Professional Documents

Culture Documents

Pressure Vessel Lifting Lug Calculation PDF

Pressure Vessel Lifting Lug Calculation PDF

Uploaded by

Aji Bagus0 ratings0% found this document useful (0 votes)

33 views2 pagesThis document provides calculations to analyze the stresses on a lifting lug attachment on a pressure vessel. It details the vessel dimensions, material properties, load conditions, and performs calculations following standard PD5500 to determine the membrane and bending stresses at points on the attachment. It finds that the maximum calculated stresses are below the allowable stress limits specified in the standard.

Original Description:

Original Title

165014137-Pressure-Vessel-Lifting-Lug-Calculation.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides calculations to analyze the stresses on a lifting lug attachment on a pressure vessel. It details the vessel dimensions, material properties, load conditions, and performs calculations following standard PD5500 to determine the membrane and bending stresses at points on the attachment. It finds that the maximum calculated stresses are below the allowable stress limits specified in the standard.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

33 views2 pagesPressure Vessel Lifting Lug Calculation PDF

Pressure Vessel Lifting Lug Calculation PDF

Uploaded by

Aji BagusThis document provides calculations to analyze the stresses on a lifting lug attachment on a pressure vessel. It details the vessel dimensions, material properties, load conditions, and performs calculations following standard PD5500 to determine the membrane and bending stresses at points on the attachment. It finds that the maximum calculated stresses are below the allowable stress limits specified in the standard.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Page 1

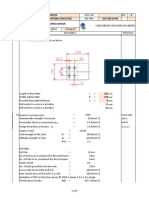

Input Echo, PD:5500 Annex G Item 1, Description: LIFTING LUG

Diameter Basis for Vessel Vbasis OD

Design Internal Pressure Dp 0.00 MPa

Corrosion Allowance for Vessel Cas 0.0000 mm

Vessel Diameter Dv 1466.000 mm

Vessel Thickness Tv 10.000 mm

Vessel Shell Design Allowable Stress f 153.022 MPa

Vessel Shell Yield Strength fy 229.533 MPa

Attachment Type TYPE Rectangular

Attachment length along vessel long. axis 2*cx 20.00 mm

Attachment length along vessel cir. axis 2*cy 150.00 mm

Does the Attachment cut a hole in the shell No

Radial Load (positive outward) Fr -6568.00 N

Circumferential Moment Mc 568805.0 N-mm

Longitudinal Moment Ml 568805.0 N-mm

Allowable Stress Intensity Factor (Mem + Bend) 2.25

Print Membrane Stress at the Attachment junction Yes

Allowable Stress Intensity Factor (Membrane) 1.20

Solid Attachment on a Spherical Shell per PD 5500 section G.2.4:

Resultant Moment (from ML and MC):

= Sqrt( ML² + MC² ) = Sqrt( 568805² + 568805² ) = 804411 N-mm

At the edge of the Solid Attachment

Rectangular Attachment

ro = Sqrt(Cx * Cy) = Sqrt(10.000 *75.000 ) = 27.3861 mm

Sphere effective Outside Diameter:

= Do + 2.tpad = 1466.000 + 2 * 0.000 = 1466.0000 mm

Effective Sphere Wall Thickness:

= t + tpad - c = 10.000 + 0.000 - 0.000 = 10.0000 mm

Shell Mean Radius r:

= (Do+tpad-t+c) / 2 = (1466.000 +0.000 -10.000 +0.000 ) / 2 = 728.0000 mm

Sphere Membrane Stress:

= p * r / ( 2t) = 0.000 * 728.000 / (2*10.000 ) = 0.000 MPa

Graph dimensionless values:

s = 1.82 * ro/Sqrt(r * t) = 1.82 * 27.386 / Sqrt(728.000 *10.000 ) = 0.5842

Note: s = u in our case

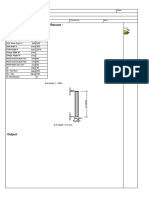

Graph y ord resolved

---------------------------------------------------

G2.4.3 -0.23896 Delta W: -0.05441

G2.4.9 -0.21200 Delta M: -0.06927

G2.4.4 0.13212 Mx W: 867.74335

G2.4.5 0.03911 Mphi W: 256.86380

G2.4.6 -0.18401 Nx W: -120.85675

G2.4.7 -0.05495 Nphi W: -36.09119

G2.4.13 -0.04858 Nphi M: -45.78116

G2.4.12 -0.16132 Nx M: -152.02533

G2.4.11 0.13138 Mphi M: 1238.16235

G2.4.10 0.44163 Mx M: 4161.89307

fmembrane = N / t fbending = 6M/t²

Summation of stresses - MPa

Point A Point B

------- -------

Membrane stresses : MPa

fphi W: -3.609 -3.609

fphi M: -4.579 4.579

Press.: 0.000 0.000

---------- ----------

fphi memb: -8.188 0.969

Bending stresses: MPa

Page 2

fphi W: 15.413 15.413

fphi M: 74.296 -74.296

---------- ----------

fphi bend: 89.709 -58.883

---------- ----------

fphi m + b: 81.521 -57.914

Membrane stresses: MPa

fx W: -12.087 -12.087

fx M: -15.204 15.204

Press.: 0.000 0.000

---------- ----------

fx memb: -27.291 3.117

Bending stresses: MPa

fx W: 52.069 52.069

fx M: 249.735 -249.735

---------- ----------

fx bend: 301.804 -197.666

---------- ----------

fx m + b: 274.513 -194.549

Intensities Max(fx - fphi, fx + p, fphi + p) for m and m + b: MPa

Stress

Stress Intensity Factor Allowable Stress Result

----------------- ------ ---------------- ------

membrane A 27.291 1.200 183.627 Pass

membrane B 3.117 1.200 183.627 Pass

bend+mem A 274.513 2.250 344.300 Pass

bend+mem B 194.549 2.250 344.300 Pass

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2012

You might also like

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- Aisc Chevron BraceDocument42 pagesAisc Chevron Bracegvlanusha100% (1)

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckManish542No ratings yet

- Beer GameDocument8 pagesBeer Gamelay fengNo ratings yet

- Ghana Livestock Development Policy and Strategy FinalDocument107 pagesGhana Livestock Development Policy and Strategy FinalGodsonNo ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Trunnion AnalysisDocument45 pagesTrunnion AnalysisChiragJansariNo ratings yet

- 11.2 Lifting Lug Cal Rev 1Document17 pages11.2 Lifting Lug Cal Rev 1Astle DsouzaNo ratings yet

- Davit CalculationDocument13 pagesDavit CalculationNiraj PandyaNo ratings yet

- Lifting LugDocument2 pagesLifting LugSACHIN PATELNo ratings yet

- Fea n6 14 in FeaDocument31 pagesFea n6 14 in FeaAstle DsouzaNo ratings yet

- Document 1Document13 pagesDocument 1Prince SharmaNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- FlangeDocument6 pagesFlangekamardheen majithNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Fea N5 20in FeaDocument30 pagesFea N5 20in FeaAstle DsouzaNo ratings yet

- Finglow N7Document2 pagesFinglow N7RobinReyndersNo ratings yet

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorNo ratings yet

- Deep Beam CheckDocument10 pagesDeep Beam CheckNikhil AgrawalNo ratings yet

- Nozzlepro V2023.05.1192 Output Report: Title: Client: Contract: Engineer: Date: DescriptionDocument27 pagesNozzlepro V2023.05.1192 Output Report: Title: Client: Contract: Engineer: Date: DescriptionAstle DsouzaNo ratings yet

- Output: Pile Cap Beam Calculation For Most Critical Zone 1Document7 pagesOutput: Pile Cap Beam Calculation For Most Critical Zone 1Prakash Singh RawalNo ratings yet

- Flange Input CalcDocument12 pagesFlange Input CalcdharwinNo ratings yet

- Unnamed Gornja GredaDocument7 pagesUnnamed Gornja GredasehmediaNo ratings yet

- Flange Input Data Values Description: FLGDocument4 pagesFlange Input Data Values Description: FLGAnonymous AyDvqgNo ratings yet

- Design of Baseplate (BP-1) - Without Shear Key - GRID 101 TO 104Document14 pagesDesign of Baseplate (BP-1) - Without Shear Key - GRID 101 TO 104prabhash kumarNo ratings yet

- Connection Surge Bin Supp Beam1Document5 pagesConnection Surge Bin Supp Beam1Venkatesh HebbarNo ratings yet

- M2-CV-RC-D-005 (R1)Document22 pagesM2-CV-RC-D-005 (R1)ksshashidharNo ratings yet

- PB6 2024 05 016 - NEW.w07 - D202428Document9 pagesPB6 2024 05 016 - NEW.w07 - D202428박유림No ratings yet

- The Properties of The Section Are As Follows A 0013 M 2 R B 94 MM SX 000099 M 3 - 97641300Document36 pagesThe Properties of The Section Are As Follows A 0013 M 2 R B 94 MM SX 000099 M 3 - 97641300humamoynicoleNo ratings yet

- Beam Design of Reinforced ConcreteDocument2 pagesBeam Design of Reinforced ConcreteAmanda SmithNo ratings yet

- Pole CalcDocument11 pagesPole CalcMia SaquingNo ratings yet

- Concrete Section Design For Flexure:: Input DataDocument12 pagesConcrete Section Design For Flexure:: Input DataSandesh KumarNo ratings yet

- Excel Tools To Check Beam JackettingDocument10 pagesExcel Tools To Check Beam JackettingPrakash Singh RawalNo ratings yet

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document20 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Mr IncognitoNo ratings yet

- Lifting Lug CalcDocument4 pagesLifting Lug CalcdharwinNo ratings yet

- Mathcad V1 BDocument11 pagesMathcad V1 BDoğan ArslanNo ratings yet

- Design Calculation Report Job No. Building No. Rev. No. Customer Date Description Designed by Checked byDocument7 pagesDesign Calculation Report Job No. Building No. Rev. No. Customer Date Description Designed by Checked bysprasannaaNo ratings yet

- Mset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)Document17 pagesMset Engineering Corporation SDN BHD: (Ref:Pressure Vessel Design Manual 3rd Edition by Dennis R. Moss Page 291 295)threedlabsNo ratings yet

- Lifting Lug AnalysisDocument8 pagesLifting Lug AnalysisTrishul Nath PallayNo ratings yet

- Reporte de Tensión de Analísis Modal: Project Info (Iproperties)Document17 pagesReporte de Tensión de Analísis Modal: Project Info (Iproperties)raul urquizaNo ratings yet

- Note de Calcul Ancrage Rev3Document3 pagesNote de Calcul Ancrage Rev3Bilel MahjoubNo ratings yet

- Quick PrintDocument2 pagesQuick PrintSimeon ArabovNo ratings yet

- Deep Beam TypicalDocument6 pagesDeep Beam TypicalArpit SinghNo ratings yet

- Triangle Beam B1Document6 pagesTriangle Beam B1sallysel90No ratings yet

- Quick PrintDocument2 pagesQuick PrintSimeon ArabovNo ratings yet

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- 3.base Plate WF 350Document3 pages3.base Plate WF 350Yudi BahrainNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number EngineerGirindraDamarNo ratings yet

- Design of Column SpliceDocument2 pagesDesign of Column SpliceAndro Rebuyas100% (1)

- Post Tension Slab Design ExampleDocument6 pagesPost Tension Slab Design ExampleKiran D AnvekarNo ratings yet

- 03 CalDocument56 pages03 Calnatarajan RavisankarNo ratings yet

- Column DesignDocument14 pagesColumn DesignRonald CostalesNo ratings yet

- NTC 2008 Example 002Document14 pagesNTC 2008 Example 002Anitha Hassan KabeerNo ratings yet

- V-340 OutDocument14 pagesV-340 OutSachin5586No ratings yet

- Handrail Coring Check (Calculation)Document56 pagesHandrail Coring Check (Calculation)Rey GonzalesNo ratings yet

- PV Design Calc3Document6 pagesPV Design Calc3evrim77No ratings yet

- Crane Lifting Lug DesignDocument3 pagesCrane Lifting Lug DesignsajadbeNo ratings yet

- Flange DesignDocument6 pagesFlange DesignDinesh VaghelaNo ratings yet

- MC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPDocument12 pagesMC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPdonnybtampubolonNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Qo010-A231310 Fisher MovDocument6 pagesQo010-A231310 Fisher MovAji BagusNo ratings yet

- Dokumen - Tips - Bolt Torque Asme b16 5 Flanges Sheet Gaskets 02 PDFDocument26 pagesDokumen - Tips - Bolt Torque Asme b16 5 Flanges Sheet Gaskets 02 PDFAji BagusNo ratings yet

- Bagan Pertandingan Billiard TRC Masters: Pool ADocument1 pageBagan Pertandingan Billiard TRC Masters: Pool AAji BagusNo ratings yet

- TT 389 Municipal Wastewater Management Part231 PDFDocument1 pageTT 389 Municipal Wastewater Management Part231 PDFAji BagusNo ratings yet

- TT 389 Municipal Wastewater Management Part249Document1 pageTT 389 Municipal Wastewater Management Part249Aji BagusNo ratings yet

- AISSA Leader - FinalDocument20 pagesAISSA Leader - Finaltarn260627No ratings yet

- Economics and EmigrationDocument24 pagesEconomics and EmigrationMarius ComperNo ratings yet

- Panasonic PT-AE2000U LCD Projector ManualDocument58 pagesPanasonic PT-AE2000U LCD Projector Manualspock_cowNo ratings yet

- Rhythm Music and Education - Dalcroze PDFDocument409 pagesRhythm Music and Education - Dalcroze PDFJhonatas Carmo100% (3)

- PEGA Rule ResolutionDocument5 pagesPEGA Rule ResolutionSravanSravan0% (1)

- Empress Bass Compressor Manuel Utilisateur en 81366Document12 pagesEmpress Bass Compressor Manuel Utilisateur en 81366MURPHYNo ratings yet

- Weld Inspection SolutionsDocument1 pageWeld Inspection SolutionsElyJoaquinMalbuesoNo ratings yet

- iVMS-4200-Client-Software Datasheet V3.11.0 20240126Document9 pagesiVMS-4200-Client-Software Datasheet V3.11.0 20240126Yasmin SunartaNo ratings yet

- Medidores Rotativos Série FMRDocument3 pagesMedidores Rotativos Série FMRmateuNo ratings yet

- How Are The Working Hours at TTECDocument1 pageHow Are The Working Hours at TTECTeletechNo ratings yet

- A Review of Methods For Burstleakage Detection andDocument13 pagesA Review of Methods For Burstleakage Detection andalaaagala248No ratings yet

- Kaizene 2 EditeDocument53 pagesKaizene 2 EditeHabteNo ratings yet

- ETCE MICRO (Group 2)Document19 pagesETCE MICRO (Group 2)19IF001 Chaitali AkhareNo ratings yet

- GX120 GX160 GX200: Engine Adjustment InformationDocument1 pageGX120 GX160 GX200: Engine Adjustment Informationjac marchandNo ratings yet

- KDE - Direct Plug-In MethodDocument5 pagesKDE - Direct Plug-In MethodNumXL ProNo ratings yet

- r6PcK Q7Q2uj3Cv0O3NrUw Activity-Template - Project-CharterDocument5 pagesr6PcK Q7Q2uj3Cv0O3NrUw Activity-Template - Project-CharterAli KaraNo ratings yet

- OECSwceDocument12 pagesOECSwceChristopher WeeksNo ratings yet

- IBM InfoSphere QualityStageDocument6 pagesIBM InfoSphere QualityStagechand1255No ratings yet

- Applying Backcasting and System Dynamics Towards Sustainable Development The Housing Planning Case For Low-Income Citizens in BrazilDocument40 pagesApplying Backcasting and System Dynamics Towards Sustainable Development The Housing Planning Case For Low-Income Citizens in BrazilM VlogNo ratings yet

- Addis Business: Covid 19 & RemittancesDocument9 pagesAddis Business: Covid 19 & RemittancesPeter MuigaiNo ratings yet

- Audition Form EngDocument2 pagesAudition Form EngJessie IsabelNo ratings yet

- Hercuvan Catalogue DetailDocument192 pagesHercuvan Catalogue Detaillehieua8No ratings yet

- 031 Calanza v. PICOPDocument3 pages031 Calanza v. PICOPthornapple25No ratings yet

- Overhead Line Equipment CatalogueDocument32 pagesOverhead Line Equipment CatalogueMBAVHALELO FUNYUFUNYUNo ratings yet

- Automotive Test Probe ConstructionDocument4 pagesAutomotive Test Probe ConstructionLy Fotoestudio DigitalcaNo ratings yet

- Activity Based Costing HCCDocument8 pagesActivity Based Costing HCCIhsan danishNo ratings yet

- Unit 1 Test - B1+: Listening GrammarDocument5 pagesUnit 1 Test - B1+: Listening GrammarMarjorieNo ratings yet

- 2019-56 - KartikSolanki - Professional Ethics, Accountancy For Lawyers and Bar-Bench RelationsDocument17 pages2019-56 - KartikSolanki - Professional Ethics, Accountancy For Lawyers and Bar-Bench RelationsKartik SolankiNo ratings yet