Professional Documents

Culture Documents

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Uploaded by

alCopyright:

Available Formats

You might also like

- 5 4 Gizmo Energy ConversionsDocument5 pages5 4 Gizmo Energy Conversionsapi-27357852653% (174)

- Big Science Competition Year 8 2020Document21 pagesBig Science Competition Year 8 2020PepsicleNo ratings yet

- ScantlingDocument39 pagesScantlingSky R100% (1)

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Asupu Nano BubblesDocument10 pagesAsupu Nano BubblesAgung50% (2)

- Saturation Lab ReportDocument4 pagesSaturation Lab ReportYas Tairab0% (1)

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- JAWAD Khalid (41) & SHEHROZE Malik (36) FYP-1Document21 pagesJAWAD Khalid (41) & SHEHROZE Malik (36) FYP-1jawad khalidNo ratings yet

- Submarine ReportDocument10 pagesSubmarine ReportShahzeb Bin TariqNo ratings yet

- Problem 1 Dphe Kusnaryo Hal 19 NFDDocument7 pagesProblem 1 Dphe Kusnaryo Hal 19 NFDLDK UISINo ratings yet

- API 650 Calculation ThicknessDocument20 pagesAPI 650 Calculation ThicknessHsein WangNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Heat Balannce:: Fluid AllocationDocument16 pagesHeat Balannce:: Fluid AllocationUsama AkramNo ratings yet

- Mixer - 01: A. Menentukan Volum Tangki (V)Document13 pagesMixer - 01: A. Menentukan Volum Tangki (V)kurniawanNo ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- Pompa Util SulsulDocument90 pagesPompa Util SulsulMaRhaenia TheresaNo ratings yet

- Reactor 20Document1 pageReactor 20Kriengsak RuangdechNo ratings yet

- Example 3Document2 pagesExample 3RindangNo ratings yet

- 100-E4 (Reduced Crude/Vacuum Bottoms Heat Exchanger 4 Design)Document10 pages100-E4 (Reduced Crude/Vacuum Bottoms Heat Exchanger 4 Design)MuhammadTanzeeLUsmanNo ratings yet

- 11.mixing TankDocument16 pages11.mixing TankZaidatu ImtinanNo ratings yet

- External Forced Convection: Pipe 90 °CDocument16 pagesExternal Forced Convection: Pipe 90 °CiosuarizNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Document64 pagesBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)christian abogadoNo ratings yet

- Line Sizing Calculation 1Document9 pagesLine Sizing Calculation 1SAMUEL UDOHNo ratings yet

- Inner Vessel Check Shell Thickness For Internal PressureDocument6 pagesInner Vessel Check Shell Thickness For Internal PressureSAMER OSMANNo ratings yet

- Calculation For Steel Lift Pit at Concourse LevelDocument5 pagesCalculation For Steel Lift Pit at Concourse LevelSUBIR KARMAKARNo ratings yet

- Perhitungan Tugas 1 Perancangan HEDocument3 pagesPerhitungan Tugas 1 Perancangan HELuthfanNo ratings yet

- Bolt Connection Design Based On NDS 2018: Input Data & Design SummaryDocument2 pagesBolt Connection Design Based On NDS 2018: Input Data & Design Summaryalejahrojas96No ratings yet

- Div 2 THK CalcDocument10 pagesDiv 2 THK CalcelleNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC 360-10/16Document1 pageBeam Connection of Conventional Configuration Based On AISC 360-10/16Karen Esther Acuña VelasquezNo ratings yet

- 5.3 Design of Waste Heat Boiler: (13) : DataDocument7 pages5.3 Design of Waste Heat Boiler: (13) : Datamoni beeNo ratings yet

- Tangki BufferDocument6 pagesTangki BufferdwirustantoNo ratings yet

- Final GP2 Process Plantfor Aromatic ExtractionDocument81 pagesFinal GP2 Process Plantfor Aromatic ExtractionLuxainne Tremont EchegarayNo ratings yet

- Boiler CalcDocument92 pagesBoiler CalcPrasanta Kumar BeheraNo ratings yet

- Kristalizer (Cr-01)Document5 pagesKristalizer (Cr-01)Winda Nirmala DewiNo ratings yet

- Cantelever Retaining WallsDocument7 pagesCantelever Retaining WallsChristina Daoud BarmoNo ratings yet

- Appendix - Flash and Storage TK-101,102,103Document14 pagesAppendix - Flash and Storage TK-101,102,103Kudo ShinichiNo ratings yet

- Lampiran Perhitungan DesainDocument13 pagesLampiran Perhitungan DesainPuspita PuspitaNo ratings yet

- Calc WT - Lbm-Tanara - Z2Document6 pagesCalc WT - Lbm-Tanara - Z2bertaNo ratings yet

- Bracket Design For ReactorDocument32 pagesBracket Design For ReactorbrencejunNo ratings yet

- Calculation D44Document6 pagesCalculation D44hilal permanaNo ratings yet

- Boiler Stack Height Calculation From DLDocument2 pagesBoiler Stack Height Calculation From DLNasrul HazimNo ratings yet

- 11.3 KernDocument78 pages11.3 KernChou ChouNo ratings yet

- Monteron Jaji C4 5Document3 pagesMonteron Jaji C4 5John Lloyd TulopNo ratings yet

- Machine Design of Stepper MotorsDocument12 pagesMachine Design of Stepper Motorsabhrajit ghoshNo ratings yet

- Die CalculationsDocument13 pagesDie CalculationsDhinakaran R100% (1)

- HEATER (H-01) : LMTD (-T) - (T - T) LN - T - TDocument8 pagesHEATER (H-01) : LMTD (-T) - (T - T) LN - T - TJofanny Ferdian RahmansyahNo ratings yet

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (2)

- Chapter 6 eDocument22 pagesChapter 6 eVoora GowthamNo ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- 2.TankSurge Plate FOundationDocument2 pages2.TankSurge Plate FOundationdanjidNo ratings yet

- Acc FirdaDocument13 pagesAcc FirdaFierda Anjelina PaneNo ratings yet

- Chap 8. CondenserDocument9 pagesChap 8. CondenserAli Ahsan100% (1)

- RW Condenser V1.1Document9 pagesRW Condenser V1.1Steve WanNo ratings yet

- Chapter 8aDocument157 pagesChapter 8aSolehah OmarNo ratings yet

- Appendiks C Spesifikasi PeralatanDocument2 pagesAppendiks C Spesifikasi PeralatanridanormaNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- SBC CalculationDocument3 pagesSBC CalculationStandardtec EngineersNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Speaker 0Document12 pagesSpeaker 0alNo ratings yet

- Simple Amine System V1.0Document7 pagesSimple Amine System V1.0alNo ratings yet

- Neraca MassaDocument2 pagesNeraca MassaalNo ratings yet

- English Language Education Department: Application For Field Study in AustraliaDocument11 pagesEnglish Language Education Department: Application For Field Study in AustraliaalNo ratings yet

- Bulk Properties of MatterDocument11 pagesBulk Properties of Matterstock hackNo ratings yet

- Hydrogen Perspectives 21st Century Refineries Part2 PDFDocument5 pagesHydrogen Perspectives 21st Century Refineries Part2 PDFOmkarNo ratings yet

- Line Sizing InstructionsDocument2 pagesLine Sizing InstructionsjimualdoNo ratings yet

- 9th Stucture of Atom Test Paper-2Document2 pages9th Stucture of Atom Test Paper-2Sabu VincentNo ratings yet

- Na PerDocument39 pagesNa PerHarsh TyagiNo ratings yet

- G9 - Q4 Long Test - 2022 2023Document5 pagesG9 - Q4 Long Test - 2022 2023Jarnel CabalsaNo ratings yet

- Nptel: Chemical Process Industries - Web CourseDocument2 pagesNptel: Chemical Process Industries - Web Coursejeas grejoy andrewsNo ratings yet

- Letter of MotivationDocument2 pagesLetter of MotivationSajib Chandra RoyNo ratings yet

- Lecture 1Document15 pagesLecture 1Kourosh AdlparvarNo ratings yet

- Metal Matrix CompositesDocument3 pagesMetal Matrix CompositesgrimfiendNo ratings yet

- Ground Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per EachDocument1 pageGround Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per Eachmhmedgomaa74No ratings yet

- 7 1. Vapor Liquid EquilibriumDocument9 pages7 1. Vapor Liquid Equilibriumwaseemkhan49No ratings yet

- Ponce, Angelica Christine P. Biochemistry/ N1A 2O2O21OO285 11/16/2O2ODocument5 pagesPonce, Angelica Christine P. Biochemistry/ N1A 2O2O21OO285 11/16/2O2OfallenNo ratings yet

- PH Eur - Botulinum Toxin Type A For Injection 2113eDocument3 pagesPH Eur - Botulinum Toxin Type A For Injection 2113eErna Von Der WaldeNo ratings yet

- Hastelloy B2 Welding Rod, Hastelloy Alloy B2 UNS N10665 Welding Rod Manufacturer in IndiaDocument3 pagesHastelloy B2 Welding Rod, Hastelloy Alloy B2 UNS N10665 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNo ratings yet

- 0620 w12 Ms 32 PDFDocument6 pages0620 w12 Ms 32 PDFafriliawsNo ratings yet

- ENERPEEL MA - Rev - 0 - 2011Document21 pagesENERPEEL MA - Rev - 0 - 2011CHONG WEI SHENGNo ratings yet

- Chennuri Et Al. 2020 PDFDocument9 pagesChennuri Et Al. 2020 PDFkrtheekNo ratings yet

- Influence of Post-Heat Treatment On Microstructure, Mechanical, and Wear Properties of Maraging Steel Fabricated Using Direct Metal Laser Sintering TechniqueDocument17 pagesInfluence of Post-Heat Treatment On Microstructure, Mechanical, and Wear Properties of Maraging Steel Fabricated Using Direct Metal Laser Sintering TechniqueANIGANI SUDARSHAN REDDYNo ratings yet

- Question Report 398Document64 pagesQuestion Report 398iamrakeshmahto2005No ratings yet

- Testing For Macromolecules in FoodDocument7 pagesTesting For Macromolecules in FoodTue-sy PhamNo ratings yet

- Fiitjee: Internal TestDocument15 pagesFiitjee: Internal TestPRAKHAR GUPTANo ratings yet

- Chemistry - Long Term - Academic CALENDER (2022 & 23) : Velammal Bodhi Campus, PonneriDocument14 pagesChemistry - Long Term - Academic CALENDER (2022 & 23) : Velammal Bodhi Campus, PonneriSPS BALAADITHYA P G12No ratings yet

- Phy 103, Physics-IDocument2 pagesPhy 103, Physics-ISüleymanNo ratings yet

- VL2023240107488 DaDocument5 pagesVL2023240107488 Dapranavdeshpande2499No ratings yet

- Ramie-Degumming Methodologies A Short ReviewDocument7 pagesRamie-Degumming Methodologies A Short ReviewPrabhu TexcomsNo ratings yet

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Uploaded by

alOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C., Baile and Friend

Uploaded by

alCopyright:

Available Formats

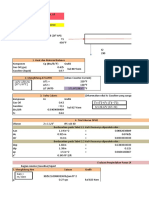

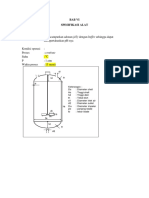

REAKTOR (R-01)

I. Fungsi : Tempat terjadikan reaksi hidrodealkilasi pembentukan benzen

Laju alir massa : 31137.238 kg/jam 𝑗𝑢𝑚𝑙𝑎ℎ 𝑡𝑢𝑏𝑒 (𝑁

Q pendingin :

Tekanan : 25 atm

Temperatur : 600 °C

(Analysis, Synthesis and Design of Chemical Processes by Richard T., Richard C.,

Baile and Friend)

𝜌�=(𝐵𝑀� 𝑥 𝑃)/(𝑅 𝑥

Densitas Campuran : 𝜌𝑐𝑎𝑚𝑝𝑢𝑟𝑎�=ρi .Xi 𝑇)

P = 25 atm

T = 873 K

R = 0.0821 L.atm/mol.K

Komponen ni fraksi mol i BM ρi ρcamp.

(Berdasarkan laju alir masuk (i) (mol/jam) (Xi) (g/mol) (gr/dm3) (gr/dm3)

Reaktor) Benzena 718.8 0.0003873128 78 27.207 0.01053754

Toluena 304096.8 0.1638572389 92 32.09 5.25818749

Hidrogen 1550893.6 0.8356718754 2 0.6976 0.58297293

Metana 155.1 8.35729207E-05 16 5.5809 0.00046641

Total 1855864.3 1 5.85216437

Densitas Campuran : 5.85216437 gr/dm3 𝜌=𝑚/� �=𝑚/ρ

Volumetrik Rate (V) : 5320636.27 dm3/jam

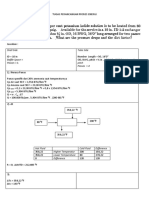

II. Spesifikasi Katalis

Jenis Katalis : Chromia Alumina (Al2O3-Cr2O3)

Diameter Katalis : 3.1 mm

Panjang : 3 mm (US Patent 378388)

GHSV : 815 /jam

Bentuk : Pellet

Porositas : 0.8

III. Volume Katalis

𝐺𝐻𝑆�= (�𝑜𝑙𝑢𝑚𝑒𝑡𝑟�𝑘 𝑟𝑎𝑡𝑒 𝑔𝑎𝑠)/(�𝑜𝑙𝑢𝑚𝑒 𝑘𝑎𝑡𝑎𝑙�𝑠 (𝑣𝑜𝑙𝑢𝑚𝑒�𝑜𝑙𝑢𝑚𝑒

𝑟𝑒𝑎𝑘𝑡𝑜𝑟))

𝐾𝑎𝑡𝑎𝑙�𝑠= (�𝑜𝑙𝑢𝑚𝑒𝑡𝑟�𝑘 𝑟𝑎𝑡𝑒 𝑔𝑎𝑠)/𝐺𝐻𝑆�

Volumetrik rate gas = 5320636.27 dm3/jam

GHSV = 815 /jam

Volume katalis = 6528.38806 dm3

Faktor keamanan 20% = 7834.06567 dm3

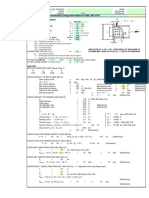

REAKTOR (R-01)

P design = 30.017252059 atm 441.430177

r tube = Tube OD(in)/2 = 0.375 in

f = 8500 psia = 578 1 psia = 0,068 atm

effisiensi = 0.8 atm

penyambungan

C (faktor = 0,0125 in/tahun= 0.125 in

korosi)

𝑡𝑒𝑏𝑎𝑙 𝑡𝑢𝑏𝑒=(𝑃𝑑𝑒𝑠�𝑔� 𝑥 (𝑟 𝑡𝑢𝑏𝑒 (𝑂�)))/(𝑓 𝑥 𝑒 − (0,6𝑃𝑑𝑒𝑠�𝑔�))+�

tebal tube = 0.1503301794 in

= 0.1875 in (mengikuti standar tabel 5.6 brownell young)

ID tube = OD - 2 (tebal tube) = 0.375 in

ID tube = 0,375 in

V. Diameter Shell

ID shel= 39 in = 0.9906 m

VI. Tebal Shell

tebal shell = 1.44216933 in

= 1.5 in (mengikuti standar tabel 5.6

brownell young)

OD shell = ID shell + 2 (tebal shell)

= 39 + 3

OD shell = 42 in

VII. Tebal Head

Tebal Head = (Pdesign x radius of crown x W)/((2 x f x e)-(0,2 x P design))

r = 42

icr = 3.75 3 3/4 (Tabel 5.7 Brownell young)

W = 1/4 x ((3+(r/icr))^0,5) Torispherical head (Flanged and dishead head)

= 0.94207218

f = 578 atm

e = 0.8

P desig= 25.0143767 atm

Tebal Head = 1.07604667 in

Tebal Head standar = 1.125 in (Tabel 5.6 Brownell Young)

1 1/8

REAKTOR (R-01)

VIII. Tinggi head dan volume head

Thickness (in) = 1,125 in

Sf dipilih = 1.5 1 1/2 in

icr = 2.375 3 3/8 in

r = 42 in

Dengan demikian direncanakan reaktor fixed bed dengan spesifikasi :

Shell :

ID = 39 in = 0.9906 m

OD = 42 in = 1.0668 m

Tebal shell = 1.5 in = 0.0381 m

Tube :

ID = 0,375 in = 0.009525 m

OD = 0,75 in = 0.01905 m

Jumlah tube dengan 2-P = 1330 tube

Pitch = 15/16 in triangular pitch = 0.0238125 m

Panjang tube = 1000 in = 25.4 m

Tebal tube = 0.1875 in = 0.0047625 m

Tebal head = 1.125 in = 0.028575 m

Tinggi head = 8.8916122513 in = 0.2258469512 m

Volume head = 0.0001477538 m3 = 0.0001477538 m3

Tinggi reaktor= 25.851693902 m = 25.8516939024 m

Volume total = 0.0128087648 m3 = 0.0128087648 m3

reaktor

Bahan yang digunakan adalah stainless steel SA-167 grade 11 tipe 316

Bentuk head Torispherical head (Flanged and dishead head)

REAKTOR (R-01)

III. Jumlah Tube (Nt) 1 in = 0,0254 m

𝑗𝑢𝑚𝑙𝑎ℎ 𝑡𝑢𝑏𝑒 (𝑁𝑡)= (�𝑜𝑙𝑢𝑚𝑒 𝑘𝑎𝑡𝑎𝑙�𝑠)/((1−𝑋)𝑥(0,25� 〖��〗 ^2 𝐿)) 1 ft = 0,305 m

Spesifikasi tube : (Tabel 10. Kern)

(pendekatan) OD (in) = 1.5

BWG = 18

ID (in) = 1.4 0.03556 m

Flow area = 1.54

per tube

(in2)

Surface = 0.3925

per lin

(ft2/ft)

Volume Katalis = 6528.388 dm3 = 6.528388 m3

X = 0.8

ID = 0.03556 m

L (panjang tube) = 1000 in = 25.4 m

Nt = 1294.64

Nt = 1330 (mengikuti standar Tabel 9. Kern)

Shell ID (in) = 39

2-P = 1330 tube

Tube OD (in) = 0.75 (3/4) (Tabel 9 Kern)

15/16 in Triangular pitch

L (in) = 1000

Laju alir umpan dalam tube = Feed masuk / jumlah tube

= 4000.478 dm3/jam

IV. Tebal Tube

𝑡𝑒𝑏𝑎𝑙 𝑡𝑢𝑏𝑒=(𝑃𝑑𝑒𝑠�𝑔� 𝑥 (𝑟 𝑡𝑢𝑏𝑒))/(𝑓 𝑥 𝑒 − (0,6𝑃𝑑𝑒𝑠�𝑔�))+�

P design = P operasi + P hidrostatik psi

P operasi = 25 atm

P hidrostat= ρ.g.tinggi cairan tinggi cair = 1000 in

= 1456720.755 gr/m.s2 = 25.4 m

= 1456.720755 kg/m.s2 ρcampuran= 5.852164 gr/dm3

= 1456.720755 Pa = 5852.164 gr/m3

= 0.014376716 atm g = 9.8 m/s

P design = 25.01437672 atm 1 atm = 101325 Pa

Faktor = 30.01725206 atm

Keamanan

20%

REAKTOR (R-01)

Bahan yang digunakan adalah stainless steel SA-167 grade 11 tipe 316

Allowable stress (f) = 8500 psia 1112 F 600 °C

(item 4, allowable stress p.342)

Dari Figure 5.8 Process Equipment Design by Brownell and Young

a = ID/2 = 19.5 in

AB = a-icr = 17.125 in

BC = r-icr = 39.625 in

AC = (BC2-AB2)^0,5 = 35.73339 in

b = r-AC = 6.266612 in

OA = Tinggi hea= th + b + Sf

= 1.125 + 6.266612 + 1.5

Tinggi hea= 8.891612 in

Tinggi hea= 0.225847 m

1 in = 0,0254 m

Volume head = 2 x 0,000076 x ID3 1 ft = 0,305 m

= 0.000147754 m3

IX. Tinggi reaktor dan volume reaktor

- Tinggi reaktor = Tinggi shell+ 2xTinggi Head

= 25.4 + 0.451694

Tinggi reaktor = 25.85169 m

- Volume total reaktor

x P design)) Vt = Vsilinder + Vhead + 2Vsf

V silinder = 1/4 x π x IDshell2 x L

= 0.012623142 m3

V head = 0.000147754 m3

Vsf = 1/4 x π x IDshell2 x sf

= 1.89347E-05 m3

2Vsf = 3.78694E-05 m3

Vt = 0.012808765 m3

You might also like

- 5 4 Gizmo Energy ConversionsDocument5 pages5 4 Gizmo Energy Conversionsapi-27357852653% (174)

- Big Science Competition Year 8 2020Document21 pagesBig Science Competition Year 8 2020PepsicleNo ratings yet

- ScantlingDocument39 pagesScantlingSky R100% (1)

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Asupu Nano BubblesDocument10 pagesAsupu Nano BubblesAgung50% (2)

- Saturation Lab ReportDocument4 pagesSaturation Lab ReportYas Tairab0% (1)

- Perancangan Alat CekDocument19 pagesPerancangan Alat CekLilyNo ratings yet

- JAWAD Khalid (41) & SHEHROZE Malik (36) FYP-1Document21 pagesJAWAD Khalid (41) & SHEHROZE Malik (36) FYP-1jawad khalidNo ratings yet

- Submarine ReportDocument10 pagesSubmarine ReportShahzeb Bin TariqNo ratings yet

- Problem 1 Dphe Kusnaryo Hal 19 NFDDocument7 pagesProblem 1 Dphe Kusnaryo Hal 19 NFDLDK UISINo ratings yet

- API 650 Calculation ThicknessDocument20 pagesAPI 650 Calculation ThicknessHsein WangNo ratings yet

- TubesheetDocument8 pagesTubesheetVaibhavNo ratings yet

- Line Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Document12 pagesLine Sizing of The Main Production Header (A Gas / Liquid Two Phase Line)Engr TheyjiNo ratings yet

- Heat Balannce:: Fluid AllocationDocument16 pagesHeat Balannce:: Fluid AllocationUsama AkramNo ratings yet

- Mixer - 01: A. Menentukan Volum Tangki (V)Document13 pagesMixer - 01: A. Menentukan Volum Tangki (V)kurniawanNo ratings yet

- Vessel Heat LossDocument2 pagesVessel Heat LossakisdassasNo ratings yet

- Pompa Util SulsulDocument90 pagesPompa Util SulsulMaRhaenia TheresaNo ratings yet

- Reactor 20Document1 pageReactor 20Kriengsak RuangdechNo ratings yet

- Example 3Document2 pagesExample 3RindangNo ratings yet

- 100-E4 (Reduced Crude/Vacuum Bottoms Heat Exchanger 4 Design)Document10 pages100-E4 (Reduced Crude/Vacuum Bottoms Heat Exchanger 4 Design)MuhammadTanzeeLUsmanNo ratings yet

- 11.mixing TankDocument16 pages11.mixing TankZaidatu ImtinanNo ratings yet

- External Forced Convection: Pipe 90 °CDocument16 pagesExternal Forced Convection: Pipe 90 °CiosuarizNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)Document64 pagesBeam Connection of Conventional Configuration Based On AISC Manual 13th Edition (AISC 360-05)christian abogadoNo ratings yet

- Line Sizing Calculation 1Document9 pagesLine Sizing Calculation 1SAMUEL UDOHNo ratings yet

- Inner Vessel Check Shell Thickness For Internal PressureDocument6 pagesInner Vessel Check Shell Thickness For Internal PressureSAMER OSMANNo ratings yet

- Calculation For Steel Lift Pit at Concourse LevelDocument5 pagesCalculation For Steel Lift Pit at Concourse LevelSUBIR KARMAKARNo ratings yet

- Perhitungan Tugas 1 Perancangan HEDocument3 pagesPerhitungan Tugas 1 Perancangan HELuthfanNo ratings yet

- Bolt Connection Design Based On NDS 2018: Input Data & Design SummaryDocument2 pagesBolt Connection Design Based On NDS 2018: Input Data & Design Summaryalejahrojas96No ratings yet

- Div 2 THK CalcDocument10 pagesDiv 2 THK CalcelleNo ratings yet

- Beam Connection of Conventional Configuration Based On AISC 360-10/16Document1 pageBeam Connection of Conventional Configuration Based On AISC 360-10/16Karen Esther Acuña VelasquezNo ratings yet

- 5.3 Design of Waste Heat Boiler: (13) : DataDocument7 pages5.3 Design of Waste Heat Boiler: (13) : Datamoni beeNo ratings yet

- Tangki BufferDocument6 pagesTangki BufferdwirustantoNo ratings yet

- Final GP2 Process Plantfor Aromatic ExtractionDocument81 pagesFinal GP2 Process Plantfor Aromatic ExtractionLuxainne Tremont EchegarayNo ratings yet

- Boiler CalcDocument92 pagesBoiler CalcPrasanta Kumar BeheraNo ratings yet

- Kristalizer (Cr-01)Document5 pagesKristalizer (Cr-01)Winda Nirmala DewiNo ratings yet

- Cantelever Retaining WallsDocument7 pagesCantelever Retaining WallsChristina Daoud BarmoNo ratings yet

- Appendix - Flash and Storage TK-101,102,103Document14 pagesAppendix - Flash and Storage TK-101,102,103Kudo ShinichiNo ratings yet

- Lampiran Perhitungan DesainDocument13 pagesLampiran Perhitungan DesainPuspita PuspitaNo ratings yet

- Calc WT - Lbm-Tanara - Z2Document6 pagesCalc WT - Lbm-Tanara - Z2bertaNo ratings yet

- Bracket Design For ReactorDocument32 pagesBracket Design For ReactorbrencejunNo ratings yet

- Calculation D44Document6 pagesCalculation D44hilal permanaNo ratings yet

- Boiler Stack Height Calculation From DLDocument2 pagesBoiler Stack Height Calculation From DLNasrul HazimNo ratings yet

- 11.3 KernDocument78 pages11.3 KernChou ChouNo ratings yet

- Monteron Jaji C4 5Document3 pagesMonteron Jaji C4 5John Lloyd TulopNo ratings yet

- Machine Design of Stepper MotorsDocument12 pagesMachine Design of Stepper Motorsabhrajit ghoshNo ratings yet

- Die CalculationsDocument13 pagesDie CalculationsDhinakaran R100% (1)

- HEATER (H-01) : LMTD (-T) - (T - T) LN - T - TDocument8 pagesHEATER (H-01) : LMTD (-T) - (T - T) LN - T - TJofanny Ferdian RahmansyahNo ratings yet

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 pagesMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiNo ratings yet

- Project 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataDocument13 pagesProject 90 TPH Fluidized Bed Combustion Boiler: Ibr Calculations For Steam Drum Design DataP s Jagatheesan100% (2)

- Chapter 6 eDocument22 pagesChapter 6 eVoora GowthamNo ratings yet

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoNo ratings yet

- 2.TankSurge Plate FOundationDocument2 pages2.TankSurge Plate FOundationdanjidNo ratings yet

- Acc FirdaDocument13 pagesAcc FirdaFierda Anjelina PaneNo ratings yet

- Chap 8. CondenserDocument9 pagesChap 8. CondenserAli Ahsan100% (1)

- RW Condenser V1.1Document9 pagesRW Condenser V1.1Steve WanNo ratings yet

- Chapter 8aDocument157 pagesChapter 8aSolehah OmarNo ratings yet

- Appendiks C Spesifikasi PeralatanDocument2 pagesAppendiks C Spesifikasi PeralatanridanormaNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- SBC CalculationDocument3 pagesSBC CalculationStandardtec EngineersNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Speaker 0Document12 pagesSpeaker 0alNo ratings yet

- Simple Amine System V1.0Document7 pagesSimple Amine System V1.0alNo ratings yet

- Neraca MassaDocument2 pagesNeraca MassaalNo ratings yet

- English Language Education Department: Application For Field Study in AustraliaDocument11 pagesEnglish Language Education Department: Application For Field Study in AustraliaalNo ratings yet

- Bulk Properties of MatterDocument11 pagesBulk Properties of Matterstock hackNo ratings yet

- Hydrogen Perspectives 21st Century Refineries Part2 PDFDocument5 pagesHydrogen Perspectives 21st Century Refineries Part2 PDFOmkarNo ratings yet

- Line Sizing InstructionsDocument2 pagesLine Sizing InstructionsjimualdoNo ratings yet

- 9th Stucture of Atom Test Paper-2Document2 pages9th Stucture of Atom Test Paper-2Sabu VincentNo ratings yet

- Na PerDocument39 pagesNa PerHarsh TyagiNo ratings yet

- G9 - Q4 Long Test - 2022 2023Document5 pagesG9 - Q4 Long Test - 2022 2023Jarnel CabalsaNo ratings yet

- Nptel: Chemical Process Industries - Web CourseDocument2 pagesNptel: Chemical Process Industries - Web Coursejeas grejoy andrewsNo ratings yet

- Letter of MotivationDocument2 pagesLetter of MotivationSajib Chandra RoyNo ratings yet

- Lecture 1Document15 pagesLecture 1Kourosh AdlparvarNo ratings yet

- Metal Matrix CompositesDocument3 pagesMetal Matrix CompositesgrimfiendNo ratings yet

- Ground Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per EachDocument1 pageGround Floor Plan: Existing Fcu-01 1-SCD 600X600 MM, NECK 150X150 MM 30 L/S Per Eachmhmedgomaa74No ratings yet

- 7 1. Vapor Liquid EquilibriumDocument9 pages7 1. Vapor Liquid Equilibriumwaseemkhan49No ratings yet

- Ponce, Angelica Christine P. Biochemistry/ N1A 2O2O21OO285 11/16/2O2ODocument5 pagesPonce, Angelica Christine P. Biochemistry/ N1A 2O2O21OO285 11/16/2O2OfallenNo ratings yet

- PH Eur - Botulinum Toxin Type A For Injection 2113eDocument3 pagesPH Eur - Botulinum Toxin Type A For Injection 2113eErna Von Der WaldeNo ratings yet

- Hastelloy B2 Welding Rod, Hastelloy Alloy B2 UNS N10665 Welding Rod Manufacturer in IndiaDocument3 pagesHastelloy B2 Welding Rod, Hastelloy Alloy B2 UNS N10665 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNo ratings yet

- 0620 w12 Ms 32 PDFDocument6 pages0620 w12 Ms 32 PDFafriliawsNo ratings yet

- ENERPEEL MA - Rev - 0 - 2011Document21 pagesENERPEEL MA - Rev - 0 - 2011CHONG WEI SHENGNo ratings yet

- Chennuri Et Al. 2020 PDFDocument9 pagesChennuri Et Al. 2020 PDFkrtheekNo ratings yet

- Influence of Post-Heat Treatment On Microstructure, Mechanical, and Wear Properties of Maraging Steel Fabricated Using Direct Metal Laser Sintering TechniqueDocument17 pagesInfluence of Post-Heat Treatment On Microstructure, Mechanical, and Wear Properties of Maraging Steel Fabricated Using Direct Metal Laser Sintering TechniqueANIGANI SUDARSHAN REDDYNo ratings yet

- Question Report 398Document64 pagesQuestion Report 398iamrakeshmahto2005No ratings yet

- Testing For Macromolecules in FoodDocument7 pagesTesting For Macromolecules in FoodTue-sy PhamNo ratings yet

- Fiitjee: Internal TestDocument15 pagesFiitjee: Internal TestPRAKHAR GUPTANo ratings yet

- Chemistry - Long Term - Academic CALENDER (2022 & 23) : Velammal Bodhi Campus, PonneriDocument14 pagesChemistry - Long Term - Academic CALENDER (2022 & 23) : Velammal Bodhi Campus, PonneriSPS BALAADITHYA P G12No ratings yet

- Phy 103, Physics-IDocument2 pagesPhy 103, Physics-ISüleymanNo ratings yet

- VL2023240107488 DaDocument5 pagesVL2023240107488 Dapranavdeshpande2499No ratings yet

- Ramie-Degumming Methodologies A Short ReviewDocument7 pagesRamie-Degumming Methodologies A Short ReviewPrabhu TexcomsNo ratings yet