Professional Documents

Culture Documents

Air and Flue Gas Tightness Test

Air and Flue Gas Tightness Test

Uploaded by

Dipnarayan KumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air and Flue Gas Tightness Test

Air and Flue Gas Tightness Test

Uploaded by

Dipnarayan KumarCopyright:

Available Formats

LANCO AMARKANTAK POWER PRIVATE LIMITED

1200 MW THERMAL POWER PLANT

KORBA, CHATTISGARH

AIR AND GAS TIGHTNESS TEST

INDEX:-

1) OBJECTIVE

2) PROPOSAL

3) PRE-COMMISSIONING CHECKS

4) PROCEDURE OF THE LEAKAGE TEST

5) COMPLETION CRITERIA

INSPECTION DATE NAME SIGN.

INSPECTED BY

CLEARED BY

LANCO AMARKANTAK POWER PRIVATE LIMITED

1200 MW THERMAL POWER PLANT

KORBA, CHATTISGARH

AIR AND GAS TIGHTNESS TEST

A) OBJECTIVE

The air & gas tightness test is carried out in Boiler furnace, air and Gas ducts, in

order to find out

The leaks, incomplete weld joints, left out portion of the weld, flange joint leaks, etc

and to arrange

for repair/ rectification.

The air tightness test is only a Test to find out the tightness of the Boiler furnace, air

and gas ducts

With the respect to the outside environment and is not performed to assess the

strength to withstand

the operating pressure.

B) PROPOSAL

The test will be carried out by furnace leak detection method in the following Stages.

1. Furnace penthouse & rear arch.

2. Scanner air line.

3. PA fan discharge & Coal pipes.

4. Scanner air fan discharge ducts.

5. ID/ FD air fan duct.

C) SERVICES REQUIRED

1. Soap water.

2. Bucket & Mug.

3. Cotton waste.

4. Marker.

5. Lighting arrangement.(Hand Lamps).

6. Man power for conducting the Test.

INSPECTION DATE NAME SIGN.

INSPECTED BY

CLEARED BY

LANCO AMARKANTAK POWER PRIVATE LIMITED

1200 MW THERMAL POWER PLANT

KORBA, CHATTISGARH

AIR AND GAS TIGHTNESS TEST

D) PRECOMMISSIONING CHECKS

REFERENCE

STATUS

S.NO. ACTIVITY DOC/ACCEPTANC

ok/not ok

E CRITERIA

Ensure completion of erection of Boiler first Refer filled up log

pass/horizontal/rear passes, sheet of the

1.

IDF/FDF/PAF/APH and all ducting of air & erection Quality

flue gases system. plan.

Check the clearance is obtained from ducting

2. system, Fans, AH and main Boiler erection

group.

3. Check the following in the ducts( ID

suction /discharge, ESP inlet /outlet/ inter-

connection, AH O/L to ESP I/L,FD discharge,

AH I/L & O/L, WIND BOX, PA DISCHARGE,, Cold

air bus tampering air, mill I/L.

A) Completion of all supports/sliding

points.

B) Completion of all instruments point.

C) Completion of all bracing.

D) No visible leakage point.

E) Removal of the expansion bellows

locking.

F) Completion of erection &

commissioning of the damper.

G) Tightness of the flange joint.

H) Completion of the flange joint.

4 Check AH for any visible leakage point.

Check ID/FD/PA/Seal air fans for any visible

5

leakage points in the casing.

6 Check wind box for any visible leakage points.

Check the ESP casing, shaft/support

insulator covers Hoppers etc for any visible

7

leakage points.

INSPECTION DATE NAME SIGN.

INSPECTED BY

CLEARED BY

LANCO AMARKANTAK POWER PRIVATE LIMITED

1200 MW THERMAL POWER PLANT

KORBA, CHATTISGARH

ACTIVITY REF. DOC./

AIR AND GAS TIGHTNESS TEST STATUS

S.No. ACCEPTANCE

Ok/not ok

CRITERIA

8 Check the main Boiler in the following area.

a) Seal trough- Seal plate to trough

proper clearance and proper water level

in seal trough & completion of the

welding.

b) Completion of seal welding in the boiler

bottom arch panel to the panel joint.

c) Completion of the seal welding in the

rear arch (dog house) panel to panel

joint.

d) Completion of the all instrumentation

point.

e) Completion of the burner blocks

connection with the furnace opening &

wind box.

f) Completion of the scallop plate joint

between wind box and furnace left and

right water wall.

g) Completion of all installation of all oil

guns/ igniters/ scanners.

h) Completion of furnace roof sealing skin

casing i.e. between roof panel to side

wall, super heater entry point through

roof, roof entry points at upper drum.

i) Completion of all refractory job in the

roof, rear arch, burner block top

bottom area.

j) Completion of the sealing in rear arch

tubes entry points to the lower drum.

k) Installation of all soot blowers with

proper sealing at gland & entry point.

l) Proper tightness of the manhole and

peephole at various location.

m) Completion of the 2nd pass Eco inlet &

AH I/L duct with proper sealing.

9. Checking seal air ducting, seal air filter

cleaning duct, scanner air duct for any visible

leakage point.

INSPECTION DATE NAME SIGN.

INSPECTED BY

CLEARED BY

LANCO AMARKANTAK POWER PRIVATE LIMITED

1200 MW THERMAL POWER PLANT

KORBA, CHATTISGARH

\ AIR AND GAS TIGHTNESS TEST

E) PROCEDURE OF THE LEAKAGE TEST

REF.

S.No.

DOCUMENT /

ACTIVITY STATUS

ACCEPTANCE

CRITERIA

1 Repeat the tests

Run ID/FD Fans & pressurize furnace to +25 till all leakages

to +50 mmWc. Check air leakages points in are attended

various ducting, ID/FD Fans. ESP. Spread

soap solution on the pent house roof & check

the leakages and rear arch leakages to be

checked physically.

2 Run PA Fan & pressurized PA & Milling Repeat the tests

System ( keeping burner I/L gate closed) till all leakages

and check the air leakages in the duct, are attended &

casing, mill body, Pf piping & Seal air fan Test is declared

suction duct ( physical leakage detection) over when all

the leakages are

attended.

3 Run the seal air fan and check for the air Repeat the tests

leakages in the seal air discharge & seal air till all leakages

filter cleaning air duct .( Physical leak are attended &

detection.) Test is declared

over when all

the leakages are

attended.

4 Run the scanner air fan & check for air Repeat the tests

leakages in scanner air duct( physical leak till all leakages

detection) are attended &

Test is declared

over when all

the leakages are

attended.

F. COMPLETION CRITERIA

Air and gas tightness for any stage declared complete when identified all the leakages

point attended satisfactorily.

Insulation work for any stage could be taken up after completion of the

Air & Gas tightness Test.

INSPECTION DATE NAME SIGN.

INSPECTED BY

CLEARED BY

You might also like

- Micro Oil Ignition System (MOIS) : Minimising Fuel Oil ConsumptionDocument19 pagesMicro Oil Ignition System (MOIS) : Minimising Fuel Oil Consumptionravi singh100% (1)

- NTPC Telangana: Standard ChecklistDocument3 pagesNTPC Telangana: Standard ChecklistVikrant Deshmukh100% (1)

- Air Tightness Test of FurnaceDocument7 pagesAir Tightness Test of FurnaceRupesh Sinha100% (1)

- Checklist For Roof Skin CasingDocument7 pagesChecklist For Roof Skin CasingRamalingam PrabhakaranNo ratings yet

- U#2 Oh Report 2003Document45 pagesU#2 Oh Report 2003Sony RamaNo ratings yet

- Air-Preheater Leakage TestDocument2 pagesAir-Preheater Leakage TestAamirMalikNo ratings yet

- Bends Requirement As Ibr AsmeDocument3 pagesBends Requirement As Ibr AsmeAgniva DuttaNo ratings yet

- Condenser Flood Test 8 of 11Document14 pagesCondenser Flood Test 8 of 11Sara LopezNo ratings yet

- Ice 1.1 Steam Welding PrincipleDocument82 pagesIce 1.1 Steam Welding PrincipleThilagavathy SethuramahNo ratings yet

- Major Overhauling of Boiler and Auxiliaries of U 4Document32 pagesMajor Overhauling of Boiler and Auxiliaries of U 4appireddy_scribdNo ratings yet

- Erection Sequence of AphDocument37 pagesErection Sequence of AphNaveen ChodagiriNo ratings yet

- Place of Posting: NTPC VindhyachalDocument16 pagesPlace of Posting: NTPC Vindhyachalscentpcbarauni BARAUNINo ratings yet

- Welcome: Presentation ON Boilers & AuxiliariesDocument58 pagesWelcome: Presentation ON Boilers & Auxiliariestanuja singhNo ratings yet

- Bhel Recommendations On Tube FailuresDocument4 pagesBhel Recommendations On Tube FailuresNaveen ChodagiriNo ratings yet

- Analysis of Tube Failure in Water Tube BoilerDocument16 pagesAnalysis of Tube Failure in Water Tube BoilerHussseinmubarkNo ratings yet

- l6ll2l20L8: Fifth 2018Document16 pagesl6ll2l20L8: Fifth 2018dileepNo ratings yet

- PROJECT F2 (Dushyanth)Document85 pagesPROJECT F2 (Dushyanth)saiNo ratings yet

- Chemistry in Power Plant-PDocument25 pagesChemistry in Power Plant-PNitin SinghNo ratings yet

- Procedure For Alkali BoiloutDocument9 pagesProcedure For Alkali BoiloutBapu612345No ratings yet

- Boiler Erection of Pressure Parts PDFDocument44 pagesBoiler Erection of Pressure Parts PDFAK100% (1)

- Materials: Pressure Parts and Applicable Service TemperaturesDocument14 pagesMaterials: Pressure Parts and Applicable Service Temperaturesmohan babuNo ratings yet

- Vizag Steel Plant WHRB RussiaDocument47 pagesVizag Steel Plant WHRB RussiakaustavNo ratings yet

- CFBC DCPP at A Glance.Document20 pagesCFBC DCPP at A Glance.Sumit SuryavanshiNo ratings yet

- Engineering Declaration Unit # 2 JindalDocument16 pagesEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- SERIES 22.2: Heavy Duty Gear ReducersDocument2 pagesSERIES 22.2: Heavy Duty Gear ReducersAmir KhanNo ratings yet

- FGD PresentationDocument32 pagesFGD PresentationSaravanan RagupathyNo ratings yet

- Feasibility Study Report (1) ESPDocument32 pagesFeasibility Study Report (1) ESPrajanarsuNo ratings yet

- Bed Coil Chang Procedure PDFDocument8 pagesBed Coil Chang Procedure PDFMahadev KovalliNo ratings yet

- Biomass (Rice Straw) Fired BoilerDocument9 pagesBiomass (Rice Straw) Fired BoilerSnehashis MaityNo ratings yet

- Water QualityDocument21 pagesWater QualityLakshmi NarayanNo ratings yet

- Once Through: Steam GeneratorsDocument21 pagesOnce Through: Steam Generatorsrajrampally100% (1)

- Super Critical Boiler Technology SKDDocument35 pagesSuper Critical Boiler Technology SKDSwapnil TingusleNo ratings yet

- 1) Tube & Pipe Comparison TableDocument2 pages1) Tube & Pipe Comparison Tablevalli raju100% (1)

- Cleaning Force RatioDocument1 pageCleaning Force Ratioahmad isnaidiNo ratings yet

- Boiler Inspection Tips 1Document146 pagesBoiler Inspection Tips 1SenakeNo ratings yet

- Boiler Pressure PartsDocument25 pagesBoiler Pressure PartsAnfal Barbhuiya100% (1)

- Dry Cleaning & Inspet Esp #1Document16 pagesDry Cleaning & Inspet Esp #1ShahNo ratings yet

- Design Life of Thermal Power PlantDocument2 pagesDesign Life of Thermal Power Plantdnageshm4n244100% (2)

- Low Nox Emission TargetDocument13 pagesLow Nox Emission Targetprasanna1990No ratings yet

- Super Critical Boiler Materials - Metallurgical Aspects: R N Mehrotra, GM Energy TechnologyDocument41 pagesSuper Critical Boiler Materials - Metallurgical Aspects: R N Mehrotra, GM Energy TechnologyVIBHAV100% (1)

- CFB Boiler BrochureDocument2 pagesCFB Boiler BrochuremechguybalaNo ratings yet

- Boiler Hydro Test by R K JaintDocument9 pagesBoiler Hydro Test by R K JaintRajeevAgrawalNo ratings yet

- CAVTDocument4 pagesCAVTRaj EaswarmoorthiNo ratings yet

- Steam Turbine Components Welding PDFDocument228 pagesSteam Turbine Components Welding PDFShoaib AhmedNo ratings yet

- Training R&M of BoilersDocument45 pagesTraining R&M of BoilersSam100% (1)

- CFBC SHORT NOTESDocument8 pagesCFBC SHORT NOTESanbarasanNo ratings yet

- Boiler Inspector TRAINING - 2021Document8 pagesBoiler Inspector TRAINING - 2021SUNIL BABURAO GAVADENo ratings yet

- Rockwool Insulation LRB MatressDocument1 pageRockwool Insulation LRB MatressJaveed KhanNo ratings yet

- PLTU Nagan Raya NAD 2X110MW: Boiler Operation Manual (Startup Boiler Operation Manual) Vol.1 - 4ADocument27 pagesPLTU Nagan Raya NAD 2X110MW: Boiler Operation Manual (Startup Boiler Operation Manual) Vol.1 - 4AWahyuda IckyNo ratings yet

- Specification For Smoke Bomb Test PDFDocument4 pagesSpecification For Smoke Bomb Test PDFARUNNo ratings yet

- Boiler Feed PumpDocument52 pagesBoiler Feed PumpArun Kumar100% (1)

- 190 TPH Start Up ProcedureDocument19 pages190 TPH Start Up ProcedurepothanNo ratings yet

- Thermal Power Plant Color Code For Piping PDFDocument11 pagesThermal Power Plant Color Code For Piping PDFalwynnithinherbert50% (4)

- GEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingDocument24 pagesGEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingAkasthiyanNo ratings yet

- Boiler Tubular Air Pre-Heater - TaphDocument18 pagesBoiler Tubular Air Pre-Heater - TaphsbmmlaNo ratings yet

- RLA of Power Plant EquipmentDocument12 pagesRLA of Power Plant EquipmentSnehashis MaityNo ratings yet

- Animated Soot BlowerDocument15 pagesAnimated Soot BlowerPrudhvi RajNo ratings yet

- 045 - Tech. Dairy of Shree PowerDocument81 pages045 - Tech. Dairy of Shree PowerAamirMalikNo ratings yet

- Boiler: Sabari Girish N Sr. Engineer (O)Document37 pagesBoiler: Sabari Girish N Sr. Engineer (O)Deepak SinghNo ratings yet

- SOP Boiler HydrotestDocument3 pagesSOP Boiler HydrotestSachin nandgaye0% (2)

- Weldolet and Dimension of WeldoletDocument10 pagesWeldolet and Dimension of WeldoletMAHESH CHANDNo ratings yet

- Department of Technical Education Andhra PradeshDocument35 pagesDepartment of Technical Education Andhra PradeshSHEKHARNo ratings yet

- Ducts and Diffusers DesignDocument106 pagesDucts and Diffusers Designmister_no34No ratings yet

- Rate List For HVAC (Updated June 2021)Document6 pagesRate List For HVAC (Updated June 2021)muhammad bilal ahmedNo ratings yet

- Tica Tims VRF 2023Document71 pagesTica Tims VRF 2023Marketing Jaga Citra IntiNo ratings yet

- DBH Commercial: Base Efficiency Heat Pump Belt-Drive Packaged Rooftop Unit DBH Commercial 3-5 Nominal TonsDocument40 pagesDBH Commercial: Base Efficiency Heat Pump Belt-Drive Packaged Rooftop Unit DBH Commercial 3-5 Nominal TonsChin Heng LimNo ratings yet

- Standard Thermal Store Dec 21Document2 pagesStandard Thermal Store Dec 21ErikNo ratings yet

- Elmadaen Static PressureDocument40 pagesElmadaen Static PressureKarthy GanesanNo ratings yet

- Submittal - High Static Ducted - ARNU363BGA4Document2 pagesSubmittal - High Static Ducted - ARNU363BGA4RedHammerNo ratings yet

- 2023puremind CatalogDocument28 pages2023puremind CatalogCadnel ZOHANNo ratings yet

- Dunham-Bush Air Cooled Rotary Screw ChillersDocument44 pagesDunham-Bush Air Cooled Rotary Screw ChillersZainudin AzmiCONo ratings yet

- Piping S Specificat Tion "BA1" ": C Class: An CS SI 300#, RFDocument4 pagesPiping S Specificat Tion "BA1" ": C Class: An CS SI 300#, RFJhonny Chugá MejíaNo ratings yet

- Visio-Alarm Control Cooling TowerDocument1 pageVisio-Alarm Control Cooling TowerDamsarMeangNo ratings yet

- Design, Calculation and Cost Estimation of HVAC System For School BuildingDocument12 pagesDesign, Calculation and Cost Estimation of HVAC System For School BuildingMd KaleemNo ratings yet

- MNT 003-04 Multicolumn Distillation Plant OperationDocument3 pagesMNT 003-04 Multicolumn Distillation Plant OperationAniket kopateNo ratings yet

- Chillers: The Machine Which Produce The Chilled Water To Distribute It To Different SpacesDocument11 pagesChillers: The Machine Which Produce The Chilled Water To Distribute It To Different SpacesMostafa Elmaghraby 467No ratings yet

- SUNCUE Steam Paddy Dryer - Whatsapp: +91-9554191168Document2 pagesSUNCUE Steam Paddy Dryer - Whatsapp: +91-9554191168SUNCUENo ratings yet

- Usp H Series Marine Type Water Cooled Packaged AirDocument70 pagesUsp H Series Marine Type Water Cooled Packaged AirhassNo ratings yet

- 23 31 13 DuctworkDocument4 pages23 31 13 DuctworkLangzkie NalipaNo ratings yet

- Tabla de Tuberias R-410aDocument8 pagesTabla de Tuberias R-410aRamgueNo ratings yet

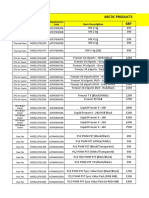

- Arctic Price List AS OF June 2021Document4 pagesArctic Price List AS OF June 2021Jhover BernalNo ratings yet

- LG AC ManualDocument39 pagesLG AC ManualAllauddin BhattiNo ratings yet

- Fcu PipingDocument20 pagesFcu PipingRamadan RashadNo ratings yet

- 2019 ASHRAE Boston Product Guide Final PDFDocument75 pages2019 ASHRAE Boston Product Guide Final PDFFrank UrsNo ratings yet

- MEC 4205 Exam - May - 2016 - FinalDocument5 pagesMEC 4205 Exam - May - 2016 - FinalBirimumaso DavidNo ratings yet

- CL (09,12) 216 - Service Manual - ENDocument64 pagesCL (09,12) 216 - Service Manual - ENTatiana DiazNo ratings yet

- Week 6Document6 pagesWeek 6shmyeNo ratings yet

- CBA38MV Air Handler Installation InstructionsDocument46 pagesCBA38MV Air Handler Installation InstructionsmarkargentNo ratings yet

- Oil Cross Reference PDFDocument4 pagesOil Cross Reference PDFModussar IlyasNo ratings yet

- Hot and Cold Water Supply FinalDocument40 pagesHot and Cold Water Supply FinalAmit Kumar YadavNo ratings yet