Professional Documents

Culture Documents

Ohsas 18001 2007

Ohsas 18001 2007

Uploaded by

sanjeev kumar0 ratings0% found this document useful (0 votes)

109 views32 pagesOHSAS

Original Title

OHSAS 18001 2007

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOHSAS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

109 views32 pagesOhsas 18001 2007

Ohsas 18001 2007

Uploaded by

sanjeev kumarOHSAS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 32

BS OHSAS 18001:2007

OCCUPATIONAL HEALTH AND SAFETY ASSESSMENT SERIES

Occupational health and safety

management systems — Requirements

raising standards worldwide™

British Standards

BS OHSAS 18001:2007

National foreword

Publishing information

"This itih Seandard wae published by BS. th oficial UIC

{inplewentation of OHSAS TeDD1-2007 which superndee OHSAS 18001900,

[BS OHSAS 16001 wil be maintained in ine with any change

‘OHSAS 18001, sje: tothe approval of BSI Tereal Commitee BSI,

Dssipetional holt and vfty management, which allatod the UK comments

‘on te seco Working Dra @f OHSAS 19001 and at rward ie prefored

‘Ait of organisations reproented on thie commie can be obtainel on

Contractual and legal considerations

Inthe UK and Burope generally, there aro various gal soguzomente for

cecpatiogal health cad sat hat apply to te potentially harmfal fats of

store action and which extend befond the workplce othe afected Uy

‘tonnes sot (ae Noe to 8.13 on the dofinton of oneuptiosl heat

nd aft It saental for the organization ote the matters addreaeed

iy shee eal roguromentnt acum sablasing eplomentie ond

‘Sentfyng hazard, ateoing ak ad determining contela Ge 48.1

Spd 48.2) Ths standard ough thorforo to bo readin eonguncainn wih

[BS e800 and HSE 0 witch give good practice pudanca on complying with

‘uch legal quirements ia the UR

‘Tale publieation doce not purport ty incude all the ncssary provision of

fontraat User are responsible forts crrect pition

Compliance with British Standard cannot cenfer immunity foun

Tegal obligations

Publishing and copyright information

‘Be coh min plein i aan nat an te

Publication history

Pit pied ay 2007

Amendments issued since publication

528 and fe mama

[BS OHSAS 18001:2007

Contents

Acknomledgement

Foreword tt

Introduction ©

1 Scope 7

2 Reference publications 1

8 Temsanddefations 2

4 OH&S management system rquiremests 5

‘Annex A (formative) Correspondence between OHSAS 18001:2007,

180 14001:2004 and 180 9001-2000. 15

Annex B (nfomatie) Correspondence between OHSAS 18001,

‘OWISAS 18002, and te ILO-O81:2001 Guidelines on cecupational

fey and health management syste. 15

Bibliography 22

List of igures

Figure 1 = OFS managemont ystm medal for this OHSAS

Standard vf

List of tables

‘Table A.1 = Correspondence between OHSAS 18001:2007,

180 14001-2004 and 180 9001:2000 15

"Table B.1—Corrspondoncsbatwean the clsses of the OHSAS

ocaiments and the causes of th IL0-OSH Guidelines 20

‘Summary of pages

“This document comprise a ron over an nde font cover,

‘pages toi pages 1 2, sn side buck cover and a back cover.

eustanor =

BS OHSAS 18001:2007

A + onsacor

Acknowledgement

‘Ts etna OHSAS 1801 his een eveopd ih the astm oe

along capris epmizane

Amen iui Hye Asoiton AA)

‘chk apt de Narain Cnc (ABNOR)

‘Neos of Bis Crtinn Bea BCE)

‘ita Suda tan SD)

ata Veta

‘Comin Fee ch (CH, (Geren negra ni)

‘inch craton tte A

De Nea eras DNV)

Ds cenicton 8

[BEF the maar ogilston

[BAAR Coaplnnce Semen ee

eh aly Hane

ng ang Qty Aarne Agcy KON)

Inspec Crtexioe

Inston af reac Suey an Heth 10S)

ins Aatin de Normans Cerin CRAM)

Inst Chinn de Noma Tees y Cert ]CONTEC)

Tn de Nira nos de Costa Rn INTECO)

Instat Mesean te Narmlancny Cortes (NC)

Inst Upp de arma Temas UN)

{nds Sey meat Aston ISHN)

Spanase Sante Asoc A)

area Gus Seley Corpartn (80 Corte Dison)

ryder Quy Aras)

Maasgemen Stems Crteatina Led

Nato standard Abort orn OSA)

atonal Uae af Singer US).

‘ofeds Sorat ttt OES)

yaw

aly Manges ste 3)

‘SBS Comer (a) Ue

‘Sere Normateston nr Mave SADE

‘TO Rein Cer Gi TOV Riad Gro

Starman ot inabe(3A)

‘We woud eo apse eal coaraioe made ye may

noon oe ne oven he work at of

‘rks 18001, aad wo ated comment for air. Tet

‘roy in improving the aa iach Spe

© maa ty mpi hath nc

yt eg ea sn ney gions tn cE

‘i snd ean

i

|

(OHSAS 18001:2007

Foreword

‘This Occupational Hea and Safety Assessment Series (OHSAS)

‘Standard and the accompanying OHSAS 18002, Gudolins forthe

‘implementation of OHSAS 18001, vee devlopedinresponse to

‘stoner demand fr arecogniableoccupona hoalth and safety

‘management system standard against which hls management ems

‘an be aseved and cere.

‘OHSAS 18001 tas boon developed tobe compatible wih the

180 9001:2000 (Qaliy) and TSO 14001-2004 (nvtrmnental)

management sysams standards, inorder tofactta the integration of

‘aly, environmental and occupational bath and sty agement.

sjstoms by crpnizations, should they wish 0 do so

‘This OHSAS Standard wil be reviewed of snended when considered

appropeate. Reviews Wl be conducted wha new eins of either

180.9001 or 150 14001 ae peblshed, to ene conning

compari

‘This OHSAS Standard wil be wihdrsn on publication of te contnts|

in, oras, an ntrational Standard,

‘This OHSAS Standard has boon drafted in cordance with ha rlos

‘sven inthe ISOMEC Ducsvas, Part 2

"Tis soon ation canal and replat the ft eton

{(@HS4S 18001:1900), whieh has Don teculealy revised.

‘The principal changes with respetto the previous edition area

fellows.

*+ The importance of helt" has now bem sven greater emphasis.

“+ OHSAS 18001 now refers to se sa standard, nat 2

speciation, or documenta inthe eater eon This reects

{he increasing option of OTSAS 18001 asthe basi for national

‘tandardson occupational beath and salty management eyes

+ Tho"PlanDo-Chock-Ac” model diagram is onl given inthe

Innvoducon, ss entire and not als as soctonal diagrams at

(he art ofeach major clause

+ Reference publications in Cause 2 have been tio to parly

{nterational documents,

+ New definitions have boen added and sting deintons revised

+ Sgniscant improvement i algnme vith 80 14001:2004

‘azoughout the standard, and improved compat with

180 9001:2000.

+ ‘Theor lesb raha Bon replace hy the term

acceptable” (se 8.1.

‘+ ‘The term “accent” ow inked nthe tom cident”

Gee),

+The definition of he tm “hasnt” no Inger fre “damage |

‘property or danago tothe workplace envtronen” (se 8.6).

‘omaaver + i

BS OHSAS 18001:2007

Ww + ens 2007

Tete now consiored that such “damage” eno rely rita to

‘ceupatonal nan and safety management, which isthe pespse of

‘his OHSAS Standard and that ts incuded ie the eld of asset

‘management. teed, the sof such “amage” having an eiflot on

‘ecupatonal oath aed safety should be iene through the

‘orguzation' ok assessment process and by contrllod tough the

pplication of appropiate risk contol

+ Subsclouses 4.8.8 and 48.4 have boon merge, in in with

180 14001-2008.

“+ -Anow rgulemont has boon introduced forth considration of

‘the hierarchy’ of conte a part of OHAS planing (see 48.1).

“+ Management of changes now more exp adaressd

(eee dS and 446)

‘+ -Anow clause onthe "Evalunson of compancs” (508 4.8.2) has

tea introduced,

‘+ Now requirements hav been intoce fr participation ant

connulaton (soe 4.48.2).

“+ New requirements have been introduced fr the ineestgntion of

Incidents 606 45.8.1),

‘This publiation doesnot purpor to ineude al necessary provisions of

‘contract: Users ar response for its corre aplication

‘Compliance with ths Occupational Health and Safety

‘Assessment Series (OHSAS) Standard eazaot confer immunity

‘rom legal obligations.

BS OHISAS 18001:2007

Introduction

‘Organizations of al kinds ae increasingly oncerned with achieving

sand demonstrating sound occupational hell and safety (OH&S)

perfomance hy cooling thelr OHS risk, conser wih oir

‘OAS poi an olecives. Tey do so i te conten of mereasingly

stungert ogslation, the devlopmont of eccome policies and other

‘measures that foster good OHS practices, ad increased concern

‘xpresed by interest patos about OUAS issues.

Many organizations have detakon OHS reviews" of ands" to

‘aves tei OHS performance, On their, however, ese

“review and “audi” ray not be siento provide an erguization

‘wah de essurance tats performance notony meets, ba vl

contzweto moe islegal nd poley requirements, Tobe effective, hey

‘nod tobe condacted within a sructurod managment syste tat is

‘eegrte wahin the orgalaton.

"Tho OHSAS Standards covering OHS management are infonde to

provide organizations wt he eloments fa effective OHS

‘management system that canbe integrated wh other management

‘equements and ep organizations achieve OMS and economic

btjctives, These standards, ke othe international Standards are not

Intended to be wed to eres nonarftrads aries or oineresse ot

charge an organization's egal obligations,

“This OHSAS Standard spetiesroqulrementsforan OHAS management

stom to enable sn organization to develop an implement pole and

‘objectives which tak into account Iga requirements and information

tout OHS sks. Its intended to apply taal iypos an szes of

‘tguzations ano accommodate diverse geographical, cata and

‘Steal conttions. The basis ofthe approac i shown in Faure 1. The

‘Succes ofthe system depends on commutzat from al evel a

Inetions ofthe organization, and espacll rom top mazagement, A

‘jst of this kind enables an organization to develop an OHS policy,

‘eb objectives and process to achiev te oly commltnents,

{ake ction as needed to improve its parformance ged demortirats the

confor ofthe stem to the requcemens ofthis OHSAS Standard

‘The overall aim ofthis OHSAS Standards tsupport a promot ood

‘OHS practices, in balance wih soco-coremie neds Ie should be

noted hat many ofthe euements can beaddresced concurrent or

“The socond edition of this OHSAS Standards focused on eariication|

‘ofthe fst edition, end hs taken de consideration of the provisions of

150 0001, 18014001, 110-054, and ether OFS management system

‘standards oe publications to eahanes the campaty of thse

‘Standds forth benot ofthe user contin.

enue + v

BS OHSAS 18001:2007

wi + esa007

‘ewe 1

‘Tere ean important datintionbeoween this OHSAS Standard, which

Aeseibr th requirements or an organizatie's OHS management

‘tem and can be wed for corication tegration andor

‘Sidelaration ofan organization's OHS management system and

‘noteortifiabe guideline intended to provide generic asstanceto an

‘ngunzatin for establishing implementing or improving an OHS

‘management sytem. OHS management encompass fll ange of

‘Shue, ncuding hase wih strategie and conpetive implications.

Demonstration of acces ipersenction is OHSAS Standard

canbe usod by en organization fo assure intcsted partie tha an

Appropriate OFS management sytem sin Pace.

‘Ths organizations requing more gone dance ona broad range

‘of FAS management system suas te eltred to OHSAS 18002, Any

‘ference to ott Inoratonsl Standards for nformation ony

‘OH&S management system model for this OHSAS Standard

Ce

[NOME his OHSAS Standard i based on tha methedlgy oun as

PlauChocteet (PDCA). POCA canbe ri derrtdalo

+ Plan: estadsh the objec and proses neces diver

‘ult aceordancs oth the orgaaton 8 OES pty.

‘es iplomnt he proce.

+ Check: montor and measwe process against OFS pai,

‘nective laa and ctor reurements, ad report the ess.

1+ Aet: take atone continually mpreve OHS performance

Many orgnizations manage the oportions athe application of &

"et rose nl hot oration, hh com be fore athe

‘proces approach SO G0 promot the wa th graces approach

‘Since PC con be oped el proces, the hee metho re

oideed compat.

_3S.OHSAS 18001:2007

"This OHSAS Standard contains roquirment that canbe ofecively

ated; however it doas not establish beats ragulemments or OH&S

performance beyond the coranitimens nthe OHS policy, to comply

‘wi applicable Inga requirements and wih athe requirments to

‘which the organzation subscribes, othe prevezion of jury and it

‘halk ano continual provement. Th, ro organizations caring

‘out sna operations but having ferent ORS performancecan bath

‘conform tos equbemans.

‘This OHSS Standard doesnt ince requltments specie o other

‘management systems, suchas those for quay, environmental

secuny, of nancial management, thoagh is lents canbe aligned

‘rintgretod wat thos of ether managamcr sytem. Is possible for

‘an organization to adapt its existing management system(s) in order to

‘Stsblsh an ONS managemest sistem that conforma othe

requirements ofthis OHSAS Standard Is flutd ot, however, that

‘the applition of verous elements ofthe management system might

‘fer depending onthe Intended purpose andthe interested partes

involved.

‘The evel of dtall and complenty of the OHAS management system, the

extent of documentation athe resources avoid to it depend oa

‘umber of factor, such as the scope of the syst the sz of an

‘ongaation and the natre of ts ates, products and services, and

tho organizational eure. This may be te casein partes for small

medi sted esterpries

|

|

‘me pap dort ep an

38 OHSAS 18001:2007

Occupational health and safety

management systems —

Requirements

Scope

‘his Ocption shan Salty Asssnnt Serie (1515)

Standard soso regenera or nowt hatha ty

(Otis rage ryt, estes gntaton io col Be

{nas rat and improve OAS promt Ie dosnt ae

specie OS paromanc rerio ow dete

Spectator rth eign of manage tn.

Tis OHSAS Sana appl tony nit ht ss:

2 ti n OFS manga stm imino minis

‘Sioteprsnl der need pris who col te

‘posed Ot arrested wh atv

>) Implement, mala an continual ingove an O68

gene to

© see ox conformity wth sted OFS por,

6) mons confoity with hs OSHS Saad

1 making idtermition and selon ot

2) seskng coin ft confor yas ang 2

‘tare nthe rnin sch roe oF

3) seskng onion fi edna pty extern

‘othe rpmtaton oF

4 seskng etatongitasion ot 14S management

‘sm ys oral epniton.

‘tie egies in his OFS Sd intend tb

incompornd osy OH&S managenet rem. The exe e

‘Stas wi operon uch ae OF8S poly fhe

‘Stanton the ar ofan an a ss atc

‘operator.

“hs ONSAS Stn ind oar ocnptoa a

‘hy nd ned ron tor one oe en eh

‘Sele welling progenies pod sey, roper

‘Samage or envionment impacts

Reference publications

ther pubeations that provide information or uldance aro sted ine

biography ts advisable tt the latest eons a such publeations

be conmted Specialy, reference should be made

(OHSAS 18002, Ocoupational helth and syety management

systems ~ Gualins forthe plementation of OHSAS 18001

lnveoatonal Labour Organization 2001, Galina on Oooupatioat

lath and Safty Management Systems (OSE-MS)

opsiae7 + 1

S 18001:2007

2 + ensizeor

Ba

a2

33

a4

a6

a6

a7

Terms and definitions

For the purposes of thls document, the following arms and dftions|

ppl.

cceptable risk

‘skeet ha Doe reduced to evel ht can he tolerate bythe

tngeiaton having regard to loa ebligatons nd it ow

‘OHS policy 8.16)

sualt

"stemate,indapenden and document pres or obtaining “ait

‘donee an evaating objectively to detrmie the exert 0 whch

Sei exter are ile

{1s0 9000:2005, 3.9.11

OTE] dena done ncn mom lr he

‘open cab damon by hrs fom repens ty or

tho ccity ting audio

NOT Foret pide on ot dr and cr’

‘continual improvement

‘uring roca of enancing the OHSS management

tystem (3-13) mordr to achieve snproverasn overall

‘OUSS performance (8.16) consstentwith tts organization’ (3-17)

OTS potiey 3.16)

[NOME 1. The proce nod nat take place nallaras of acy

‘naoneay

[NOME 2 Aaped from 19015001300, 3.2.

corrective action

‘tio o emits the cause ofa detected nonconformity (3.11) oF

‘ther undesirable situation

[NOTE 1 Tare canbe more tha on aus fora nnconormity

NOTE 2 Corrective ation thon prevent roowrence whereas

recent atom (8.18) taken o proven orrren.

[1s0 9000:2005, 3.6.5]

document

Informtion audits supporting medium

NODE The madi can be paper, magnate, eatrnic or epic

Computer dss, photograph o mason sample, or combinaion Derae.

(150 14001:2004, 8.4)

hazard

Source, imation, or act witha potenti for em in tems of human

injury orl health (3.8), ora combination of these

hazard identification

proces of roogriing at «hazard (3.6) exits an defining its

‘harsteriior

a8

39

3.0

aan

aa

aa

[BS OHSAS 18001:2007

‘M1 eaten

‘dentable, adverse physical or mana condton arising fom andioe

made worse by a work acti andor worklated sisation

incident

worried even() in which an injury ort health 3.8) eognrdos|

‘of sever) o fatality occurred, or cond ave oceured

[NOME 1 Am acide ton tcldent Nc ha en at to ir

‘oat or fatal

[NOME 2m incident hare no injury ithe, flat occurs may

ltr be reforred oat "nowe ear, se call” or angrone

NOTES so omergoncy stuation (20 17) ea particular ype

‘kone

interested party

person or group, ise or outs the workplace (8.23), concerned

“hor affected by tho OH&S performance (3.18) of an

‘Organization (8.17),

nonconformity

‘on-fuiner fa reglrement

[150 9000:2006, 3.6.2; 150 14001, 3.15}

[NOTE_A nonconformity can be ay deviation fom

1+ seowant work standard, practice, roid, gad

‘oguironents

+ 0185 monagement oystem (8.18) rouronents

‘occupational heslth and safety (OH&S)

‘conditions and factors that affect, o could aet the helt and safty

‘of employees or other workers (including eaporary workers and

‘contactor personnal) vistors, or any oer person in the

‘workplace (3:28)

[NOTE Orpanieaton can oslo totaal -vguroments forth heath

‘nd ety of porto yoni meat workplan, or co are

‘Spon othe wortpace actos

OH&S management system

part ofan organization's (3.17) managemat syst used to develop

{nd implement ts OHS poley (8.16) and manage ts OHS.

sks (321)

[NOTE 1 A anagerent stem i of erated elements wd o

‘Stab poly ant objected to acho te oberties

‘NOTE Amanageren! stom incase orgenentionalsrcture,

‘awning ation (incucing, for ecg, ik oseemant tl he

‘eit ain) rot, res preare .1)

‘NOTES Adopted from 180 14001:003, 88.

enstamor + a

[BS OHSAS 18001:2007

4+ easier

sas

3.6

aa7

3.8

a9

3.20

On&s objective

(OWS goal interme of OHS performance (8.15) dat. an

‘organization (8.17) sts sl to achiewe

[NOME 1 Objectios should bo quantified whsover praca.

NOTE 2 9.88 raqirs that OBS objector re consent withthe

Ones poiey 816)

18S portormance

‘measurable ress ofan onganlaaton’s (8.17) management of ts

OWS risks (8.21)

[NOTE 1 OFS performance measurement ines measuring th

‘cine of the organization's core

NOME? Joihe content of HBS management ystims (2.13) resus can

‘ts te measur aga hs organtsaton (3-17) NGS pty (3.10),

(Ota objectier (8.18), and wher HGS prformance reurenents

On&S policy|

‘vecalmtenions and diction ofan organization (8.17) elated tots

‘OWS performance (3.18) a formally expressed by lop management

[NOME 1 The OHS poloy provides a famouer or ation on forthe

‘Secing of OMS ohfoctoe 8.19)

[NOTE 2 Adept from 190 19001200, 8.1

organization

company, corporation, fin, enterprise ator or inition, part

‘orcombinaton thereof, whether incorporated or ot, publ or peste,

‘hat hs com unesons and administration

NOTE) or ongoniaton with more than one porting wn, «single

‘peraingwot myt dfie xorpaatin.

{180 140012004, 8.16]

preventive action

‘con o elimina» the case ofa potent nonconformity (8.11) oF

‘other undestable potential sittin

[NOTE 1 There can be mor than ae couse fora pote! nonconformit

[NOTE 2 Provntive actions taken to proven owourenc whereas

‘arrectve action (9) takonto pron’ recone

{180 9000:2006, 5.6.41

procedure

“specied way to cary out an activity or a process

[NOTE Protaras can be dacwnented or nt

{130 9000:2008, 3.4.5]

record

‘document (3.6) stating ess schoved or proving erence of

sctvies performed

[180 14001:2004, 8.20)

isk

‘combination of the Hketnood of an occurence of za vest of

fexposire(s) andthe severity of inary or sate (8.8) that can be

‘nus bythe event or expasue(s)

3.23

4a

42

BS OHSAS 18001:2007

risk assessment

proces of erating the rsk() (3.21) arising from ahszard() taking

Jno aceoan the adequacy of any existing ental, and deciding

‘whother or not te s() is acceptable

workplace

‘ny phyla oation in which work elated settles are performed

‘under he cone ofthe organization

NOTE, Whon giving consideration what coutites a workplace, the

‘ergantetion (2.17) sho tas io acount the OBS afin

Dorsal ho ar, jor aap, troaling ori rant (29. ing,

Buna boas o tana), wanking a tho proses faten or some,

‘rvcnking at home.

OH&S management system

requirements

General requirements

‘Tho organization shall establish, document, mplamen, maintain ant

contnly improve an OHS management mater in accordance with

‘he requirements ofthis OHSAS Stanard an determine how il a

tase requrements

“The organization shall define and document the scope ofits OHS

management syeem.

OURS policy

‘Top management shal define and storie the organization's OHS

policy and ensure hat within the defined scope of fs ORAS

‘anagement system

9) teapproprite wo the nace and scale ofthe organization's OH&S

ss,

1) ‘includes «commitment to prevencon of nur andl health and

‘continual zaprovereat in OHS management and OHSS.

performance,

©) includes commitnen to a last cont with appicable gat

ezements nnd wth er regres ta which the

‘rgantaton subsea that eat toe OHS hazards;

4) provides the fxmework for tng and reviewing OHSS

‘hietive:

Ss documented, implomented an maintained;

1) Se communicte to al persons working under the contol of the

‘ongalation wth the iat tha they ary made sare of heir

individual OHS obligations,

{© Se svaible otras partis and

2) Se revowed periodelly co ens that trea relevant and

sopropmate to the organization.

‘ensiamor + 6

[BS OHSAS 18001:2007

43

434

Planning

Hazard identification, risk assessment and

determining controls

‘The organisation shall estas, implemen and inn 2

procera for the onglnghscardeneiesson,rikasesmmet, and

‘ecerminaton of recess contol

“Tae procedare() for hazard Menification and risk assessment shall

take into account:

2) route and non outine setivites;

) activities o al persons having acces tote workplace (including

‘Contractors and Wtors)

©) an behavior, expat and oer Yanan fers

{enti hazards originating outside the workplace capable of

‘vert afeting the belt and safty of persons under the

‘contol ofthe organiation within the woes;

©) haar ceated in the vin ofthe wortpice hy work related,

scvies under the control of te organaation,

NOTE 1 may bomore appropriate for sch hazards tobe assed

‘arom noone ape

5) feasructure equipment and materi the workplace, whether

rove by the erganzation or others;

|® changes or proposed change inthe organization its ates, oF|

materials

1) moaications othe OH4S management tem, inching

temporary changes, and thar npc on operations, processes,

sand nts

1) ary applcabstga obligations resting risk assossment and

Implemenistion of necessary contol (ss alo the NOTE to 3-12),

2D Me design of work areas, processes, installations,

rachinorfequipment, operating procedtras and wore

‘rgunzation, Incuding ther adaptation shaman eapabiis.

‘The organiation's mthodology for hazard nian and sk

seseseent bal:

8) bedeina wth respect is scope, nar and ming io ensure it

4s prose rather an react; aad

1) provide for the Kentisistion, proitston an documentation of|

"ss, andthe aplication of eontols, s appropri.

For the management of chan, the orzaninaon shal nti the

‘OHS haaads and OL8S risks associated wih changes nthe

‘organization, the OHAS management sytam, or is aces, prior to

the intredaction of seh changes.

‘The orgniation shal ensure thatthe results of those assessments are

cone when determining conzals

|

}

433

‘When determining contol or considering changes o exiting,

contol, consideration shal be gion to redusngth risks arconding to

‘he folowing hierarchy:

8) bination;

1B) sbattution,

©) engiouringconzols;

4) signagotrarnings andlor edministrative cons;

©) personal protective equipment.

‘The organization stall document and koe the resus of kentiieaion

lor hanrds, risk asessments ae determined contol up-to-date,

‘Th organization shall ensure that the OHS sks and detemined

contol are taken ito accent when etabshing, implementing and

‘mainfining its OAS management systom.

[NOTE2 Por rthorquttnce om hard insfctin is ase

‘and dtormning comity, ee OHSAS 18002

Legal and other requirements

‘The onganizaton stall establish, implement and maintain a

procedures) for identifying and acessng tho lgal and other OHS

‘Fequoments that are applicable ts

‘The organization shall ensue that these appcale lag requirements

and other requirements to which the organtation subscribes are taken

{no sceount in estalishng, implementing aod malalning ts OFS

‘management sjstom,

"The ongasizaton shall kep ths information uptodate

‘The organization stall communicate eleva nformicn on ag and

‘thee ruiement to persona working cer the conte of he

‘organization, another relorare intrested pats,

Objectives and programme(s)

‘The ongaaton sl xa mplerient and maintain documented

‘O11 objectives, atrelvan functions and level win the

‘organization,

‘The objectives shall be measurable, where practical and consistent

‘vi ie OB yoy nh the conunkients ote prevention |

Injury and il et, to compliance with applabl legal requements

‘and wih other requirements to which the organisation series, ad

to continalimprovemet.

“When establishing and reviewing ts objectv, an oganizatin shall

{ake into account the legal roquirenents and owe roquiemens

‘which the organization subse, and ts O38S risks, Isl also

‘Considers techaologia options its nana operational an

‘business requrements, andthe vewsofrlrantinerestod partis

ousianer + 7

BS OHSAS 18001:2007

"The orgaiation shal estas mplament ad malin a

programmes) fr achieving is jects, Programs) shal incale

ssa minima:

5) designation of rexponsbity and authority for achiesng objectives

st sovant fonctions and levels ofthe ongsiaton and

1) the means andtimesame by which the objectives are to be

achive.

‘Te programme(s) shal be reviewed regula and panne intervals,

su adjust as nocosay, to ensure tha the sjectives are achivod.

. 44 Implementation and operation

44.1 Resources, roles, responsibility, accountability and i

authority

‘Top management sal take ultimate responsibilty for ONAS and the

OFS management sytem,

‘Top managemeot shall demonstrat its comment by:

2) ensuring the scanty of resources eset to establish,

Implement, maiiain and improve the OFS management stem;

[NOME 1 Resowroes cue human rear nd acai skill,

ongenzaonalsasiracrs,osnolgy anna reso.

1) dering roles allocating responsibilities end accountabilities, and

‘delegating autores, ofits effective OHAS management,

roles, responsibility, sccountaiies, and authorities shal be

‘ocumented and communicated.

‘The orgnieaton shall appoiet a members) of tp management with

specie responsiblity fr OHS, respective other responsiitis,

fd with defined roles and thon for

8) ensuring that the OHS management sysem i staid,

lnmplomerted and maintained i acordanc with this OHSAS i

‘Standard

1) ensuring thn reports onthe performance ofthe OHS

‘management stem are presented to lop management fr review

sand used as a basi for improvement of tn O14 management

‘The organization shal ensure tat persons in ha workplace take

responsibility for arpa of OHS over wick they have control

‘including adherence to the onganization'sappicable OHSS

requirments

8+ omar

442

443

444

4432

BS OHSAS 18001:2007

Competence, training and awareness

“The orpaizaton shall ensure tha any person(s) under ts ontot

perfoning tasks that can impact on OHS Is (are) competent on the

bss of appropriate education, teining or experlence, adsl tan

sSvociated record

“The organzation shal ently taining neds ssocatd with ts OHBS

risks and its OHAS management syst, Isal provide taining o tae

ther action to meet these needs, evaluate the effectiveness ofthe

[alnng or ation taken, and vetln associated cords

‘The organization shal esas, imploment aod mein a

procadure(s 1o wake persons working under its cont aware of

8) the OHS consaguancs, actual or poten oftheir work

actvie, die batouy, and the OHS betas of proved

1) ‘thee roles and sponses and tnpoxtanco in achieving

©) the potential consoquences of departure fom specified

‘Traing procedures shall take ao acount fering ovals of

5) reaponsiity aby Language sland eacy and

) ae

‘Communication, participation and consultation

Communication

‘Wat gad ots 8S hazards and OHRS management sytem, the

ongaization shal establish implement and mntlnsproendar(s)

for

18) Internal communication among the various levels and fnctons of

the organization;

1) communication with contractors and oh vistors to the

workplace

©) recving, documenting and respond relevant

‘comission rom exer inert paxson

Participation and consultation

"Tae organization shall esas, implement nt maintain 2

procedures) for

4) the parasipaon of workers by de

“+ appropriate nolvement in hazard Wentieation, ak assessments

‘id dotormintion of eontas,

“+ appropriate volvement in neon vestigation;

+ volvementin the development and revi of OH&S polices and

objectives,

ensizeer + 9

BS OHSAS 18001:2007

10 + ensioor

4Ad

+ consultation where there are any changes that fet their OHA;

+ presentation on OBS mations

‘Werks stall einformed about ce participation arrangements,

‘nluding whois thir representatives) on OBES mater

1) sonsltion wth contractors where there are changes affect

thei OFS,

‘The orgnition shall ensure that wher appropriate reloran external

Interesied partes are consid about prtner® ORS mato.

Documentation

‘The OH&S managment system documentation shall neta:

1) the OFS poy and objectives

1) description of the scope of the OHS mamgement system;

©) decrpion ofthe main lente ofthe OAS management sytem

‘and ther intraton and etree to eked documents;

aim ea ety, ged hr OSA Saat

1) documents incuting records, determined by tho organization

‘be necessary to ensure the effective planning operation and

‘contol of process that rel oth naagement of ts OH&S.

tila,

[NOTE important hat documentation i prapotona tthe lve ef

‘pet harden ike concord nd kept the idee,

‘rs for afecisnee ad fon.

Control of documents

Documents que bythe OHS managemert system and by thi

OFFSAS Standard sal be conto, Records a special ype of

Aocement and shal ba controlled in sccordans wih te eegurements

faven ind

“Th ongaiztion shall estab, impoment and malnain 3

proce) ts

8) approve documents for aloquay prior to su;

1) revew and update as necessary and reappove documents;

ensure that changes and the current revision sats of documents

seidentifed

ensure tat relevant version of applicable documents ae avaiable

at pints we;

©) ensure that documents remain gible and renilidntifbl;

1) ensure that documents of exter origin etersined by the

‘rguztion tobe nctasary forthe planing an operation of the

‘OFS management system ae enti wid ther distibution

contobed: end

{© prevent he unintended we of obsolete documents nd apply

Stable detifcaron to Uhm i yar mained for ny Purp,

[BS OHSAS 18001:2007

44.6 Operational control

‘Th organization shall detrmine those operations and actives that are

sssctated wa the Hanif hazaé(s) whet the implementation of

‘onto s necssary to manage the OH&S ri) Ths shalnclade tho

smanagement of change (ee 43.1),

For those operations and activites, the orgalztion shall implement

sand manta

9) operational controls, applicable tothe organization ants

activites; the onpanization shall integra those operations

‘conto int es overall O88 management syste,

1) control relate to purchased goods, equlpment and sevices;

(9) contrlsreatd to contactors and other vistors tothe workplace;

4) documented procedaes, to cover stations where thelr absence

‘could lead deviations rom the OHBS policy and he objectives;

©) siplated operating err wher thar absence could aed 10

‘evans from the OHES poly and ofjetves.

4.4.7 Emergency preparedness and response

‘Tho ongaizaton shall exablish implement and manana

procedar(s):

5) to entiy the potential or emergency dustions;

1) toreepond io such emergency stations

‘The organization shall respond to actual emerency stations ad

preven or miigate assole edverse OHSS consequences

“mn panning ts emergency response the oration shal ake account

‘ofthe needs of elovint intrested partes. emergency sevice and

neighbours.

‘The organtzaton shale perodcalytst ts procadure(s) to respond

toremergency stations, where practicable, voting relevant

Interested partis as appropriate

“The organization stl porodielly review ao, were necosiay, revise

ltsemengoncy proparedness ard reeponse procedures), patil,

sir periodical toting and afer the occurrense of eergency sions

(Gee 483)

45 Checking

4.5.1 Performance measurement and monitoring

‘The organtation shal etabs, implement sn maintain a

procedar(s to monte and measur O1AS performance ona regular

‘ass This procetures) shal provide for

8) both qualitative and quantitative measures, appropiate to the

eods of the organtation,

1) monitoring ofthe exentto which the onnization's 1S

‘bjectives are et

2) monitoring the efoctvenes of conto (for heath aswel as for

fen);

eusia007 + a

BS OHSAS 18001:2007

12 + ens2o0r

452

45.31

4) proactive means of performance that monitor conformance

‘ith the OHS programme(s), contro and operational eter;

© reakire measures of performance that monitor il health neers

(Cosuding acidents, near-miss, ee) and other historical

rience of deficient OH&S performace;

1) recording of data and rests of monitoring and messiremert

Sufcient to factat subsequent coretiv action and proventive

setion alysis.

equine requlsed to montor or mesmare perfomance the

‘onguntzation shal sabish and matin procedure for he calbation

‘ant maintonanco of such squiprment, © appropriate. Records of

‘ait ad maintenance stv and resis shall be retained,

Evaluation of compliance

4.5.2.1 Consistent wih ts commitment to compliance (see 426) the

‘organization shall stabs, implement anmainaina procedures) or

pevodialy evaluating complance with aplcable legal requirements

(oe 4.3.2),

“Tae organization stall keep rocords of terest ofthe periodic

‘ratinions.

[NOME Mafroquency of erade esaluation may vary for Siering legal

reroments

45.2.2 Tho onganiatin shall ovate compliance wit ober

requlrements to wich I subscribes (se 48.2. Tho organization may

‘wah to combine thi evaluation vith the eration of legal compllance

‘efor to in 45.2.1 oF to establish a spsrte procedure).

“The orgniation stall keep records ofthe results ofthe pride

ciation

NOTE. The froqumcy of arias satuationmay vary for fering eer

‘rund ohh he rgatnon bre

Incident investigation, nonconformity, corrective

action and preventive action

Incident investigation

‘The organization shal establish, implemest and maintain 2

procedere(o) 0 Fecord vestigate nn aml eden fm order to

8) determine underying OHAS deicencns andor factors that

mig be easing or contain to te occurrence of icents

1) dent the med for corrective action

©) denity opportunities fox preventive ation;

|) dentifyopporeuntes for continual improvement;

19) communicate the rests of uch investigations,

‘Th investigations shal be performed in atimaly manor.

Ay Wetted nee for conrectve etion or ppentuia for preventive

‘tion sal be dea with in socordance wi the relevant pats

of48.32.

45.02

45.4

455

[BS OHSAS 18001:2007

‘The resus incident investigations shal be documented and

ainsi

‘Nonconformity, corrective action and preventive action

‘The organization shall establish, mpement a maintains

rocedares) for dealing with ate and potent nonconfrmy(es)

fn for aking corrective ston and proves ction, The

procedures) shal dfine requirements for:

8) etifying and corecting ronconformi(es) and aking cions)

‘omligate their OHLS consequences;

')_incotgnting nonconformiy(s), determining thie easn() and

‘thing scion inorder to avoid thir oes

©) vahting the need for setion() to prevent nonconformityls)

‘ad implementing appropriate ations dined to avoid hat

4) recording and communieating th resus of corrective action(s)

‘ad prventve action(s) taken; ant

©) reviwing the effectiveness of corrective action() and preventive

actions) ake

‘Where the corrective ation and proven action iontifin new oF

changed hazards othe ned for new or changed corel, te

rocedare shal equ thatthe proposed acta shal betaken through

‘risk asesoment peor to inpementaton.

Any coretve action or prevontive action tant eliminate the causes

‘of scalar potatal nonoonforay(es) sal be appropiate othe

‘agnitae of problems and coninensirate withthe OWS rks)

‘encounters,

"The organization sal ensure that any necomary changes arising fom

corrective action and preventive action ate wade othe OH&S

‘management sjstem documentation.

Control of records

"The organization shal stash nd mana cord as necessary to

demonstrate conformity tothe rqulremons of ts OHS managament

‘tam and ofthis SAS Standard, and the resus shied

‘Te orgeniztion shall eras, xplnont and mania x

rocedur(s) forthe entiation, storage, woteclon, reser

fetenion and disposal of records.

Records sl be and remain lege, enti and traceable

Internal audit

‘The organization stall ensure hat internal aus of the OH&S

management system ste condactd planted tervals to:

28), determine whether the OHAS management sytem:

2) conforms to planed arrangement for 1S management,

‘eluding the reqltements of this ORSAS Standard and

2) ‘as been properly implemented ands matntined: and

8) is etfective in meeting the organizations poley and obsctives,

emsmer + 1s

[BS OHSAS 18001:2007

14 + enia0or

46

1) provide nfrmation onthe resus of slits to management

Adit programme) salt be planed, xabiste,implemetid nd

"mallinesty thecrgaization, based onthe eis of io seas

‘ofthe organization’ activites, andthe ref previous waits

Aut procedures) shal be estabishod, implemented and maintained

hat arose

8) the responsible, competencies, and requirements for planing

sl condeting ais, reporting ress ad retaining associated

cords ar

1) the determination of audit err, scope, teueney and methods,

Selection of anton conuct of audits shal ensue objective nd

the impart ofthe anit proces.

‘Management review

‘Top management shall review the organizations OHS management

stom, a planned intervals, to ensue its conteuing suai,

‘tiequcy and effectiveness. Reviews shal ichdeamessng

‘pportuitis for improvement and the need fr changes tthe OHSS

‘management stom, cui th OHS poi and OAS objectives

cords ofthe management reviews shall be rained.

Input to management reviews sal inci

8) eet of internal aia and evabatons of compliance: wi

pplicabl ogal requirements and with oe equremnts to

‘hich the organization eubaeibes

1) the resis of participation and consultation (ee 4.4.8);

(©) relovant communications) fom externa intersted partes,

Inctding complaints;

©) ORS performance ofthe organization,

(©) te extont co which obactives have been me

1. status of incident investigations, corectiveactions and preventive

setions;

{© follow actions from previous management reviews;

1) changing creunstances, including development a legal and

1 recommandadons for inproveent.

‘The oupats rom management reviews shal be consistant wth ths

‘orgunzaon's cmutment a conta improvsnet and shal ince

fry decisions andl ations related to posible changes

©) OHS performance;

2D) OFS policy and otyctves

©) resources nd

4) other clements of the OH&S management stem

Relevant outpts from management reve sal be made avalale for

‘smuruicaton and consubation (se 4.4.2).

sus opr 2007

Annex A (informative) Correspondence between

OHSAS 18001:2007, ISO 14001:2004

and ISO 9001:2000

‘able Al Correspondence between OHSAS 18001:2007, 150 14001:2004

‘and 150 9001:2000,

[OHSAS 180012007 180 1001001

= an i Piedaaion

foe fa

ee

[Tener anddeiasons |__| Term nd etitions

[2 [ona aragennee apa [4 Enoromnasal manages

seen eon). sytem rua as

ln.

lad — [aerate far —|Genalroqarenas

55.1 _|Rpoeshey sod autory

fea fons paar [aaa pay |5.1 [Magee commie

[53 [atin poe

[88.1 [Sand toyoreent

= (ecb) [63 Ping i op) [dP il no)

13rd Wesco TAK 481 [Ezormenalogpats —]5:2 | Ontomer oc

sneer and 2 | Deeition of

[deeming comes egret la oo

peo

722 Redon ofrequrenente

rst othe es

laa legates oer aaa [leew ae 52 |lstoner oes

ewarenons sewsrances 721 |Dowrminaton of

eat

Faas Joti na 43:3 ~ |Obpeaees egaraad [BAL ay lps

loeanael) rowan) [542 [ate maosemer syst

Jas | Ger mgmt

[Et [iaemen aad 24 —ingnision and [7 | odie ration Ge

operates Ce a) oper eo) on)

ensizcar + 15

'BS OHSAS 18001:2007

‘Tle A

‘Correspondence between OHSAS 18001:2007, 150 14001:2004

‘and 180 9001:2000 (continues)

[OnsAS ia001:2007

80 140013000

180 soerab00

laa

Resour rh,

eosin,

‘reouair and

arty

Resor

[espera and

bert

ies

ea

[en

capers, ang ad

eae

as

oo

(comin

oar

roy

Doses

leas

[Coa oc

leas

ont or aac

as

[Spat enzo

leas

Open onal

sas

as

at

t=

2558

16 + enst2o07

Thole A

BS OHSAS 18001:2007

Correspondence between OHSAS 18001:2007, 150 14001-2004

and 180 8001:2000 (contaued)

iso 1001008 80 veni000

[AF [Baer nares |B Corl of wont

laden pret!

TS) Gekng Cae oi) [8] beraree,aaaae

Iinroveent (ie on

aaa oat 8 Coa of montig

(stent, ena and

tyrone)

. lex [Geen

[828 aestocing and mensroment

at rocanes

lane [Neorg id meanrmene

at roar

jas [anavas o ae

oF faa reo AS a RTT |B mg a TR

ls24 ator and meanenent

ot

ome == ==

sence

evetve ston (ile

om)

[ESRI [inst wagon —[———[— EE

AE |Nonentomiy, Saar a nna

forex and preventive brelue,

ion ay dara

Sorte acon

Prevent ston

aa | Conta ates [8a [Conah chron [424 [Cond a eons

53 [neal eat 58 eran (522 [rena a

[68 |ianagemene new [48 tagenentomaw 5.1 [Magnet commits

seme ise |icageec or i ot)

[562 |Recew moat

1503 [Rew ope

Jet [Conia provement

eusizoor + 17

BS OHSAS 18001:2007

Annex B Gaformative)

Ba

pe

mat

Correspondence between

OHSAS 18001, OHSAS 18002, and

the ILO-OSH:2001 Guidelines on

occupational safety and health

management systems

Introduction

Tals annex denies the hey difference betwen the Inematinsl

labour Organization 10-0SH Guldlios ste OHSAS documents,

and provides a comparative assessment of tiring requirements

should benoted that no areas of algnifican difference have been

identified.

Consequety, those organizations ha have eplemontsd an OHS

‘management sjsem tats compat wth OHSAS 18001 maybe

"easauted that heir 18S management systen wala be compatible

‘wt te reconmendstions ofthe 1L0-OSH Guiteines.

‘correspondence tble between tho inddual class of the OSA

Acumen and ehow ofthe 1L0-OSH Gude given in,

Overview

‘The two pine objectives ofthe ILO-OSH Guidlines ate:

8} to asist counts in the establishment of anational framework for

‘ceapationl ath and safety mnagemert sens; and

) to provide guidance to mua organiaons regarding the

lnteralion of O85 cements ino thelr veal plc ae

‘anagetneaterandoment

(OHSAS 18001 speci requirements fr OAS managunet syste,

temo organzations to conel risks sd to inprove nis OF8S.

performance: OHSAS 18002 gives gudance on the impementstion ot

‘OHSAS 18001. The OFSAS documents ae thee fore comparable wth

Section 5 ofthe 1L0-0SHE Guidlines “The ocewpational sty and

‘health management system inthe orgnsation”

Detailed analysis of Section 3 of the ILO-OSII

Guidelines against the OHSAS documents

Scope

‘he few of he ILO.OSH Guideline is on wore. The focus ofthe

OFISAS Stanari, towards pesons under the conzo ofthe

ongunzain and other interested pare, x breed,

OH&S management system models

‘The models pleturng the main elements of an OHS management

“ystam are rect eutalent bobween ths IL0-0SH Guidelines andthe

(OHSAS document,

B33

Bad

3s

B36

Baz

nas

Bao

BS OHISAS 18001:2007

ILO-0SH Section 3.2, Worker participation

Inthe ILO-OSH Gusdetines, subsection 8.2.4recomments hl: “The

‘mployer shoul encere as expropriata, the extablshmont and

‘ficient fenctioning of health and safety commiltce and the

‘recognition of workers health and safety representatives in

‘sccordance with national laws and patie

CSAS 18001 4.4.8, requis the organizatiosoetabish procedure

for communication, purteipaion and consult, ant involve 8

‘wit specerum of intrested partes (ue Tote reader scape of

{pletion ofthe docunend)

1L0-0SH Section 3.8, Responsibility and

accountability,

‘The LOS Guidelines recommand in 8.3108) the esabishmentof|

prevengon and ath prometionprogratnes, Tete requirement

{nthe OUSAS Standards or hi

1L0.0SH Section 3.4, Competence and training

‘The recommendation of the 1LOOSH Guidetinesaubsscion B.A

"Tvaining shouldbe provided io all particpamts ot no cat al

hon take place dering working hours if poseble’, 08 8

1L0-08H Section 3.10.4, Procurement

‘The ILO-OSH Gulden emphasis hat sae and health requirements

ofthe organization sald be incorporated int purchasing ad easing

specications

‘The OTISAS Standards address procure by the reqlrments for

"sk assessment, entifiaion of log requires and he

fstabishnent of operational conto

1L0-0SH Section 3.10.5, Contracting

‘The LO-OSHHGuiines deine the saps to be taken to ensure tat tho

bvganaaon safety andhelehrequremensareappied contactors

(they ab provide a summary ofthe ations woded to ens tha thoy

so) Tiss implictn OHSAS,

1L0-0SH Section 3.12, Investigation of work related

injuries, I health, diseases and incidents, and their

Impact on safety and health performance

‘The LO-OSH Guiles donot require came ations ox preventive

ction tobe reviewed through the isk assesment process pir 10

finplemetation, as they are OHSAS 18001, 45.8.2

IL0-0SH Section 3.13, Audit

‘The IL0-0SH Guidelines recommend conmantion onthe scion of

‘aio. In contrast, the OHSAS documents requ aud personnel to

eimparcial and objective

onstisor + 19

[BS OHSAS 18001:2007

B10

TL0.0SH Section 3.16, Continual improvement

‘hls sa separate subcaane inthe 110-OSH Gudelies, 1 dts

rangement that should be taken ito accout forthe achievement of|

‘conta improvement. Sime srangements re deta throughout

the OHSAS documents, which consequently de not have &

‘corresponding itn

4 Correspondence between the clauses of the

OHSAS documents and the clauses of the

1L0-0SH Guidelines

‘TbleB.1 Correspondence between the clauses of te OHSAS documents

and the clauses of the ILO-OSH Guidelines

(Ciso= [ous [Ciasse [10-081 Guidlines

ion xoeicion

5:0 [Tae compton ae nd hess anageene

ssn inthe ogee

Raw [=] he ern Labor ORGS

7 [Bee 1.9 [Obecves

a er = igre

[3 arms as [= [ower

7 OHS manage tem dames] = |=

ee at)

ao [0 Ae acca I mama

Sst ine osuiaen

a oma paar Ocspaiona sty acealpaley

[Cental inproeane

3 Pisa (alee) Ping el pletion eo)

Tard ein, ncaa ealrevew

[ecrminig contr

[aad ga and oer raranes

[aaa [Onetes ad ogee)

Conan imaroweiet

|e a operon oa |— =

“6A |searcs, ss, rps, [83 |Repanaiy nd oo

sccounay ad oor [28 | System plang, ceveoynat seaplane

20+ onstzo0r

BS OHSAS 1800):2007

‘ThbleB.1 Correspondence between the clauses ofthe OHSAS documents

‘and the clatwes of the ILO-OSH Gtdellnes(omtinued

Gaase [OHSAS [iain [COOSA Galdlines

a | Compe ang ma es 4 | Compre ae a

443 | Covinanioaton, partipwion snd 3a [Woe partcoation

scares 34 [Commons

Pon inv,

AS Coa ooo ae oe

‘cm Scere

a8 persion cont SIGE fees oc

2308 |Caracg

[ar ere ean cae |S.10 | Bergen EON Barnes ap

fas — [Cea on [= [Bran eo)

[eI [Petamincr mere aa Rang —_[Revorcr motor ad meee

[oa — [ett uve, nomen ——]= |=

[sri acon and penne ton

te)

ER ela vei fae — avenge a AT

oo

STR Sore STE

a

neo aco

as.

eral

Mager

‘enatsoor - 21

BS OHSAS 18001:2007

Bibliography

{8}180 900:2005, Quality managemont dems — Pendamentals

nd vocbaary

{21180 9001:2000, Quality management sytem Reiements

{51130 14001:2006, Environmental managonent ystems

Roquimons with quan fore

{41180 190112002, Guidlines for avaityomd/orensironmental

‘management atoms ousting

22 + paar

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5835)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 08 - First Aid Box Inspection ChecklistDocument1 page08 - First Aid Box Inspection Checklistsanjeev kumar100% (1)

- Iso 45001Document10 pagesIso 45001sanjeev kumar0% (1)

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumarNo ratings yet

- Legal Register For Constriction SiteDocument33 pagesLegal Register For Constriction Sitesanjeev kumarNo ratings yet

- FT39-Emergency Rescue PlanDocument25 pagesFT39-Emergency Rescue Plansanjeev kumarNo ratings yet

- 10 - Cherry Picker Inspection ChecklistDocument1 page10 - Cherry Picker Inspection Checklistsanjeev kumarNo ratings yet

- 01 - Gas Cutting Set Inspection ChecklistDocument1 page01 - Gas Cutting Set Inspection Checklistsanjeev kumar100% (1)

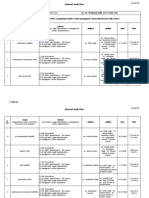

- FT20 Internal Audit PlanDocument5 pagesFT20 Internal Audit Plansanjeev kumarNo ratings yet

- OHSE - ISO 45001-2018 Overview - GoldDocument73 pagesOHSE - ISO 45001-2018 Overview - Goldsanjeev kumar94% (17)

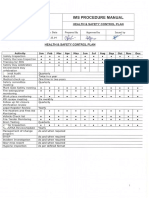

- o Ehs 08 Health & Safety Control PlanDocument1 pageo Ehs 08 Health & Safety Control Plansanjeev kumarNo ratings yet

- 9 Colour Code of Lubricants Alt 1Document3 pages9 Colour Code of Lubricants Alt 1sanjeev kumarNo ratings yet

- Total Productive Maintenance (TPM) : DescriptionDocument3 pagesTotal Productive Maintenance (TPM) : Descriptionsanjeev kumar100% (1)

- House Keeping Check List: Sl. No. DescriptionDocument24 pagesHouse Keeping Check List: Sl. No. Descriptionsanjeev kumarNo ratings yet

- TML Sop HT Switch BoardDocument4 pagesTML Sop HT Switch Boardsanjeev kumarNo ratings yet

- Rating: Company Rating A 2 B 1 C 2 D 3 E 4 F 2 G H I J KDocument2 pagesRating: Company Rating A 2 B 1 C 2 D 3 E 4 F 2 G H I J Ksanjeev kumarNo ratings yet

- Safety AuditSDocument5 pagesSafety AuditSsanjeev kumarNo ratings yet

- Root Causes and CAPADocument27 pagesRoot Causes and CAPAsanjeev kumarNo ratings yet

- Plant IlluminationDocument1 pagePlant Illuminationsanjeev kumarNo ratings yet

- Floor PlanDocument1 pageFloor Plansanjeev kumarNo ratings yet

- Airr CPPDocument121 pagesAirr CPPsanjeev kumarNo ratings yet

- Sr. No Equipment Name Activity 17-Sep-17Document32 pagesSr. No Equipment Name Activity 17-Sep-17sanjeev kumarNo ratings yet