Professional Documents

Culture Documents

Assignment 1 (Ship Resistance)

Assignment 1 (Ship Resistance)

Uploaded by

KikiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assignment 1 (Ship Resistance)

Assignment 1 (Ship Resistance)

Uploaded by

KikiCopyright:

Available Formats

INTRODUCTION

The ship’s hull is a streamlined body designed to create favourable pressure gradients so that

it encounters minimum resistance to forward motion. However, we have to impose on the hull

surface certain add-on so as to improve the controllability and maneuverability, sea-keeping,

strength and structural aspects or to fulfil operational requirements. These attachments which

alter the flow around the hull are called ship hull appendages. Appendage resistance is frictional

resistance caused by the underwater appendages, like rudders, shaft brackets, struts, stabilisers

and bilge keels. Appendages can be designed to improve resistance and propulsion

characteristics.

Typical appendages found on ships include rudders, stabilisers, bossings, shaft brackets, bilge

keels and water inlet scoops and all these items give rise to additional resistance. The main

appendages on a single – screw ship are the rudder and bilge keels, with a total appendage drag

of about 2% - 5%. On twin – screw vessels, the main appendages are the twin rudders, twin

shafting and shaft brackets, or bossings, and bilge keels. These may amount to as much as 8%

- 25% depending on ship size.

The net effect of appendages is thought to bring about the following changes.

Increase in frictional resistance.

Alteration of flow around the hull.

Alteration of ship motions.

Induced vibration or cavitation.

Bilge Keel Ship Rudders

You might also like

- A - Level Project Work Insights & ReflectionsDocument3 pagesA - Level Project Work Insights & ReflectionsKou Uraki0% (1)

- Simulation of Flow Around KCS HullDocument11 pagesSimulation of Flow Around KCS HullMilovan PericNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Woytowich R.calculation of Prope - dec.1979.JSRDocument7 pagesWoytowich R.calculation of Prope - dec.1979.JSRJohn KokarakisNo ratings yet

- Shallow Water Resistance Charts For Preliminary Vessel DesignDocument18 pagesShallow Water Resistance Charts For Preliminary Vessel DesignshahjadaNo ratings yet

- Ship Motions in WavesDocument8 pagesShip Motions in WavesAnonymous e3ceN15No ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- Scotvec (Stabiltiy) Theory: Table of ContentsDocument25 pagesScotvec (Stabiltiy) Theory: Table of ContentsMohan KrishnanNo ratings yet

- Classification Society - WikipediaDocument6 pagesClassification Society - WikipediaFlavio MoraesNo ratings yet

- STA Article 30jan2013 PDFDocument11 pagesSTA Article 30jan2013 PDFpriyoNo ratings yet

- ENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Document5 pagesENGR 4011 Resistance & Propulsion of Ships Assignment 3: 2018Luis De GraciaNo ratings yet

- The Dynamics of Mooring Systems PDFDocument141 pagesThe Dynamics of Mooring Systems PDFMirsoNo ratings yet

- Introduction To TSSDocument11 pagesIntroduction To TSSnoczviviNo ratings yet

- Resistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) WhereDocument11 pagesResistance (MA R) 1: The Power Necessary To Overcome This Resistance Is Called The) Wheresupriadi90315No ratings yet

- Sustainable Marine Structures - Volume 05 - Issue 01 - March 2023Document52 pagesSustainable Marine Structures - Volume 05 - Issue 01 - March 2023Bilingual PublishingNo ratings yet

- Ittc - 7.5-02-02-01Document13 pagesIttc - 7.5-02-02-01Jose AntonioNo ratings yet

- Analysis of Ship MotionsDocument89 pagesAnalysis of Ship MotionsPrashant RajoraNo ratings yet

- FPSO Swivel Load MonitoringDocument1 pageFPSO Swivel Load MonitoringKim OanhNo ratings yet

- Numerical Simulation of Ship Motion Due To Waves and ManoeuvringDocument48 pagesNumerical Simulation of Ship Motion Due To Waves and ManoeuvringHung NguyenNo ratings yet

- PHD Wicaksono 2019 PDFDocument145 pagesPHD Wicaksono 2019 PDFEric KulbiejNo ratings yet

- Lecture 04Document26 pagesLecture 04Junaid JavaidNo ratings yet

- Variation - Swing MethodDocument5 pagesVariation - Swing MethodDuy Ngô0% (1)

- Predicting The Slamming Force On The HullDocument52 pagesPredicting The Slamming Force On The HullEgwuatu UchennaNo ratings yet

- Ultramarine Moses CrackDocument3 pagesUltramarine Moses CrackpothirajkalyanNo ratings yet

- Estimation of Shipmotions Using Closed-Form Expressions: Jørgen Juncher Jensen, Alaa E. Mansour, Anders SmærupolsenDocument25 pagesEstimation of Shipmotions Using Closed-Form Expressions: Jørgen Juncher Jensen, Alaa E. Mansour, Anders SmærupolsenyapsguanNo ratings yet

- Stability of CatamaransDocument8 pagesStability of CatamaransVinayak29No ratings yet

- The Technical University of Norway: Norwegian Ship Model Experiment TankDocument56 pagesThe Technical University of Norway: Norwegian Ship Model Experiment TankDeepak PooranachandranNo ratings yet

- Marine 2017 18 - Propeller Nozzles DesignDocument13 pagesMarine 2017 18 - Propeller Nozzles DesignMaciej ReichelNo ratings yet

- A General Discussion On Ship StabilityDocument6 pagesA General Discussion On Ship StabilityAnonymous UCveMQNo ratings yet

- Abyc H4Document12 pagesAbyc H4NavalcatNo ratings yet

- ENGR 4011 Resistance & Propulsion of Ships Assignment 1: 2017Document1 pageENGR 4011 Resistance & Propulsion of Ships Assignment 1: 2017Bagas Somporn Supriadi PutraNo ratings yet

- PraveenDocument64 pagesPraveeng k azadNo ratings yet

- CODAC Final ReportDocument98 pagesCODAC Final ReportChristopher GarciaNo ratings yet

- (Mooring) : 1. GeneralDocument18 pages(Mooring) : 1. GeneralSushanta Kumar RoyNo ratings yet

- My Notes On Savitsky Method PDFDocument25 pagesMy Notes On Savitsky Method PDFy_596688032No ratings yet

- Visualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelDocument13 pagesVisualization of The Bubble Sweep-Down Phenomenon Around The Bow of A Ship ModelAnthonyNo ratings yet

- Seakeeping 19301en2 PDFDocument2 pagesSeakeeping 19301en2 PDFTullio OpattiNo ratings yet

- T2381602 - LTR - Lightweight Calculation - 137656518Document2 pagesT2381602 - LTR - Lightweight Calculation - 137656518vishnu thulasidasNo ratings yet

- Analysis of Ship Hull Girder VibrationDocument10 pagesAnalysis of Ship Hull Girder VibrationLucas Barrozo BrunNo ratings yet

- 2 Displ TPC & Coef of Forms 2Document20 pages2 Displ TPC & Coef of Forms 2Aamir SirohiNo ratings yet

- Simplified Fatigue Analysis of Structural Details of An Ageing LPG CarrierDocument11 pagesSimplified Fatigue Analysis of Structural Details of An Ageing LPG CarrierflcwkNo ratings yet

- 10 Propeller Ship InteractionDocument19 pages10 Propeller Ship InteractionAbdelrahman Atef ElbashNo ratings yet

- Double Hull Tank BargesDocument10 pagesDouble Hull Tank BargesNithin KannanNo ratings yet

- Exercicio KT-J2 MICHIGAN 2016 PDFDocument4 pagesExercicio KT-J2 MICHIGAN 2016 PDFLucas VieiraNo ratings yet

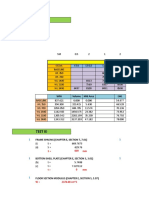

- Test Ii: WPA Volume Mid Area LWLDocument9 pagesTest Ii: WPA Volume Mid Area LWLMark Lester AndayaNo ratings yet

- Anchor Chain Locker Volume CalculationDocument1 pageAnchor Chain Locker Volume Calculationbasant_konatNo ratings yet

- Damaged StabilityDocument4 pagesDamaged StabilityUjjwal VermaNo ratings yet

- CFD and CAD in Ship DesignDocument57 pagesCFD and CAD in Ship DesignslamienkaNo ratings yet

- Xiaobo Chen. Offshore Hydrodynamics and ApplicationsDocument19 pagesXiaobo Chen. Offshore Hydrodynamics and ApplicationsYuriy KrayniyNo ratings yet

- 02.06 Chapter 6 - Ship StructuresDocument25 pages02.06 Chapter 6 - Ship StructuresMogie TalampasNo ratings yet

- Maxsurf ManualDocument239 pagesMaxsurf ManualRenato Nicoli MendesNo ratings yet

- Lecture 05Document35 pagesLecture 05Junaid JavaidNo ratings yet

- Resistance PDFDocument96 pagesResistance PDFPutra AdamNo ratings yet

- Compass and Gyroscope: Integrating Science And Politics For The EnvironmentFrom EverandCompass and Gyroscope: Integrating Science And Politics For The EnvironmentNo ratings yet

- Harvesting Freedom: The Life of a Migrant Worker in CanadaFrom EverandHarvesting Freedom: The Life of a Migrant Worker in CanadaNo ratings yet

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDocument3 pagesExploded View & Parts Listing Air Operated Double Diaphragm PumpEdgar NercarNo ratings yet

- Camarines Norte - AlbayaldeDocument56 pagesCamarines Norte - AlbayaldeJChris EsguerraNo ratings yet

- Pipe System Friction Loss CalculationDocument4 pagesPipe System Friction Loss Calculationtorbenchr100% (1)

- 1 Case IDC PDFDocument7 pages1 Case IDC PDFPilar Dueñas Maldonado0% (1)

- Normal Lab ValuesDocument4 pagesNormal Lab Valuesrmelendez001No ratings yet

- Microbiology 101: Laboratory Exercise #22: Carbohydrate MetabolismDocument16 pagesMicrobiology 101: Laboratory Exercise #22: Carbohydrate Metabolismmaraki998No ratings yet

- Board Question Paper - March 2023 - For Reprint Update - 641b040f4992cDocument4 pagesBoard Question Paper - March 2023 - For Reprint Update - 641b040f4992cSushan BhagatNo ratings yet

- Guide To Laboratory Establishment For Plant Nutrient AnalysisDocument1 pageGuide To Laboratory Establishment For Plant Nutrient AnalysisOsama MadanatNo ratings yet

- Hospital Management System: Dept. of CSE, GECRDocument30 pagesHospital Management System: Dept. of CSE, GECRYounus KhanNo ratings yet

- CM07 Sphere ConstructionDocument146 pagesCM07 Sphere ConstructionHuy Thieu Bui100% (1)

- ME Lab 2 LectureDocument5 pagesME Lab 2 LectureIan Paul TongolNo ratings yet

- Physiology of Lymph SystemDocument7 pagesPhysiology of Lymph SystemMwangi NyawiraNo ratings yet

- 555-Timer AStable and MonostableDocument13 pages555-Timer AStable and MonostableenzuekNo ratings yet

- Lyric - Grey HuffingtonDocument371 pagesLyric - Grey HuffingtonCaptain AtomNo ratings yet

- Anthe Junior Sample Paper Class IXDocument14 pagesAnthe Junior Sample Paper Class IXMota Chashma85% (62)

- ..Document11 pages..Rizka Nur FadhilahNo ratings yet

- Is Your Body Infested With Self-Replicating Nano-FibersDocument4 pagesIs Your Body Infested With Self-Replicating Nano-Fibersthisdraft100% (3)

- Thesis Van Ende FinalDocument277 pagesThesis Van Ende FinalArtem KravchenkoNo ratings yet

- Drug Ana Surgery WardDocument11 pagesDrug Ana Surgery WardJames QuilingNo ratings yet

- The Development of A Heat Wave Vulnerability Index For London-2013Document10 pagesThe Development of A Heat Wave Vulnerability Index For London-2013gilberto777No ratings yet

- An International Cohort Study of Cancer in Systemic Lupus ErythematosusDocument10 pagesAn International Cohort Study of Cancer in Systemic Lupus ErythematosusCristina TudorNo ratings yet

- Carbon & Its CompoundDocument13 pagesCarbon & Its CompoundNeeraj PoddarNo ratings yet

- Mbarang 10102022Document3 pagesMbarang 10102022zeta chenkNo ratings yet

- Basic Symbals P&ID PDFDocument736 pagesBasic Symbals P&ID PDFPavar RavitejaNo ratings yet

- Stilboestrol Tablets MSDSDocument6 pagesStilboestrol Tablets MSDSIsaac lauricNo ratings yet

- 7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFDocument56 pages7.44.session VI EHa and LTR Process Flow and Steam Gathering System v3 PDFadityaNo ratings yet

- Problem Sets For Solutions AnalysisDocument2 pagesProblem Sets For Solutions AnalysisKamil Guillergan100% (1)

- Compact Evaporators: New Buffalo Trident GaccDocument16 pagesCompact Evaporators: New Buffalo Trident GaccPreeti gulatiNo ratings yet

- Interactive Effect of Caste and Disability: An AnalysisDocument8 pagesInteractive Effect of Caste and Disability: An AnalysisIJELS Research JournalNo ratings yet