Professional Documents

Culture Documents

0902-170!01!5 General Project Datasheet

0902-170!01!5 General Project Datasheet

Uploaded by

ivanlizano5721Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0902-170!01!5 General Project Datasheet

0902-170!01!5 General Project Datasheet

Uploaded by

ivanlizano5721Copyright:

Available Formats

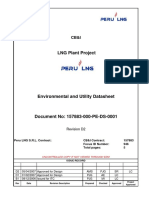

CNP Project No.

0902

Requisition No.

GENERAL PROJECT DATA Client PO :

Client Job No.

Client PETROCOMERCIAL, Filial de PETROECUADOR Prepared EvL EvL EvL MB EvL

Plant 200 MTD LNG Approved

Unit Natural Gas Liquefaction Date 8/5/2009 12/08/09 7/9/2009 14/9/2009 1/29/2010

Document No. 0902-171-01 Issue no. 1 2 3 4 5

Issued for: Information

Rev.

Ambient Temperature MIN 18 deg C

(dry bulb) Performance Guarantee

30 deg C

Point

MAX 37 deg C

Ambient Pressure MIN 980 mbar

Performance Guarantee

1013 mbar

Point

MAX 1020 mbar

Relative Humidity MIN 10%

MAX 90 %

Performance Guarantee

Wet bulb Temperature 26.5 deg C

Point

5 Windspeed MED 4 m/s

5 MAX Normal 10 m/s

SITE DATA

5 MAX for Struct. Design 170 km/h

Winter Prevailing Wind Direction NW

Summer Prevailing Wind Direction NW

Earthquake Zone Zone III according to UBC

Special issues Close to Sea (Standard machine requested, Vendor to inform if special precautions to be observed)

Air Compositon H 20 39 000

(max. impurities, CO2 430

in ppm) H2 1

CO 1

N20 1

SO2 1

H2 0.5

03 0.1

CH4 10

C2 0.1

C3 0.1

C4 0.2

C5+ 0.1

Cooling Water MIN Temp appr. 15 deg C

Performance Guarantee

32 deg C

Point

MAX Temp 32 deg C

Max ∆t over consumers 10 deg C

MIN pressure 1.8 bar(g)

MAX pressure 6 bar(g)

Cooling Water Quality El. Conductance <1000 µS/cm

Hardness <150 mg/L as CaCO3

M-alkanility < 100 mg/L as CaCO3

Turbidity <20 degree

pH 6.5-9.5 @ 25 deg C

UTILITIES

LSI 0.0-1.0

Fe < 1.0 mg/L

Cl- <200 mg/L

SO42- <200 mg/L

SiO2 <50 mg/L

+

NH4 <1.0 mg/L

Instrument MIN 5.5 bar(g)

Air MAX 6.5 bar(g)

Dew point - 40 deg C

Max. Particle Size 10 µm

Hot Oil: Press. TBD

Temp. TBD

Electrical Power: Control/Auxiliaries 120V / 60 Hz

<400 kW 480V / 60 Hz

>400 kW 690V / 60 Hz

Control signals 24 V DC

4 - 20 mA (Profibus PA wherever possible)

Interface Connections Flanges ASME B16.5

MECHANICAL

Thread NPT acc. ASME B1.20.1

0902-170-01 General Project datasheet, page 1 of 2, printed 1/29/2010, 5:32 PM

CNP Project No. 0902

Requisition No.

GENERAL PROJECT DATA Client PO :

Client Job No.

Client PETROCOMERCIAL, Filial de PETROECUADOR Prepared EvL EvL EvL MB EvL

Plant 200 MTD LNG Approved

Unit Natural Gas Liquefaction Date 8/5/2009 12/08/09 7/9/2009 14/9/2009 1/29/2010

Document No. 0902-171-01 Issue no. 1 2 3 4 5

Issued for: Information

Rev.

Adiabatic head 18

m deg C Molar Cp kJ/(kmol*°C)

API Gravity Molar Cv kJ/(kmol*°C)

Compressibility Molar Density kmol/m^3

CpCv Ratio Molar Enthalpy kJ/kmol

Dynamic Viscosity cP Molar Entropy kJ/(kmol*°C)

Enthalpy kJ/h Molar Flow kmol/h

Entropy kJ/(h*°C) Molar Gibbs Free Energy kJ/kmol

Gibbs Free Energy kJ/h Molar Internal Energy kJ/kmol

Gross Ideal Gas Heating Value MJ/m^3 Molar Volume m^3/kmol

Gross Liquid Heating Value MJ/kg Mole Fraction Heavy Liquid %

Heat Duty kW Mole Fraction Light Liquid %

Ideal Gas CpCv Ratio Mole Fraction Vapor %

Internal Energy kJ/h Molecular Weight kg/kmol

Joule-Thomson Coefficient °C/bar Net Ideal Gas Heating Value MJ/m^3

Kinematic Viscosity cSt Net Liquid Heating Value MJ/kg

Liquid Volumetric Flow m^3/h Normal Vapor Volumetric Flow Nm^3/h

UNITS

Mass Cp kJ/(kg*°C) Polytropic Head m

Mass Cv kJ/(kg*°C) Power kW

Mass Density kg/m^3 Pressure bar

Mass Enthalpy kJ/kg Pressure Drop bar

Mass Entropy kJ/(kg*°C) Pseudo Critical Pressure bar

Mass Flow kg/h Pseudo Critical Temperature °C

Mass Fraction Heavy Liquid % Specific Gravity

Mass Fraction Light Liquid % Std Liquid Volumetric Flow m^3/h

Mass Fraction Vapor % Std Vapor Volumetric Flow m^3/h

Mass Gibbs Free Energy kJ/kg Surface Tension dyne/cm

Mass Internal Energy kJ/kg Temperature °C

Mass Volume m^3/kg Thermal Conductivity W/(m*°C)

UA W/°C

Vapor Volumetric Flow m^3/h

Volume Fraction Heavy Liquid %

Volume Fraction Light Liquid %

Volume Fraction Vapor %

Process air RAL 4004

Cooling water RAL 5012

COLORS

Heating Oil RAL 8023

Mixed gas RAL 6027

Nitrogen RAL 6018

Natural gas RAL 1021

Structural steel RAL 7000

0902-170-01 General Project datasheet, page 2 of 2, printed 1/29/2010, 5:32 PM

You might also like

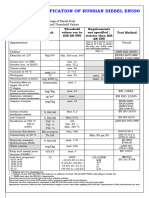

- Icpo NG En590 2704231111Document3 pagesIcpo NG En590 2704231111Nikita Novikov100% (1)

- Bio Diesel b20, En590-Biodiesel b5 SpecsDocument1 pageBio Diesel b20, En590-Biodiesel b5 Specsmohammed wajid100% (1)

- Greater Nile Petroleum Company Limited OGP Technical Services SDN BHDDocument2 pagesGreater Nile Petroleum Company Limited OGP Technical Services SDN BHDwado11No ratings yet

- Sop FobDocument3 pagesSop FobAdnan IsmailNo ratings yet

- MixerDocument4 pagesMixerMarcelo PerettiNo ratings yet

- Instrument Data For Coriolis Flow TransmitterDocument2 pagesInstrument Data For Coriolis Flow Transmitterdilip matalNo ratings yet

- 10J01762 Ict DS 000 012 D0Document14 pages10J01762 Ict DS 000 012 D0Sardar PerdawoodNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document5 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- 2.3 - APPENDIX-1C - Site ConditionsDocument2 pages2.3 - APPENDIX-1C - Site ConditionsSubrata DasNo ratings yet

- MAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)Document16 pagesMAVSP-P19002-W01-M-DS-0002 Rev. 0 Data sheet for Fire Pumps (Elctrical, Diesel and Jockey)fendi zulfiantoNo ratings yet

- Monoethanolamine (MEA) : - Technical Data SheetDocument2 pagesMonoethanolamine (MEA) : - Technical Data Sheetmsh16000No ratings yet

- DatasheetDocument3 pagesDatasheetphantuan080213No ratings yet

- Ldo ArlDocument1 pageLdo Arlsyed.ahmadaltafNo ratings yet

- Pertamina-Dex English VersionDocument1 pagePertamina-Dex English VersionrekaelektraNo ratings yet

- DS Pressure Transmitter PDFDocument3 pagesDS Pressure Transmitter PDFadrian bargasNo ratings yet

- GV001-267-00-1A Datasheet Condensate TankDocument2 pagesGV001-267-00-1A Datasheet Condensate TankJUAN ORTEGANo ratings yet

- Property Unit Test Method Specification Limits Typical Data Astm MIN MAXDocument1 pageProperty Unit Test Method Specification Limits Typical Data Astm MIN MAXDianMulyadiNo ratings yet

- Coriolis Meter Sizing CalculationDocument3 pagesCoriolis Meter Sizing CalculationJeyhan M DonavistaNo ratings yet

- 1-MVCP00116-885PSVr2 20210524100343 852 XDocument4 pages1-MVCP00116-885PSVr2 20210524100343 852 XŁukasz BolewskiNo ratings yet

- 2 Specification Russian EN590Document1 page2 Specification Russian EN590Sephiwe MafilikaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument2 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Sheet For Temperature Gauges and ThermowellsDocument29 pagesData Sheet For Temperature Gauges and ThermowellsSardar PerdawoodNo ratings yet

- BNO Thermo Oil-32 (Mineral Based) : Product Data SheetDocument2 pagesBNO Thermo Oil-32 (Mineral Based) : Product Data SheetAyon HossenNo ratings yet

- PMFTC Dga ResultDocument38 pagesPMFTC Dga ResultLeo Tabita Jr.No ratings yet

- Check List Issue 19-JETA1Document4 pagesCheck List Issue 19-JETA1achillidesnNo ratings yet

- Jet A-1 (Mesaieed) SpecsDocument3 pagesJet A-1 (Mesaieed) SpecsPiping OrdersNo ratings yet

- CERTIFICATE OF PRODUCT QUALITY JET A - 1 Gasoilene 2000,000BBL-1Document2 pagesCERTIFICATE OF PRODUCT QUALITY JET A - 1 Gasoilene 2000,000BBL-1Sephiwe MafilikaNo ratings yet

- D2 JP54 Spec PDFDocument3 pagesD2 JP54 Spec PDFcesarjabbour1No ratings yet

- Data Sheet EjectorDocument4 pagesData Sheet EjectorGunturMudaAliAkbarNo ratings yet

- Specification Att 3-1 - A642-000-04-41-PDB-0001 - R2 - Site Condition N Measure UnitDocument4 pagesSpecification Att 3-1 - A642-000-04-41-PDB-0001 - R2 - Site Condition N Measure UnitAvinash ShuklaNo ratings yet

- HG Mini en V4Document2 pagesHG Mini en V4ViridianaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument6 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Boiler DataDocument16 pagesBoiler DataKalyankumar KrishnamoorthyNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document4 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- 02a Sag Tension Cal EwDocument1 page02a Sag Tension Cal EwCHANDANA KHANNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- 000 Pe DS 0001Document5 pages000 Pe DS 0001Dar FallNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Multiphase Pump DataDocument1 pageMultiphase Pump DataUmar Ijaz KhanNo ratings yet

- Pp-Push FittingDocument9 pagesPp-Push FittingRahmatNo ratings yet

- Alloy Steel p22 PlatesDocument3 pagesAlloy Steel p22 PlatesMiguel PulidoNo ratings yet

- Data Sheet: Boiler Feed PumpsDocument4 pagesData Sheet: Boiler Feed PumpsJason Wei Han LeeNo ratings yet

- Aq Pro: The Latest in Handheld IAQ Monitoring & Real Time Data Logging For Complete Air Quality AnalysisDocument2 pagesAq Pro: The Latest in Handheld IAQ Monitoring & Real Time Data Logging For Complete Air Quality AnalysisTreerat VacharanukrauhNo ratings yet

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFDocument24 pagesV94.2 Beggenum Experience & Improve Concept For Syngas Application PDFEliyanto E BudiartoNo ratings yet

- Data Sheet: Dehydration and Desalting System Akal J-1 Platform HD-H-006Document3 pagesData Sheet: Dehydration and Desalting System Akal J-1 Platform HD-H-006figuev2208No ratings yet

- Data Sheet Co2 Cylinder AssemblyDocument2 pagesData Sheet Co2 Cylinder AssemblyPinjala AnoopNo ratings yet

- Astm d6751 b100 Specification PDFDocument1 pageAstm d6751 b100 Specification PDFZak YanNo ratings yet

- Za Total C HP en V9Document2 pagesZa Total C HP en V9Jose David BoteroNo ratings yet

- Anexo Ii Gea BischoffDocument16 pagesAnexo Ii Gea BischoffFelipe Andres Jaque DelgadoNo ratings yet

- Shellsol A150 ND q7497 Eu 18042016Document3 pagesShellsol A150 ND q7497 Eu 18042016sizmaruNo ratings yet

- MPP Pumps For Antibiotic Solvent Circulation PDFDocument1 pageMPP Pumps For Antibiotic Solvent Circulation PDFAnonymous ua66zYwrpNo ratings yet

- Shellsol A100 q7591 Eu 2023Document3 pagesShellsol A100 q7591 Eu 2023I Love MusicNo ratings yet

- Nuclear Fuel Complex: Tata Projects LimitedDocument4 pagesNuclear Fuel Complex: Tata Projects LimitedAniket GaikwadNo ratings yet

- MSRC Cfa - 20230622 - 0001Document3 pagesMSRC Cfa - 20230622 - 0001Saad MuzaffarNo ratings yet

- 1416 PS PDS V 104 - Rev.0Document4 pages1416 PS PDS V 104 - Rev.0KrunalNo ratings yet

- Anexo 5 - Hoja de DatosDocument2 pagesAnexo 5 - Hoja de DatosCesar Ricardo Lopez ValerioNo ratings yet

- B - 5371 - Used Oil Limits 2009Document1 pageB - 5371 - Used Oil Limits 2009Dennis Alexander Oseguera OsegueraNo ratings yet

- Ejector, Series EBS: Technical DataDocument3 pagesEjector, Series EBS: Technical DataDobos LászlóNo ratings yet

- Ejector, Series EBS: Technical DataDocument3 pagesEjector, Series EBS: Technical DataDobos LászlóNo ratings yet

- Angels International CollegeDocument10 pagesAngels International CollegeTahira ZahidNo ratings yet

- Atividade Prática N.º3 - Identificação de Biomoléculas. (Inglês)Document3 pagesAtividade Prática N.º3 - Identificação de Biomoléculas. (Inglês)Rita Goulart SNo ratings yet

- Type KDocument4 pagesType KAmal ..No ratings yet

- 7 FDD1622 D 01Document6 pages7 FDD1622 D 01dizismineNo ratings yet

- 1 - Masterseal-M-262-MsDocument2 pages1 - Masterseal-M-262-MsPaul ManiquisNo ratings yet

- Engineering Chemistry End Semester ExaminationDocument4 pagesEngineering Chemistry End Semester ExaminationShivam SinghNo ratings yet

- RF Sputtering Manual 2010Document23 pagesRF Sputtering Manual 2010sinytells0% (1)

- RP-HPLC Method Development and Validation of Gallic Acid in Polyherbal Tablet FormulationDocument6 pagesRP-HPLC Method Development and Validation of Gallic Acid in Polyherbal Tablet FormulationLela MirelaNo ratings yet

- Hach Sample CellsDocument8 pagesHach Sample CellsKania LouisNo ratings yet

- Language of ChemistryDocument12 pagesLanguage of ChemistryVenkatNo ratings yet

- Lecture - 3 Dosimetric Quantities and Biological EffectsDocument33 pagesLecture - 3 Dosimetric Quantities and Biological Effectsmz2v8rs7srNo ratings yet

- Cambridge O Level: CHEMISTRY 5070/22Document20 pagesCambridge O Level: CHEMISTRY 5070/22Ayman Obaidur RahmanNo ratings yet

- STPM Trial 2012 Chemistry Qa SmkSeafield SJDocument27 pagesSTPM Trial 2012 Chemistry Qa SmkSeafield SJVitez RaoNo ratings yet

- US20030075077A1Document12 pagesUS20030075077A1Kyaw Kyaw LinnNo ratings yet

- Mr. Saifeldeen Alsmani Abdelkareem StructreDocument24 pagesMr. Saifeldeen Alsmani Abdelkareem StructretahaelnourNo ratings yet

- CC ConvolutionDocument3 pagesCC Convolutionapi-280277788No ratings yet

- Light NotesDocument11 pagesLight NotesGodfrey OkothNo ratings yet

- And Thermal Conductivity and Uses The VBA Functions For Those PropertiesDocument6 pagesAnd Thermal Conductivity and Uses The VBA Functions For Those Propertieshansenmike698105No ratings yet

- Advanced Reinforced Concrete (Assignment-1)Document14 pagesAdvanced Reinforced Concrete (Assignment-1)Suzon IkramNo ratings yet

- Quiz Cet PDFDocument1 pageQuiz Cet PDFdiablokenwayNo ratings yet

- 1b. PET - RawMaterials-SAMEA March 2008Document29 pages1b. PET - RawMaterials-SAMEA March 2008Muhammad Noman MehboobNo ratings yet

- 04 - The - Logic - of - SynthesisDocument31 pages04 - The - Logic - of - SynthesisamelNo ratings yet

- Hydrogen Sulfide h2s SDSDocument10 pagesHydrogen Sulfide h2s SDSSyahrul Nizam AnuarNo ratings yet

- 2 LUBRİCANTS and MOLD RELEASE AGENTSDocument27 pages2 LUBRİCANTS and MOLD RELEASE AGENTScigdemakdumanNo ratings yet

- Distillation Boiling Point DeterminationDocument5 pagesDistillation Boiling Point DeterminationBryanNo ratings yet

- 2 Methods of PolymerizationDocument13 pages2 Methods of Polymerizationbt21102047 Vishwajeet YadavNo ratings yet

- Inkjet-Printed High Mobility Transparent-Oxide SemiconductorsDocument5 pagesInkjet-Printed High Mobility Transparent-Oxide Semiconductorsjulio perezNo ratings yet

- Laser CleaningDocument1 pageLaser CleaningDan IvancNo ratings yet

- Car & BicarDocument12 pagesCar & BicarWard QutaibaNo ratings yet

- Astm F2999-19Document8 pagesAstm F2999-19nickhoNo ratings yet