Professional Documents

Culture Documents

Inweld: Chemical Composition of Inweld 8010-G

Inweld: Chemical Composition of Inweld 8010-G

Uploaded by

Triyono0 ratings0% found this document useful (0 votes)

49 views1 pageInweld 8010-G is an electrode for welding high strength pipe joints vertically or overhead. It achieves full penetration and yield strengths over 80,000 psi, making it suitable for pipelines grades X56-X70. The electrode has a deep penetrating arc and superior puddle control. It is used with DC+ polarity and produces X-ray quality welds when used at recommended parameters of 120-200 amps depending on electrode size and welding position.

Original Description:

solar system

Original Title

solar panel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentInweld 8010-G is an electrode for welding high strength pipe joints vertically or overhead. It achieves full penetration and yield strengths over 80,000 psi, making it suitable for pipelines grades X56-X70. The electrode has a deep penetrating arc and superior puddle control. It is used with DC+ polarity and produces X-ray quality welds when used at recommended parameters of 120-200 amps depending on electrode size and welding position.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

49 views1 pageInweld: Chemical Composition of Inweld 8010-G

Inweld: Chemical Composition of Inweld 8010-G

Uploaded by

TriyonoInweld 8010-G is an electrode for welding high strength pipe joints vertically or overhead. It achieves full penetration and yield strengths over 80,000 psi, making it suitable for pipelines grades X56-X70. The electrode has a deep penetrating arc and superior puddle control. It is used with DC+ polarity and produces X-ray quality welds when used at recommended parameters of 120-200 amps depending on electrode size and welding position.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

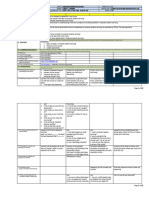

Inweld 8010-G

AWS A5.5 E8010-G

Chemical Composition of Inweld 8010-G

Fe C Cr Ni Mo Mn Si P S N Cu

Balance 0.20 0.30 1.00 0.50 1.20 0.60 0.03 0.03 --- ---

Description and Applications

Inweld E8010-G is a deep penetrating, high silicon spray arc electrode for welding high strength pipe joints in

vertical up or vertical down welding applications. Inweld 8010-G achieves full penetration, X-Ray quality weld

deposits and yield strengths greater than 80,000 psi which is necessary for high silicon pipeline applications.

Has superior weld puddle control and light slag. Typical pipeline assemblies include API 5LX-56 through X-70

grade pipe and sheet metal applications.

Instructions - Clean the weld area of all contaminants. Bevel heavy sections to a 60 “V”. For best results and if

at all possible, preheat thicker pipes at 300-500°F. Always use this electrode with DC+ (reverse polarity). Set

your amperage to the proper range for the size electrode you are using, maintain a short arc length and hold the

electrode at a 15° angle in the direction of travel. Weaving technique should be used but do not exceed 3 times

the diameter of the electrode. Do not use the whipping technique as this will cause porosity in the weld deposit.

Allow to air cool slowly before removing slags.

Typical Weld Metal Properties

AWS Spec

Tensile Strength: 80,000 ksi

Yield Strength: 67,000 ksi

Elongation: 19%

Charpy V-Notch at -20°F: 81 ft-lbs

Recommended Parameters

SMAW (DCEP)

Wire Diameter Flat Amperage Vertical & Overhead Amperage

5/32” 120-160 110-150

3/16” 160-200 130-170

Arc Length: Very short arc, Flat use 15° angle from 90°, Vertical up & Overhead use weaving techniques within

puddle

INWELDCORPORATION.COM

Pennsylvania North Carolina Texas California

3962 Portland Street 1029 S. Marietta St. 9300 Lawndale St. 6201 Coliseum Way, Unit A

Coplay, PA 18037 Gastonia, NC 28054 Houston, TX 77012 Oakland, CA 94621

You might also like

- Mitech Welder ManualDocument13 pagesMitech Welder ManualkapasuduNo ratings yet

- SM 26Document510 pagesSM 26TriyonoNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- J05C+Injection+Pump+Timing PDFDocument1 pageJ05C+Injection+Pump+Timing PDFTriyonoNo ratings yet

- Lcci Level I Solution BookDocument90 pagesLcci Level I Solution BookThuzar Lwin83% (6)

- Book Layout With Bold Typographic Accents Stock Template - Adobe StockDocument4 pagesBook Layout With Bold Typographic Accents Stock Template - Adobe StockJoseph DanielNo ratings yet

- Easyarc E7016P BAG 3Document2 pagesEasyarc E7016P BAG 3Andri AjaNo ratings yet

- Trade Test Questions For WelderDocument2 pagesTrade Test Questions For WelderMd ishteyaque100% (1)

- STTDocument11 pagesSTTamr kouranyNo ratings yet

- What Is The Difference Between Welding TransformerDocument33 pagesWhat Is The Difference Between Welding TransformerAkhilesh KumarNo ratings yet

- D&H Secheron in Cement ApplicationDocument1 pageD&H Secheron in Cement ApplicationGyanaranjan2011No ratings yet

- Iw&tt GmawDocument50 pagesIw&tt GmawHimanshu MishraNo ratings yet

- HTLS Conductor ComparisonDocument45 pagesHTLS Conductor ComparisonJamil Salman Marcos100% (1)

- Job Knowledge 17Document4 pagesJob Knowledge 17Mehmet SoysalNo ratings yet

- Submerged Arc Welding Metal Inert Gas Welding Tungsten Inert Gas Welding Oxy-Acetylene Gas WeldingDocument42 pagesSubmerged Arc Welding Metal Inert Gas Welding Tungsten Inert Gas Welding Oxy-Acetylene Gas WeldingRaj singhNo ratings yet

- WELDING ESAB Welding Handbook XA00106720 - Pipeline Catalogue (Ebook, 66 Pages)Document66 pagesWELDING ESAB Welding Handbook XA00106720 - Pipeline Catalogue (Ebook, 66 Pages)Denny SyamsuddinNo ratings yet

- Welding Materials 5Document45 pagesWelding Materials 5Avimiled Manosalva RincónNo ratings yet

- KG-K125 Latching RelayDocument3 pagesKG-K125 Latching RelayCésar Andrés Barrios ArroyoNo ratings yet

- Multiconductor TechnicalDocument24 pagesMulticonductor TechnicalJuan Felipe Vieira GaviriaNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Technical Update Methods For Removal of Welds and Opening of Cracks PDFDocument12 pagesTechnical Update Methods For Removal of Welds and Opening of Cracks PDFBogdan PopescuNo ratings yet

- Thermocouple Colour CodesDocument1 pageThermocouple Colour CodesAlfredNo ratings yet

- Eknoweld 18 8 6Document1 pageEknoweld 18 8 6Narendra RankaNo ratings yet

- Commonly Used Welding Process Techniques-OverviewDocument51 pagesCommonly Used Welding Process Techniques-OverviewaadmaadmNo ratings yet

- IP Code Operating Torque Number of Contacts Capacity of Contacts Operating Angle Cable Size Mechanical Life Electrical Life Working Temp. Working Humidity Material N.WDocument2 pagesIP Code Operating Torque Number of Contacts Capacity of Contacts Operating Angle Cable Size Mechanical Life Electrical Life Working Temp. Working Humidity Material N.WArnold StevenNo ratings yet

- A-80 RailrodDocument1 pageA-80 RailrodSyed AbudhakirNo ratings yet

- Intellectual Welding TrainingDocument45 pagesIntellectual Welding Traininggaganesan1972100% (1)

- Medium-Extra High Voltage Power CablesDocument56 pagesMedium-Extra High Voltage Power CablesApichartj Jusuay100% (2)

- Maximum Kit-#400-420mA-ManualDocument14 pagesMaximum Kit-#400-420mA-ManualIvo MozaraNo ratings yet

- Miller Submerged Arc HandbookDocument32 pagesMiller Submerged Arc Handbookbjrhunter0% (1)

- Lincoln Submerged ArcDocument54 pagesLincoln Submerged ArcjdNo ratings yet

- 24UTP Railway GBDocument8 pages24UTP Railway GBwpsssamsungNo ratings yet

- Arc WeldingDocument48 pagesArc WeldingSumma ThanNo ratings yet

- Indian Institute of Welding - ANB Refresher Course - Module 09Document43 pagesIndian Institute of Welding - ANB Refresher Course - Module 09dayalramNo ratings yet

- AW Tech Datasheet 80 20 NI CRDocument2 pagesAW Tech Datasheet 80 20 NI CRtrần quang đứcNo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- Stel - Max223cDocument2 pagesStel - Max223cmtonellyNo ratings yet

- 200acdc TigDocument14 pages200acdc TigAngelo GrausoNo ratings yet

- SOW 7018A11 8 SpecSheetDocument2 pagesSOW 7018A11 8 SpecSheetKmi GutierrezNo ratings yet

- Job Knowledge 16Document4 pagesJob Knowledge 16Mehmet SoysalNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Welding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)Document52 pagesWelding Methods & Technology.: V.R.Ekbote Ces (Insp), Ril (PG)cyNo ratings yet

- Welding MachineDocument3 pagesWelding MachinetuanNo ratings yet

- Quantum Devices 2011 CatalogDocument21 pagesQuantum Devices 2011 CatalogElectromateNo ratings yet

- LS XLPE & AccessoriesDocument26 pagesLS XLPE & AccessoriesNavneethNo ratings yet

- 80m Vertical On A 12m SpiderpoleDocument3 pages80m Vertical On A 12m SpiderpoleAdrian CelaNo ratings yet

- High Temperature Low Sag ConductorDocument27 pagesHigh Temperature Low Sag Conductortanto_deep_15No ratings yet

- Fco - PreciseDocument8 pagesFco - PreciseDebiKrisNo ratings yet

- Royal 6010Document1 pageRoyal 6010Santosh SharmaNo ratings yet

- Technical - Specs - Tai Lieu Ve Han TIGDocument12 pagesTechnical - Specs - Tai Lieu Ve Han TIGthanhdung20061085No ratings yet

- Rail WeldingDocument4 pagesRail WeldingOlga Sandoval RomeroNo ratings yet

- TIG WeldingDocument12 pagesTIG WeldingZuberYousuf100% (2)

- The multilayer piezo actuators can reach full performance at very low operating voltage. The plate actuator NAC2023 is 15x15 mm and provides a free stroke of 3.1 μm and a blocking force of 9450 NDocument7 pagesThe multilayer piezo actuators can reach full performance at very low operating voltage. The plate actuator NAC2023 is 15x15 mm and provides a free stroke of 3.1 μm and a blocking force of 9450 NJisu RyuNo ratings yet

- Quantum Devices 2011 CatalogDocument21 pagesQuantum Devices 2011 CatalogServo2GoNo ratings yet

- HTLSCDocument29 pagesHTLSCNadia Felicia Baines100% (1)

- Boehler CN 13 4-MC - SWDocument1 pageBoehler CN 13 4-MC - SWSebastian AcostaNo ratings yet

- Indian Institute of Welding - ANB Refresher Course - Module 07Document55 pagesIndian Institute of Welding - ANB Refresher Course - Module 07dayalram0% (1)

- Fabricator ES 410icDocument10 pagesFabricator ES 410icaxisd47No ratings yet

- AbraTec 6715Document2 pagesAbraTec 6715Luis MoriNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Engine Related Parts: D31E-20 S/N 42001-UPDocument539 pagesEngine Related Parts: D31E-20 S/N 42001-UPTriyonoNo ratings yet

- Excavator Komatsu PC200-7 PDFDocument10 pagesExcavator Komatsu PC200-7 PDFTeresa Marina Peralta100% (1)

- Design and Construction of An Electric Incubator For Hatching Chicken EggsDocument8 pagesDesign and Construction of An Electric Incubator For Hatching Chicken EggsTriyonoNo ratings yet

- Cajas JBL Line Array PDFDocument12 pagesCajas JBL Line Array PDFTriyonoNo ratings yet

- Hydraulic TrainingDocument32 pagesHydraulic TrainingbadralislamNo ratings yet

- IM Nov 18Document24 pagesIM Nov 18TriyonoNo ratings yet

- Smart Eggs Incubator System: M. F. Omar H. C. M. Haris M. N. Hidayat I. Ismail M. N. SerojiDocument7 pagesSmart Eggs Incubator System: M. F. Omar H. C. M. Haris M. N. Hidayat I. Ismail M. N. SerojiTriyonoNo ratings yet

- Timing Gear PDFDocument12 pagesTiming Gear PDFTriyonoNo ratings yet

- The Development of Quail Eggs Smart Incubator For Hatching System Based On Microcontroller and Internet of Things (Iot)Document6 pagesThe Development of Quail Eggs Smart Incubator For Hatching System Based On Microcontroller and Internet of Things (Iot)TriyonoNo ratings yet

- Course Komatsu Wb93r5 Wb97r5 Backhoe Loaders Hydraulic SystemDocument41 pagesCourse Komatsu Wb93r5 Wb97r5 Backhoe Loaders Hydraulic SystemTriyonoNo ratings yet

- D6R Iii PDFDocument6 pagesD6R Iii PDFTriyonoNo ratings yet

- Komatsu Reusable PartDocument44 pagesKomatsu Reusable PartTriyonoNo ratings yet

- Course Komatsu Wb93 97r5 Backhoes Engine Fuel Injection Structure Operation Workshop Data TroubleshootingDocument24 pagesCourse Komatsu Wb93 97r5 Backhoes Engine Fuel Injection Structure Operation Workshop Data TroubleshootingTriyono100% (1)

- Course Engine Diesel Series 40e Detroit Electronic System FeaturesDocument160 pagesCourse Engine Diesel Series 40e Detroit Electronic System FeaturesTriyono100% (1)

- REP Needed: Step 1 Step 2Document2 pagesREP Needed: Step 1 Step 2TriyonoNo ratings yet

- List of Providers Suspended From Participating in PPDA ProceedingsDocument6 pagesList of Providers Suspended From Participating in PPDA ProceedingsMuhindoNo ratings yet

- Bilateral Cooperation Agreement On Claims Settlement According To The Internal RegulationsDocument4 pagesBilateral Cooperation Agreement On Claims Settlement According To The Internal RegulationsDragan StanišićNo ratings yet

- Online Shopping Can Be Worse For The Environment Than Driving To A StoreDocument6 pagesOnline Shopping Can Be Worse For The Environment Than Driving To A StoreSunshine GrNo ratings yet

- Payors Data For I-Network Mailer CampionDocument276 pagesPayors Data For I-Network Mailer Campionsaksham shrivastavaNo ratings yet

- CSS G11 Module 1Document8 pagesCSS G11 Module 1Shendelzare Silkwood Quinto AronNo ratings yet

- Industrial Disputes ActDocument127 pagesIndustrial Disputes ActsandeepNo ratings yet

- Sovereign Wealth (OBrien, Justin, McKibbin, Warwick J., Fry Etc.) (Z-Library)Document217 pagesSovereign Wealth (OBrien, Justin, McKibbin, Warwick J., Fry Etc.) (Z-Library)Win Htet MinnNo ratings yet

- pcb007 May2022Document120 pagespcb007 May2022Yasser AbrahantesNo ratings yet

- Atheniac Solutions Brand IdentityDocument16 pagesAtheniac Solutions Brand Identityv89wytwpynNo ratings yet

- Assignment-1 For All Subjects 2023Document3 pagesAssignment-1 For All Subjects 2023KanchanNo ratings yet

- PO # 025 N1091 Fire Fighting Materials - AL BILADDocument7 pagesPO # 025 N1091 Fire Fighting Materials - AL BILADAsad Maher100% (1)

- A1 Assignment 7Document13 pagesA1 Assignment 7Chandrakant VadluruNo ratings yet

- I-O Mode, and Resource-Based ModelDocument4 pagesI-O Mode, and Resource-Based ModelShabbirAhmad100% (1)

- Marketing Plan Report - Samsung Galaxy S10Document29 pagesMarketing Plan Report - Samsung Galaxy S10Hồng PhúcNo ratings yet

- Adobe Scan 22 Mar 2023Document3 pagesAdobe Scan 22 Mar 2023Justin D'souzaNo ratings yet

- Daily Lesson Log For Css g12 SY 2019 2020Document82 pagesDaily Lesson Log For Css g12 SY 2019 2020Emily S. AwaNo ratings yet

- Mco-04 (E)Document11 pagesMco-04 (E)ArunNo ratings yet

- p1 Sabi Dirce Presentation EngDocument28 pagesp1 Sabi Dirce Presentation EngdavidNo ratings yet

- Adjective Plus Preposition WorksheetDocument4 pagesAdjective Plus Preposition WorksheetRUTH MARIBEL MAMANI MAMANINo ratings yet

- Economics GR 12 Exam Guidelines 2021 EngDocument34 pagesEconomics GR 12 Exam Guidelines 2021 EngMAPULE LEBALLONo ratings yet

- Companies ActDocument45 pagesCompanies ActJanavi KalekarNo ratings yet

- Aip Final 2024Document16 pagesAip Final 2024elaiamapalo395No ratings yet

- Uncommon ServiceDocument3 pagesUncommon ServiceEmanuel Gomez TapiaNo ratings yet

- Laptop As StudentsDocument2 pagesLaptop As StudentswellaNo ratings yet

- Company ProfileDocument7 pagesCompany ProfileRaja BanggalaNo ratings yet

- The National DebtDocument13 pagesThe National DebtdeepfriedcatsNo ratings yet

- STMT Ent BookDocument2 pagesSTMT Ent BookNasir GhaniNo ratings yet

- A Quick Guide To Credit Linked Notes, (CLN)Document2 pagesA Quick Guide To Credit Linked Notes, (CLN)Keval ShahNo ratings yet