality and performance of

1. Introduction emulsion paint depends largely on the properties of its

The terms ‘paint’ and ‘surface coating’ are often used constituents and the ratios of these constitutions. The

interchangeably. Surface coating is the more general constituents generally used for the production of emulsion

description of any material that may be applied as a thin house paints include; prime pigments, solvents, extenders

continuous layer to a surface. Paint was traditionally used to pigments, binders and additives [4].

describe pigmented materials as distinct from clear films In the constituents for production of emulsion house paints,

which are more properly called lacquers or varnishes [1]. Paint binder (PVA) usually takes between 17 to 33% total cost of

is a loosely word covering a whole variety of materials; production depending on paint type and this raw material is not

enamels, lacquers, varnishes, undercoats, surfacers, primers, available locally, therefore imported. Hence, high cost of this

sealers, fillers, stoppers and many others. If the pigment is raw material (binder) and consequently high cost of production

omitted, the material is usually called a varnish [2]. The due to the use of expensive binder. In addition, PVA is not

pigmented varnish – the paint – is sometimes called an enamel, environmentally friendly because of its non-biodegradability

lacquer, finish or topcoat, meaning that it is the last coat to be which can contaminate the environment if not properly handled.

applied and the one seen when the coated object is examined. This is because PVA releases toxic fumes when burned. It can

Paints and coatings can be classified into the following major be hazardous to the environment, especially if it is mixed with

categories; architectural coatings, product coatings for original water and comes in contact with fish [5].

equipment manufacturers and special purpose coatings [3]. Of Polyvinyl acetate, PVA, poly (ethenyl ethanoate), poly

these three major categories, emulsion house paints fall in the (1-acetyloxiethylene) is a rubbery synthetic polymer with the

first category. Therefore, emphasis was given to this class. formula (C4H6O2)n. it has a molar mass of 86.09 g/mol/unit. It

Emulsion house paint is a water based paint principally belongs to the polyvinyl esters family with the general formula:

used for internal and external surface coatings, mostly in RCOOCHCH2. It is a type of thermoplastic [6]. It is used as an

buildings for appearance and protection. The processes emulsion in water, and as a binder in paints and coatings. PVA

International Journal of Materials Science and Applications 2015; 4(5): 350-353 351

emulsions are used as adhesives for porous materials, Muda-Lawal Market Bauchi, Bauchi State-Nigeria. List of

particularly for wood, paper, and cloth, and as a consolidant for materials, their brands and a typical ‘Emulsion House Paint’

porous building stone, in particular sandstone [7]. formulation are presented in Table 1.

Gum Arabic, also known as acacia gum, chaar gund, char

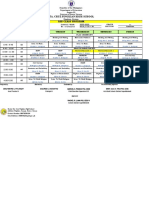

goond, or meska, is a natural gum made of hardened sap taken Table 1. Raw materials and formulation of a typical emulsion house paint.

from two species of the acacia tree; Acacia Senegal and Raw Material Brand Quantity

Acacia Seyal. The gum is harvested commercially from wild Water (L) - 2.160 000

trees throughout the Sahel from Senegal and Sudan to Somalia, Pexi Chem Priveate Ltd,

Polyvinyl acetate (L) 0.500 000

New Delhi

although it has been historically cultivated in Arabia and West

Gum Arabic Grade 1 (Acacia Senegal) -

Asia. Gum Arabic is a complex mixture of glycoproteins and Calcium carbonate (kg) Calco, Freedom Groups 2.040 000

polysaccharides. It was historically the source of the sugars Titanium dioxide (kg) Du Pont Ti Pure 0.560 000

arabinose and ribose, both of which were first discovered and Sodium tripolyphosphate(kg) Innophos 0.000 166

isolated from it, and are named after it. Antifoam (kg) SAF 130 0.000 166

Texanol (kg) East Man TexanolTM 0.016 600

Gum Arabic is used as a binder for watercolor painting

Genepor (kg) Drugbrand DB00305 0.006 670

because it dissolves easily in water. Pigment of any color is Bamboo Charcoal

suspended within the acacia gum in varying amounts, Formalin 0.500 000

Technology

resulting in watercolor paint. Water acts as a vehicle or a Ammonia, (28%) (L) Bird Brand Ammonia 0.016 600

diluent to thin the watercolor paint and helps to transfer the Natrosol PerformaxTM,

Thickener (Natrosol) (kg) 0.250 000

Ashland

paint to a surface such as paper. When all moisture evaporates,

Total (L) - 5.000 000

the acacia gum binds the pigment to the paper surface. After

the water evaporates, the acacia gum in the paint film Source of formulation: Anonymous [8]

increases luminosity and helps prevent the colors from

lightening. Gum Arabic allows more precise control over Gum Arabic Solution Preparation

washes, because it prevents them from flowing or bleeding Gum Arabic exudate was oven dried for six hours (6 h) then

beyond the brush stroke. allowed to cool. Dirt and other foreign materials were

In addition, acacia gum slows evaporation of water, giving removed from the dried exudates by hand picking. The

slightly longer working time. Powdered gum Arabic for artists, screened gum Arabic was ground using mortar and pestle and

one part gum Arabic is dissolved in four parts distilled water sieved using a sieve stack consisting of 600µm, 425µm,

to make a liquid suitable for adding to pigments. It is also used 300µm and the receiver. 1.3 kg of the ground gum Arabic

in photography, printmaking and food industries. powder was dissolved in 2 L of distilled water for 24 h to

Due to the aforementioned problems, the aim of the study produce a 65% wt/v solution. This concentration was chosen

was to produce emulsion house saints using PVA and GA as in order to obtain a binding strength same as that of PVA (i.e.

binder. The objectives were; to determine the effectiveness of to save as basis for comparison).

gum Arabic as binder in ‘Emulsion House Paint’ and to 2.2. Procedure for Paint Production

determine the quality parameters of the produced paint.

The production of emulsion house paint using gum Arabic Two point one-six liters (2.16 L) of water was measured

as supplement binder will definitely alleviate the problems of into a mixer; the stirrer (Model 50111, Type RZR1), then it

unavailability and high cost of PVA, increase cultivation of was switched on. Measured amount of calcium carbonate as

gum Arabic and add value to the agricultural produce due to indicated in Table 1 was gradually dispersed into the mixing

increase in demand, and on a long run saves as means of tank and allowed to grind for 5 min. Measured amounts of

creating employment. In addition, it will also reduce the titanium dioxide and STPP as indicated in Table 1 were then

hazard to the environment. dispersed and allowed to grind for another 10 min and other

This research is limited to the production of emulsion house ingredients were added as itemized in Table 1 in their

paint using a single grade of Gum Arabic (i.e. grade 1. Acacia measured quantities. It should be noted that the thickener was

Senegal) as supplement binder to polyvinyl acetate and to added gradually, after which the mixture was allowed to grind

carry out the quality parameters tests on thee produced paint. properly before packaging.

These parameters include: viscosity, pH, binding strength,

coverage and brightness. 2.3. Quality Parameters Tests of Paints Produced

Quality parameters tests were carried out on the six paint

2. Materials and Methods samples produced using the following methods; viscosity [9],

binding strength (using testometric 200), pH (digital pH

2.1. Raw Materials meter), and brightness (visual observation). Procedure for

Raw materials used for the production of emulsion paint paint coverage is as follows;

were purchased from Sunny Wax International Agency, Paint Coverage

Panteka Market Kaduna, Kaduna State-Nigeria. Except the Ceiling board was used for the paint coverage; the width

grade 1 gum Arabic (Acacia Senegal) that was obtained from and length of the ceiling board were 60.5 and 81.3cm

respectively which gave a surface area of 4918.65cm2

352 Surajudeen Abdulsalam and Zebulu Dauma Maiwada: Production of Emulsion House Paint Using

Polyvinyl Acetate and Gum Arabic as Binder

(0.492m2). Sixty milliliters (60 ml) of the paint sample were must be reduced, hence, reduction in cost of production.

used to paint the surface and the area of the ceiling board that

was painted was recorded for each sample. Table 3. Viscosity and binding strength of paints.

Sample Viscosity (s) B.stgth (kgf)

A 103±1.73 0.66±0.16

3. Results and Discussion B 113±0.82 0.60±0.07

C 153±7.85 0.68±0.08

3.1. pH of Paint

D 157±2.08 0.56±0.06

E 127±4.24 0.82±0.07

From Table 2, pH values of paint samples produced fell

F 132±1.41 0.81±0.21

within the specified range by the Standard Organization of

Nigeria (SON) [10]. From these results obtained, sample A B.stgth: Binding strength

had a pH of 9.05 while samples B, C, D, E and F had pH

values of 7.62, 7.27, 7.32, 7.50 and 7.35 respectively. Samples 3.3. Binding Strength of Paint

that had gum Arabic solution in their compositions had lower Binding strengths of the six samples are presented in Table

pH values as compared to sample A. These differences in pH 3, as the proportion of GA increased in a sample, there was

values are attributed to differences in pH values of PVA and corresponding increase in binding strength except for samples

gum Arabic; PVA has a pH value of 5-6.5 [11] while gum B and D which had binding strengths of 0.60 and 0.56 kgf

Arabic has a pH value of 4.5-5.0 [12]; this shows that gum respectively, which is less than the Control (Sample A). This

Arabic is slightly more acidic than PVA. may be attributed to experimental errors. The durability and

Samples B, C, D, E and F had pH values between 7.27 and performance of paint coatings depend on two basic properties;

7.62, which is within the pH range where bacteria strives [13], cohesion and adhesion [14]. The test conducted tested both

therefore they are susceptible to bacterial attack because of cohesion and adhesion of the paint samples and the interfacial

favorable environment to strive. Hence, microbial growths bonds showed that the paint samples have good binding

were observed in all samples three months after production strengths. This was confirmed by a good adhesion of the paint

except in Sample A. To address this problem, the pH value for when it was used on a substrate. The painted boards showed

all the Samples affected have to be adjusted to 9.0 using no chalking effects two months after applications.

ammonia solution.

3.4. Coverage of Paint

Table 2. pH and viscosity of paints.

The result in Table 4 shows that equal volume of paint covered

Sample pH Bacteria growth

A 9.05 NG equal surface area of the ceiling boards used for analyses. Sample

B 7.62 GP A was adjudged to have the best coverage while samples B, C, D,

C 7.27 GP E and F had better coverages. However, as the proportion of GA

D 7.32 GP increased in the paint samples, it brightness diminished, Sample

E 7.50 GP

F being affected the most. This in no doubt is attributed to the

F 7.35 GP

brownish color of gum Arabic which is in contrast to the whitish

NG: no growth; GP: growth present. color of PVA. This result showed that 60 ml (0.06 L) of paint

samples gave adequate coverages for the six samples (covered an

3.2. Viscosity of Paint area of 0.492 m2). From this result, it can be deduced that 1 L will

Table 3 shows the viscosities of various paint samples, it cover a surface area of 8.2 m2 of ceiling board which conforms to

could be seen that gum Arabic solutions have effects on their NIS 269 as in [10].

viscosities; the higher the proportion of GA in the paint, the Table 4. Coverage and brightness of paints.

higher its viscosity and vice versa [4]. The use of proper paint

viscosity is critical for obtaining a quality finish; excessive Sample Coverage (m2) Brightness

A 0.492 Excellent

viscosity can cause orange peel while a low viscosity can

B 0.492 Excellent

create a film that is too wet and creates runs [14]. According to C 0.492 Very good

ASTM D1200-70 [9], the effluent time for viscosity D 0.492 Good

measurement of emulsion paints should fall between 40 and E 0.492 Fairly good

100 s at temperature of between 20 and 30oC using a Ford F 0.492 Fair

viscosity cup. The paint samples had effluent times above 100

s and this is attributed to disparity between the orifices of the 4. Conclusions and Recommendations

laboratory funnel used and that of Ford viscosity cup.

However, since ‘Sample A’ is the ‘Control’, it gives the basis From the results obtained in this study, the following

for comparison. The paint samples displayed good flow and conclusions and recommendations were drawn; Gum Arabic

ease of application which can be attributed their viscosities. (Acacia Senegal) can be used as an effective supplement

However, to control these viscosities to the acceptable range binder to polyvinyl acetate in PVA to GA ratios of 80:20%;

or value, the quantity of thickener used in various paint sample 60:40%, 40:60% and 20:80% without compromising standard

International Journal of Materials Science and Applications 2015; 4(5): 350-353 353

for the production of emulsion house paint. Since the cost of [5] Http. 1 (2014): http://www.ehow.com/list_7641940_properties-pva.

GA is less than that of PVA taken at an equivalent basis, Retrieved on 10th March, 2014.

blending both types of binders will definitely lead to cost [6] G. T. Murray, “Handbook of Materials Selection for

reduction; Sample E being the most cost effective, followed Engineering Applications” CRC Press, pp. 242, 1997.

by Samples D, C and B respectively. All the blends except

[7] M. E. Young, M. Murray and P. Cordiner, “Stone Consolidants

Sample A (PVA-100%: GA-0%) were susceptible to bacteria and Treatments in Scotland”, Robert Gordon University, 1999.

growth three months after production (Table 2), therefore the

pH values for these Samples should be adjusted to 9.0. In [8] Anonymous (2014). “Emulsion Paint Formulation. Baygo

addition, the findings of this study can be scale-up for the Consult Nig. Enterprises”.

production of cost-effective emulsion house paint. [9] Annual Book of ASTM Standards, “Paint Test for Formulated

Products and Applied Coatings” Part 27. ASTM 1916 Race St.,

Philadelphia, Pa. 19103. Pp. 393-394, 397, 1982.

References [10] T. Rodger, “Paint Technology Handbook”, CRC Press. pp. 82,

2007.

[1] R. Lambourne, “Paint and Surface Coatings: Theory and

Practice”, Ellis Horwood Limited. New York. Pp. 25-29, 35-39, [11] Nigerian Industrial Standard “Specifications for Emulsion

1988. Paints for Decorative Purposes”, Standards Organisation of

Nigeria. ICS: 87.040, 2008.

[2] G. P. A. Turner, “Introduction to Paint Chemistry and

Principles of Paint Technology”, Third Edition. Chapman and [12] S. K. Saxena, “Polyvinyl Alcohol (PVA) Chemical and

Hall. London. pp. 85-88, 1990. Technical Assessment (CTA)”, 61st JECFA, FAO, 2004.

[3] J. C. Dean, “Coatings: the U. S Coatings Industry Strategy for [13] A. Jumbo “Gum Arabic an Ancient Ingredient for the 22nd

Survival in the 80’s”, the Chem Week, Volume 29, 1981. Century”, American Journal of Clinical Nutrition. Vol. 63. pp.

392-398, 1996.

[4] S. Abdulsalam, and Yahaya, Y. U. (2010), “Effectiveness of

Gum Arabic as a Binder in Emulsion House Paint”, Global [14] J. E. Bailey and D. F. Ollis, “Biochemical Engineering

Journal of Engineering Research, 10 (1 & 2): pp. 83-89, 2010. Fundamentals”, International Student Edition, McGraw-Hill

Kogakusha, Ltd, New Delhi, 1977.

View publication stats

You might also like

- Paint ProductionDocument40 pagesPaint ProductionNemerem Ignatius83% (6)

- Emulsion PaintDocument1 pageEmulsion PaintFazlul HoqueNo ratings yet

- Project Report On Red Oxide PrimerDocument7 pagesProject Report On Red Oxide PrimerEIRI Board of Consultants and PublishersNo ratings yet

- RHOPLEX™ MC-1834P: Cement Mortar ModifierDocument6 pagesRHOPLEX™ MC-1834P: Cement Mortar Modifierhemantrulz100% (1)

- MSDS Liquid Shoe PolishDocument4 pagesMSDS Liquid Shoe PolishAhmAd GhAziNo ratings yet

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesFrom EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesNo ratings yet

- Paint 24442Document8 pagesPaint 24442DeDexterNo ratings yet

- Water Repellent Cement Paint ProjectDocument9 pagesWater Repellent Cement Paint ProjectSwaroop MnNo ratings yet

- EmulsionDocument8 pagesEmulsiontata_77No ratings yet

- Water Base PaintDocument18 pagesWater Base PaintMuhammad Kamran AsgharNo ratings yet

- Exterior Paint FormulationDocument1 pageExterior Paint FormulationSrun BunsroeunNo ratings yet

- Crown Paints Kenya Limited Supply Chain Value Analysis in Manufacturing FirmsDocument9 pagesCrown Paints Kenya Limited Supply Chain Value Analysis in Manufacturing FirmsAlexander DeckerNo ratings yet

- Use of Soya Lecithin in Making PaintDocument1 pageUse of Soya Lecithin in Making PainttunlajiNo ratings yet

- Chapter 3 Traffic Paint: ObjectivesDocument10 pagesChapter 3 Traffic Paint: ObjectivesCloudy DayNo ratings yet

- Chemical Formulations For Acrylic Matt and Acrylic Gloss PaintsDocument12 pagesChemical Formulations For Acrylic Matt and Acrylic Gloss PaintsDean HidayatNo ratings yet

- Allnex Phenolic Resins GuideDocument12 pagesAllnex Phenolic Resins GuideMOHAMEDNo ratings yet

- DECORATIVE CEMENT COLOR WASHINGpptDocument10 pagesDECORATIVE CEMENT COLOR WASHINGpptKhalida ParveenNo ratings yet

- Emulsion Polymerization MachanismDocument13 pagesEmulsion Polymerization MachanismLuan GabrielNo ratings yet

- Pva 2019Document7 pagesPva 2019kashyap8291100% (1)

- Paints and CoatingsDocument10 pagesPaints and CoatingsJesus Erazo100% (1)

- Smooth Masonry PaintDocument1 pageSmooth Masonry Paintvanhung88No ratings yet

- Paints and Coatings - How Surfactants Can Advance New DevelopmentsDocument9 pagesPaints and Coatings - How Surfactants Can Advance New Developmentsboyo17meiNo ratings yet

- MSDSDocument14 pagesMSDSErna AyuNo ratings yet

- Antifouling ArticleDocument16 pagesAntifouling ArticleAbbas Ali100% (1)

- Byk Ts-A5 Putties enDocument6 pagesByk Ts-A5 Putties enSebastian GonzalezNo ratings yet

- How To Disperse A Matting AgentDocument2 pagesHow To Disperse A Matting Agenttessaro18230% (1)

- Long Durability Exterior CoatingDocument1 pageLong Durability Exterior CoatingAmit BholaNo ratings yet

- Latex Paint Formulations: University of Bristol School of Chemistry Cantock's Close Bristol BS8 iTSDocument13 pagesLatex Paint Formulations: University of Bristol School of Chemistry Cantock's Close Bristol BS8 iTSAriane MochéNo ratings yet

- High-Pcv Water-Based Paint Ingredients % by Weight: Ginshicel MH 96-SdDocument3 pagesHigh-Pcv Water-Based Paint Ingredients % by Weight: Ginshicel MH 96-Sdfernando reyesNo ratings yet

- Arkema Generalbrochure SmallDocument9 pagesArkema Generalbrochure SmallRajNo ratings yet

- 816-00138-01-Metalworking-Fluids-Selection-Guide DOWDocument38 pages816-00138-01-Metalworking-Fluids-Selection-Guide DOWDidier FARATNo ratings yet

- Wood PreservationDocument23 pagesWood PreservationNalaka SanthajeewaNo ratings yet

- Experiment 1 TITLE: Alkyd Resin Preparation Based On Soya OilDocument3 pagesExperiment 1 TITLE: Alkyd Resin Preparation Based On Soya OilBakar Sulaiman100% (3)

- Alkox - Concrete ApplicationDocument9 pagesAlkox - Concrete ApplicationWahid KarolNo ratings yet

- Acrylic Resin PodelaDocument7 pagesAcrylic Resin Podelaslavica_restauroNo ratings yet

- Paint AdditivesDocument3 pagesPaint AdditivesAnonymous yy8In96j0rNo ratings yet

- 20 - Alkyd Emulsifier - ES 4045 - 2019 EditionDocument4 pages20 - Alkyd Emulsifier - ES 4045 - 2019 Editionumar buttNo ratings yet

- Alkyd Resin ManufacturerDocument5 pagesAlkyd Resin ManufacturerDonald_12No ratings yet

- AkzoNobel Paint Eng Tcm54-18194Document20 pagesAkzoNobel Paint Eng Tcm54-18194a2009sNo ratings yet

- Alkyd Emulsion Satin PaintDocument2 pagesAlkyd Emulsion Satin Painthardik3578No ratings yet

- Cymel® 303 LF: Product Description Typical PropertiesDocument2 pagesCymel® 303 LF: Product Description Typical Propertiesهیمن مNo ratings yet

- AIR PRODUCTS Agrochemical Adjuvants GuideDocument8 pagesAIR PRODUCTS Agrochemical Adjuvants GuideRomán M Martín del CNo ratings yet

- Industrial Coating Road Marking Paint, Yellow: Guide FormulationDocument1 pageIndustrial Coating Road Marking Paint, Yellow: Guide FormulationFabio Samir CuzinskyNo ratings yet

- 2.2e Coating Formulation CalculationDocument6 pages2.2e Coating Formulation CalculationSwapnil SononeNo ratings yet

- Tinta Inkjet Basis AirDocument24 pagesTinta Inkjet Basis Airpakde jongkoNo ratings yet

- Glossary and Basic Review of PolyurethanesDocument2 pagesGlossary and Basic Review of Polyurethanesuocmogiandi_aNo ratings yet

- Wanhua Interior Coating SolutionsDocument28 pagesWanhua Interior Coating SolutionsThanh Vu100% (1)

- Paint VarnishesDocument52 pagesPaint Varnishespmanish16No ratings yet

- Cement, Concrete & Mortar: Product Characteristics Brand NameDocument2 pagesCement, Concrete & Mortar: Product Characteristics Brand NameAliaksandr PrybauNo ratings yet

- PvaDocument5 pagesPvaShrinil DesaiNo ratings yet

- Ucar Latex 379G: The Best Just Got BetterDocument12 pagesUcar Latex 379G: The Best Just Got BetterQuimicosgenericosgaffaro GaffaroNo ratings yet

- Glossy FillersDocument6 pagesGlossy Fillerskensley oliveira100% (1)

- Castor Oil A Vital Industrial Raw MaterialDocument6 pagesCastor Oil A Vital Industrial Raw MaterialVictor LopezNo ratings yet

- Formulation andDocument9 pagesFormulation andAsadoumo AbrahamNo ratings yet

- Paint: Properties, Uses & DefectsDocument12 pagesPaint: Properties, Uses & DefectsAparajita VibuNo ratings yet

- 2006, Production of Alkyd Resin - Effect of CatalystDocument5 pages2006, Production of Alkyd Resin - Effect of CatalystNhu TranNo ratings yet

- Silquest: Product Selection GuideDocument4 pagesSilquest: Product Selection GuideJust4545No ratings yet

- Handbook of Vinyl FormulatingFrom EverandHandbook of Vinyl FormulatingRichard F GrossmanRating: 3 out of 5 stars3/5 (1)

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachFrom EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudRating: 5 out of 5 stars5/5 (1)

- Laydown Area Civil WorksDocument4 pagesLaydown Area Civil WorksMohammed MinhajNo ratings yet

- Mathematics: Primary: EYFS, Key Stage 1, Key Stage 2Document38 pagesMathematics: Primary: EYFS, Key Stage 1, Key Stage 2Mihaela AnticiNo ratings yet

- An Historicist Perspective On Daniel 11Document343 pagesAn Historicist Perspective On Daniel 11רודריקNo ratings yet

- FEMSSISA Grade 9 Mathematics Olympiads 2022 PDFDocument5 pagesFEMSSISA Grade 9 Mathematics Olympiads 2022 PDFMinh NgôNo ratings yet

- Macine Element I Worksheet For Final ExamDocument4 pagesMacine Element I Worksheet For Final Examdagimawgchew777No ratings yet

- Jensen: Unit 4 Pretest ReviewDocument11 pagesJensen: Unit 4 Pretest ReviewKarma TenzinNo ratings yet

- Full Download Introduction To Measure Theoretic Probability 2nd Edition Roussas Solutions ManualDocument6 pagesFull Download Introduction To Measure Theoretic Probability 2nd Edition Roussas Solutions Manualirisybarrous100% (38)

- Vedic Astrology Books You Should Read Before You DieDocument6 pagesVedic Astrology Books You Should Read Before You DieopparasharNo ratings yet

- Orca Share Media1676204784901 7030512434130423961Document40 pagesOrca Share Media1676204784901 7030512434130423961Chester BoliquenNo ratings yet

- The National Institute of Engineering: Comparative CFD Analysis On Laminar Flow Through Nozzle Attached To PipeDocument6 pagesThe National Institute of Engineering: Comparative CFD Analysis On Laminar Flow Through Nozzle Attached To PipeAny BodyNo ratings yet

- HW5 SolutionDocument7 pagesHW5 SolutionMuhammad Saqib IrshadNo ratings yet

- Ius Spring2024 Undergraduate Schedule 22feb2024Document5 pagesIus Spring2024 Undergraduate Schedule 22feb2024Adnela ImamovicNo ratings yet

- TrustAutomation WP LinearDigitalDrivesDocument7 pagesTrustAutomation WP LinearDigitalDrivesvnetawzNo ratings yet

- Individual Proposal Format-CSRI-2021Document12 pagesIndividual Proposal Format-CSRI-2021Dr. Manoj Kumar SharmaNo ratings yet

- 6DL1132-6BL00-0PH1 Et200sp - Ha - DQ - 32x24vdc - 0 - 5a - en-US - en-USDocument36 pages6DL1132-6BL00-0PH1 Et200sp - Ha - DQ - 32x24vdc - 0 - 5a - en-US - en-USTanase GeorgetaNo ratings yet

- The Effect of Controlled Permeable Formwork Liner On The Mechanical Properties of ConcreteDocument11 pagesThe Effect of Controlled Permeable Formwork Liner On The Mechanical Properties of ConcreteVijayNo ratings yet

- Er - Kumar Dhamala Urban Planner 2023-11-3Document17 pagesEr - Kumar Dhamala Urban Planner 2023-11-3kumardaiNo ratings yet

- FP1 Listening Skills 2Document2 pagesFP1 Listening Skills 2Jordi Sánchez RodríguezNo ratings yet

- IEEE - 0446 - 1995 (Orange) Emergency and Standby Power SystemsDocument319 pagesIEEE - 0446 - 1995 (Orange) Emergency and Standby Power SystemsJOHAN ARLEY DELGADO VARGAS100% (3)

- Godrej and Boyce Corporate ProfileDocument2 pagesGodrej and Boyce Corporate ProfileSahili SalveNo ratings yet

- Assignment 1 Psychology and EducationDocument2 pagesAssignment 1 Psychology and EducationRheque GnarNo ratings yet

- DICOM and Slicer: A TutorialDocument75 pagesDICOM and Slicer: A TutorialLaura Cursaru100% (1)

- Daily Lesson Log Grade 8 1.ADocument4 pagesDaily Lesson Log Grade 8 1.ARaymund AlilingNo ratings yet

- 2024 GeES 1011 Group AssignmentDocument1 page2024 GeES 1011 Group AssignmentLemma Deme ResearcherNo ratings yet

- CogniPlus en Katalog SCHUHFRIED #3Document36 pagesCogniPlus en Katalog SCHUHFRIED #3Oana GheorghitaNo ratings yet

- Standard Penetration TestDocument4 pagesStandard Penetration TestIrita Kayna Gobile100% (1)

- Value Educatvdffion Mcqs Part 1Document20 pagesValue Educatvdffion Mcqs Part 1virupakshaNo ratings yet

- Recycled CarpetsDocument10 pagesRecycled Carpetsken riveraNo ratings yet

- Steel Sheet Pile CatalogueDocument80 pagesSteel Sheet Pile CatalogueBrian TanNo ratings yet

- Green BuildingDocument69 pagesGreen BuildingBS EntertainmentNo ratings yet