Professional Documents

Culture Documents

Sop For Ta Compressor

Sop For Ta Compressor

Uploaded by

SonratOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sop For Ta Compressor

Sop For Ta Compressor

Uploaded by

SonratCopyright:

Available Formats

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 7

STANDARD OPERATING PROCEDURE

FOR

TRANSPORT AIR

COMPRESSORS

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 7

STANDARD OPERATING PROCEDURE FOR AIRCOMPRESSOR

OBJECTIVE: For Smooth Operation of Air Compressor.

SCOPE: This SOP is applicable for 24 nos. of Air Compressor.

INTRODUCTION: This Compressor is needed to evacuate fly ash from buffer hopper to fly ash silo

thru positive air pressure, this system called as fly ash pressure conveying system.

PRE CHECKS:

AIR COMPRESSOR TECHNICAL DATA:-

Make Bolaite Shanghai Quantity 24 sets

Type Model: BLT-475W/8 Outlet air quantity 69 m³/m

TYPE 1616 7066 82

Air pressure 0.75MPa Rotating speed 1485r/min

Sealing fan’s motor

Type Y2-HV450-4 Power 355kW

Voltage 415V Current A

Rotating speed 1485r/min

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 7

AIR DRYER TECHNICAL DATA:-

Make HANGZHOU SHANLI Quantity 24 sets

PURIFY EQUIPMENT

CO., LTD.

Type Outlet air quantity 69 m³/m

Air pressure 0.75MPa Rotating speed 1485r/min

Sealing fan’s motor

Type Y2-HV450-4 Power 355kW

Voltage 415V Current A

Rotating speed 1485r/min

RESPONSIBILITY: Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

1. Ensure no permit to work is pending on regarding this system by checking with EE/MRSE.

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

PRECHECKS AND ACTION BY FIELD ENGINEER

S No Description Ok Not Ok Remarks

1 All permits and cross permits have been returned.

2 Area is clear of any other materials.

3 Check coupling guard is not touching with coupling.

4 Check the I/L damper open - close operation

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 7

i) Open the I/L damper operate normally

i i) Check open limit shown on DCS

iii) Close the I/L damper operate normally

i v) Check Close limit shown on DCS

5 Casing Windows Should be Close

6 Close the Discharge Damper

7 Check the I/L damper is close

8 Check fan is not rotate in reverse direction

PRECHECKS AND ACTION BY DESK ENGINEER

S No Description Ok Not Ok Remarks

1 Check open limit of I/L &O/L damper comes on DCS

2 Check close limit of I/L &O/L damper comes on DCS

3 Check I/L damper is close

Check coal mill’s seal air inlet motor- operated valve is

4 closed.

5 Check fan is permissible to start

Check the Brg temperature of motor & fan on DCS are

6 normal

OPERATING PROCEDURE -

Sr. Description RESPONSIBILITY

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 7

No. UCE DE FE EE

PRE- START CHECKS:

1 All permits and cross permits have been returned. √ √ √ √

2 Power supply and control power supply available. √ √

3 Sealing fan’s bearing temperature is in permissible limit. √ √

4 At least one primary air fan is running √ √

5 The sealing fan’s inlet regulating damper is closed. √ √

6 The coal mill’s seal air inlet motor- operated valve is closed. √ √

START PERMISSIVE :

1 Fan bearing temp normal. √ √

2 Motor bearing temp normal. √ √

3 Motor winding temp normal. √ √

4 Coal mill’s seal air inlet valve closed. √ √

5 Fan inlet damper is closed. √ √

6 One PA Fan is in running condition. √

7 Emergency push button is in release condition. √

FAN START UP SEQUENCE :

1 Start the seal air fan and slowly adjust the sealing fan’s inlet regulating baffle √

so that the sealed air pressure is higher than the primary air pressure by 4

KPa (FLC-318 amp/415 volt).

2 The fan bearing and motor bearing temperature of the seal air fan is less √ √

than 75deg C, winding temp. of motor less than 100 deg C .

3 Put the automatic regulation of the sealing fan into operation. √

4 Set the back-up sealing fan as "standby." √

SHUTDOWN SEQUENCE:

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 6 of 7

1. PLANNED SHUTDOWN :

1 The seal fan can be shut down only after the coal mill is fully shut down. √

2 Release the interlock of standby sealing fan. √

3 Switch the sealing fan’s inlet regulating baffle from "automatic" to "manual." √

4 Gradually close the sealing fan’s inlet regulating baffle. √ √

5 Shut down the Fan. √

6 Rack out the breaker. √

7 Rectify the probable problem, if any.

√ √

2. TRIPPING OF FAN :If suddenly fan trips

1 If the running fan is tripped or header air pressure is lower than 12kPa, the √

√

back-up fan should be linked.

2 If the other fan does not start in auto, try to start it from local and if fails, shut

down the coal mills. √ √

3. EMERGENCY SHUT DOWN:

1 There is the apparent abnormal noise after starting the fan. √ √

2 The fan bearing temperature is higher than 80 deg C and continues to rise. √ √

3 When the inlet filter screen differential pressure of the fan is more than 1kPa

√

and header air pressure has a downward trend.

4 When endangering the safety of person and equipment. √ √ √ √

INTERLOCKS : Remarks

1 Two primary air fan stopped. 15s time-delay

2 After the seal fan startup, the inlet baffle is still in close position. 120s time-delay

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 7 of 7

ABRIVIATIONS / NOTATIONS:-

o SOP:StandardOperating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

DO’s & DONT’s :

DO’s :

1. Ensure Cooling Water Pressure is sufficient before starting the compressor.

2. Ensure loading & unloading of Service Air Compressor is happening properly.

3. Ensure Air Dyer is properly working (i.e. dew point is to be properly monitored).

4. Ensure periodical draining of condensate from Dryer.

DONT’s :

1. Don’t run the Compressor if Oil Level is low.

2. Don’t run the Compressor if Oil temperature is continuously high.

3. Don’t run the Compressor if Oil is coming out from the discharge.

4. Don’t start/stop the Compressor frequently.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant

KMPCL / Opr. / TAC/ 01

Power from knowledge SOP FOR DRY ASH PRESSURE CONVEYING SYSTEM

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 8 of 7

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

You might also like

- SMP For Screw Air Compressor (Transport Air)Document13 pagesSMP For Screw Air Compressor (Transport Air)Sonrat100% (3)

- Sop For Dry Ash Pressure Conveying SystemDocument7 pagesSop For Dry Ash Pressure Conveying SystemSonratNo ratings yet

- Sop For Oil Purification SystemDocument8 pagesSop For Oil Purification SystemSonrat100% (1)

- Liquid-Ring Vacuum Pump L-900 SeriesDocument144 pagesLiquid-Ring Vacuum Pump L-900 SeriesReinaldo RamirezNo ratings yet

- PM For Bottom Ash Wet System SystemDocument7 pagesPM For Bottom Ash Wet System SystemSonratNo ratings yet

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDocument6 pagesKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratNo ratings yet

- Sop For Concentrator (r1)Document5 pagesSop For Concentrator (r1)Sonrat100% (1)

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- PM WORK For Fluidizing Blower of Fly Ash SiloDocument4 pagesPM WORK For Fluidizing Blower of Fly Ash SiloSonratNo ratings yet

- Sop For Eco SystemDocument6 pagesSop For Eco SystemSonratNo ratings yet

- Sop For Ba-Hp Pump (r1)Document6 pagesSop For Ba-Hp Pump (r1)SonratNo ratings yet

- Sop For LP Pump (R1)Document6 pagesSop For LP Pump (R1)Sonrat100% (1)

- Final KSK Sop Instrument CompressorDocument10 pagesFinal KSK Sop Instrument CompressorSonratNo ratings yet

- Sop For Eco-Hp Pump (r1)Document6 pagesSop For Eco-Hp Pump (r1)SonratNo ratings yet

- Sop For Dry Ash Vacuum Conveying SystemDocument8 pagesSop For Dry Ash Vacuum Conveying SystemSonratNo ratings yet

- PM FOR FLY ASH Dry SystemDocument30 pagesPM FOR FLY ASH Dry SystemSonratNo ratings yet

- Fahp Water PumpDocument9 pagesFahp Water PumpMithun Singh RajputNo ratings yet

- Bahp Water PumpDocument4 pagesBahp Water PumpMithun Singh RajputNo ratings yet

- Sop For Vent FilterDocument6 pagesSop For Vent FilterSonratNo ratings yet

- SMP For Vacuum PumpDocument9 pagesSMP For Vacuum PumpSonratNo ratings yet

- PM Work For Bag Filters of Fly Ash SiloDocument4 pagesPM Work For Bag Filters of Fly Ash SiloSonrat0% (1)

- Silo D-PumpDocument2 pagesSilo D-PumpMithun Singh RajputNo ratings yet

- Standard Operating Instruction: Sop For Condenser Ball CleaningDocument6 pagesStandard Operating Instruction: Sop For Condenser Ball CleaningSonratNo ratings yet

- Sop For HCSD PumpDocument6 pagesSop For HCSD PumpSonrat100% (2)

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonrat100% (1)

- SMP For Agitator (Slurry Sump)Document9 pagesSMP For Agitator (Slurry Sump)SonratNo ratings yet

- Functional Change of Sac Into Iac: Standard Field Operating ProcedureDocument7 pagesFunctional Change of Sac Into Iac: Standard Field Operating ProcedureMithun Singh RajputNo ratings yet

- CCCWDocument7 pagesCCCWSonratNo ratings yet

- MDBFP Sop KSK-1Document12 pagesMDBFP Sop KSK-1SonratNo ratings yet

- Ash Handling SystemDocument7 pagesAsh Handling Systemrbdubey2020No ratings yet

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- PM Work For Dry Ash UnloaderDocument4 pagesPM Work For Dry Ash UnloaderSonratNo ratings yet

- O&M Manual - Part 1 of 5 PDFDocument58 pagesO&M Manual - Part 1 of 5 PDFYOUTH FUTURENo ratings yet

- Extraction Flow Calculation by IterationDocument6 pagesExtraction Flow Calculation by Iterationarunrajmech09No ratings yet

- ACWDocument9 pagesACWrohit_me083No ratings yet

- HMBD Review Check ListDocument4 pagesHMBD Review Check Listctraminst_81No ratings yet

- Ash Handling PlantDocument24 pagesAsh Handling Plantsekhar_ntpcNo ratings yet

- STG Instrument ListDocument12 pagesSTG Instrument Listhari reddyNo ratings yet

- BHEL ASh Handling Equp QA RequiremntDocument27 pagesBHEL ASh Handling Equp QA Requiremntamol1321100% (2)

- Sop Ldo Charging r01Document4 pagesSop Ldo Charging r01jp mishraNo ratings yet

- Boiler Operation Rev 2 - EngDocument24 pagesBoiler Operation Rev 2 - EngElhwis Mule100% (1)

- Control Write Up A388Document57 pagesControl Write Up A388Juhi SinghNo ratings yet

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument11 pagesBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan Sundararaj100% (1)

- Operation Procedure: 1 P.B.MohapatraDocument8 pagesOperation Procedure: 1 P.B.MohapatraSanjay SharmaNo ratings yet

- Stator CW SOP - Docx-1Document12 pagesStator CW SOP - Docx-1SonratNo ratings yet

- Sha80m - M45MM100 ADocument545 pagesSha80m - M45MM100 ASamir ZaghloolNo ratings yet

- Dosing System Design DescriptionDocument4 pagesDosing System Design DescriptionHai NguyenNo ratings yet

- PM Work For Fly Ash Wet System-1Document15 pagesPM Work For Fly Ash Wet System-1Sonrat100% (1)

- Ash Handling 0Document6 pagesAsh Handling 0蓉蓉No ratings yet

- Sop For Total Power Failure.Document4 pagesSop For Total Power Failure.anon_251342212No ratings yet

- Boiler Light UpDocument19 pagesBoiler Light Upm_ganesh1983No ratings yet

- O & M ManualDocument37 pagesO & M ManualNguyễn Thanh Lâm0% (1)

- Tripping Report FD Fan VFD Earth FaultDocument4 pagesTripping Report FD Fan VFD Earth FaultAnuragNo ratings yet

- Training DuctingDocument20 pagesTraining Ductingpanji uteNo ratings yet

- Flash Steam ... : What Is Flash Steam..? How Is It Formed..? What Can We Do With It..?Document20 pagesFlash Steam ... : What Is Flash Steam..? How Is It Formed..? What Can We Do With It..?rafiradityaNo ratings yet

- HRSG SpecificationsDocument2 pagesHRSG SpecificationsBv RaoNo ratings yet

- Instrument List: J300 011 405 REV-01Document5 pagesInstrument List: J300 011 405 REV-01hari reddyNo ratings yet

- Filtration: Chapter 13: Return Relief, and Exhaust Chapter 14: ScrubbersDocument6 pagesFiltration: Chapter 13: Return Relief, and Exhaust Chapter 14: ScrubbersSailaja Pemmanaboina100% (1)

- Ash Handling System SOPDocument18 pagesAsh Handling System SOPCo-gen ManagerNo ratings yet

- Gland Sealing Systeam011Document6 pagesGland Sealing Systeam011Sonrat100% (1)

- Control Write Up HCSDDocument10 pagesControl Write Up HCSDSonrat100% (1)

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- SMP For Slurry PumpDocument14 pagesSMP For Slurry PumpSonrat100% (2)

- SMP For Vacuum PumpDocument9 pagesSMP For Vacuum PumpSonratNo ratings yet

- SMP For Sealing Water Pump Multi Stage.Document13 pagesSMP For Sealing Water Pump Multi Stage.SonratNo ratings yet

- Stator CW SOP - Docx-1Document12 pagesStator CW SOP - Docx-1SonratNo ratings yet

- Sop For Vent FilterDocument6 pagesSop For Vent FilterSonratNo ratings yet

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- Pdi EspDocument1 pagePdi EspSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonrat100% (2)

- SMP For Agitator (Slurry Sump)Document9 pagesSMP For Agitator (Slurry Sump)SonratNo ratings yet

- Silo Blower Compressor ModelDocument1 pageSilo Blower Compressor ModelSonratNo ratings yet

- State Nodal Officers DS GuidelinesDocument3 pagesState Nodal Officers DS GuidelinesSonratNo ratings yet

- ESP-FLD. BLOWER-Model PDFDocument1 pageESP-FLD. BLOWER-Model PDFSonratNo ratings yet

- Buffer Hopper & Air Lock Tank-ModelDocument1 pageBuffer Hopper & Air Lock Tank-ModelSonratNo ratings yet

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDocument6 pagesKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratNo ratings yet

- Standard Operating Procedure For Hy-Lp Bypass System: ObjectiveDocument8 pagesStandard Operating Procedure For Hy-Lp Bypass System: ObjectiveSonratNo ratings yet

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Turbine Drains SOPDocument6 pagesTurbine Drains SOPSonrat100% (1)

- Stator CW SOP-2Document12 pagesStator CW SOP-2SonratNo ratings yet

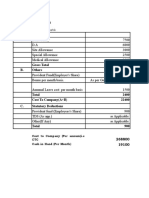

- Salary Structure Siddharth KaushikDocument1 pageSalary Structure Siddharth KaushikSonratNo ratings yet

- Seal Oil SopDocument18 pagesSeal Oil SopSonrat100% (2)

- Sop For LP PumpDocument5 pagesSop For LP PumpSonratNo ratings yet

- Curriculum Vitae: Nageshwar Prasad RathoreDocument2 pagesCurriculum Vitae: Nageshwar Prasad RathoreSonratNo ratings yet

- Salary AnnextureDocument1 pageSalary AnnextureSonratNo ratings yet

- Stabilus CatalogDocument32 pagesStabilus CataloghoiNo ratings yet

- Extended Coverage SprinklerDocument94 pagesExtended Coverage SprinklerbenNo ratings yet

- Project Report Cash Management and Credit Policies With Special Reference Bharat Heavy Electricals Limited (Bhel)Document72 pagesProject Report Cash Management and Credit Policies With Special Reference Bharat Heavy Electricals Limited (Bhel)syed shaibazNo ratings yet

- Testbank Problems For Chapter 8Document7 pagesTestbank Problems For Chapter 8Jenny VarelaNo ratings yet

- 0000 20221010 Weekly Report 01 ZAWIA GT 11 C-Inspection Project - Rev 01Document11 pages0000 20221010 Weekly Report 01 ZAWIA GT 11 C-Inspection Project - Rev 01Mohamed JalilNo ratings yet

- SNCR NozzleDocument8 pagesSNCR Nozzlelbc123No ratings yet

- Liebert CRV+ Precision Air Conditioner: User ManualDocument98 pagesLiebert CRV+ Precision Air Conditioner: User Manualjuan guerreroNo ratings yet

- Stenhoj PL75 TE75 Spare PartsDocument1 pageStenhoj PL75 TE75 Spare Partsmogwai71No ratings yet

- LNG Boil-Off Re-Liquefaction Plants and Gas Combustion UnitsDocument7 pagesLNG Boil-Off Re-Liquefaction Plants and Gas Combustion UnitsP.No ratings yet

- FH2511Z Kz1aDocument1 pageFH2511Z Kz1aAndres VargazNo ratings yet

- Penwaybrochure PDFDocument12 pagesPenwaybrochure PDFRonak PanchalNo ratings yet

- Ice Plant Test RigDocument9 pagesIce Plant Test Rigramniwas123No ratings yet

- Catalyst Attrition in Ebullated-Bed Hydrotreator Operations: Ezra K.T. Kam, Fatma Jasam, Mohammad Al-MashanDocument12 pagesCatalyst Attrition in Ebullated-Bed Hydrotreator Operations: Ezra K.T. Kam, Fatma Jasam, Mohammad Al-MashanLindsey BondNo ratings yet

- Dmitriyev & Pisarenko (1984)Document3 pagesDmitriyev & Pisarenko (1984)Francisco OppsNo ratings yet

- Boge S 4 Series - 512 PDFDocument9 pagesBoge S 4 Series - 512 PDFIlic SlobodanNo ratings yet

- Rmpu PDFDocument56 pagesRmpu PDFdivisional electrical enggNo ratings yet

- Air Compressor ROLLAIR 60TDocument10 pagesAir Compressor ROLLAIR 60TJonson CaoNo ratings yet

- What Is Piping PDFDocument7 pagesWhat Is Piping PDFZaytj CondorNo ratings yet

- Chapter 4 Energy Analysis For A Control VolumeDocument103 pagesChapter 4 Energy Analysis For A Control Volumeshriramdhumal24744No ratings yet

- RTHDE3G2G1Document2 pagesRTHDE3G2G1Arif MinhajNo ratings yet

- RAC Unit - 2 IMPDocument4 pagesRAC Unit - 2 IMPShubham ModakNo ratings yet

- HCR L110 HD828 Type HD836 Type: Dimensions & WeightDocument2 pagesHCR L110 HD828 Type HD836 Type: Dimensions & WeightOthmanNo ratings yet

- BN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesDocument13 pagesBN-S-UC001B Checklist For The Mechanical Completion, Incl. Pre-Commissioning ActivitiesGiftObionochieNo ratings yet

- Trim Balancing ProcedureDocument8 pagesTrim Balancing ProcedureSallar QaziNo ratings yet

- VSP White Tiger UCP@A - Report - Aug22Document32 pagesVSP White Tiger UCP@A - Report - Aug22Khoa Nguyen MinhNo ratings yet

- Kirloskar Pneumatic Co. LTD., PuneDocument80 pagesKirloskar Pneumatic Co. LTD., PuneMaroof AliNo ratings yet

- Laporan Stoc Gudang Sparepart Per 17 Jun 2022 Jam 1751Document190 pagesLaporan Stoc Gudang Sparepart Per 17 Jun 2022 Jam 1751Operational NLGNo ratings yet

- Owner Manual: Ucm-Cld Chiller Control SystemDocument44 pagesOwner Manual: Ucm-Cld Chiller Control SystemMário OliveiraNo ratings yet