Professional Documents

Culture Documents

Ashish Ramesh Kelkar: (Associate Member Imeche)

Ashish Ramesh Kelkar: (Associate Member Imeche)

Uploaded by

Kelkar AshishOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashish Ramesh Kelkar: (Associate Member Imeche)

Ashish Ramesh Kelkar: (Associate Member Imeche)

Uploaded by

Kelkar AshishCopyright:

Available Formats

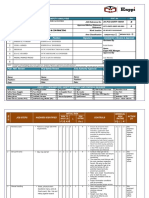

Ashish Ramesh Kelkar (Associate Member IMechE)

14/6, A-6, Shubharambh Soc., Anand Nagar, Sinhgad Road, India 411051.

Phone - +919764066363 Email - ashishrkelkar@gmail.com,

Skype ID: live:792f6f32cfebaf0e

LinkedIn - https://www.linkedin.com/in/ashish-kelkar-9b661898/

Nationality - Indian

Personal Statement

A mechanical engineering graduate with 2:1 honours degree from the University of Teesside, UK. As a

Process Safety Engineer, I offer a track record of success in planning and executing safety engineering

processes and projects for complex assignments for the oil and gas corporations and manufacturing

operations. Throughout my career, I have developed and adopted the best analysis tools for documenting

and addressing risk while ensuring compliance to strict contract terms and federal, state, and industry

regulations.

Education

July 2018 B.Eng. Tech Hons Mechanical Engineering, Teesside University (Grade 2.1)

Modules Applied Mechanics

Computer Aided Design Analysis

Product Quality and Reliability

Employment Skills

Group Design and Manufacturing (Mini-Hovercraft)

Dissertation Project (CFD Analysis on NACA 0012 Airfoil)

June 2014 Diploma in Production Engineering, Bharati Vidyapeeth University, Pune. “First

Class”

Modules Manufacturing Process Mechanics

Engineering Design Advance Manufacturing

Quality and Reliability Strength of Material

Theory of Machines Tool Design

Design and manufacturing project CAD, FEM

– Pipe bending machine using

screw jack.

Experience

Process Safety Engineering Consultant (September 2018 – Present)

Organisation: Salvus Engineering Pvt. Ltd.

Work Brief: It is a consultancy company dealing with Oil and Gas Industry. It provides process

safety, HSE Management, Risk Management etc. studies to Petroleum companies globally.

Responsibilities: Leading Project team and performed following roles for HAZOP, generating results

from software’s, P&Id reading and node marking, Report writing, Data collection

(geographical as well as materialistic) Preparing Input Data Sheet, checking the compliance

to international standards like (OGP, AIP or UK-HSE) etc. Also involved in Tendering and

budgeting for projects as well as looks after the business development.

Risk Engineer (September 2015-Aug 2017)

Organisation: Salvus Engineering Pvt. Ltd.

Work Brief: It is a consultancy company dealing with Oil and Gas Industry. It provides process

safety, HSE Management, Risk Management etc. studies to Petroleum companies globally.

Responsibilities: Conduct and prepare the following studies, HAZOP, generating results from

software’s, P&Id reading and node marking, Report writing, Data collection (geographical as

well as materialistic) Preparing Input Data Sheet, checking the compliance to international

standards like (OGP, AIP or UK-HSE) etc.

1 Hazard and Operability Study (HAZOP) Scribe

2 Fire and Gas Detector 3D Mapping

3 Quantitative Risk Assessment (QRA)

4 Semi Quantitative and Qualitative Risk Assessment

5 Preparing Emergency Response Disaster Management Plan (ERDMP) as per PNGRB

Regulations 2010

6 Escape Evacuation and Rescue Analysis (EERA)

7 Safety Reports as per MHISCH Rules

Production Technician (July 2014 – July 2015)

Organisation: Sandvik Asia Ltd.

Work Brief: It is a Sweden based tool manufacturing company which has a production unit in

Pune, India.

Responsibilities: Worked in Insert grinding department where main responsibilities is to check the

product quality and production process.

Trainee Maintenance Technician (June 2009 – May 2011)

Organisation: Excellent Maintenance Works, India

Work Brief: It is a India based machine maintenance company which has a unit in Pune, India.

Responsibilities: Assisted in following machine maintenance works –

1. 17 ft lathe machine

2. Cylindrical Grinding

3. Surface Grindings

4. Boring Machine.

Projects Executed

SN Refinery Projects Company

1 QRA of Crude Distillation Unit –II of Haldia Refinery to

assess control room location and new modifications IOCL Haldia Refinery

GAP Analysis for CDU-II Block Control Room of Bharat Bharat Petroleum Corporation

2

Petroleum Corporation Limited Kochi Refinery Limited, Kochi Refinery

Bharat Petroleum Corporation

3 ERDMP of Kochi Refinery

Limited, Kochi

4 ERDMP of MRPL Refinery, SPM, Jetty and Pipelines ONGC MRPL, Mangalore

5 ERDMP of OMPL Aromatic complex and associated pipelines OMPL, Mangalore

ERDMP of Bharat Petroleum Corporation Limited, Mumbai Bharat Petroleum Corporation

6

Refinery Limited, Mumbai

SN Pipeline Projects Company

Quantitative Risk Assessment (QRA) and HAZOP of Mumbai – Hindustan Petroleum Corporation

7

Pune – Solapur (More than 500km) multiproduct white oil pipeline Ltd.

SN Pipeline Projects Company

Quantitative Risk Assessment (QRA) of Cross Country Pipelines ONGC – Mangalore

8

running between OMPL and MRPL through MSEZ corridor. Petrochemicals Ltd. (OMPL)

QRA and HAZOP of Lube Oil pipeline from Mumbai Refinery to Hindustan Petroleum Corporation

9

Sewree Ltd.

QRA and HAZOP of Black oil pipeline from Trombay to Vashi at Hindustan Petroleum Corporation

10 Mumbai Ltd.

QRA for cross-country Pipelines from Kochi Jetty to BPCL KR Bharat Petroleum Corporation Lts,

11

carrying MS, HSD, VGO, Crude, Naptha etc. Kochi Refinery

SN Terminal Projects Company

12 SIMOP study, Review of Risk Managemenet Policy, Revire MAFFFL

of QRA of Mumbai Aviation Fuel Farm Facility terminal

Hindustan Petroleum Corporation

13 HAZOP, QRA and ERDMP of Sewree-I Terminal Ltd.

Hindustan Petroleum Corporation

14 HAZOP, QRA and ERDMP of Sewree-II Terminal Ltd.

HAZOP and QRA of Sewree-II (after modifications) and Hindustan Petroleum Corporation

15 Ltd.

Wadala-I Terminal for PESO submissions

Hindustan Petroleum Corporation

16 HAZOP, QRA and ERDMP of Solapur IRD Terminal, Pakni Ltd.

Bharat Petroleum Corporation

17 Hazardous Area Classification of POL depot at Miraj, Maharahstra

Limited

18 HAZOP, QRA and ERDMP for Reliance Kolkata Aviation Terminal Reliance Industries Limited

19 HAZOP, QRA and ERDMP for Reliance Surat Aviation Terminal Reliance Industries Limited

HAZOP, QRA and ERDMP for Reliance Jamnagar Aviation

20 Terminal

Reliance Industries Limited

Bharat Petroleum Corporation

21 Safety Report Mangalia Depot, Indore, MP

Limited

Bharat Petroleum Corporation

22 Safety Report Rairu Depot, Gwalior, MP

Limited

Bharat Petroleum Corporation

23 Preparation of ERDMP for BPCL Miraj POL Depot

Limited

SN LNG, CNG, LPG Projects Company

Escape Evacuation and Rescue Analysis (EERA) of LNG Jetty,

24 LNG Regasification Terminal and LPG Terminal of Adani Gas at RINA India

Dhamra Port, Odisha

Fire and Gas Detection 3D Mapping study of PRMS Skid of Shell

25 Enteprose, Nigeria

Nigeria at Ota, Agbara, Nigeria

HAZOP of entire City Gas Distribution (CGD) network in Mathura

26 city and surroundings.

Sanwariya Gas Ltd., Mathura, UP

HAZOP and QRA of Mother CGS Station at Talegaon Dabhade,

Three (3) Daughter Booster Stations (DBS) co-located in petrol

27 Mahesh Gas Ltd (Torrent)

stations, 100 km Steel Pipeline and 30km MDPE Pipeline Network

in Pune

Quantitative Risk Analysis (QRA) and HAZOP studies of proposed

28 LNG regasification plant, LNG and CNG Dispensing Stations at Ecotainer LNG Pvt Ltd

Chennai

QRA and HAZOP of LNG facilities of SMIORE at Hospet,

29 Beerens Gas Limited

Karnataka

30 BPCL-KR to IOCL-BP LPG Pipeline and Terminals KSPPL, Kochi

31 HAZOP of Natural Gas Network in Ranjangaon MIDC Mahesh Gas Ltd (Torrent)

32 HAZOP of Natural Gas Network in Talegaon MIDC Mahesh Gas Ltd (Torrent)

SN LNG, CNG, LPG Projects Company

33 QRA, HAZOP and ERDMP of West Godavari District CNG Godavari Gas Pvt Ltd., (APGDCL)

gas Distribution and associated Stations

34 QRA, HAZOP and ERDMP of East Godavari District CNG Godavari Gas Pvt Ltd., (APGDCL)

gas Distribution and associated Stations

Preparation of ERDMP (Emergency Response Disaster

35 Management Plan) for Aegis Mahul LPG Terminal

Aegis Logistics Limited

Additional Information

Technical • Process Safety Management Training from Salvus

• TUV SUD certified Lean Six Sigma Green Belt

Quality Management, Quality Assurance

8D Problem Solving, Lean Manufacturing

Failure Mode and Effects Analysis (FMEA)

Statistical Process Control

• NEBOSH International General Certificate in OH&S (Pursuing)

• Excellent knowledge of Microsoft – Office

• Software’s known:

1. PHA-Pro

2. Auto CAD

3. Catia V5

4. Solidwork

5. Siemens NX

6. Detect 3D (Fire and gas mapping software)

7. Ansys 18.1 – Fluid Fluent (Computational Fluid Dynamics)

• Report Writing

• Good Communication Skills

Personal • Member of Billingham Cricket Club in NYSD League

• Team member of Teesside university Cricket Club

• Represented college in inter college Cricket .

• Coordinator in college festival named as “Techno Evolution” (organized by Bharati

Vidyapeeth University)

• Attended two years in NCC (National Cadet Corpe) Defence Training in School

Awarded as Best Sargent of the year

References

• Mrs. Gayatri (HSE Manager/ Director)

Salvus Engineering India Pvt Ltd

+91-8390070000

gayati@salvusindia.com

• Mrs. Ashwini Vaidya (DGM Quality)

Sandvik Asia Ltd.

+91-9767107350

ashwini.vaidya@sandvik.com

You might also like

- English Translation of A Birth Certificate From Honduras PDFDocument1 pageEnglish Translation of A Birth Certificate From Honduras PDFDulce m vazquez67% (6)

- Goshe Corporation - EditedDocument3 pagesGoshe Corporation - EditedNasir HussainNo ratings yet

- Pre-Lab: 1Dph BBBBBBBBBBBBBBBBBBBBBBBBBB ,' BBBBBBBBBBBBBB /de 6Hfwlrq BBBBBBBDocument2 pagesPre-Lab: 1Dph BBBBBBBBBBBBBBBBBBBBBBBBBB ,' BBBBBBBBBBBBBB /de 6Hfwlrq BBBBBBBAhnafHabibKhanNo ratings yet

- O.safety Engineer Mohammed MoinuddinDocument3 pagesO.safety Engineer Mohammed MoinuddinMohammed MoinuddinNo ratings yet

- Resume: Name: Akshay Narendra Potdar Email: Mobile No.Document3 pagesResume: Name: Akshay Narendra Potdar Email: Mobile No.Akshay PotdarNo ratings yet

- Curriculum Vitae: Dharmendra Kumar NishadDocument3 pagesCurriculum Vitae: Dharmendra Kumar NishadUrmila RajanNo ratings yet

- Chirag Barad-EHSDocument4 pagesChirag Barad-EHSChirag BaradNo ratings yet

- OLAYINKA A A (Safety Officer With 8 Years Experience) 30500570Document4 pagesOLAYINKA A A (Safety Officer With 8 Years Experience) 30500570emmyNo ratings yet

- A J I S H S A S I K U M A R M I I R S M M R S P HDocument5 pagesA J I S H S A S I K U M A R M I I R S M M R S P HRichu PaliNo ratings yet

- HSE Trainer Profile-Devisen, 05.09,23Document3 pagesHSE Trainer Profile-Devisen, 05.09,23pusatlatihanstemnknNo ratings yet

- Alison Transcript 1412 10003199Document2 pagesAlison Transcript 1412 10003199vseem zahirNo ratings yet

- 0 Nagendra Singh Resume PDFDocument5 pages0 Nagendra Singh Resume PDFSingh NagendraNo ratings yet

- Wa0001Document5 pagesWa0001Manda Khel Apna DesNo ratings yet

- GrivanceDocument108 pagesGrivanceAshwani kumarNo ratings yet

- AbhijitBarik (12 0)Document3 pagesAbhijitBarik (12 0)SAMSON GLOBALNo ratings yet

- Updated-list-NOC-Issued HECDocument88 pagesUpdated-list-NOC-Issued HECWorld WideNo ratings yet

- Akhil Nair: Profile Summary Key SkillsDocument3 pagesAkhil Nair: Profile Summary Key SkillsSarabjitNo ratings yet

- Victor Scaffolding Supervisor CVDocument12 pagesVictor Scaffolding Supervisor CVvictor joeNo ratings yet

- Curriculum-Vitae: Hse Officer Current Address Permanent Address E-Mail / MobileDocument4 pagesCurriculum-Vitae: Hse Officer Current Address Permanent Address E-Mail / MobilePositivesolutionNo ratings yet

- Safety CDocument3 pagesSafety CjoseNo ratings yet

- Safety Officer CVDocument5 pagesSafety Officer CVSALOME ILOABUCHINo ratings yet

- YasirRehman HSEDocument2 pagesYasirRehman HSEBilal MasoodNo ratings yet

- Abrar Hse OfficerDocument4 pagesAbrar Hse OfficerW AlamNo ratings yet

- Human Machine InterfaceDocument10 pagesHuman Machine Interfacesushma29nNo ratings yet

- Internship ReportDocument21 pagesInternship ReportmughalsairaNo ratings yet

- Abdul Wahab Shakir-CVDocument2 pagesAbdul Wahab Shakir-CVSaif Ur RehmanNo ratings yet

- Arey Aravind Sainath Reddy: Mobile No: 9985540840 / 9966336604 E MailDocument3 pagesArey Aravind Sainath Reddy: Mobile No: 9985540840 / 9966336604 E MailRaghu SravNo ratings yet

- Application For Industrial Training (Diploma in Occupational Safety & Health, City University (City U) )Document3 pagesApplication For Industrial Training (Diploma in Occupational Safety & Health, City University (City U) )afiqzaNo ratings yet

- Sub: Application For The Post Of:: Safety Officer/Inspector /coordinatorDocument5 pagesSub: Application For The Post Of:: Safety Officer/Inspector /coordinatorArchana SinghNo ratings yet

- CVDocument2 pagesCVgkNo ratings yet

- Vill - Babhanauli, Po - Vijaypur, Dist - Gopalganj (Bihar) E-Mail: Cell No.: +91 9963477489, +91 9652352093Document2 pagesVill - Babhanauli, Po - Vijaypur, Dist - Gopalganj (Bihar) E-Mail: Cell No.: +91 9963477489, +91 9652352093Vayu Puthra0% (1)

- Project Report On Hse Management and HazDocument104 pagesProject Report On Hse Management and HazHarsha sriNo ratings yet

- Curriculum Vitae: Subject: Auto Electrician TechnicianDocument2 pagesCurriculum Vitae: Subject: Auto Electrician Technicianbalwinder Singh100% (1)

- 1 Hse Management ResponsibilityDocument13 pages1 Hse Management ResponsibilityRATAN BHATIANo ratings yet

- Curriculum Vitae Vankayala Gopi KrishnaDocument4 pagesCurriculum Vitae Vankayala Gopi Krishnajaya sekhar PhillipNo ratings yet

- Safety Statistics Audit ObservationsDocument2 pagesSafety Statistics Audit ObservationsSHAH NAWAZ SAEEDNo ratings yet

- WWW - Mgli.gujarat - Gov.in: (An Autonomous Institute of The Govt. of Gujarat)Document1 pageWWW - Mgli.gujarat - Gov.in: (An Autonomous Institute of The Govt. of Gujarat)feafvaevsNo ratings yet

- Senior Safety EngineerDocument2 pagesSenior Safety EngineerFakhrul FirdausNo ratings yet

- Sudheer CVDocument2 pagesSudheer CVsri pragnaNo ratings yet

- 6g Tig and Arc WelderDocument30 pages6g Tig and Arc WeldertrdybrnqxjNo ratings yet

- CV - Ashwini Kumar Kushwaha - Safety EngineerDocument3 pagesCV - Ashwini Kumar Kushwaha - Safety EngineerChiranjibi BiswalNo ratings yet

- CINCO - Safety PlanDocument113 pagesCINCO - Safety PlanAli Akbar100% (1)

- 00 - Petrobel IMS Overview FinalDocument52 pages00 - Petrobel IMS Overview FinalAhmed El AmraniNo ratings yet

- NSDC - PROFESSIONAL PROGRAMME CERTIFICATE IN FIRE AND INDUSTRIAL SAFETY MANAGEMENT SyllabusDocument26 pagesNSDC - PROFESSIONAL PROGRAMME CERTIFICATE IN FIRE AND INDUSTRIAL SAFETY MANAGEMENT Syllabusbasant26No ratings yet

- CV Waseem HSE Manager 1 2023 UpdatedDocument4 pagesCV Waseem HSE Manager 1 2023 UpdatedAhmed Ali KhanNo ratings yet

- Proximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)Document1 pageProximity Warning Alarm System - PWAS Daily Checklist: Hawiyah Unayzah Gas Reservoir Storage Project (HUGRS)RabbanNo ratings yet

- Qaqc E&i Engineer - AzmatDocument3 pagesQaqc E&i Engineer - AzmatManda Khel Apna DesNo ratings yet

- Qatar Engineering and Construction Company WLLDocument12 pagesQatar Engineering and Construction Company WLLboen jaymeNo ratings yet

- Project Repot SafetyDocument164 pagesProject Repot SafetyShubham SenNo ratings yet

- Minutes of MeetingDocument4 pagesMinutes of Meetingsiti nur fatihahNo ratings yet

- Zubair HSE Position - 2024Document6 pagesZubair HSE Position - 2024Saqib JavedNo ratings yet

- Nabeel Najam HSE (CV)Document3 pagesNabeel Najam HSE (CV)Adil BashirNo ratings yet

- TOKICO - Presentation of Fuel DispenserDocument45 pagesTOKICO - Presentation of Fuel DispenserbangladetNo ratings yet

- Stevan Damjanovic - Master of Civil Engineering. Licence 412Document3 pagesStevan Damjanovic - Master of Civil Engineering. Licence 412Lazar AndonovNo ratings yet

- Attachment 7 Scaffolding PermitDocument2 pagesAttachment 7 Scaffolding PermitAviects Avie JaroNo ratings yet

- Demolition of Hvac System - Isd Security Building #07Document12 pagesDemolition of Hvac System - Isd Security Building #07Izaaz AhamedNo ratings yet

- Muhammad Nouman Aleem - Program - 30GDocument1 pageMuhammad Nouman Aleem - Program - 30GJesmin AkterNo ratings yet

- Muhammad Azeem Sarwar: Safety EngineerDocument5 pagesMuhammad Azeem Sarwar: Safety EngineerHareekirishnan LrkNo ratings yet

- Post Applied For: HSE/Safety Engineer: Kamal AhmadDocument3 pagesPost Applied For: HSE/Safety Engineer: Kamal Ahmadsudeesh kumarNo ratings yet

- Team Leader (Process and Functional Safety) : CO / May. 19Document6 pagesTeam Leader (Process and Functional Safety) : CO / May. 19sathish kumarNo ratings yet

- Eddy Current Testing Equipment Scope in IndiaDocument19 pagesEddy Current Testing Equipment Scope in IndiaDanielNo ratings yet

- CEPL Company ProfileDocument8 pagesCEPL Company ProfileAjay SatputeNo ratings yet

- Read 2Document15 pagesRead 2Tran Ngo Tra My (FGW DN)No ratings yet

- 2B3.1. Robbery, FSG 2B3.1Document4 pages2B3.1. Robbery, FSG 2B3.1RichardNo ratings yet

- Industrial Safety and Health Management 6th Edition Asfahl Test BankDocument9 pagesIndustrial Safety and Health Management 6th Edition Asfahl Test Bankfelicityto1jbn100% (27)

- Pumps Request LetterDocument1 pagePumps Request LetterJazz SicatNo ratings yet

- Archies LTD Imc Assignment: Group No 04, IMC - BDocument6 pagesArchies LTD Imc Assignment: Group No 04, IMC - BNirmal KumarNo ratings yet

- Maruti PresentationDocument3 pagesMaruti PresentationBiswadeep GogoiNo ratings yet

- Goat Production HandbookDocument100 pagesGoat Production HandbookAdrianNo ratings yet

- By Rick Conlow: 7 Lessons For Team MasteryDocument37 pagesBy Rick Conlow: 7 Lessons For Team MasteryYemi AdetayoNo ratings yet

- Pa2 Class 11 Commerce Blue Print PDFDocument1 pagePa2 Class 11 Commerce Blue Print PDFKash Ghuman tvNo ratings yet

- Entrainment Losses in Barometric TowersDocument5 pagesEntrainment Losses in Barometric TowersGeorge Isaac McQuilesNo ratings yet

- Duterte Term Ender and Marcos JR 6mosDocument156 pagesDuterte Term Ender and Marcos JR 6mosMarlon LesterNo ratings yet

- Magnum PDFDocument11 pagesMagnum PDFHarman Bhullar100% (1)

- Laudon Traver Ec16 PPT Ch09 Accessible 26022023 080617pmDocument49 pagesLaudon Traver Ec16 PPT Ch09 Accessible 26022023 080617pmGreson JamesNo ratings yet

- (Cambridge Iberian and Latin American Studies) A. C. de C. M. Saunders - A Social History of Black Slaves and Freedmen in Portugal, 1441-1555-Cambridge University Press (1982)Document304 pages(Cambridge Iberian and Latin American Studies) A. C. de C. M. Saunders - A Social History of Black Slaves and Freedmen in Portugal, 1441-1555-Cambridge University Press (1982)MagdalenaNo ratings yet

- Mitac 8066mpDocument154 pagesMitac 8066mpcosminconstantinNo ratings yet

- Identification and Prediction of Piping System NoiseDocument7 pagesIdentification and Prediction of Piping System NoisejjirwinNo ratings yet

- Team Manager Appraisal Sample DocumentDocument14 pagesTeam Manager Appraisal Sample DocumentVeeNo ratings yet

- Concrete Discharge Time (ASCC)Document1 pageConcrete Discharge Time (ASCC)V. ManilalNo ratings yet

- Vesda Laser Focus 250Document2 pagesVesda Laser Focus 250WERMERMNo ratings yet

- Wahab PTDU Lab 6Document5 pagesWahab PTDU Lab 6Ali ArshadNo ratings yet

- 2009 JulyDocument17 pages2009 JulyLingua ItalianaNo ratings yet

- City of Baguio Vs MarcosDocument12 pagesCity of Baguio Vs MarcosPam MiraflorNo ratings yet

- United States v. Colonial Motor Inn, Inc., and Maurice Shear, 440 F.2d 1227, 1st Cir. (1971)Document3 pagesUnited States v. Colonial Motor Inn, Inc., and Maurice Shear, 440 F.2d 1227, 1st Cir. (1971)Scribd Government DocsNo ratings yet

- InventorymanualDocument133 pagesInventorymanualArti MongaNo ratings yet

- SAN Troubleshooting PDFDocument510 pagesSAN Troubleshooting PDFSanjay DeyNo ratings yet

- Data Quality Symp, June 2008, Sun City - Natie VenterDocument26 pagesData Quality Symp, June 2008, Sun City - Natie VenterpetercheNo ratings yet

- ENS 10.5 InstallationDocument67 pagesENS 10.5 InstallationSecret SantaNo ratings yet

- Social MediaDocument1 pageSocial MediaReham Al-EkhtiarNo ratings yet