Professional Documents

Culture Documents

0001

0001

Uploaded by

Vic Valdez0 ratings0% found this document useful (0 votes)

10 views18 pagesCivil inspector. Review

Original Title

DOC-0001

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCivil inspector. Review

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views18 pages0001

0001

Uploaded by

Vic ValdezCivil inspector. Review

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 18

BeNNby since

abe (Specter,

CIVIL QA/OC QUESTIONAIRE

A Clear space of 44 shall be maintained on all sides ofthe

excavation,

(a) 2

(b) 3ft.

(4t

(@ ste

(6) Allof the above

2 Shoring shall be installed or sides shall be sloped or benched when the depth

of excavation reaches \-L :

(a) 0.8m

(b) 1.5m

(o) 12nt

(d) 1.4m

(e) All of the above

3. Liquid limit and plastic limit tests are required for select fill material when

the percentage passing the #200 sieve is__{( q - Liquid & plastie

Timit tess ae requirce ifthe % passung ihe h 40 sieve is more thar 1S Yo.)

(a) 10%

(b) 14%

(16%

(a) @) & (e)

(© Allof the above

4." The sufficient thickness for cohesive capping material required when sand

was used as fill material was Samm.

(a) 150mm

(b) 200mm

(c) 250mm

(4) All of the above

(e) None of the above

5. What are the two basic types of concrete as per SAES-Q-01? (Write your

answer.) Structural & non-structural concrete

Structural & non-structural concrete

6. What is the maximum temperature of concrete that can be poured into a

concrete structure?

(a) 25 degrees C

(b) 30 degrees C

(©) 32 degrees C

@ab&e

(e) None of the above

7. What is the acceptable temperature of asphalt mix prior to and during

placing and compaction?

Tenperatureisiall be 139 to 163 degreey

je

(a) 135 degrees C

(b) 140 degrees C

{c) 163 degrees

(awe

cc

8. The maximum 28 ~ day compressive stren,

SAES-Q-001 was Girys .

(@yg000 psi}

(b) 4500 psi

(c) 5000 psi s

(d) All of the above

(e) None of the above

gth of structural concrete as per

9. The minimum thickness of concrete slab that is subject to vehicular traffic

as per SAES-Q-001 was__\&v ma)

(a) 100mm

(basonimy

(©) 200mm

(d) All of the above

(©) None of the above.

10. Plant scales shall be calibrated _({__times a year and shall be certified

by an independent laboratory.

(a) two

(b) three

(

(d) five

(©) None of the above

11. Concrete mixifig watér shall have no more than_{v=

dissolved solids (TDS).

(a) 300

(b) 450,

(@ys007

(a) 1000

(e) Allof the above

ppm of toral

12. The minimum clear distance of anchor bolts or anchor bolts sleeves from the

edge of concrete shall be _ {6 ‘

(a) 50mm

() 75mm.

(Qqaomm »

pysaedvon (ORT, x

hea aterrie tery ee ia.

4 Pate v : spa, Tutt dicated Sot

Com ba

zinek

a ype

pebiy meow b 34

ROE conan taal

cee ye

(4) 120mm

(e) None of the above

13. Concrete can be dropped freely at aheight of _ (1

(a) half meter

(b)onemetes

(6) one and a half meter

(daeb

(e)a&e

14. Concrete GiiHi8g Wate? shall not have more than _) 7 ¥4 1 of total

dissolved solids (TDS).

(a) 500 ppm

(b) 750 ppm

(cJioooppAn |

(d) All of the above

(e) None of the above

‘TYPICAL INTERVIEW QUESTIONS FOR CIVIL INSPECTOR

PARTI

1. What Are the most important elements of soil classification (SAES:A+114)

a. Type of soil, Gradation, and Atterberg limits. The inspector should have a

general idea how these limits (liquid limit, Plastic, & plasticity index)

correlate with selecting approved Select Fill)

2. WhatisCBR"((SAESIO-006)%

@. CalifornisyBearingRatioglt is a laboratory value that helps determining

soil bearing capacity and in classifying soil. It is a design parameter,

however, is a requirement by our standards to verify and check! Not

knowing what itis indicates the inspector has poor soil knowledge and

experience.

3. What is the maximum depth of regular fill lift (layer) prior to compaction (SAES

A114)?

00mm

4. What is the maximum depth of a fill lift (layer) when manual equipment is used

for compaction (SAES A-114)

‘eygoainny

5. What are the project conditions & factors that control compaction. (Experience &

SAES A-114)?

alana AMBER ORE.

oi) (for sand) and'stepping/of layers: ofmarland select

6. What are the three different types of laboratory ASTM soil density test (SAES A-

114)? And what are the minimum required density values for each of the test

mentioned above?

pe herr bn Bs EG HCE 96. sinels

1s Dele ened Dy MSH Bild 59 dad sirts DIST 7

4256

7. What are the important points to look for in Conerete forms prior to pouring

concrete (SAES Q-001, ACI and experience)? .

Tighiness, cleanness, plumbness, steadiness, shoring and bracing, rebar

‘cover, concrete top level mark correctness.

b, Also, vapour barrier must be installed prior to pouring on grade.

‘Also, Grade must receive termite chemical spray protection prior to vapor

bamier placement.

8 What are the essential elements of concrete placement (SAES Q-001, ACT, and

experience)?

a

ce

a. Maximum height of concrete drop is less than or equal to 1 meter.

b. Segregation must be prevented by ensuring transit mixture is approved,

has operating revolution counter, no adding water after batching, and

concrete is placed in such a manner to prevent segregation (ie. anly

shovels can be used to move concrete around inside the forms — no raking

allowed. Vibrators should not be used for that purpose

Proper vibration must be implemented. (Proper vibrating- dropping the

vibrator under its own weight until it gets to the desired drop height, then

leaving it there for 3-7 seconds then pulling at the count of 3~4 seconds.

atelie Cents wen BMPS 9 pone Sebink

acy an fee mess MY Sates

0: alawti le ag Aika mime!

Ansty aoe

bem

For etbreleg ar Acie

Kemi EY Fatt er 9S af Pibic om

eee

neds

ipatieineaee

foe Paine

‘When vibrating sub-sequent layers, vibrator must penetrate a centimeter

into older layer, (Any answer close to this indicates experience.)

d, Some labors must be continuously watching the forms in case a large/high

Pour to ensure no forms failure takes place. In case a wall is being poured,

proper heights (maximum heights) of each concrete lift must be observed,

Such as the usual 600mm stated normally in projects specifications. Also,

tamping on the wall is necessary to assist in the consolidation process.

The concrete temperature and the slump are two strong indicators of

inspector's knowledge. A slump between 75 mm and 125mm is normal for

normal pours. Ifthe inspector has no clue as to even the range, that's

serious! ee allowed, temperature for concrete'when/arrivitig at?

Papeete: i

9. Tell me about structural steel receiving inspection and Structural Stee] Erection

(12:SAMMS.-007/008 & AISC - American Institute of Steel Construction, Pl

STS 05130)?

8, This involved experience in structural steel inspection against abuse and

damage, proper storage, proper sequencing on job site to minimize

damage, etc.)

b. An experienced civil inspector must know about erection of structural

steel based on the AISC 9 American Institute of Steel) specification for

High Strength Bolts A325 & A490. SOLID knowledge in the Tum-Of-

The-Nut method is extremely essential for proper erection!

10. What is the minimum and maximum acceptable asphalt temperature range when

arriving on site (SAES Q-006 and AASHTO)?

11. Whatis the minimum required compaction density of asphalt (SAES Q-006 &

AASHTO)?

apesva

12.12. What is the Prime Coat, and where is it applied (SAES Q-006 & AASHTO)?

What is its curing requirement for the Prime Coat?

It is the asphalt bituminous material that is place on the substrate prior to

a

placement of the first asphalt mixture (the binder course). It must be

allowed to cure and to soak into the capping layer (usually select fill)

b, 24 hours. A good indication that the material cured is when the colors

tums to pitch black, i. The browmnness is gone)

13. What is Tack Coat (SAES Q-006 & AASHTO)?

14. What is the tolerance requirement of sub-grade asphalt surface smoothness prior

to placing asphalt

(Wg a pymeersuaight edge = omih |

15. What is tolerance requirement of finished asphalt surface smoothness (SAES Q-

006 & AASHTO)?

PART.

1. What is your job requirement as QC Inspector?

a. (the answer should coniain the word UQUGHED” in it. If his answer

Indicates he is a foreman or a site engineer, do not hire hin, as his

mentality will be focused on the schedule of his boss (The contractor

Project Engineer or Manager) and not the Quality.)

2. Who will you really work for?

through the RFI system? B@SHOldl 1 the secu

3. Would you walk me through the process of initiating an inspection point

4. Tell me about ITP’s and the QCP?

peer

He Pa ea aes

ype DO phe

por heir €

Ministry of Communication

Interview Tips for Site Inspector

1, What are the main points which you will watch where the earthwork is in

progress?

~ Materiel isiriotloversized (not riore than'8’cin)

- Notover 30cmperlaver

- Not exceeding optimum moisture content or less (not rubberizing or foaming)

~ While grading, see to it that material is not segregated

- Number of passes of rollers during compaction, and weight of compactors. (8

passes minimum with ¥ overlap)

+ Smoothness of the finished surface of subgrade. Contractor should use 4-m

straight-edge. Tolerance limit is 6mm for subgrade, 3mm for asphalt)

2. What are the different types of rollers used for the compaction of asphalt? And

the functions of each?

Initial rolling of the asphalt Only 2 passes at % overlap

-Final rolling to smoothen the surface and to see to it that the edge of the

roller is not visible in the asphalt.

- To attain the required compaction. (8 passes min, not less than 5 tons)

yg mate

3. What is the thickness of each layer allowed for an embankment and for

subgrade? sees

= For embanknient’~°30 eri thick of as oiherwise Specified

- For subgrade. Earth cut — 30 em to be laid in two layers (15 x 15)

Earth fill — 40 om to be laid in two layers (20 x 20) if possible

to attain the required 100% compaction.

+Rock cut: 20cm in one layer

4. What is the procedure for starting the first layer of earthwork if the total height

of embankment is less than 75 cm?

- Grabbing and scarifying the area till 15 cm and watering it, Removing any

unsuitable material then compacting it

5. Suppose the first layer of subgrade was compacted and tested one month back,

would you allow the laying of second layer of subgrade on this work? If not, what

will you require the contractor to do?

= No, the contactor should clean, spray water and re-compact until 100%

compaction is attained

6. What is the max size of gravel you will allow in subgrade layer? What would bea

reasonable C.B.R. for subgrade?

= 80 mm max in subgrade

- CBR value = 20% min for feeder road; 25% min for highway

7. If you find the thickness of subgrade 3 cm less. how would you allow the

contractor to complete the deficient thickness?

~ Scarify up to 12 cm and add the 3 cm layer to make it 15 cm, then re-compact

8 What is the percent compaction required for natural ground embankment,

subgrade and wearing course?

~ Natural ground = Type A (90%)

- Embankment: a below 60 cm, type

’, above 60 cm, type AA (95%)

- Subgrade = Type AAA (100%)

9, What are the requirements of slump for type ‘A’ concrete in your project?

- 75 to 100mm

10. What does 210/25 mean when related to concrete?

= 210 is the compressive strength in ka/om2

- 25 is the maximum size of aggregate

11. What is the specified mixing and rolling temperature for asphalt?

- Mixing = 139 to 163°C

- Rolling = 13525°C or 140.45°C

412. What is the recommended ratio of cement, sand and hydrated lime for grouted

rip rap?

236 : zt

13. If it rains during laying of asphalt, what action would you take?

~ Stop asphalting and continue rolling,

14, What are the tests you run to determine the suitability of subgrade material?

-a. CBR

b. soil classification

«. liquid limit

, plastic limit

15, How would you repair shrinkage cracks in bridge deck?

- Grouting with epoxy coating (resin)

16, How would you compare 7 days & 28 days compressive strength of concrete?

17. To find the loss of stability, how long and at what temperature you need to

immerse the Marshall specimen?

~ 24 hours at 601°C

18. What is the required slump for class ‘A’ vibrated concrete?

- 25 to 75 mm or as specified in the project specifications

*END*

Roads and Bridges

Site Inspection quidelines

(Questions and answers)

1. What are the duties and responsibilities of a Site Inspector?

- Supervise the actual construction in the site as guided and instructed by the civil

or resident engineer.

- Bear direct responsibility for applications of specifications in site

= Make sure that safety measures are applied by the contractor.

= Prepare daily work report in addition to memorenda

~ Not act as a foreman for the contractor.

- Not change specifications and plans

2. Min & Max temperature of asphalt at the site of paving?

+ Min. is 139°C, Max is 163°C

3. Min atmospheric (air) temperature prior-to paving?

= Minis 4°C

4. Min & Max temperature of concrete at the site prior to paving?

= Min concrete temp is 10°C, Max is 32°C

5. Atmospheric (Air) temperature allowed for pouring?

-5°C Min for cold weather

- 33°C Max for hot weather

6. Min atmospheric temperature prior to spraying MC-1 or MC-2?

= Min is 15°C

7. What are the purposes of curing?

- To maintain the amount of water in the conerete mix

- To minimize hairline cracks

8. What is hydration?

It is the formation of a compound by the combination of water and other

substances of in concrete; it is the chemical reaction between water and cement

9. Max and Min slope of chutes used in pouring concrete?

~ Max slope is 1:2 (Vertical to Horizontal), Min slope is 1:3

10. Advantages of reducing water-cement ratio of concrete mix?

+ Increased strength

~ Increased water tightness

~ Lower absorption

~ Increased resistance to weathering

~ Better bond between concrete and reinforcement

11. Max vertical height of chute used in pouring concrete?

~ 1.5 meter max but preferably less than 1.0 meter.

12, How do you determine Grades 40, 60 and 75 steel bars at the site?

~ By its longitudinal stripe marking

Grade 40 —No marking between the longitudinal strips

Grade 60 — One line between the ribs of the steel

Grade 75 ~ Two lines between the ribs of the steel

15. Min length of splicing of rebars?

- 40D or 40 x diameter of rebars.

14. Removal of forms for structures?

~ Arcand Center = 14 days

- Beam and Girder = 10 days

- Slabs: Not more than 3m =4 days

More than 3m but less than 6m =7 days

More than 6m but less than 14m = 10 days

15, What is curing membrane?

- It is @ curing compound applied at the concrete surface to prevent rapid

evaporation of water and to reflect sun's rays of sunlight thereby reducing the

temperature

16. How many times do you apply curing membrane?

~ At least two times. The second application is perpendicular to the first and

applied after the first application has set.

17. What is the purpose of retarder?

- To delay the initial setting of concrete

- To accelerate the effect of hot weather on the setting of concrete.

18, What is the purpose of slump test?

- To determine the consistency or workability of the concrete mix and to check for

the required slumps

19, Allowable slumps?

20. Types of curing?

ret

21. What is plasticizer?

- Usually applied at a low water-cement ratio concrete to make it workable.

- Usually used in pre-stressed concrete.

22, What is composite structure?

24. Types of cement?

-TypeI = Normal or standard cement ( for general use)

Type I-A = Air-entraining cement: same as type I

Moderate Sulfate resistance cement

-Type It

-Type II-A= Air-entraining cement: same as type II

-Type I = High-early strength cement: usually used in pre-stressed concrete

7 -Type IV" = Low Sulfate Resistance cement

-Type V = High Sulfate Resistance cement

25. What is the effect of seawater on concrete?

27. Two types of pre-stressed concrete?

+ 2 = The tendons are tensioned to a desired force before

pouring of concrete, then released after the concrete has attained the desired

strength

- éPet® = The tendons are positioned to their locations, then

poured concrete mix. After the concrete has attained the required strength, then

the tendons are stressed to the specified force.

28, Minimum compressive strength of concrete before applying the force?

mateRst 850 Keema

2. a” strength of the concrete before a

1g concrete before applying the fo:

30. Reasons behind racks?

resuleinysegregation,

senses,

31, What part water-cement ratio plays in concrete?

- The lower the ratio, the stronger the concrete mix, provided it can be

consolidated properly

32. What are the concrete samples?

33. What is the difference between the two and which is preferable?

~ The difference is in their deformation when subjected to compressive loads. The

deformation in cylinder is bigger than in the cube, The cube can withstand bigger

load because of its L/D ratio. But the strength of cylinder is nearer to the actual

strength of the structure being poured than the strength of the cube. That's why

when we use the cube, we multiply the strength that wes gotten by a correction

factor depending on L/D ratio, while in cylinder there is no correction factor

applied

‘how many hours-should concrete mix be discharged after leaving the

34. Wit

cement & water are in the mixer?

batching plant or afterall the aggregat

35. Ifagitated concrete is discharged after more than one hour, what will happen?

~ TBESHEEIE Hover MNeH becomes howandtestrengthisseducee

36. What is the initial setting time of the concrete mix?

“BSNOMO tminutes /

concrete?

bef.

38, What is the mixing time of a stationary or central batching plant (concrete)?

39. For how many days are you going to cure a structure?

aseventdays

40. What is the agitating speed of the mixer?

- T4(6Tevolutions per minute (rpmi

41. What is the mixing speed of the mixer?

Selo 18ipia

42. What is concrete fatigue?

~ Iti the weakening of material caused by repeated loads

43. What is creep? - (crav@i's)

= It is the deformation due to the sustained load

44, Bends? 4

D = Diameter of bend, d= diameter of rebars

=D = 6d, for rebars dia. 22mm or less i Hh anynuee O35

-D=8d, for rebars dia. 24 to 28mm.

- D = 104, for rebars dia, 30 and above

45. How would you know if the concrete has attained its initial set?

= If there is no more water seen (brightness) on the surface of the concrete, or if

there is no water on the surface of the concrete,

ASPHALT

46. What is the differénce between MC-1 and RC-2?

~ By just looking and smelling, MC-1 smells kerosene and looks dull aad is

thicker, while RC-2 smells benzene (gasoline) and looks shiny and is thinner and

Gries rapidly.

47. What are you going to do if there is bleeding in MC-1 or if the MC-1 is not dry

after 48 hours?

- I will apply blotting by spreading sands on wet portion only then removing the

excess by take or any suitable equipment

48. What is rutting?* inet owes by reel

“It is the longitudinal settlement of asphalt pavement due to heavy loads of the

vehicles passing the road

49. What are the remedies to prevent or minimize rutting?

+ To limit or minimize the loads of vehicle

- To make the gradation of aggregates coarser but conducive to the project

= To lower the asphalt content and/or lower the asphalt penetration (as from 60-70

to 40-50)

~ To follow the instruction of the M.0.C. as to the limits of air voids which is 3-5

with 4 as the median and actual air voids to be gorten

Sine purpose af MC-4(Medium Curing Cutback Asphalt)?

50.

wranular surface or subgrade-and:to promote bonding to

bitiiitivious surface

51. What is the jirpose ar RC-2(Rapid/Curing Cutback Asphalt)?

~ Tlefsurejonpramote bonding betweeirthe previouslydaid/asphaltppavementand

‘HERewly paved lever

52. Minimum and maximum overlapping of asphalt in longitudinal and transverse

joints?

-For longitudinal joint = 15 10 30 em.

53. Why do you overlap?

~ To prevent cracking at the longitudinal joint.

54, What will happen if your asphalt content is more than 0.3%?

= It will be more than the required limits and bleeding will occur and thereby

‘weakening the pavement

55. What is the max loss of stability for asphalt?

= 25%

56. What is the max variation of asphalt content?

+ phis or minus 03% from lie approved asphalt content,

57. Types of compaction and moisture ranges?

= Type AAA = 100% compaction, 78% relative density

Moisture ranges = MR 3 (Moisture shall not be lower than 3% of

the optimum moisture)

- Type AA =95% compaction, 74% relative density

‘Moisture ranges = 0 (moisture shall be 5% of optimum moisture)

10% compaction, 70% relative density

-TypeA =

58. Temperature of asphalt pavement before breakdown or initial rolling?

= 120°C min or as what we get from tial test

59. Heating temperature of MC-1 and RC-2 before spraying?

-MC-1 should be heated to 50-80°C

-RC-2 should be heated to 65-95°C

60. Rate of application of MC-1 and RC-2?

-MC-1 =Itis 0.65 1.75 literfm2

RC-2 =Itis equal or less than 0.25 liters/m2

61, What are the two types of asphalt batching plant?

4Bstch typs\— It is easy 10 control and it is batched by weight

CofiniGus type — It has a greater output

6 ug

id Penietation Testtit is usually made to evaluate the bearing capacity of

the soll

63. What is Bleeding?

- Its the flow of water in the mix or on to the surface of the mix because of the

settlement of the mass in concrete mix.

64, How do you cure cylinder samples?

amples are Glired in JabOratoTyy in Water tank satiated With Time at 23

\advisable to eure\in the field) Sam as the structure being represented ’

65. What are the precautionary measures if the air temp. is greater than 33°C?

ades; cad] the water by using ice Cubes!

pecially the coarse with cold weter.

jattern of rolling asphalt pavement?

sthen |goitif Upward to the higher

wheel wadtls 4

67. Tolerance of asphalt using 4 meter straight edge?

- Wearing coarse; 3mm perpendicular to centerline

4mm parallel to centerline

‘6mm perpendicular to centerline

6mm parallel to centerline

-Subgrade + 10mm.

- Base course

68. Maximum thickness for base course and wearing course?

=Base course: 80mm for * layer to 60mm for 2" layer

~ Wearing course : 80mm for 1* layer to 50mm for surface layer (compacted)

69, Difference between mobile & stationary stringline?

~ Mobile stringline is attached to the power while stationary stringline is attached

to the stakes and moved manually as the power goes.

70, How many passes of rollers do you make before reaching the required density or

compaction of a pavement?

~ It depends upon the result of a trial test on a trial stretch, in which you paved a

certain stretch, then rolled it, then took coring and computed for its density, which

in tum compared to the marshall density at the laboratory. If the compaction is

satisfactory, the number of passes that the roller was made at that time is the

number of passes to be used in further paving and rolling process

71. How do you know the rate of application of MC-1 and RC-2?

= It is also by trial test on a trial stretch, in which you put @ Sem by SOcm

cardboard on the stretch then let the distributor run through this cardboard with

the known speed. Then find the weight of MC-1 or RC-2 in the cardboard, Then

compute for the rate of application

72. Study the procedures in making the following tests and the equipments used:

- Slump test

= Concrete cylinder

- Compressive test on oylinders

- Field density tests (FDT)

- Liquid Limit and Plastic Limit

- Proctor or Moisture-Density test

- California Bearing Ratio (CBR)

= Study your duties and works during and before the paving of asphalt &

concreting

SOILS.

74. What is CBR (California Bearing Ratio)?

«= It is the test used to find the bearing capacity o

moisture content and at different densities (10, 30, 65 blows)

f soil compacted at optimum

75, What is Proctor or Moisture-Density Test?

= It is the test used to find the moisture and density relation of a soil when

compacted at laboratory.

76, What is the distance of borrow pit from structur’

- Downstream: Min is 200 meters or as otherwise specified.

77. What is the distance of borrow pit from roadway toe or embankment?

- Minimum is 30 meters from the toe of embankment.

78. Study the programming of works, especially pouring of concrete, number of

mizers, volume of concrete to be poured and manpower requirements.

79. What is the test for rock fill?

> It is by consolidation in which grid points are made and then let the roller

passed, then elevations of points are taken, then again passing the roller and

elevations of points taken. The difference in elevations between the passes shall

not vary from 0 to 3 centimeter

80, What is the maximum size of rock used in rock fill?

= Not more than 60 cm (or see the green book)

81. What is the rock fill allowed?

~ At least 60 cm. (or see the green book)

82. What is the difference between Modified and Standard Proctor (using same 6

inches mold)?

~ The difference is in their compacting effort. Although its layer is compacted (5

layer) is compacted 56 blows, but the weight of the rammer of standard is 5.5 Ibs.

with 12-in, drop while that of modified is 10 Ibs. and 18-in. drop.

‘83. What is the difference between CBR 5 and CBR 10?

- CBR 10 has more strength than CBR 5.

84, For instance, in embankment you have 1x1x0.2m and have moisture of 0.2% but

at the laboratory you have 8%. How many liters of water you need? Density of soil

2Tonsim3-——

~ Solution:

Volume 2%

Water needed = 8-2=6%

400 kg

Weight = Vol. x Density = 0.2 m3 x 2 T/m3 = 0.4 Tor

Since 1 kg =1 liter for 4°C temp.

Then, water needed = 0,06 x 400 kg =24 kg = 24 liters

85, For instance, it rained the whole night and your aggregates and sands were wet.

How do you find the water?

=I should inform the Material Engineer so that he will check the aggregates and

the moisture,

86. What kind of soil you use in subgrade?

-Acd-a/ Acl-b/A-2-b

87. How about embankment?

~ Any suitable materials like A-l/A-2/ A-3 / A-8/ A-S/A-6

88. Can you use rock fill for backfilling of structures?

- No, because it will damage the structure.

89. What materials are you going to use for backfilling structures?

~ Granular materials like A-l or A-2

90. What is the temperature of asphalt required to stop rolling?

~ 80 10 90°C

91. How do you perform slump test?

- Take sample from the concrete mix, put it in the mould, and rod it 25 times each

layer, for three equal layers.

92. How do you know that the contractor is using the right mixture of aggregate? If

the aggregate is 30% natural and 70% crushed sand, not using the contro! room or

the scales.

- Close all the automatic feeders except for natural sand and let it ow for 2

certain time, s¢30 seconds, then compute the quantity at 30 sec. Then make the

same steps as to the crushed sand, this time the bin for natural sand is closed, and

the time for flowing is 70 sec, then compute the quantity of crushed sand

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Rtcmd-Esu Oct 4 2016 PDFDocument9 pagesRtcmd-Esu Oct 4 2016 PDFVic ValdezNo ratings yet

- Request 1 WeekDocument1 pageRequest 1 WeekVic ValdezNo ratings yet

- Inventory QueryDocument36 pagesInventory QueryVic ValdezNo ratings yet

- December 2023 Calendar Portrait 3 MonthsDocument1 pageDecember 2023 Calendar Portrait 3 MonthsVic ValdezNo ratings yet

- 212Document4 pages212Vic ValdezNo ratings yet

- O Core Tech International: Daily Time RecordDocument1 pageO Core Tech International: Daily Time RecordVic ValdezNo ratings yet

- LectureDocument4 pagesLectureVic ValdezNo ratings yet

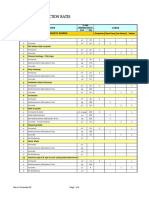

- Labor Production Rates: Concrete WorksDocument4 pagesLabor Production Rates: Concrete WorksVic ValdezNo ratings yet

- V.F. Welding Supplies 3Document1 pageV.F. Welding Supplies 3Vic ValdezNo ratings yet

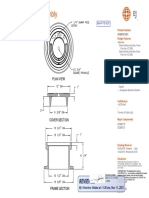

- Frame and Cover Equivalent SBF 1246SDocument1 pageFrame and Cover Equivalent SBF 1246SVic ValdezNo ratings yet

- Formats For The Geoid Models: ContentDocument7 pagesFormats For The Geoid Models: ContentVic ValdezNo ratings yet

- Timesheet 01062021Document10 pagesTimesheet 01062021Vic ValdezNo ratings yet

- Basis of Design - Structural Support BuildingDocument16 pagesBasis of Design - Structural Support BuildingVic ValdezNo ratings yet

- 153844506procedure Scope of WorkDocument20 pages153844506procedure Scope of WorkVic ValdezNo ratings yet

- FDOT Subassemblies Essentials FDOT Subassemblies EssentialsDocument21 pagesFDOT Subassemblies Essentials FDOT Subassemblies EssentialsVic ValdezNo ratings yet

- Labor and Equipment Production RatesDocument8 pagesLabor and Equipment Production RatesVic Valdez100% (1)

- Structural Design of Two Storey Recidencnce Owner: Ferdinand Dela Cruz Address: Sto. Tomas, San Jose CityDocument11 pagesStructural Design of Two Storey Recidencnce Owner: Ferdinand Dela Cruz Address: Sto. Tomas, San Jose CityVic ValdezNo ratings yet

- Conversion Tables of Measuring UnitsDocument14 pagesConversion Tables of Measuring UnitsVic ValdezNo ratings yet

- Sizing of Wires AWGDocument4 pagesSizing of Wires AWGVic ValdezNo ratings yet

- Labor and Equipment Production RatesDocument8 pagesLabor and Equipment Production RatesVic Valdez100% (1)

- Make A DTM and Drape An Image MicroStation Pre-V8i - AskInga Community Wiki - AskInga - Bentley CommunitiesDocument16 pagesMake A DTM and Drape An Image MicroStation Pre-V8i - AskInga Community Wiki - AskInga - Bentley CommunitiesVic ValdezNo ratings yet