Professional Documents

Culture Documents

VSE120

VSE120

Uploaded by

ABYASARIDER AgunCopyright:

Available Formats

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- Ramo de Marcio CostaDocument163 pagesRamo de Marcio CostaMarciel D'SeixsNo ratings yet

- Senr3130 14 00 AllDocument20 pagesSenr3130 14 00 AllAhmed MoustafaNo ratings yet

- Senr3130 19 00 - Manuals Service Modules - SpecificationsDocument24 pagesSenr3130 19 00 - Manuals Service Modules - Specificationsmostafa aliNo ratings yet

- Power Team HNS150 ManualDocument5 pagesPower Team HNS150 ManualTitanplyNo ratings yet

- Pioneer Deh-P6880mpDocument74 pagesPioneer Deh-P6880mpElton Peres0% (1)

- Options, Futures, and Other Derivatives, 8th Edition, 1Document25 pagesOptions, Futures, and Other Derivatives, 8th Edition, 1Anissa Nurlia KusumaningtyasNo ratings yet

- Tension Belt GaugeDocument2 pagesTension Belt GaugeDeni RamdaniNo ratings yet

- Safety Instructions: Model NoDocument2 pagesSafety Instructions: Model NoStormin DesNo ratings yet

- Air Needle Scaler SA50.V2: 1. Safety InstructionsDocument4 pagesAir Needle Scaler SA50.V2: 1. Safety InstructionsLalbin BabuNo ratings yet

- VS2005 V2 DFC30817Document2 pagesVS2005 V2 DFC30817ko koNo ratings yet

- Valve Collet Remover / Installer: 1. SafetyDocument2 pagesValve Collet Remover / Installer: 1. SafetyZamriNo ratings yet

- Manual VREL Valve - Sentry PDFDocument12 pagesManual VREL Valve - Sentry PDFMarcoGomesNo ratings yet

- VS2059Document2 pagesVS2059ko koNo ratings yet

- 2984 - maverick - hr - plus - rev - n еттерDocument56 pages2984 - maverick - hr - plus - rev - n еттерpeterbirtatNo ratings yet

- Sealey SMS2008Document3 pagesSealey SMS2008cabuloNo ratings yet

- High Pressure Fuel Pump Remover/ Installer - Ford 2.0D EcoblueDocument2 pagesHigh Pressure Fuel Pump Remover/ Installer - Ford 2.0D EcoblueFacundo Guzman MacedoNo ratings yet

- Catalytic Converter and Exhaust Back PressureDocument2 pagesCatalytic Converter and Exhaust Back PressureeiochoaNo ratings yet

- Exm3000 V9 Asm 072020Document18 pagesExm3000 V9 Asm 072020Arthur UchoaNo ratings yet

- Comprecion Del MotorDocument2 pagesComprecion Del Motoralex martinez coroNo ratings yet

- Vse952 DFC0166998Document2 pagesVse952 DFC0166998ابوفاطمةاليساريNo ratings yet

- CT Series Telescopic Handler Bucket Operators Parts Manual 76266rev3Document21 pagesCT Series Telescopic Handler Bucket Operators Parts Manual 76266rev3Marek WyszatyckiNo ratings yet

- Pioneer Deh-2050mp MPG SM (ET) PDFDocument60 pagesPioneer Deh-2050mp MPG SM (ET) PDFSergioNo ratings yet

- CHT Intallation ManualDocument22 pagesCHT Intallation ManualSAPTONo ratings yet

- E Stop For ParkerDocument18 pagesE Stop For ParkerpchizumilaNo ratings yet

- CRT3597 Deh-30mpDocument70 pagesCRT3597 Deh-30mpjohn.snow8786No ratings yet

- Pioneer Deh-P3000ib SMDocument68 pagesPioneer Deh-P3000ib SMrudineimarafonNo ratings yet

- Pin Brazing Gun - Electrobraze ZE7000Document16 pagesPin Brazing Gun - Electrobraze ZE7000GlennSymingtonNo ratings yet

- Pioneer Deh-P5750mp Service ManualDocument78 pagesPioneer Deh-P5750mp Service Manualinderbrar100% (2)

- CT Series Telescopic Handler Fork Carriage Operators Parts Manual 76265Document21 pagesCT Series Telescopic Handler Fork Carriage Operators Parts Manual 76265Marek WyszatyckiNo ratings yet

- GM 7200MDocument40 pagesGM 7200MFredy FigueroaNo ratings yet

- Bostitch Stick Framing NailerDocument40 pagesBostitch Stick Framing NailerRod ScottNo ratings yet

- Q&M GeneralDocument0 pagesQ&M GeneralPhu NguyenNo ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Pioneer Deh-P4850mp p4850mphDocument76 pagesPioneer Deh-P4850mp p4850mphVxr GsiNo ratings yet

- Cylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. SafetyDocument2 pagesCylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. Safetyhotmaail4No ratings yet

- VSE5640 Instructions 20190815 1 - DFC0251429Document3 pagesVSE5640 Instructions 20190815 1 - DFC0251429Алексей ЖидкевичNo ratings yet

- FM-300H FM-300HR: Electronic Disc Meter Owner's ManualDocument16 pagesFM-300H FM-300HR: Electronic Disc Meter Owner's ManualRichard FloresNo ratings yet

- Pioneer Deh-3700mp, Deh-3730mp Service ManualDocument68 pagesPioneer Deh-3700mp, Deh-3730mp Service ManualOssian Valera PinedaNo ratings yet

- Stiffness Tester A 45 Grados PDFDocument7 pagesStiffness Tester A 45 Grados PDFramonNo ratings yet

- Brother 882U73 Sewing Machine Instruction ManualDocument204 pagesBrother 882U73 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- MR 5-30 or MR 5-30N Series Fuel Meter Owner's ManualDocument8 pagesMR 5-30 or MR 5-30N Series Fuel Meter Owner's ManualTuấn VũNo ratings yet

- Operator'S & Parts Manual Gehl Ct-Series To John Deere Adapter Hitch AssemblyDocument14 pagesOperator'S & Parts Manual Gehl Ct-Series To John Deere Adapter Hitch AssemblyBart JohnNo ratings yet

- Deh 2780 2750Document62 pagesDeh 2780 2750jcgabbiNo ratings yet

- Dehp7700mp P7750MPDocument86 pagesDehp7700mp P7750MPvoldemNo ratings yet

- Knight Reel Auggie 3060 Operators Manual PDFDocument34 pagesKnight Reel Auggie 3060 Operators Manual PDFWest BeefNo ratings yet

- External TPMS Wheely SafeDocument4 pagesExternal TPMS Wheely SafevijayNo ratings yet

- Pioneer Deh 2770Document72 pagesPioneer Deh 2770SergioNo ratings yet

- Deh 2790mp/Xn/IdDocument72 pagesDeh 2790mp/Xn/Idjpsv91No ratings yet

- Wesco Drum Cutter ManualDocument2 pagesWesco Drum Cutter ManuallukisusantoNo ratings yet

- Service Instructions For Vst-Se: 10.3 Pneumatic Actuator With Spring (To Close)Document1 pageService Instructions For Vst-Se: 10.3 Pneumatic Actuator With Spring (To Close)AhmadNo ratings yet

- Steady Rest Instruction Manual Kel VersionDocument36 pagesSteady Rest Instruction Manual Kel VersionthexsamNo ratings yet

- Dpec V3 Asm 072020Document30 pagesDpec V3 Asm 072020acevedosavi2904No ratings yet

- Pioneer DEH-P510UB 5100UB 5150UB 5190UBDocument79 pagesPioneer DEH-P510UB 5100UB 5150UB 5190UBastrid28hNo ratings yet

- Revolver Cih-14: Case Ih & NH: Operator S ManualDocument30 pagesRevolver Cih-14: Case Ih & NH: Operator S Manualalaynnastaabx786No ratings yet

- Deh P4950MP PDFDocument68 pagesDeh P4950MP PDFpasantitoNo ratings yet

- Pionner Deh 1770Document62 pagesPionner Deh 1770GlennNo ratings yet

- LCD Television Kalley Service Manual: ProductDocument42 pagesLCD Television Kalley Service Manual: Productgilberto gutierrezNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- The Situation in England in The 16th CenturyDocument8 pagesThe Situation in England in The 16th CenturyHanna HalubkovichNo ratings yet

- Iso 7790Document12 pagesIso 7790Fabio StuiNo ratings yet

- App Iii Summer Midterm ExamDocument9 pagesApp Iii Summer Midterm ExamCharmaine PamintuanNo ratings yet

- 12-08-24 Supplemental Google DisclosuresDocument10 pages12-08-24 Supplemental Google DisclosuresFlorian MuellerNo ratings yet

- Accounting Fundamentals: The Accounting Equation and The Double-Entry SystemDocument70 pagesAccounting Fundamentals: The Accounting Equation and The Double-Entry SystemAllana Mier100% (1)

- Province of North Cotabato Vs GRPDocument3 pagesProvince of North Cotabato Vs GRPKristine Martinez-Uy TiocoNo ratings yet

- A Lawyer Is Not Expected To Know All The LawDocument9 pagesA Lawyer Is Not Expected To Know All The LawAilein Grace100% (1)

- Example Software Distribution Agreement TemplateDocument11 pagesExample Software Distribution Agreement TemplateksangNo ratings yet

- GDMS Administration GuideDocument124 pagesGDMS Administration GuideMOhamedNo ratings yet

- Os Week 9Document6 pagesOs Week 9Movie explained in KannadaNo ratings yet

- A-2 ResinDocument6 pagesA-2 Resinthehighlife1080No ratings yet

- Account For Home Office and Branch Transactions. ProblemDocument2 pagesAccount For Home Office and Branch Transactions. ProblemDevine Grace A. MaghinayNo ratings yet

- Bam 208 P1 (Q2)Document6 pagesBam 208 P1 (Q2)Maria Raven Joy Espartinez ValmadridNo ratings yet

- Estrada Vs Sandiganbayan DigestDocument2 pagesEstrada Vs Sandiganbayan DigestabbyNo ratings yet

- Erradicating Impunity 12 XPVDocument316 pagesErradicating Impunity 12 XPVsofiabloemNo ratings yet

- Security Guard: Security Guard Test Preparation Guide Test Preparation GuideDocument49 pagesSecurity Guard: Security Guard Test Preparation Guide Test Preparation GuideMoinul AhsanNo ratings yet

- IRCTC Next Generation ETicketing SystemDocument3 pagesIRCTC Next Generation ETicketing SystemVictoria LambertNo ratings yet

- Annex C Checklist of Safe Management MeasuresDocument6 pagesAnnex C Checklist of Safe Management MeasuresJasonTeeNo ratings yet

- Carlyle and RuskinDocument9 pagesCarlyle and RuskinAnda NeguraNo ratings yet

- Romance V R 1987 MR 57Document4 pagesRomance V R 1987 MR 57ganesen RenghenNo ratings yet

- Leave PolicyDocument4 pagesLeave PolicySHEELA SHAHNo ratings yet

- Worry-Free Services Suites: Trend MicroDocument4 pagesWorry-Free Services Suites: Trend MicroFaisal SharifNo ratings yet

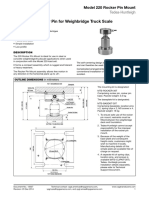

- 220 Rocket Pin MountDocument2 pages220 Rocket Pin MountEong Huat Corporation Sdn BhdNo ratings yet

- S.R. Bommai v. Union of India: CritiqueDocument4 pagesS.R. Bommai v. Union of India: Critiqueanon_913299743No ratings yet

- Broadway and Production Contract Tours: Office Receipts (80% of Minimum)Document2 pagesBroadway and Production Contract Tours: Office Receipts (80% of Minimum)Lauren BNo ratings yet

- Bi Form Cgaf-001-Rev 2Document2 pagesBi Form Cgaf-001-Rev 2Nerissa de jesus60% (5)

- G.R. No. 154130 October 1, 2003 BENITO ASTORGA, Petitioner, People of The Philippines, RespondentDocument7 pagesG.R. No. 154130 October 1, 2003 BENITO ASTORGA, Petitioner, People of The Philippines, RespondentHannah AngelesNo ratings yet

- Updated - Guidelines For Physiotherapy Service Encounter SubmissionsDocument3 pagesUpdated - Guidelines For Physiotherapy Service Encounter SubmissionsTyler Bow HudsonNo ratings yet

VSE120

VSE120

Uploaded by

ABYASARIDER AgunCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VSE120

VSE120

Uploaded by

ABYASARIDER AgunCopyright:

Available Formats

INSTRUCTIONS FOR:

TIMING BELT TENSIONER/TESTER -

UNIVERSAL

MODEL NO: VSE120

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions

and maintained properly, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Refer to Instruction

Manual

1. SAFETY

WARNING! Ensure Health and Safety, local authority and general workshop practice regulations are adhered to when using tools.

DO NOT use tools if damaged.

Maintain tools in good and clean condition for best and safest performance.

Wear approved eye protection. A full range of personal safety equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. DO NOT wear jewellery and tie back long hair.

s IMPORTANT: Always refer to the manufacturer’s service instructions, or a proprietary

manual, to establish the current procedure and data.

2. INTRODUCTION

The VSE120 Belt Tension Tester provides a simple yet effective and accurate method of testing the tension of a camshaft drive belt based on the

thickness of the belt. This universal tool will work on all timing belts up to 30mm wide.

3. OPERATION

Note: Be sure to check the manufacturers recommended belt change intervals.

The operator can assess quickly the correct camshaft drive belt tension for each individual application. There is a selection of calibration

buttons supplied for setting the unit correctly, and a belt thickness measuring gauge is supplied in the kit to select the appropriate button

to use. The belt tension is then clearly shown by the position of the tester plunger.

3.1. Calibration checking

3.1.1. Fit the number 7 button to the plunger; fit the test plate to the tester ensuring that the button sits in the indentation in the plate.

3.1 .2. The tester reading should be to the bottom edge of the lower groove (Fig 1)..

fig.1 fig.2

3.2. Checking belt tension

3.2.1. Determine the thickness of the belt using the thickness gauge, the correct slot will be determined by the lowest number that the belt will

fit into. (Fig.2)

3.2.2. Screw in the correspondingly numbered calibration button into the tester plunger.

3.2.3. Ensure that the tester plunger moves smoothly.

3.2.4. Fit the tester onto the plain side of the timing belt ensuring it is in the correct position as recommended by the vehicle manufacturer for

tension checking.

3.2.5. Note the position of the tester markings and refer to the section for tensioner readings.

© Jack Sealey Limited Original Language Version VSE120 Issue: 1- 28/06/16

3.3. Tensioner readings

3.3.1. A new belt should be tensioned so that only the top edge of the upper groove is visible. (Fig 3)

fig.3 fig.4

3.3.2. On an in-service belt the tester should show a reading between the upper and lower grooves. (Fig 4).

3.3.3. When the reading is at, or below, the lower edge of the lower groove the belt should be replaced. (Fig 5)

fig.5

Parts support is available for this product. To obtain a parts listing and/or diagram,

please log on to www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500.

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal of it according to local regulations.

NOTE: It is our policy to improve products continually and as such we reserve the right to alter data, specifications and component parts without

prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

Sole UK Distributor, Sealey Group, 01284 757500 www.sealey.co.uk

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

01284 703534 sales@sealey.co.uk

IP32 7AR

© Jack Sealey Limited Original Language Version VSE120 Issue: 1- 28/06/16

You might also like

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- Ramo de Marcio CostaDocument163 pagesRamo de Marcio CostaMarciel D'SeixsNo ratings yet

- Senr3130 14 00 AllDocument20 pagesSenr3130 14 00 AllAhmed MoustafaNo ratings yet

- Senr3130 19 00 - Manuals Service Modules - SpecificationsDocument24 pagesSenr3130 19 00 - Manuals Service Modules - Specificationsmostafa aliNo ratings yet

- Power Team HNS150 ManualDocument5 pagesPower Team HNS150 ManualTitanplyNo ratings yet

- Pioneer Deh-P6880mpDocument74 pagesPioneer Deh-P6880mpElton Peres0% (1)

- Options, Futures, and Other Derivatives, 8th Edition, 1Document25 pagesOptions, Futures, and Other Derivatives, 8th Edition, 1Anissa Nurlia KusumaningtyasNo ratings yet

- Tension Belt GaugeDocument2 pagesTension Belt GaugeDeni RamdaniNo ratings yet

- Safety Instructions: Model NoDocument2 pagesSafety Instructions: Model NoStormin DesNo ratings yet

- Air Needle Scaler SA50.V2: 1. Safety InstructionsDocument4 pagesAir Needle Scaler SA50.V2: 1. Safety InstructionsLalbin BabuNo ratings yet

- VS2005 V2 DFC30817Document2 pagesVS2005 V2 DFC30817ko koNo ratings yet

- Valve Collet Remover / Installer: 1. SafetyDocument2 pagesValve Collet Remover / Installer: 1. SafetyZamriNo ratings yet

- Manual VREL Valve - Sentry PDFDocument12 pagesManual VREL Valve - Sentry PDFMarcoGomesNo ratings yet

- VS2059Document2 pagesVS2059ko koNo ratings yet

- 2984 - maverick - hr - plus - rev - n еттерDocument56 pages2984 - maverick - hr - plus - rev - n еттерpeterbirtatNo ratings yet

- Sealey SMS2008Document3 pagesSealey SMS2008cabuloNo ratings yet

- High Pressure Fuel Pump Remover/ Installer - Ford 2.0D EcoblueDocument2 pagesHigh Pressure Fuel Pump Remover/ Installer - Ford 2.0D EcoblueFacundo Guzman MacedoNo ratings yet

- Catalytic Converter and Exhaust Back PressureDocument2 pagesCatalytic Converter and Exhaust Back PressureeiochoaNo ratings yet

- Exm3000 V9 Asm 072020Document18 pagesExm3000 V9 Asm 072020Arthur UchoaNo ratings yet

- Comprecion Del MotorDocument2 pagesComprecion Del Motoralex martinez coroNo ratings yet

- Vse952 DFC0166998Document2 pagesVse952 DFC0166998ابوفاطمةاليساريNo ratings yet

- CT Series Telescopic Handler Bucket Operators Parts Manual 76266rev3Document21 pagesCT Series Telescopic Handler Bucket Operators Parts Manual 76266rev3Marek WyszatyckiNo ratings yet

- Pioneer Deh-2050mp MPG SM (ET) PDFDocument60 pagesPioneer Deh-2050mp MPG SM (ET) PDFSergioNo ratings yet

- CHT Intallation ManualDocument22 pagesCHT Intallation ManualSAPTONo ratings yet

- E Stop For ParkerDocument18 pagesE Stop For ParkerpchizumilaNo ratings yet

- CRT3597 Deh-30mpDocument70 pagesCRT3597 Deh-30mpjohn.snow8786No ratings yet

- Pioneer Deh-P3000ib SMDocument68 pagesPioneer Deh-P3000ib SMrudineimarafonNo ratings yet

- Pin Brazing Gun - Electrobraze ZE7000Document16 pagesPin Brazing Gun - Electrobraze ZE7000GlennSymingtonNo ratings yet

- Pioneer Deh-P5750mp Service ManualDocument78 pagesPioneer Deh-P5750mp Service Manualinderbrar100% (2)

- CT Series Telescopic Handler Fork Carriage Operators Parts Manual 76265Document21 pagesCT Series Telescopic Handler Fork Carriage Operators Parts Manual 76265Marek WyszatyckiNo ratings yet

- GM 7200MDocument40 pagesGM 7200MFredy FigueroaNo ratings yet

- Bostitch Stick Framing NailerDocument40 pagesBostitch Stick Framing NailerRod ScottNo ratings yet

- Q&M GeneralDocument0 pagesQ&M GeneralPhu NguyenNo ratings yet

- DODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualDocument4 pagesDODGE SAF-XT & SAFS Pillow Blocks: Instruction ManualALFONSO FERNANDEZ MULETNo ratings yet

- Pioneer Deh-P4850mp p4850mphDocument76 pagesPioneer Deh-P4850mp p4850mphVxr GsiNo ratings yet

- Cylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. SafetyDocument2 pagesCylinder Leakage Tester 2 - Gauge Vse2020.V3: 1. Safetyhotmaail4No ratings yet

- VSE5640 Instructions 20190815 1 - DFC0251429Document3 pagesVSE5640 Instructions 20190815 1 - DFC0251429Алексей ЖидкевичNo ratings yet

- FM-300H FM-300HR: Electronic Disc Meter Owner's ManualDocument16 pagesFM-300H FM-300HR: Electronic Disc Meter Owner's ManualRichard FloresNo ratings yet

- Pioneer Deh-3700mp, Deh-3730mp Service ManualDocument68 pagesPioneer Deh-3700mp, Deh-3730mp Service ManualOssian Valera PinedaNo ratings yet

- Stiffness Tester A 45 Grados PDFDocument7 pagesStiffness Tester A 45 Grados PDFramonNo ratings yet

- Brother 882U73 Sewing Machine Instruction ManualDocument204 pagesBrother 882U73 Sewing Machine Instruction ManualiliiexpugnansNo ratings yet

- MR 5-30 or MR 5-30N Series Fuel Meter Owner's ManualDocument8 pagesMR 5-30 or MR 5-30N Series Fuel Meter Owner's ManualTuấn VũNo ratings yet

- Operator'S & Parts Manual Gehl Ct-Series To John Deere Adapter Hitch AssemblyDocument14 pagesOperator'S & Parts Manual Gehl Ct-Series To John Deere Adapter Hitch AssemblyBart JohnNo ratings yet

- Deh 2780 2750Document62 pagesDeh 2780 2750jcgabbiNo ratings yet

- Dehp7700mp P7750MPDocument86 pagesDehp7700mp P7750MPvoldemNo ratings yet

- Knight Reel Auggie 3060 Operators Manual PDFDocument34 pagesKnight Reel Auggie 3060 Operators Manual PDFWest BeefNo ratings yet

- External TPMS Wheely SafeDocument4 pagesExternal TPMS Wheely SafevijayNo ratings yet

- Pioneer Deh 2770Document72 pagesPioneer Deh 2770SergioNo ratings yet

- Deh 2790mp/Xn/IdDocument72 pagesDeh 2790mp/Xn/Idjpsv91No ratings yet

- Wesco Drum Cutter ManualDocument2 pagesWesco Drum Cutter ManuallukisusantoNo ratings yet

- Service Instructions For Vst-Se: 10.3 Pneumatic Actuator With Spring (To Close)Document1 pageService Instructions For Vst-Se: 10.3 Pneumatic Actuator With Spring (To Close)AhmadNo ratings yet

- Steady Rest Instruction Manual Kel VersionDocument36 pagesSteady Rest Instruction Manual Kel VersionthexsamNo ratings yet

- Dpec V3 Asm 072020Document30 pagesDpec V3 Asm 072020acevedosavi2904No ratings yet

- Pioneer DEH-P510UB 5100UB 5150UB 5190UBDocument79 pagesPioneer DEH-P510UB 5100UB 5150UB 5190UBastrid28hNo ratings yet

- Revolver Cih-14: Case Ih & NH: Operator S ManualDocument30 pagesRevolver Cih-14: Case Ih & NH: Operator S Manualalaynnastaabx786No ratings yet

- Deh P4950MP PDFDocument68 pagesDeh P4950MP PDFpasantitoNo ratings yet

- Pionner Deh 1770Document62 pagesPionner Deh 1770GlennNo ratings yet

- LCD Television Kalley Service Manual: ProductDocument42 pagesLCD Television Kalley Service Manual: Productgilberto gutierrezNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- The Situation in England in The 16th CenturyDocument8 pagesThe Situation in England in The 16th CenturyHanna HalubkovichNo ratings yet

- Iso 7790Document12 pagesIso 7790Fabio StuiNo ratings yet

- App Iii Summer Midterm ExamDocument9 pagesApp Iii Summer Midterm ExamCharmaine PamintuanNo ratings yet

- 12-08-24 Supplemental Google DisclosuresDocument10 pages12-08-24 Supplemental Google DisclosuresFlorian MuellerNo ratings yet

- Accounting Fundamentals: The Accounting Equation and The Double-Entry SystemDocument70 pagesAccounting Fundamentals: The Accounting Equation and The Double-Entry SystemAllana Mier100% (1)

- Province of North Cotabato Vs GRPDocument3 pagesProvince of North Cotabato Vs GRPKristine Martinez-Uy TiocoNo ratings yet

- A Lawyer Is Not Expected To Know All The LawDocument9 pagesA Lawyer Is Not Expected To Know All The LawAilein Grace100% (1)

- Example Software Distribution Agreement TemplateDocument11 pagesExample Software Distribution Agreement TemplateksangNo ratings yet

- GDMS Administration GuideDocument124 pagesGDMS Administration GuideMOhamedNo ratings yet

- Os Week 9Document6 pagesOs Week 9Movie explained in KannadaNo ratings yet

- A-2 ResinDocument6 pagesA-2 Resinthehighlife1080No ratings yet

- Account For Home Office and Branch Transactions. ProblemDocument2 pagesAccount For Home Office and Branch Transactions. ProblemDevine Grace A. MaghinayNo ratings yet

- Bam 208 P1 (Q2)Document6 pagesBam 208 P1 (Q2)Maria Raven Joy Espartinez ValmadridNo ratings yet

- Estrada Vs Sandiganbayan DigestDocument2 pagesEstrada Vs Sandiganbayan DigestabbyNo ratings yet

- Erradicating Impunity 12 XPVDocument316 pagesErradicating Impunity 12 XPVsofiabloemNo ratings yet

- Security Guard: Security Guard Test Preparation Guide Test Preparation GuideDocument49 pagesSecurity Guard: Security Guard Test Preparation Guide Test Preparation GuideMoinul AhsanNo ratings yet

- IRCTC Next Generation ETicketing SystemDocument3 pagesIRCTC Next Generation ETicketing SystemVictoria LambertNo ratings yet

- Annex C Checklist of Safe Management MeasuresDocument6 pagesAnnex C Checklist of Safe Management MeasuresJasonTeeNo ratings yet

- Carlyle and RuskinDocument9 pagesCarlyle and RuskinAnda NeguraNo ratings yet

- Romance V R 1987 MR 57Document4 pagesRomance V R 1987 MR 57ganesen RenghenNo ratings yet

- Leave PolicyDocument4 pagesLeave PolicySHEELA SHAHNo ratings yet

- Worry-Free Services Suites: Trend MicroDocument4 pagesWorry-Free Services Suites: Trend MicroFaisal SharifNo ratings yet

- 220 Rocket Pin MountDocument2 pages220 Rocket Pin MountEong Huat Corporation Sdn BhdNo ratings yet

- S.R. Bommai v. Union of India: CritiqueDocument4 pagesS.R. Bommai v. Union of India: Critiqueanon_913299743No ratings yet

- Broadway and Production Contract Tours: Office Receipts (80% of Minimum)Document2 pagesBroadway and Production Contract Tours: Office Receipts (80% of Minimum)Lauren BNo ratings yet

- Bi Form Cgaf-001-Rev 2Document2 pagesBi Form Cgaf-001-Rev 2Nerissa de jesus60% (5)

- G.R. No. 154130 October 1, 2003 BENITO ASTORGA, Petitioner, People of The Philippines, RespondentDocument7 pagesG.R. No. 154130 October 1, 2003 BENITO ASTORGA, Petitioner, People of The Philippines, RespondentHannah AngelesNo ratings yet

- Updated - Guidelines For Physiotherapy Service Encounter SubmissionsDocument3 pagesUpdated - Guidelines For Physiotherapy Service Encounter SubmissionsTyler Bow HudsonNo ratings yet