Professional Documents

Culture Documents

Design Considerations

Design Considerations

Uploaded by

saurabhjerps231221Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Considerations

Design Considerations

Uploaded by

saurabhjerps231221Copyright:

Available Formats

1.

Design Considerations Page 1

1. Design Considerations

Introduction

Types of Busbar

Choice of Busbar Material

Introduction

The word busbar, derived from the Latin word omnibus ('for all'), gives the idea of a universal system of conveyance. In the

electrical sense, the term bus is used to describe a junction of circuits, usually in the form of a small number of inputs and many

outputs. 'Busbar' describes the form the bus system usually takes, a bar or bars of conducting material.

In any electrical circuit some electrical energy is lost as heat which, if not kept within safe limits, may impair the performance of

the system. This energy loss, which also represents a financial loss over a period of time, is proportional to the effective resistance

of the conductor and the square of the current flowing through it. A low resistance therefore means a low loss; a factor of

increasing importance as the magnitude of the current increases.

The capacities of modern-day electrical plant and machinery are such that the power handled by their control systems gives rise to

very large forces. Busbars, like all the other equipment in the system, have to be able to withstand these forces without damage. It

is essential that the materials used in their construction should have the best possible mechanical properties and are designed to

operate within the temperature limits laid down in BS 159, BS EN 60439-1:1994, or other national or international standards.

A conductor material should therefore have the following properties if it is to be produced efficiently and have low running costs

from the point of view of energy consumption and maintenance:

a) Low electrical and thermal resistance

b) High mechanical strength in tension, compression and shear

c) High resistance to fatigue failure

d) Low electrical resistance of surface films

e) Ease of fabrication

f) High resistance to corrosion

g) Competitive first cost and high eventual recovery value

This combination of properties is met best by copper. Aluminium is the main alternative material, but a comparison of the

properties of the two metals shows that in nearly all respects copper is the superior material.

Types of Busbar

Busbars can be sub-divided into the following categories, with individual busbar systems in many cases being constructed from

several different types:

a) Air insulated with open phase conductors

b) Air insulated with segregating barriers between conductors of different phases.

c) Totally enclosed but having the construction as those for (a) and (b)

http://www.copperinfo.co.uk/busbars/pub22-copper-for-busbars/sec1.htm 3/18/2012 6:24:52 AM

1. Design Considerations Page 2

c) Totally enclosed but having the construction as those for (a) and (b)

d) Air insulated where each phase is fully isolated from its adjacent phase(s) by an earthed enclosure. These are

usually called 'Isolated Phase Busbars'.

e) Force-cooled busbar systems constructed as (a) to (d) but using air, water, etc. as the cooling medium under

forced conditions (fan, pump, etc.).

f) Gas insulated busbars. These are usually constructed as type (e) but use a gas other than air such as SF 6,

(sulphur hexafluoride).

g) Totally enclosed busbars using compound or oil as the insulation medium.

The type of busbar system selected for a specific duty is determined by requirements of voltage, current, frequency, electrical

safety, reliability, short-circuit currents and environmental considerations. Table 1 outlines how these factors apply to the design of

busbars in electricity generation and industrial processes.

Table 1 Comparison of typical design requirements for power generation and industrial process systems

Feature Generation Industrial Processes

1 Voltage drop Normally not important Important

2 Temperature rise Usually near to maximum allowable. In many cases low due to

Capitalisation becoming important. optimisation of first cost and running

costs.

3 Current range Zero to 40 k A a .c . with frequencies of zero to Zero to 200 kA a.c. and d.c.

400 Hz.

4 Jointing and connections Usually bolted but high current applications are Usually bolted. Joint preparation

often fully welded. Joint preparation very very important.

important

5 Cross-sectional area Usually minimum. Somewhat larger if Usually larger than minimum

optimisation is required. required due to optimisation and

voltage drop considerations.

6 Kelvin's Law Not applied. Other forms of optimisation are Applies. Also other forms of

often used. optimisation and capitalisation used

7 Construction Up to 36 k V. Individually engineered using Usually low voltage. Individually

basic designs and concepts. engineered. Standard products for

low current/voltage applications.

8 Enclosures Totally enclosed with or without ventilation. Usually open. Enclosed or protected

by screens when using standard

products.

9 Fault capacity Usually large. Designed to meet system Usually similar to running current.

requirement. Standard products to suit system

short circuit.

10 Phase arrangement Normally 3 phase flat though sometimes trefoil. Normally flat but transposition used

to improve current distribution on

large systems

11 Load factor Usually high. Normally 1.0. Usually high but many have widely

varying loads.

12 Cost Low when compared with associated plant. Major consideration in many cases.

Particularly when optimisation/

capitalisation is used.

13 Effects of failure Very serious. High energies dissipated into Limited by low voltage and busbar

fault. size.

14 Copper type High conductivity. High conductivity.

http://www.copperinfo.co.uk/busbars/pub22-copper-for-busbars/sec1.htm 3/18/2012 6:24:52 AM

1. Design Considerations Page 3

Feature Generation Industrial Processes

1 Voltage drop Normally not important Important

2 Temperature rise Usually near to maximum allowable. In many cases low due to

Capitalisation becoming important. optimisation of first cost and running

costs.

3 Current range Zero to 40 k A a .c . with frequencies of zero to Zero to 200 kA a.c. and d.c.

400 Hz.

4 Jointing and connections Usually bolted but high current applications are Usually bolted. Joint preparation

often fully welded. Joint preparation very very important.

important

5 Cross-sectional area Usually minimum. Somewhat larger if Usually larger than minimum

optimisation is required. required due to optimisation and

voltage drop considerations.

6 Kelvin's Law Not applied. Other forms of optimisation are Applies. Also other forms of

often used. optimisation and capitalisation used

7 Construction Up to 36 k V. Individually engineered using Usually low voltage. Individually

basic designs and concepts. engineered. Standard products for

low current/voltage applications.

8 Enclosures Totally enclosed with or without ventilation. Usually open. Enclosed or protected

by screens when using standard

products.

9 Fault capacity Usually large. Designed to meet system Usually similar to running current.

requirement. Standard products to suit system

short circuit.

10 Phase arrangement Normally 3 phase flat though sometimes trefoil. Normally flat but transposition used

to improve current distribution on

large systems

11 Load factor Usually high. Normally 1.0. Usually high but many have widely

varying loads.

12 Cost Low when compared with associated plant. Major consideration in many cases.

Particularly when optimisation/

capitalisation is used.

13 Effects of failure Very serious. High energies dissipated into Limited by low voltage and busbar

fault. size.

14 Copper type High conductivity. High conductivity.

15 Copper shape Usually rectangular. Tubular used for high current force-cooled. Usually large cross section rectangular. Tubular used for some low current high voltage

applications and high current force-cooled.

Choice of Busbar Material

At the present time the only two commercially available materials suitable for conductor purposes are copper and aluminium. The

table below gives a comparison of some of their properties. It can be seen that for conductivity and strength, high conductivity

copper is superior to aluminium. The only disadvantage of copper is its density; for a given current and temperature rise, an

aluminium conductor would be lighter, even though its cross-section would be larger. In enclosed systems however, space

considerations are of greater importance than weight. Even in open-air systems the weight of the busbars, which are supported at

intervals, is not necessarily the decisive factor.

Table 2 Typical relative properties of copper and aluminium

Copper(CW004A) Aluminium (1350) Units

http://www.copperinfo.co.uk/busbars/pub22-copper-for-busbars/sec1.htm 3/18/2012 6:24:52 AM

1. Design Considerations Page 4

(annealed)

Temperature coefficient of 0.0039 0.004 /° C

resistance(annealed)

Thermal conductivity at 20°C 397 230 W/mK

Coefficient of expansion 17 x 10–6 23 x 10–6 /° C

Tensile strength (annealed) 200 – 250 50 – 60 N/mm2

Tensile strength (half–hard) 260 – 300 85 – 100 N/mm2

0.2% proof stress (annealed) 50 – 55 20 – 30 N/mm2

0.2% proof stress (half–hard) 170 – 200 60 – 65 N/mm2

Elastic modulus 116 – 130 70 kN/mm2

Specific heat 385 900 J/kg K

Density 8.91 2.70 g/cm3

Melting point 1083 660 °C

The electromagnetic stresses set up in the bar are usually more severe than the stress introduced by its weight. In particular,

heavy current-carrying equipment necessitates the use of large size conductors, and space considerations may be important. It

should be realised that the use of copper at higher operating temperatures than would be permissible for aluminium allows

smaller and lighter copper sections to be used than would be required at lower temperatures.

The ability of copper to absorb the heavy electromagnetic and thermal stresses generated by overload conditions also gives a

considerable factor of safety. Other factors, such as the cost of frequent supports for the relatively limp aluminium, and the

greater cost of insulation of the larger surface area, must be considered when evaluating the materials.

From published creep data, it can be seen that high conductivity aluminium exhibits evidence of significant creep at ambient

temperature if heavily stressed. At the same stress, a similar rate of creep is only shown by high conductivity copper at a

temperature of 150°C, which is above the usual operating temperature of busbars.

Table 3 Comparison of creep and fatigue properties of high conductivity copper and aluminium

a) Creep properties

Material Testing Temp. °C Min. Creep Rate % per 1000 Stress N/mm2

h

Al (1080) annealed 20 0.022 26 *

HC Cu annealed 150 0.022 26 *

Cu-0.086% Ag 50% c.w. 130 0.004 138

Cu-0.086% Ag 50% c.w. 225 0.029 96.

* Interpolated from fig.3

b) Fatigue properties

Material Fatigue strength N/mm2 No. of cycles x 106

HC Al annealed 20 50

http://www.copperinfo.co.uk/busbars/pub22-copper-for-busbars/sec1.htm 3/18/2012 6:24:52 AM

1. Design Considerations Page 5

half-hard 115 300

If much higher stresses or temperatures are to be allowed for, copper containing small amounts (about 0.1%) of silver can be

used successfully. The creep resistance and softening resistance of copper-silver alloys increase with increasing silver content.

In the conditions in which high conductivity aluminium and copper are used, either annealed (or as-welded) or half-hard, the

fatigue strength of copper is approximately double that of aluminium. This gives a useful reserve of strength against failure initiated

by mechanical or thermal cycling.

The greater hardness of copper compared with aluminium gives it better resistance to mechanical damage both during erection

and in service. It is also less likely to develop problems in clamped joints due to cold metal flow under the prolonged application of

a high contact pressure. Its higher modulus of elasticity gives it greater beam stiffness compared with an aluminium conductor of

the same dimensions. The temperature variations encountered under service conditions require a certain amount of flexibility to be

allowed for in the design. The lower coefficient of linear expansion of copper reduces the degree of flexibility required.

Because copper is less prone to the formation of high resistance surface oxide films than aluminium, good quality mechanical

joints are easier to produce in copper conductors. Welded joints are also readily made. Switch contacts and similar parts are

nearly always produced from copper or a copper alloy. The use of copper for the busbars to which these parts are connected

therefore avoids contacts between dissimilar metals and the inherent jointing and corrosion problems associated with them.

The higher melting point and thermal conductivity of copper reduce the possibility of damage resulting from hot spots or accidental

flashovers in service. If arcing occurs, copper busbars are less likely to support the arc than aluminium. Table 4 shows that

copper can self-extinguish arcs across smaller separations, and at higher busbar currents. This self-extinguishing behaviour is

related to the much larger heat input required to vaporise copper than aluminium.

Table 4 Self-extinguishing arcs in copper and aluminium busbars

Copper Aluminium

Minimum busbar spacing, mm 50 100

Maximum current per busbar, A 4500 3220

Copper liberates considerably less heat during oxidation than aluminium and is therefore much less likely to sustain combustion in

the case of accidental ignition by an arc. The large amounts of heat liberated by the oxidation of aluminium in this event are

sufficient to vaporise more metal than was originally oxidised. This vaporised aluminium can itself rapidly oxidise, thus sustaining

the reaction. The excess heat generated in this way heats nearby materials, including the busbar itself, the air and any supporting

fixtures. As the busbar and air temperatures rise, the rates of the vaporisation and oxidation increase, so accelerating the whole

process. As the air temperature is increased, the air expands and propels hot oxide particles. The busbar may reach its melting

point, further increasing the rate of oxidation and providing hot liquid to be propelled, while other materials such as wood panels

may be raised to their ignition temperatures. These dangers are obviated by the use of copper busbars.

Finally, copper is an economical conductor material. It gives long and reliable service at minimum maintenance costs, and when

an installation is eventually replaced the copper will have a high recovery value. Because of its many advantages, copper is still

used worldwide as an electrical conductor material despite attempts at substitution.

http://www.copperinfo.co.uk/busbars/pub22-copper-for-busbars/sec1.htm 3/18/2012 6:24:52 AM

You might also like

- (CDA) Pub-22 Copper For BusbarsDocument116 pages(CDA) Pub-22 Copper For Busbarsnooruddinkhan1100% (2)

- Supercapacitors 101: A home Inventors HandbookFrom EverandSupercapacitors 101: A home Inventors HandbookRating: 5 out of 5 stars5/5 (1)

- Laboratory Experiment No. 8 Advanced Acid-BaseDocument4 pagesLaboratory Experiment No. 8 Advanced Acid-BaseShayne Angelique CongsonNo ratings yet

- Pub-22 Copper For BusbarsDocument101 pagesPub-22 Copper For BusbarssteevemrNo ratings yet

- Busbar ImpedanceDocument3 pagesBusbar Impedancesaurabhjerps231221No ratings yet

- CBSE Class 3 Mathematics - MultiplicationDocument4 pagesCBSE Class 3 Mathematics - Multiplicationsaurabhjerps231221100% (1)

- 01 - BUSBAR Copper Info (Design Considerations)Document5 pages01 - BUSBAR Copper Info (Design Considerations)Zen Azhar Bin ShuibNo ratings yet

- Copper For BusbarsDocument159 pagesCopper For BusbarsonyiabNo ratings yet

- Chapter (5) : (Bus Bars)Document28 pagesChapter (5) : (Bus Bars)Anirban SenNo ratings yet

- SH BusbarsDocument28 pagesSH BusbarsSanjeewa Hemaratne100% (1)

- Design ConsiderationsDocument5 pagesDesign ConsiderationsKhalith MansoorNo ratings yet

- Instalasi Sistem DCDocument27 pagesInstalasi Sistem DCkasurpelajar bajahitamNo ratings yet

- BusBar LiteratureDocument4 pagesBusBar LiteratureschaktenNo ratings yet

- SeminarDocument25 pagesSeminar19-413 RohithaNo ratings yet

- Copper For BusbarsDocument104 pagesCopper For Busbarst_syamprasadNo ratings yet

- Technical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power SuppliesDocument4 pagesTechnical Article: Ten Tips For Designing Small and Efficient AC/DC Switching Power Suppliesatul vijayvergiyaNo ratings yet

- Copper For BusbarsDocument104 pagesCopper For BusbarsKhaled Salahul Den100% (1)

- Calculo de Barras - Pub 22 - OesDocument136 pagesCalculo de Barras - Pub 22 - OesOscar SchmüthNo ratings yet

- Bus Bar CalculationDocument13 pagesBus Bar CalculationاحمدرضاNo ratings yet

- Single Cell Brochure S23Document27 pagesSingle Cell Brochure S23AsyrafNo ratings yet

- Grounding-Back To BasicsDocument5 pagesGrounding-Back To BasicsUsman TariqNo ratings yet

- Terminations BrochureDocument14 pagesTerminations BrochureOscar MonroyNo ratings yet

- The GEAFOL Basic - Compact Power, Convincing Data: Answers For EnergyDocument6 pagesThe GEAFOL Basic - Compact Power, Convincing Data: Answers For EnergyMohamed ElnahNo ratings yet

- Fault LevelsDocument9 pagesFault LevelssorenofayeNo ratings yet

- Mcdowall2000 PDFDocument4 pagesMcdowall2000 PDFeddisonfhNo ratings yet

- Choosing The Inductor For A Buck ConverterDocument4 pagesChoosing The Inductor For A Buck ConverterKarthikonsplashNo ratings yet

- Ring Main Units (RMUs), Construction, Working and Comparison With Switch-Gears - TurboFutureDocument1 pageRing Main Units (RMUs), Construction, Working and Comparison With Switch-Gears - TurboFuturemfah020087No ratings yet

- Preventing Failures in Isolated Phase Bus TimperleyDocument48 pagesPreventing Failures in Isolated Phase Bus TimperleyMagoroku D. YudhoNo ratings yet

- Dirty Dozen in EeDocument5 pagesDirty Dozen in EeAnabeth Tuazon SuancoNo ratings yet

- Surge Current Protection Using Superconductors: Shubham Gupta ROLL NO. - 1619221052Document24 pagesSurge Current Protection Using Superconductors: Shubham Gupta ROLL NO. - 1619221052Ajay GohreNo ratings yet

- Types of Capacitor - Wikipedia, The Free EncyclopediaDocument13 pagesTypes of Capacitor - Wikipedia, The Free EncyclopediaManitNo ratings yet

- Circuit Breaker Maintenance in Easy Steps: Transmission and DistributionDocument3 pagesCircuit Breaker Maintenance in Easy Steps: Transmission and Distributionamirtha_s2238No ratings yet

- Power Engineering: Sunday, 27 October 2013Document12 pagesPower Engineering: Sunday, 27 October 2013Ajay SheeNo ratings yet

- Busbar DetailsDocument12 pagesBusbar DetailsAjay SheeNo ratings yet

- Busbar DetailsDocument12 pagesBusbar DetailsAjay SheeNo ratings yet

- Busbar DetailsDocument12 pagesBusbar DetailsAjay SheeNo ratings yet

- Grounding and Ground Fault Protection of Multiple GeneratorsDocument5 pagesGrounding and Ground Fault Protection of Multiple Generatorsmanirup_tce0% (1)

- Design Considerations: Types of Busbar Choice of Busbar MaterialDocument96 pagesDesign Considerations: Types of Busbar Choice of Busbar MaterialNikhilesh BabuNo ratings yet

- Shunt&Series Reactors and Their FactoryDocument64 pagesShunt&Series Reactors and Their FactoryAnonymous 2l8XJIV100% (1)

- Battery Management in Wireless Sensor Networks: Doru E. TiliuteDocument4 pagesBattery Management in Wireless Sensor Networks: Doru E. TiliuteTiffany BryanNo ratings yet

- MECCOCT18-12529: Risk Based Assement of Copper Vs Zinc For Ac MitigationDocument7 pagesMECCOCT18-12529: Risk Based Assement of Copper Vs Zinc For Ac MitigationMalik Ansar HayatNo ratings yet

- Specifying A SolenoidDocument2 pagesSpecifying A SolenoidfadhlidzilNo ratings yet

- Shunt Reactors White Paper GEA31994 PDFDocument8 pagesShunt Reactors White Paper GEA31994 PDFAndré LuizNo ratings yet

- SBLSBMSBH Datos PDFDocument47 pagesSBLSBMSBH Datos PDFJose Joaquin Baeza VeluetaNo ratings yet

- BUSBAR Size and CapacityDocument8 pagesBUSBAR Size and CapacityJohn Garnet50% (2)

- SE - Specifications For LV Assembly Switch - IEC 61439-1-2Document24 pagesSE - Specifications For LV Assembly Switch - IEC 61439-1-2Djana GanibegovicNo ratings yet

- At Speed TestDocument20 pagesAt Speed TestJa JaNo ratings yet

- Current Limiting and DCM Flyback Design: LogoutDocument3 pagesCurrent Limiting and DCM Flyback Design: LogoutkishordaNo ratings yet

- Surge Current Protection Using Superconductors 8704 3SPdQYZDocument39 pagesSurge Current Protection Using Superconductors 8704 3SPdQYZsai krishna pothuNo ratings yet

- Grounding Basics 2 - Stationary System GroundingDocument18 pagesGrounding Basics 2 - Stationary System GroundingCarolNo ratings yet

- Slup 076Document11 pagesSlup 076Daniel CasasNo ratings yet

- Design and Comparison of High Frequency Transformers Using Foil and Round WindingsDocument7 pagesDesign and Comparison of High Frequency Transformers Using Foil and Round WindingsFelipe FerreiraNo ratings yet

- Redflow ZBM: The Zinc Bromide Flow BatteryDocument2 pagesRedflow ZBM: The Zinc Bromide Flow BatteryChung MinhNo ratings yet

- SCWT Acb1Document4 pagesSCWT Acb1PRABAKARAN TNo ratings yet

- House Wiring For Beginners: SafetyDocument19 pagesHouse Wiring For Beginners: Safetyalexwongks6118100% (2)

- Single Cell RangeDocument27 pagesSingle Cell RangeAngel Quijano ArmengolNo ratings yet

- PMG Newsletter (Volume 03. Issue 11)Document15 pagesPMG Newsletter (Volume 03. Issue 11)jitendra.singhNo ratings yet

- Design For Life - Linkedin - Part1Document1 pageDesign For Life - Linkedin - Part1Paul HornerNo ratings yet

- Bushings PDFDocument6 pagesBushings PDFeider yovannis payares davilaNo ratings yet

- Dimmers: by Andrew PenfoldDocument4 pagesDimmers: by Andrew PenfoldDimitrios TriantafyllidisNo ratings yet

- Circuit Elements: 3.4.3.1 CapacitorsDocument1 pageCircuit Elements: 3.4.3.1 CapacitorsCarlos SaavedraNo ratings yet

- Automoti've Batteries at Low Temperatures: Cold Regions Technical'DigestDocument25 pagesAutomoti've Batteries at Low Temperatures: Cold Regions Technical'DigestJohnny M. Pancha RamosNo ratings yet

- Surge Current Protection Using Super ConductorsDocument38 pagesSurge Current Protection Using Super ConductorsAbhishek KumarNo ratings yet

- Central Electro Trders Paragon Electricals Prime EnterprisesDocument1 pageCentral Electro Trders Paragon Electricals Prime Enterprisessaurabhjerps231221No ratings yet

- Sheet 4: Price List For H.T Xlpe Multicore Cables Dtd. 1st March 2010Document1 pageSheet 4: Price List For H.T Xlpe Multicore Cables Dtd. 1st March 2010saurabhjerps231221No ratings yet

- Indian Cables & Electricals PVT - LTDDocument2 pagesIndian Cables & Electricals PVT - LTDsaurabhjerps231221100% (1)

- Sri Balaji Enterprises - Just Another Wordpress SiteDocument3 pagesSri Balaji Enterprises - Just Another Wordpress Sitesaurabhjerps231221No ratings yet

- Syntron Price List Wef 9TH Aug 2012Document2 pagesSyntron Price List Wef 9TH Aug 2012saurabhjerps231221No ratings yet

- Frequently Asked Questions (Faqs)Document2 pagesFrequently Asked Questions (Faqs)saurabhjerps231221No ratings yet

- Atvus Buchholz RelaylDocument3 pagesAtvus Buchholz Relaylsaurabhjerps231221No ratings yet

- Ed Downloads As A MDocument3 pagesEd Downloads As A Msaurabhjerps231221No ratings yet

- CBSE Class 3 Mathematics - 4 Digit NumbersDocument3 pagesCBSE Class 3 Mathematics - 4 Digit Numberssaurabhjerps231221100% (3)

- Dasaratha Shani Stotra: Dasaratha Shani Stotra in HindiDocument8 pagesDasaratha Shani Stotra: Dasaratha Shani Stotra in HindiShalini Dass0% (1)

- International English Olympiad Class 1 Sample Paper: Word and Structure KnowledgeDocument2 pagesInternational English Olympiad Class 1 Sample Paper: Word and Structure Knowledgesaurabhjerps231221100% (1)

- CBSE Class 3 Mathematics - Addition & SubtractionDocument3 pagesCBSE Class 3 Mathematics - Addition & Subtractionsaurabhjerps231221No ratings yet

- Maths Olympiad Level 2 Sample PaperDocument5 pagesMaths Olympiad Level 2 Sample Papersaurabhjerps231221No ratings yet

- Bus Bar Insulation Tube YDDocument1 pageBus Bar Insulation Tube YDsaurabhjerps231221No ratings yet

- Babbitt Casting and Babbitt Spraying Processes Case Study PDFDocument3 pagesBabbitt Casting and Babbitt Spraying Processes Case Study PDFsaurabhjerps231221No ratings yet

- A Study On Residential Fires Due To Electrical Faults in Hong KongDocument11 pagesA Study On Residential Fires Due To Electrical Faults in Hong Kongsaurabhjerps231221No ratings yet

- Di MCB DB Pricelist01!07!2018Document1 pageDi MCB DB Pricelist01!07!2018saurabhjerps231221No ratings yet

- SAKOVA Make Automatic Oil Test Set Is Designed For Speedy and Accurate Testing ofDocument2 pagesSAKOVA Make Automatic Oil Test Set Is Designed For Speedy and Accurate Testing ofsaurabhjerps231221No ratings yet

- Quotation Request Form For SOLENOID VALVESDocument1 pageQuotation Request Form For SOLENOID VALVESsaurabhjerps231221No ratings yet

- Earth Tester: FeaturesDocument1 pageEarth Tester: Featuressaurabhjerps231221No ratings yet

- 15 Difference Between Pipe and TubeDocument5 pages15 Difference Between Pipe and TubeFebrianto Edy PratamaNo ratings yet

- Seepage Through DamsDocument12 pagesSeepage Through DamsCzar Alexis FernandezNo ratings yet

- HPDC Design Gate and VentingDocument13 pagesHPDC Design Gate and Ventingcleitononline4599No ratings yet

- PresentationDocument43 pagesPresentationPearl PrakashNo ratings yet

- Assessing Flow Conditions: Subcritical & Supercritical FlowDocument6 pagesAssessing Flow Conditions: Subcritical & Supercritical FlowMie EeNo ratings yet

- Activity A and BDocument19 pagesActivity A and BZiegfred AlmonteNo ratings yet

- HWRCP 1 PDFDocument3 pagesHWRCP 1 PDFAnonymous PCsoNCt0mFNo ratings yet

- 5CE4-04 GT Guess Paper PDFDocument3 pages5CE4-04 GT Guess Paper PDFYogesh PrajapatiNo ratings yet

- Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer MethodDocument8 pagesDensity, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer MethodAbidin SyakirinNo ratings yet

- Wa0001Document2 pagesWa0001bineshNo ratings yet

- Aerodynamics of Wind TurbinesDocument4 pagesAerodynamics of Wind TurbinesIoanna KaloNo ratings yet

- Chapter 8Document7 pagesChapter 8Ali BasheerNo ratings yet

- Journal of The Mechanical Behavior of Biomedical MaterialsDocument10 pagesJournal of The Mechanical Behavior of Biomedical MaterialsClaudia DumitriuNo ratings yet

- Refrigerator Test ProcedureDocument20 pagesRefrigerator Test ProcedureajitNo ratings yet

- The System K - mg2 (So4) 3 (Langbeinite)Document6 pagesThe System K - mg2 (So4) 3 (Langbeinite)anon_802179908No ratings yet

- Magnetizm Notes-2022Document5 pagesMagnetizm Notes-2022tmoatshe96No ratings yet

- Vessel Manual PDFDocument21 pagesVessel Manual PDFDonig FermanianNo ratings yet

- Utilização Do Espaço Subterrâneo Underground Space UseDocument12 pagesUtilização Do Espaço Subterrâneo Underground Space UseAna LagoaNo ratings yet

- The Sun and Space WeatherDocument326 pagesThe Sun and Space WeatherAyorinde T Tunde100% (4)

- Made Easy Solution Test 2Document11 pagesMade Easy Solution Test 2Amritanshu SrivastavaNo ratings yet

- Lec12 ControlDocument19 pagesLec12 ControlbalkyderNo ratings yet

- Land Vibrations, Air Blast and Their Control: Be BeDocument38 pagesLand Vibrations, Air Blast and Their Control: Be BeRidwanIrhasyuarnaNo ratings yet

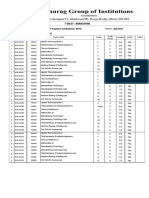

- T Sheet - Branchwise: Course/Sem: II B.TECH II SEMESTER Regular Examinations (R18) Held In: July 2021Document50 pagesT Sheet - Branchwise: Course/Sem: II B.TECH II SEMESTER Regular Examinations (R18) Held In: July 2021LE 335 P NAVEENNo ratings yet

- Waves - LabelDocument2 pagesWaves - LabelSaumia PanchalingamNo ratings yet

- Dristeem Electrode Steam Humidifiers XT Series IOM ManualDocument78 pagesDristeem Electrode Steam Humidifiers XT Series IOM Manualabeon augustineNo ratings yet

- Reviewer ScienceDocument2 pagesReviewer ScienceTbt-lion Cecilia Enriquez0% (1)

- Din 2391-2 PDFDocument10 pagesDin 2391-2 PDFtmmehta0% (1)

- Lugeon Tests at Partial Saturation: Experimental and Empirical ContributionsDocument54 pagesLugeon Tests at Partial Saturation: Experimental and Empirical Contributionsaziz fathiryNo ratings yet

- WB12Document205 pagesWB12ludihemicarNo ratings yet