Professional Documents

Culture Documents

Gri Wrap

Gri Wrap

Uploaded by

Saqib AliOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gri Wrap

Gri Wrap

Uploaded by

Saqib AliCopyright:

Available Formats

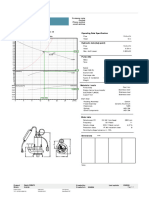

Data Input

Pipe Diameter (Dia.) 8.625 inches Allowable Defect Depth vs. Length

(at Design and Operating Pressures)

Wall Thickness (t) 0.432 inches

Pipe Strength (SMYS) 35000 psi

0.400

Defect Depth 0.34 inches Design - Length vs. Depth

Defect Length 3 inches 0.350 Operating - Length vs. Depth

Operating Pressure (MOP) 1800 psi 0.300 Defect

Depth (inches)

Design Factor (DF) 0.72

0.250

Temperature Factor (TF) 1

Pipe Joint Factor (JF) 1 0.200

Clock Spring is acceptable, Shape Factor = 1 0.150

0.100

Output Messages

Defect depth % of wall 78.7% 0.050

UTS (Approximate) 60000 psi 0.000

13

18

23

28

33

10.5

15.5

20.5

25.5

30.5

35.5

0.5

5.5

8

Design Pressure (MAOP or P) 2524 psi

Safe Operating Pressure (P') 1904 psi

Length (inches)

Clock Spring is acceptable, Shape Factor = 1

Maximum defect length and depth from B31G.

With corrosion length of 3 inches, and MOP of 1800 psi max depth is 0.346 inches.

With corrosion depth of 0.34 inches, and MOP of 1800 psi max length is 3.66 inches.

Calculations from GRIWrap Analysis.

Pressure-failure reinforced (Pfr) 3701 psi Shape factor (B) 1

Pressure-pristine yield (Pyo) 3506 psi Ratio Pfr / Pyo 1.06

GRIWrap

You might also like

- D3529 17300 2Document1 pageD3529 17300 2stinkzNo ratings yet

- CBL Interpretation Chart PDFDocument1 pageCBL Interpretation Chart PDFReza Alfiano100% (1)

- Course in CP Inspection Methods FOR Corrocean: Part I - Part IIDocument31 pagesCourse in CP Inspection Methods FOR Corrocean: Part I - Part IISaqib AliNo ratings yet

- Asset Integrity ManagementDocument9 pagesAsset Integrity ManagementSaqib AliNo ratings yet

- AssigDocument2 pagesAssignilesh7889No ratings yet

- Annex A-2.2 SIL1 New Sump PitDocument2 pagesAnnex A-2.2 SIL1 New Sump PitAchmad YusufNo ratings yet

- Sales Catalogue - 40LW AHU - Gurgaon India FactoryDocument2 pagesSales Catalogue - 40LW AHU - Gurgaon India FactorypsjjoshiNo ratings yet

- Integrated 1D-Multid Fluid Dynamic Models For The Simulation of I.C.E. Intake and Exhaust SystemsDocument5 pagesIntegrated 1D-Multid Fluid Dynamic Models For The Simulation of I.C.E. Intake and Exhaust SystemsdidNo ratings yet

- KLS1 As 303 1Document1 pageKLS1 As 303 1Victor Solis BrevisNo ratings yet

- High Air Flow Series e 2012Document22 pagesHigh Air Flow Series e 2012John Renz Caling RetiroNo ratings yet

- CM100RX-24A NDocument8 pagesCM100RX-24A NLITMAS TECHNOLOGYNo ratings yet

- Control Chart For Mean and Range: Quality CharacteristicDocument7 pagesControl Chart For Mean and Range: Quality Characteristiciosin1No ratings yet

- CPT 205488 Rep01Document2 pagesCPT 205488 Rep01rupalss1235No ratings yet

- L/s MM MM Diameter (MM) (M/S) Pa MTR Coefficients Pa/m PaDocument3 pagesL/s MM MM Diameter (MM) (M/S) Pa MTR Coefficients Pa/m PaNoorudheenEVNo ratings yet

- Filtro Carbon ActivoDocument1 pageFiltro Carbon ActivoZzmangostazZNo ratings yet

- Diaphragm Pumps For In-Vitro DiagnosticsDocument8 pagesDiaphragm Pumps For In-Vitro DiagnosticsHarold FarfanNo ratings yet

- Feb 60 - 60Document1 pageFeb 60 - 60labkurniaNo ratings yet

- Constant Rate Pressure Injection TestDocument1 pageConstant Rate Pressure Injection TestToddy SamuelNo ratings yet

- BAA382CHDocument2 pagesBAA382CHlibraliNo ratings yet

- 1in SB36WBAC21 8Document1 page1in SB36WBAC21 8poiuytNo ratings yet

- Color TV Horizontal Deflection Output ApplicationsDocument3 pagesColor TV Horizontal Deflection Output ApplicationsJose M PeresNo ratings yet

- Cr8Pm: Mitsubishi Semiconductor ThyristorDocument5 pagesCr8Pm: Mitsubishi Semiconductor ThyristorMahfud Adhi AnsoriNo ratings yet

- Vortrag Bulus UmutDocument34 pagesVortrag Bulus UmutUmut BulusNo ratings yet

- SUPERNATANTDocument1 pageSUPERNATANTDocu CenterNo ratings yet

- 10V Drive NCH MOSFET: R6025ANZDocument6 pages10V Drive NCH MOSFET: R6025ANZTuribio Almeida BarbosaNo ratings yet

- E Cores and Accessories E42/21/15: General Data For 10-Pins E42/21/15 Coil Former Parameter SpecificationDocument1 pageE Cores and Accessories E42/21/15: General Data For 10-Pins E42/21/15 Coil Former Parameter SpecificationAngamuthu AnanthNo ratings yet

- High-Voltage Switching Applications: Package Dimensions FeaturesDocument5 pagesHigh-Voltage Switching Applications: Package Dimensions Featuresabdkrim31No ratings yet

- C 5388Document4 pagesC 5388Rex DelaPenaNo ratings yet

- Ultrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsDocument3 pagesUltrahigh-Definition CRT Display Horizontal Deflection Output ApplicationsPhilip EgyNo ratings yet

- Ultrahigh-Definition Color Display Horizontal Deflection Output ApplicationsDocument4 pagesUltrahigh-Definition Color Display Horizontal Deflection Output ApplicationsManuel MartinezNo ratings yet

- Plano Viv. Unifamiliar Primera Planta PDFDocument1 pagePlano Viv. Unifamiliar Primera Planta PDFRivera Quispe , MiltonNo ratings yet

- Bateria Mesa de Operaciones Schmitz Diamond 40 KDocument2 pagesBateria Mesa de Operaciones Schmitz Diamond 40 KGuillermo PortugalNo ratings yet

- Rectification Proposal For Ecc Pile: Untuk: Tetuan CGH Industry SDN BHDDocument14 pagesRectification Proposal For Ecc Pile: Untuk: Tetuan CGH Industry SDN BHDTom YeeNo ratings yet

- Classic Dripline With Flat Dripper and Long Labyrinth: Ideal For Orchards!Document2 pagesClassic Dripline With Flat Dripper and Long Labyrinth: Ideal For Orchards!Mk TouamiNo ratings yet

- 2 SK 546Document3 pages2 SK 546Joaquin Guzman murilloNo ratings yet

- DICARE Basic Curves: Engine 9 M 25 Nr. 44133 Constant Speed PlantDocument1 pageDICARE Basic Curves: Engine 9 M 25 Nr. 44133 Constant Speed PlantFrancis O. AlcantaraNo ratings yet

- Operating Data Specification: Faixa de AplicaçãoDocument1 pageOperating Data Specification: Faixa de AplicaçãoScaramouche SualkNo ratings yet

- FC4 Standard Units Pressure CurvesDocument12 pagesFC4 Standard Units Pressure CurvesTiago Karina ElisaNo ratings yet

- B08 3 A6t PDFDocument2 pagesB08 3 A6t PDFRakESaN SoundwangS100% (1)

- IR NDT On Aeronautical Plastics-Flores-BolarinDocument8 pagesIR NDT On Aeronautical Plastics-Flores-BolarinalexanderNo ratings yet

- Fuel Pump ModuleDocument1 pageFuel Pump ModuleSaeed MohammedNo ratings yet

- Low-Frequency Amplifier Applications: Package Dimensions FeaturesDocument4 pagesLow-Frequency Amplifier Applications: Package Dimensions FeaturesautreraNo ratings yet

- (1.5 To 2.5 (Sec) ) : 1.00 35.00 Tubing Pressure BuildupDocument2 pages(1.5 To 2.5 (Sec) ) : 1.00 35.00 Tubing Pressure BuildupMario HernándezNo ratings yet

- Hytrex Cartridge Filter Fact SheetDocument2 pagesHytrex Cartridge Filter Fact SheetAndrea OblatoreNo ratings yet

- 04020VA Data SheetDocument5 pages04020VA Data Sheetahmad16_ftua6999No ratings yet

- Incremental, digital interface, resolution 1 μm, scaling factor 1250Document5 pagesIncremental, digital interface, resolution 1 μm, scaling factor 1250Dwi SaputroNo ratings yet

- Power Transistor ( 40V, 2A) : 2SB1183 / 2SB1239Document1 pagePower Transistor ( 40V, 2A) : 2SB1183 / 2SB1239Angel Simo MoralesNo ratings yet

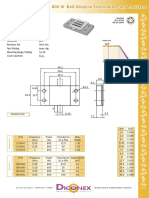

- 800 W Beo Stripline Terminations and ResistorsDocument1 page800 W Beo Stripline Terminations and ResistorsMarcos MillerNo ratings yet

- Nisen Dikis Mukavemet - Is TensDocument2 pagesNisen Dikis Mukavemet - Is TensEbrar AyarNo ratings yet

- 8 3....... 2225 PDFDocument29 pages8 3....... 2225 PDFنيرمين احمدNo ratings yet

- Mathematical Models For Alkaline Pulp and Paper Properties of Oil Palm Empty Fruit Bunch Fibre (Efb)Document2 pagesMathematical Models For Alkaline Pulp and Paper Properties of Oil Palm Empty Fruit Bunch Fibre (Efb)Rushdan IbrahimNo ratings yet

- Detalle de Gras 01Document1 pageDetalle de Gras 01Miguel Angel Lizana MarcasNo ratings yet

- Supreme 2020 - Trial TM6 - BalinusraDocument14 pagesSupreme 2020 - Trial TM6 - BalinusraPradika ErtaNo ratings yet

- High Fedility SimulationDocument11 pagesHigh Fedility SimulationEdison Collinao RoblesNo ratings yet

- PTC (Posistorr) For Motor Starters: Resistors/ThermistorsDocument2 pagesPTC (Posistorr) For Motor Starters: Resistors/Thermistorsangel eyesNo ratings yet

- Arquitectura - Plano 1Document1 pageArquitectura - Plano 1JHON CHULLO TINTANo ratings yet

- Performance Test On Double Stage Reciprocating: SpecificationDocument1 pagePerformance Test On Double Stage Reciprocating: SpecificationKomal SinghNo ratings yet

- Description T OP M1 M2 M3 Description T OP M1 M2 M3Document1 pageDescription T OP M1 M2 M3 Description T OP M1 M2 M3Germán Mendoza RamírezNo ratings yet

- Serie 115 RTC CouplingsDocument4 pagesSerie 115 RTC CouplingsHIDRAFLUIDNo ratings yet

- DIN 2391-2 Cijevi SpecijalneDocument10 pagesDIN 2391-2 Cijevi SpecijalneMiran VidovićNo ratings yet

- Plate Buckling StressDocument2 pagesPlate Buckling Stressvanshika.hlengineersNo ratings yet

- Successful Service Design for Telecommunications: A comprehensive guide to design and implementationFrom EverandSuccessful Service Design for Telecommunications: A comprehensive guide to design and implementationNo ratings yet

- Dacon Tube Inspection GuidebookDocument28 pagesDacon Tube Inspection GuidebookSaqib AliNo ratings yet

- PWHT PQR P3-3, P4-3, & P5a-3Document2 pagesPWHT PQR P3-3, P4-3, & P5a-3Saqib AliNo ratings yet

- 01 - WH-43-01Document1 page01 - WH-43-01Saqib AliNo ratings yet

- Muthukkumaran Anbalazhan - CVDocument4 pagesMuthukkumaran Anbalazhan - CVSaqib AliNo ratings yet

- 0 - Meridium APM - Level 1 Solution WorkflowsDocument4 pages0 - Meridium APM - Level 1 Solution WorkflowsSaqib AliNo ratings yet

- Meridium RBI-580 Inspection Strategies - Q12016Document161 pagesMeridium RBI-580 Inspection Strategies - Q12016Saqib Ali100% (1)

- Safety OfficerDocument21 pagesSafety OfficerSaqib AliNo ratings yet

- E NDE: Advanced Eddy Current Flaw Detector Multi-Frequency & Multi-ChannelDocument4 pagesE NDE: Advanced Eddy Current Flaw Detector Multi-Frequency & Multi-ChannelSaqib AliNo ratings yet

- Credo: Integrity Management SoftwareDocument12 pagesCredo: Integrity Management SoftwareSaqib AliNo ratings yet

- B.W.G. Chart PDFDocument1 pageB.W.G. Chart PDFSaqib AliNo ratings yet

- Questions Sheet 1Document4 pagesQuestions Sheet 1Andiappan PillaiNo ratings yet

- Api580 QuizDocument5 pagesApi580 QuizSaqib Ali100% (1)

- AIMDocument8 pagesAIMSaqib AliNo ratings yet

- E 10 Brinell Hardness of MetalsDocument9 pagesE 10 Brinell Hardness of MetalsSaqib Ali100% (1)

- R P RP O501 E W P S: Ecommended RacticeDocument43 pagesR P RP O501 E W P S: Ecommended RacticeSaqib AliNo ratings yet

- Healthcare ModelDocument7 pagesHealthcare ModelStanley ANo ratings yet

- 21 Structural Conceptual Design ReportDocument12 pages21 Structural Conceptual Design Reportsofianina05No ratings yet

- Compare-Contrast Essay Writing: All: Most: SomeDocument10 pagesCompare-Contrast Essay Writing: All: Most: SomeGayatri Maniksha ParsekarNo ratings yet

- Lab 1Document10 pagesLab 1DaniNo ratings yet

- Ejercicios PDFDocument4 pagesEjercicios PDFOrlando FernandezNo ratings yet

- HVAC ValidationDocument15 pagesHVAC Validationpiyusharora1964100% (4)

- 1.2. COTELCO (July Release-June)Document1 page1.2. COTELCO (July Release-June)jack macabatalNo ratings yet

- Buehrle Final Action Research ReportDocument50 pagesBuehrle Final Action Research ReportsbyearlyNo ratings yet

- Sr. No. Activity Description Responsibility: 4.0 ActivitiesDocument1 pageSr. No. Activity Description Responsibility: 4.0 ActivitiesKamal SolankiNo ratings yet

- Installation Guide v9 02-EnDocument36 pagesInstallation Guide v9 02-Enمحمد دانشNo ratings yet

- Technical Presentation Coating Paint ApplicationDocument39 pagesTechnical Presentation Coating Paint ApplicationRengarajan Thiruvengadaswamy100% (2)

- Mesin SinkronDocument52 pagesMesin SinkronMuhammad Sulthon Novera Rega100% (1)

- FANUC Series 30 Improvement of The Feedrate Command When G93/G94/G95 Is ChangedDocument7 pagesFANUC Series 30 Improvement of The Feedrate Command When G93/G94/G95 Is ChangedofanNo ratings yet

- Ds Erhard Roco WaveDocument27 pagesDs Erhard Roco Wavekad-7No ratings yet

- How To Download and Install JDK 1Document19 pagesHow To Download and Install JDK 1Leira Orlando Quispe HuallpaNo ratings yet

- Z5 Float ZoneDocument113 pagesZ5 Float ZoneLambert StrongNo ratings yet

- ST8A-EM 11.3 W/4000K 900 MM: Product DatasheetDocument4 pagesST8A-EM 11.3 W/4000K 900 MM: Product DatasheetАлина ВладиславовнаNo ratings yet

- Fundamentals of Aerodynamics (REVIEW COURSE)Document22 pagesFundamentals of Aerodynamics (REVIEW COURSE)Adrian Delizo100% (2)

- Solutions To Home Work # 1: 3-14C Convection Heat Transfer Through The Wall Is Expressed AsDocument6 pagesSolutions To Home Work # 1: 3-14C Convection Heat Transfer Through The Wall Is Expressed Aspriyadarshini212007No ratings yet

- Comment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Document3 pagesComment Management Sheet (CMS) P-A Ramp C A1 CO+Design 20181107Amila SampathNo ratings yet

- PEST On ProtonDocument2 pagesPEST On ProtonStarvinder SinghNo ratings yet

- CFM Equipped Fleet AtlanticDocument34 pagesCFM Equipped Fleet AtlanticJohn KevinNo ratings yet

- Bu2506df 1Document8 pagesBu2506df 1pepo1974No ratings yet

- ASD WSD vs. LRFD PDFDocument4 pagesASD WSD vs. LRFD PDFJackNo ratings yet

- GE Revolution CTDocument4 pagesGE Revolution CTMae ANo ratings yet

- BELDocument21 pagesBELNirmal KhajuriaNo ratings yet

- OP-FIB Field Isolator Box STD PDFDocument2 pagesOP-FIB Field Isolator Box STD PDFzsmithNo ratings yet

- Bor MasinaDocument28 pagesBor MasinaLohon TatianaNo ratings yet

- Chapter 3 Significance of Materials Used in ArtDocument17 pagesChapter 3 Significance of Materials Used in ArtAmelito JungoyNo ratings yet