Professional Documents

Culture Documents

Sec-02 Underground Drainage System

Sec-02 Underground Drainage System

Uploaded by

Omer HayatOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec-02 Underground Drainage System

Sec-02 Underground Drainage System

Uploaded by

Omer HayatCopyright:

Available Formats

UNOPS General Specifications

SECTION 2

UNDERGROUND DRAINAGE SYSTEM

2.0 Underground and Drainage System

2.1 General

This section specifies the requirements for laying of underground sanitary drain pipes and

associated works.

The work includes the supply and installation of the whole of the entire underground sanitary

drainage system including inspection chambers, concrete sumps, gully traps, grease

interceptors, drain lines, all frames and covers, excavation, concreting, piling, backfilling,

reinstallment of existing ground surfaces, and connections to the last manhole. All internal

components of inspection chambers and sumps shall also be included.

The Registered/Licensed Plumber shall be solely responsible for the satisfactory performance of

the whole sanitary drainage system.

2.2 Installation

2.2.1 Excavation

All excavation shall be carried out as may be necessary for the construction of the

works. Excavation for pipe trenches shall not be less than 600 mm wider than the

diameter of the pipes and the ground under beds shall be carefully graded. Proper

necessary shoring, planking, strutting, or sheet piling strutting shall be constructed and

maintained to ensure that the trench will not collapse.

When excavating trenches in existing carriageways, the paving blocks that have already

been laid or constructed shall be removed by the Contractor and stacked aside and kept

separate from the general trench excavated material for re-use in reinstatement. All

existing and/or constructed ground surfaces disturbed shall be reinstated.

Surplus excavation soil shall be removed from the Site.

All excavation shall be kept free from water at all times by pumping or temporary

drainage. In the event of the excavations being made deeper than necessary they shall

be filled to the proper level with lean concrete.

The Contractor shall be completely responsible for the safety of all excavations,

trenches, pits, etc. from collapse and for the safety of any surrounding structures which

may become endangered by the works and he shall ensure that all safety measures

necessary shall apply to any works during any excavations.

The Engineer shall have the right to order excavation and construction work to be

carried out in such lengths and in such sections of the works as will, in his opinion,

minimize the danger of such open excavations affecting the stability of any nearby

structures or ground. There shall be no claim for any extra payment on this account.

SEC-02 UNDERGROUND DRAINAGE SYSTEM SPS 2 - 1 MEINHARDT

UNOPS General Specifications

Trenches shall be left open for the inspection of the Engineer and shall not be covered

up until the drains have been properly tested and approved by the Engineer.

2.2.2 Backfilling

All concrete shall be thoroughly set before refilling is commenced. In refilling the

excavations, only selected hard dry material free from lumps exceeding 75 mm in size

and from stones shall be used in the initial refilling and shall be carefully placed next to

the permanent work and well packed and well rammed in layers of 150 mm. The

remainder of the excavations shall be filled in with the best and most suitable portions

of the excavated material, in layers of not more than 300 mm deep each layer shall be

thoroughly rammed before the next layer is placed. Surplus soil shall be piled on top of

the filling to the extent of possible subsidence. All refilled trenches shall be maintained

to the satisfaction of the Engineer.

2.2.3. Pipeline Setting Out

Excavation for trenches shall be to straight lines and gradients required for the pipes

and beds as specified. The trench bottom shall be of sufficient width to allow adequate

working space for pipe layers and jointers but beyond these requirements, the width

must be kept to a minimum.

Before any work commences, the pipe trench shall be set out. For the lengths of the

pipe-lines which are curved in plan or in elevation, the curve shall be obtained by

deflecting the pipes at each joint. No work shall be carried out till the detailed

proposals are reviewed by the Engineer.

2.2.4. Concreting Works

Cement shall be of the approved type and comply with BS No. 12. It shall be fresh

when delivered. Cement of different brands shall not be mixed with one another. Sand

or fine aggregate shall be cleaned, graded natural sand. Sand with coagulated lumps

and having a portion of silt exceeding 10% shall be rejected. Course aggregate shall be

clean, crushed stone and shall be free from dust, clay or other deterious materials.

Water shall be that obtained from the supply mains and not from excavation or drains.

Reinforcement used shall be hard drawn steel wire BRC fabric mesh complying with

BS 1221 and BS 785 for mild steel rods. BRC mesh and steel bars shall be free from

dust or mill scale.

Concrete beds shall be 150 mm thick and shall have at least 150 mm width at each side

of the external diameter of the pipe barrels when laid. Unless otherwise specified, the

concrete shall be 1:2:4. For pipe to be haunched, the concrete shall be carried up for

the full width of the bed to the level of the horizontal diameter of the pipe and shall be

splayed from this level and carried upwards to meet the pipe barrel tangentially.

SEC-02 UNDERGROUND DRAINAGE SYSTEM SPS 2 - 2 MEINHARDT

UNOPS General Specifications

All drain lines passing under buildings and driveways are to be surrounded with

concrete which shall be carried up from the bed in a square section with a minimum of

150 mm thickness over the barrel of the pipes. Traps and gullies shall be properly

bedded on and surround with concrete.

2.3 Pipe Gradient

Pipe gradient for all sanitary drain lines and waste pipes shall be as shown on the drawings or

otherwise indicated below:

PIPE DIAMETER GRADIENT

100 mm 1 in 20 to 1 in 60

150 mm 1 in 30 to 1 in 90

225 mm 1 in 40 to 1 in 150

300 mm and above 1 in 150 to 1 in 250

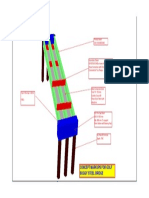

2.4 Pipe Laying

The pipe shall be laid singly with the whole length of the barrel of each pipe on a solid concrete

bed. No pipes shall be joined together before having been laid.

Flexible jointed pipes shall be laid completely embedded in granular material to a thickness of

at least 100 mm all round unless soil conditions and loaders indicate otherwise. Granular

material for bedding shall be of such ranging from 3 mm to 12 mm or of a free running coarse

sand.

Socket shall face up the gradient. The spigot of each pipe shall be well driven home into the

socket of the pipe previously laid and the joint completed as specified and the bore of the pipe

cleared of any obstruction before the next pipe is laid. Care shall be taken that there is no

irregularity in the invert of the joints.

The level of each pipe shall be tested by a straight edge laid in the invert of the pipe previously

laid and in the nearest level peg. If the bottom of the trench has been taken too low, it shall be

made up with concrete or cement mortar or other approved granular material.

Where it is required to shorten any pipe it shall be cut off square and cleanly, and cast iron and

ductile iron pipes shall be cut only with approved pipe-cutting machines. In the event of any

pipe being fractured from any cause whatsoever after having been to all appearances properly

laid, the Contractor in every instance shall replace such defective pipe to the satisfaction of the

Engineer.

Where laid in hard core or fill cast iron and ductile iron pipes subjected to a superimposed load

shall be supported from natural ground level throughout their lengths by walls and hunching.

Where laid in hard core or fill and not subjected to a superimposed load, or where laid above

ground, cast iron and ductile iron pipes shall be supported on piers behind the socket of the pipe

and at intervals of not more than 2700 mm.

SEC-02 UNDERGROUND DRAINAGE SYSTEM SPS 2 - 3 MEINHARDT

UNOPS General Specifications

The soil conditions shall be investigated before laying of pipework. In soft or yielding ground,

piles and a bed or reinforced concrete and embodiment of pipework in concrete to a thickness of

at least 150 mm all round shall be provided as instructed by the Engineer.

Pipes of 300 mm/225 mm diameter where shown laid through or under walls, shall be protected

by means of sleeves in such a manner that the weight of the wall shall not bear on the pipes.

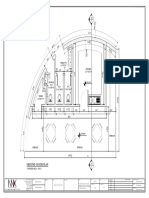

2.5 Tumbling Bays and Backdrops

Where required or specified, tumbling bays or backdrops are to be constructed.

When branch drain pipe is connected directly into an inspection chamber more than 1.5 m deep,

then a tumbling bay or backdrop shall be provided.

Special reversed spigot and socket junctions or backdrop junctions shall be used in the junction

between two lines of pipes.

The tumbling bay pipes shall be laid on a reinforced concrete foundation of concrete as

specified and completely encased in concrete. Backdrop pipes shall be completely encased in

150 mm concrete surround.

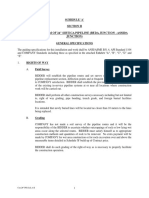

2.6 Inspection Chambers (Manholes)

The maximum distance between inspection chambers shall be as shown on the drawing.

Inspection chambers shall be of concrete construction.

Only in case where the inspection chamber cannot be constructed in concrete due to site

conditions, it shall be constructed in bricks and be 225 mm thick constructed on cement mortar

beds. Vertical joints shall be completely filled with mortar as the bricks are laid. Joints shall be

flushed cut as the work proceeds.

Inspection chambers shall be rendered internally and externally with cement and sand (1:3) in

two coats to a total thickness of 16 mm, trowelled smooth. On firm ground, the inspection

chamber shall be constructed on a reinforced concrete base at least 150 mm thick and such base

shall extend at least 150 mm beyond the external walls of the inspection chambers.

On soft or yielding ground, the inspection chamber shall be constructed on piles and a base of

reinforced concrete.

The depth of the main channels shall not be less than the diameter of the outgoing pipe. Main

channel inverts for pipes up to and including 225 mm diameter shall be vitrified clay channels.

Main channel inverts for pipes over 225 mm diameter shall be formed in concrete trowelled

smooth.

Branch bends up to and including 150 mm diameter shall be vitrified clay to 3/4 section curved

in the direction of flow and set to deliver over the main channel invert. Branch bends over 150

mm diameter shall be curved in the direction of flow and shall be formed in concrete trowelled

smooth.

SEC-02 UNDERGROUND DRAINAGE SYSTEM SPS 2 - 4 MEINHARDT

UNOPS General Specifications

Spaces between branch bends shall be completely filled with concrete and the faces above the

main and branch channel inverts shall be trowelled smooth. Benching shall be formed in

concrete trowelled smooth and shall open towards the main channel at a slope of 1 in 6. Pipes

passing through inspection chamber walls shall be solidly built in and the walls made watertight

throughout.

Precast concrete sections shall be used where the inspection chamber exceeds 2.5 m deep and is

located in soil. Precast inspection chamber ring shall be of proprietary make, 1050 mm internal

diameter and to be installed to details as shown on the drawings.

Covers and frames shall be of the types approved by the local Sewerage Department. They

shall be fixed in the positions shown. All frames shall be solidly bedded on cement mortar so

that the covers when in position are fair and even with the adjacent surfaces. Heavy duty cast

iron frames and covers shall be used in every driveway and car park or in area subject to heavy

loading. Medium duty covers shall be used in all other external inspection chamber, sump, etc.

Recessed pattern covers shall be provided and filled and surfaced with materials to match

surrounds. Frames of light duty covers shall be set with covers in position to avoid distortion of

frames.

One set of lifting keys for each type of manhole cover shall be provided.

Iron steps shall conform to BS 1247. Round bar corner pattern steps shall be used in brick

inspection chambers and shall be built in at 300 mm vertical interval as shown. Iron steps shall

be used in precast concrete sections and unless otherwise directed they shall be provided and

fixed in the concrete inspection chamber components by the Component Manufacturer before

delivery, in accordance with BS 556.

2.9 Tests

2.9.1. Pipework

Pipework shall be hydrostatically tested to a water head of 1.2 m at the high end and not

more than 3.0 m at the low end and shall show no appreciable loss of water after elapse

of two hours.

In every test, the water used shall be left in the pipes until they are covered with earth or

other trench filling material to a depth of at least 1 m over the top of pipes and until

permission is given by the Engineer for the water to be released.

SEC-02 UNDERGROUND DRAINAGE SYSTEM SPS 2 - 5 MEINHARDT

You might also like

- Advanced Engineering Mathematics 8Th Edition Oneil Solutions Manual Full Chapter PDFDocument36 pagesAdvanced Engineering Mathematics 8Th Edition Oneil Solutions Manual Full Chapter PDFbetty.slaton822100% (23)

- Outline Specifications (One 1 Storey Residential)Document5 pagesOutline Specifications (One 1 Storey Residential)mark manalang67% (3)

- Detailed Specification of PlumbingDocument7 pagesDetailed Specification of PlumbingNava PavanNo ratings yet

- Ada Guide To Digital Dental Photography and Imaging PDFDocument53 pagesAda Guide To Digital Dental Photography and Imaging PDFLynda M. Naranjo100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Drainage System Specification FinalDocument3 pagesDrainage System Specification FinalRico EdureseNo ratings yet

- Drainage SanitationDocument16 pagesDrainage Sanitation2011kumarNo ratings yet

- 29.sec.2900 (Pipe Culverts)Document4 pages29.sec.2900 (Pipe Culverts)Rakesh ParaliyaNo ratings yet

- Method Statement - Water RecDocument6 pagesMethod Statement - Water Rechadi putraNo ratings yet

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- Section-2900 Pipe CulvertsDocument2 pagesSection-2900 Pipe CulvertsErMelvinDiasNo ratings yet

- SECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)Document9 pagesSECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)akvosmNo ratings yet

- Uganda Standards Series 2000 - DrainageDocument37 pagesUganda Standards Series 2000 - DrainageKintu Munabangogo100% (2)

- General Building Spec.Document20 pagesGeneral Building Spec.Barry Daniel Saunders0% (1)

- SECTION 2700 FinalDocument17 pagesSECTION 2700 Finalkartick adhikaryNo ratings yet

- Specifications For Highway Drainage - OxfordshireDocument11 pagesSpecifications For Highway Drainage - OxfordshirexkishanNo ratings yet

- SECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralDocument4 pagesSECTION 02221 Trench Excavating and Backfilling: Part 1 GeneralJojolasNo ratings yet

- KMC Schedule of Rates For 2018 - DescriptionDocument32 pagesKMC Schedule of Rates For 2018 - DescriptionKalyan GaineNo ratings yet

- METHODOLOGYDocument8 pagesMETHODOLOGYAdam ArclightNo ratings yet

- MOS For Electrical UG Ducts (PVC Pipes) InstallationDocument3 pagesMOS For Electrical UG Ducts (PVC Pipes) Installationmagdi badran100% (2)

- Pipeline InstallationDocument6 pagesPipeline InstallationSurya Kiran KNo ratings yet

- Item 103 and Item 506Document42 pagesItem 103 and Item 506Wilbert Carlo RachoNo ratings yet

- Wearing CoatDocument5 pagesWearing Coatnandi_scrNo ratings yet

- Item 103 Structure ExcavationDocument3 pagesItem 103 Structure ExcavationGerry Velicaria100% (1)

- Construction MethodologyDocument38 pagesConstruction Methodologydesigners.starlightNo ratings yet

- SCH A - IIGenSpec Rev - 1 24'' 5 KMDocument12 pagesSCH A - IIGenSpec Rev - 1 24'' 5 KMJabel Oil Services Technical DPTNo ratings yet

- 4 - Technical SpecificationDocument73 pages4 - Technical SpecificationRutik PatelNo ratings yet

- 2000 Apr04Document36 pages2000 Apr04Enermy-123No ratings yet

- ManholeDocument11 pagesManholeNia ZainorinNo ratings yet

- Public Health Specs P1Document14 pagesPublic Health Specs P1Comofco GibraltarNo ratings yet

- B Excavation1Document15 pagesB Excavation1Camie TanNo ratings yet

- Item 803Document8 pagesItem 803Ester MarianNo ratings yet

- FAA APPROVED: November 15, 1988Document4 pagesFAA APPROVED: November 15, 1988Imam Arif RahmanNo ratings yet

- Project TitleDocument7 pagesProject TitleGerlie Joy CastanosNo ratings yet

- City of Olathe Revised June 1, 2007 TS/60-1Document9 pagesCity of Olathe Revised June 1, 2007 TS/60-1Hizbar ArsjadNo ratings yet

- Qcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFDocument5 pagesQcs 2010 Section 20 Part 4 Drainage Pipes in Trenches PDFbryanpastor106No ratings yet

- B17 SpecsDocument7 pagesB17 SpecsbenbenpastorNo ratings yet

- PROJECTDocument3 pagesPROJECTErin Trisha Kristel GaspanNo ratings yet

- General Instructions and SpecificationsDocument28 pagesGeneral Instructions and SpecificationsAnna Rose PueblaNo ratings yet

- SPecifications-FOR PERMIT VITASDocument6 pagesSPecifications-FOR PERMIT VITASPHEBY MOOGNo ratings yet

- Methodology of ConstructionDocument19 pagesMethodology of Constructionsumit249100% (1)

- PT Konsultan International: T.Y.LinDocument13 pagesPT Konsultan International: T.Y.LinWempy WiryaatmajaNo ratings yet

- General Specifications (One Storey)Document5 pagesGeneral Specifications (One Storey)joyce karen cadacioNo ratings yet

- 29.12.2016 PipingDocument12 pages29.12.2016 PipingharshNo ratings yet

- CCTV Construction MethodologyDocument12 pagesCCTV Construction MethodologyMarkNo ratings yet

- Technical Specifications: Site Works 1. RequirementsDocument13 pagesTechnical Specifications: Site Works 1. RequirementsThomasNo ratings yet

- Plumbing Scope of WorksDocument5 pagesPlumbing Scope of WorksJoven E. Vizcara100% (1)

- Construction Method Statements - Method Statement For Bored PilingDocument5 pagesConstruction Method Statements - Method Statement For Bored PilingLin ChayNo ratings yet

- General SpecificationDocument12 pagesGeneral SpecificationAmyrah SyahyerahNo ratings yet

- SPECIFICATIONSDocument5 pagesSPECIFICATIONSLeah FernandoNo ratings yet

- Cold Water SpecDocument17 pagesCold Water Specmunim87No ratings yet

- E Part 2 Technical SpecificationsDocument418 pagesE Part 2 Technical Specificationsjun floresNo ratings yet

- Plumbing SpecsDocument15 pagesPlumbing Specssakeedfaheed100% (1)

- Water 02724 DrainagePipeDocument2 pagesWater 02724 DrainagePipefarhanNo ratings yet

- Section 15155 - Sanitary & Drainage System (Exterior Works)Document2 pagesSection 15155 - Sanitary & Drainage System (Exterior Works)Kurt Darryl SabelloNo ratings yet

- Detailed Specifications - EarthworkDocument10 pagesDetailed Specifications - EarthworkKishan KumarNo ratings yet

- A7 0 SewerDocument13 pagesA7 0 SewerDmitry PigulNo ratings yet

- Specification For Drainage & Infrastructure WorksDocument33 pagesSpecification For Drainage & Infrastructure WorkskhuanozNo ratings yet

- Method Statement Construction & Casting of Concrete Manholes P-3Document4 pagesMethod Statement Construction & Casting of Concrete Manholes P-3a.nunezNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionFrom EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNo ratings yet

- 10 Marla EE (C036A, C036B)Document20 pages10 Marla EE (C036A, C036B)Omer HayatNo ratings yet

- Roof Floor HalfKanalDocument1 pageRoof Floor HalfKanalOmer HayatNo ratings yet

- Pile ScheduleDocument3 pagesPile ScheduleOmer HayatNo ratings yet

- 2 Villas Detailed ReportDocument1 page2 Villas Detailed ReportOmer HayatNo ratings yet

- Haifway HutDocument3 pagesHaifway HutOmer HayatNo ratings yet

- Plinth Beam Layout Plan: Beam-Pb1 (300 X 450) Beam - Pb1Document1 pagePlinth Beam Layout Plan: Beam-Pb1 (300 X 450) Beam - Pb1Omer HayatNo ratings yet

- For Markups - 3D-Golf BridgeDocument1 pageFor Markups - 3D-Golf BridgeOmer HayatNo ratings yet

- ST 1013Document1 pageST 1013Omer HayatNo ratings yet

- Main Girder - Steel BridgeDocument5 pagesMain Girder - Steel BridgeOmer HayatNo ratings yet

- Pile Capacity Assessment - OHDocument3 pagesPile Capacity Assessment - OHOmer HayatNo ratings yet

- Raft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Document1 pageRaft Section A-A: 50 Thk. PCC 1:3:6 4 Thk. Water Proofing Membrane 100 Thk. PCC 1:4:8Omer HayatNo ratings yet

- Columns Layout Plan: NotesDocument1 pageColumns Layout Plan: NotesOmer HayatNo ratings yet

- AUDITORIUM - zone02-GA MARKUPS& REINF-2 - 147Document1 pageAUDITORIUM - zone02-GA MARKUPS& REINF-2 - 147Omer HayatNo ratings yet

- CBD Dome Design ReportDocument88 pagesCBD Dome Design ReportOmer HayatNo ratings yet

- Comments On Anchor Design 19-2-22Document3 pagesComments On Anchor Design 19-2-22Omer HayatNo ratings yet

- Structural Drawing (Sleeves in Raft)Document3 pagesStructural Drawing (Sleeves in Raft)Omer HayatNo ratings yet

- AUDITORIUM - zone02-GA MARKUPS& REINF-2 - 101Document1 pageAUDITORIUM - zone02-GA MARKUPS& REINF-2 - 101Omer HayatNo ratings yet

- AUDITORIUM - zone02-GA MARKUPS& REINF-2 - 148Document1 pageAUDITORIUM - zone02-GA MARKUPS& REINF-2 - 148Omer HayatNo ratings yet

- Footing 1.5m BELOW EGL: Remove Backfill From This Area Under Suspended SlabDocument1 pageFooting 1.5m BELOW EGL: Remove Backfill From This Area Under Suspended SlabOmer HayatNo ratings yet

- Site Quality Observation Report 1Document13 pagesSite Quality Observation Report 1Omer HayatNo ratings yet

- Update The Levels As Per Architecture: 200 MM RC WallDocument1 pageUpdate The Levels As Per Architecture: 200 MM RC WallOmer HayatNo ratings yet

- Sign Board Frame Design For Offshore AreDocument14 pagesSign Board Frame Design For Offshore AreOmer HayatNo ratings yet

- Rendered To: Newtechwood LTD 19111 Walden Forest Dr. Suite B Humble, TX 77346, UsaDocument27 pagesRendered To: Newtechwood LTD 19111 Walden Forest Dr. Suite B Humble, TX 77346, UsaOmer HayatNo ratings yet

- Aerofarms AD - Selection and DWG - 3 Sep 20Document3 pagesAerofarms AD - Selection and DWG - 3 Sep 20Omer HayatNo ratings yet

- Wind Load On Light Pole - 6.2m - RMEDocument3 pagesWind Load On Light Pole - 6.2m - RMEOmer HayatNo ratings yet

- Form M Mra Chartered Member Mutual Recognition 20200401 PDFDocument4 pagesForm M Mra Chartered Member Mutual Recognition 20200401 PDFOmer HayatNo ratings yet

- Srs Airbag Control System: SectionDocument331 pagesSrs Airbag Control System: SectionMarcelo MendozaNo ratings yet

- TR - Smaw NC IDocument59 pagesTR - Smaw NC Imbranzuela_blanquero73% (11)

- Basic Types of Fans Used For Ventilating Underground MinesDocument15 pagesBasic Types of Fans Used For Ventilating Underground MinesNag Raj RockssNo ratings yet

- Mento - Katalog API 6A Valves & Manifolds - 21.06.21 - Rev18Document46 pagesMento - Katalog API 6A Valves & Manifolds - 21.06.21 - Rev18DIEGO CONCEIÇÃO DE OLIVEIRANo ratings yet

- Oriana Phase 3 CFC: Project ContractorDocument1 pageOriana Phase 3 CFC: Project ContractorCivil SanamNo ratings yet

- How To Claim Land and Not BuyDocument36 pagesHow To Claim Land and Not BuyJoshua Sygnal GutierrezNo ratings yet

- Hawkeye InsightDocument2 pagesHawkeye InsightRetno UtamiNo ratings yet

- Quiz 3 詳解 2014.11.26 1 PDFDocument2 pagesQuiz 3 詳解 2014.11.26 1 PDFAnonymous 8209ZTNo ratings yet

- Gorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsDocument8 pagesGorman-Rupp Pumps - Selection & Application of Self-Priming Centrifugal PumpsVic Van PeborghNo ratings yet

- XLR129 P 1 DemEngineDesign V3Document214 pagesXLR129 P 1 DemEngineDesign V3nab05No ratings yet

- Security Control Assessment RFP Questions and Answers FinalDocument3 pagesSecurity Control Assessment RFP Questions and Answers FinalCraig O'DonnellNo ratings yet

- Various Types of Shear ConnectorsDocument6 pagesVarious Types of Shear Connectorssilverware1No ratings yet

- Safety Data Sheet: Paraplast X-TRA®Document7 pagesSafety Data Sheet: Paraplast X-TRA®meganingtyasNo ratings yet

- FinalDocument26 pagesFinalRitesh KumarNo ratings yet

- NORSOK S-001 Fire IntegrityDocument4 pagesNORSOK S-001 Fire IntegrityAle BrambiNo ratings yet

- IFC Guide 2xed2 v3p5Document79 pagesIFC Guide 2xed2 v3p5Pierre RoringNo ratings yet

- Ce TopicDocument8 pagesCe TopicKyle MarfsNo ratings yet

- E-Up Electrical SystemsDocument48 pagesE-Up Electrical SystemsRepo_67No ratings yet

- Directquery in The Tabular Bi Semantic ModelDocument46 pagesDirectquery in The Tabular Bi Semantic ModelabacusdotcomNo ratings yet

- 5113-QAP-001 - QAP Skid Fabrication - Rev-B0Document4 pages5113-QAP-001 - QAP Skid Fabrication - Rev-B0mohana priyaNo ratings yet

- Paper - 1: All India Open Test (Aiot) Jee AdvancedDocument24 pagesPaper - 1: All India Open Test (Aiot) Jee AdvancedNinad Akolekar100% (5)

- Load Chart-Wire RopeDocument2 pagesLoad Chart-Wire RopeRajmohan Babu100% (1)

- 4.1.1 What Is The Policy of The Institution For Creation and Enhancement of Infrastructure That Facilitate Effective Teaching and Learning?Document9 pages4.1.1 What Is The Policy of The Institution For Creation and Enhancement of Infrastructure That Facilitate Effective Teaching and Learning?coolrajeeeNo ratings yet

- Libble EuDocument240 pagesLibble EuΚυριάκος ΒαφειάδηςNo ratings yet

- CVX SignageGuidelines091310 1.pdf - SFLB PDFDocument88 pagesCVX SignageGuidelines091310 1.pdf - SFLB PDFLeni Marfitri MaldiNo ratings yet

- ARM Cortex M3 Based Collision Detection SystemDocument3 pagesARM Cortex M3 Based Collision Detection SystemseventhsensegroupNo ratings yet

- Tension Control SystemsDocument2 pagesTension Control SystemsSheik HassanNo ratings yet

- Critical Design Configuration Control LimitationsDocument3 pagesCritical Design Configuration Control LimitationsHESTI BASUKINo ratings yet