Professional Documents

Culture Documents

4.0 Processes Are Employed in The Treatment Plant and Detailed Description On The Size of The Treatment Units

4.0 Processes Are Employed in The Treatment Plant and Detailed Description On The Size of The Treatment Units

Uploaded by

Azizul HakimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.0 Processes Are Employed in The Treatment Plant and Detailed Description On The Size of The Treatment Units

4.0 Processes Are Employed in The Treatment Plant and Detailed Description On The Size of The Treatment Units

Uploaded by

Azizul HakimCopyright:

Available Formats

4.

0 Processes are employed in the treatment plant and detailed description on the size of

the treatment units

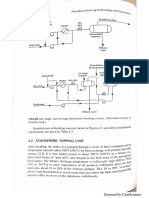

The existing Brockville WPCC is a primary plant. Unit treatment processes include duty/standby

mechanical screens, aerated grit removal channels, chemically assisted primary clarification and

disinfection using chlorination (CH2M HILL, 2008). Anaerobic digestion of primary sludge is carried

out, followed by sludge thickening with centrifuges for off-site use and/or disposal. Disinfection at

the existing plant is achieved by means of chlorination with sodium hypochlorite, using a concrete

contact chamber.

The proposed treatment processes for the Brockville WPCC and proposed design basis are outlined

in Table 4.1 and Process flow diagram in Appendix A.

Table 4.1: Treatment Processes and Design Parameters (CH2M HILL, 2008).

Treatment Unit Design basis

Screening Existing process sized based on peak flow up to

54,500 m3/d.

Grit Removal Existing process sized based on peak flow up to

54,500 m3/d.

Primary Clarification Existing process sized based on 21,800 m3/d

average day, peak flow up to 54,500 m3/d.

Aeration Sized to treat flow of 21,800 m3/d average day,

and 54,500 m3/d peak instantaneous.

Final Clarification Sized to treat flow of 21,800 m3/d average day,

and 54,500 m3/d peak instantaneous.

Disinfection UV Disinfection sized to treat flows up to

54,500 m3/d, duty/standby channels.

Digestion Existing digesters checked based on sludge

production from existing primary process and

new secondary process – new WAS thickening

to be added to economize on digester capacity

and allow for secondary sludge to be digested

without additional digester construction.

Dewatering Existing process reviewed for flows up to 132

m3/day or 2640 kg/d at 2% dry solids (projected

solids feed rate with secondary treatment).

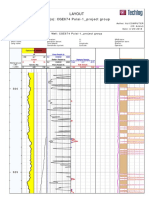

All proposed process equipment detail description in terms of number of units, basic unit sizing, tank

area and volume are outlined in Table 4.2. The proposed sizing is based on conceptual level process

modelling and calculations, and is approximately only (CH2M HILL, 2008).

Table 4.2: Summary of Process tankage and Equipment Sizing (CH2M HILL, 2008).

Treatment Unit Number of Unit and Basic Sizing

Screening

No. of Screens 2 (Duty/Standby mechanical)

No. of Screening Washer/Compactor 1

Grit Removal

No. of Grit Tanks 2 (Duty/Standby mechanical)

Volume of total tanks (m3) 103

Volume of per tanks (m3) 52

Dimension per tank

Length (m) 7.6

Width (m) 3.7

Depth (m) - Liquid 3.66

Primary Clarification

No. of tanks 4

Primary clarification area total tanks (m2) 1160

Primary clarification area per tank (m2) 290

Dimension per tank

Length (m) 29

Width (m) 8

Depth (m) 4

Aeration

No. of Aeration Tanks 3

Total Aeration Tank Volume (m3) 6600

Volume per Aeration Tank(m3) 2200

Dimension per tank

Length (m) 27

Width (m) 15

Depth (m) 5.5

Aeration Blowers 4 ( 3 Duty, 1 Standby)

75 kW (100 HP)

Process Air per tank 2178 m3/hr (average daily flow)

3267 m3/hr (peak flow)

Final Clarification

No. of final tanks 3

Final clarification area (m2) total tanks 1800

Final clarification area (m2) per tank 600

Dimension per tank

Length (m) 40

Width (m) 15

Depth (m) 5

Scum Pumps 3 (1 Duty per tank)

1.5 kW (2 HP)

Return and Waste Sludge Pumping

RAS Pumps 6 (1 Duty, 1 Standby per aeration tank)

RAS Pumping Rate 100% Avg. Day Flow returned to aeration tanks

11 kW (14 HP)

WAS Pumps 4 (1 Duty per tank, 1 Common standby)

WAS Pumping Rate 650 m3/d

3.7 kW (5 HP)

Biosolids Treatment

Type of Digesters Anearobic

No. of Digesters 2

Digester volume (m3) total tank 2180

Digester volume (m3) per tank 1060

WAS Holding Tank 120 m3

Digested Sludge Holding Tank 120 m3

Sludge Dewatering

Type of Equipment Centrifuge

No. of Units 2 (Duty/Standby)

Capacity (m3/d) per centrifuge 5103 kg/d at feed

Centrate Holding Tank 100 m3

APPENDIX A

You might also like

- Manual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components Systems PDFDocument30 pagesManual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components Systems PDFLuis Reinaldo Ramirez Contreras100% (2)

- STP Design 50KLDDocument3 pagesSTP Design 50KLDmurugaraj92% (13)

- STP Adequacy Report - To SubmitDocument7 pagesSTP Adequacy Report - To SubmitJagannathan SNo ratings yet

- Dual Media FilterDocument4 pagesDual Media FilterPandiaraj Mk100% (2)

- Wastewater QuestionDocument18 pagesWastewater Questionth3mannnNo ratings yet

- SAP2000 Base Isolation PDFDocument34 pagesSAP2000 Base Isolation PDFoscavier100% (2)

- Pool Balancing Tank Calculation: A) Bathing Load - Equation 1Document1 pagePool Balancing Tank Calculation: A) Bathing Load - Equation 1MohMohkNo ratings yet

- Fire Water & Foam Demand CalculationDocument1 pageFire Water & Foam Demand CalculationMohsin Shaikh100% (1)

- Calculation of Septic Tank & Sock PitDocument11 pagesCalculation of Septic Tank & Sock Pitakram1978No ratings yet

- Design Sheet STPDocument17 pagesDesign Sheet STPBhagyashree Rath0% (1)

- Fire Water ProtectionDocument68 pagesFire Water ProtectionZakyAlFatony100% (1)

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- 8MW Mytrah 01 MCS DES Module Cleaning System Design CalculationDocument5 pages8MW Mytrah 01 MCS DES Module Cleaning System Design CalculationAnonymous ciKyr0t100% (1)

- BRC Textbook List 2012mech PTDocument3 pagesBRC Textbook List 2012mech PTkothat82No ratings yet

- WTP Calc.Document23 pagesWTP Calc.abhishek5810No ratings yet

- Fire Water DemandDocument7 pagesFire Water DemandamolbagadeNo ratings yet

- Swimming-Pool-Sizing-1Document5 pagesSwimming-Pool-Sizing-1awaisatherNo ratings yet

- Saff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Document4 pagesSaff Reactor: Design Flow 600 Incoming BOD To SAFF 300 % BOD Removal 94Rakesh Verma100% (3)

- Metrología Semana 3Document5 pagesMetrología Semana 3jonathan arayaNo ratings yet

- FMR 1250Document7 pagesFMR 1250Shine Water ExpertsNo ratings yet

- Advanced Waste-Water Treatment: Indian Institute of Technology Jodhpur RajasthanDocument9 pagesAdvanced Waste-Water Treatment: Indian Institute of Technology Jodhpur RajasthanDeepak Manihar (M20CI002)No ratings yet

- CalculosDocument1 pageCalculosPablo AdueNo ratings yet

- Design of Pro. WTP (6.8 MLD) For BasavkalyanDocument27 pagesDesign of Pro. WTP (6.8 MLD) For BasavkalyanPradeep Kumar SharmaNo ratings yet

- Process Design: Value Unit Parameter 1. Mass BalanceDocument3 pagesProcess Design: Value Unit Parameter 1. Mass BalanceunconformistNo ratings yet

- Sol EqDocument3 pagesSol EqArgie AdduruNo ratings yet

- Clarifier Settling Tank PDFDocument25 pagesClarifier Settling Tank PDFvenustasiaNo ratings yet

- Assignmnet 2-CPE675-Sept20 - Feb21Document2 pagesAssignmnet 2-CPE675-Sept20 - Feb21NAJIHANo ratings yet

- Sec 10 SecondClar Jun0109Document22 pagesSec 10 SecondClar Jun0109NataliaKNo ratings yet

- PROCESS FAB PACKAGE 390 SubDocument4 pagesPROCESS FAB PACKAGE 390 SubSandeep VaishnavNo ratings yet

- Faculty of Engineering and The Built Environment Department of Civil EngineeringDocument3 pagesFaculty of Engineering and The Built Environment Department of Civil EngineeringTshidi MuneriNo ratings yet

- Chapter 8 Grit RemovalDocument20 pagesChapter 8 Grit RemovalAce ThunderNo ratings yet

- Bewerage Industry RecheckDocument4 pagesBewerage Industry RecheckdishaenvirocareNo ratings yet

- PerhitunganDocument8 pagesPerhitungantsaniya.mardhiyahNo ratings yet

- CPI SeparatorDocument3 pagesCPI SeparatorRajdeepsinhNo ratings yet

- YKK DesignDocument10 pagesYKK Designbasu_soumen2011No ratings yet

- Instruction: Please Answer and Submit The Answer Script Before 3 .00 PM, 29 May, 2014 Q1Document7 pagesInstruction: Please Answer and Submit The Answer Script Before 3 .00 PM, 29 May, 2014 Q1znyaphotmail.comNo ratings yet

- 1m3-Calculation Design - AnzirDocument8 pages1m3-Calculation Design - AnzirMohammad Mahedi100% (1)

- Cold Water Tank (Plumbing)Document3 pagesCold Water Tank (Plumbing)Jin FongNo ratings yet

- Fallsem2020-21 Che2002 Eth VL2020210101718 Cat-1 QP Key Cat I PedeDocument2 pagesFallsem2020-21 Che2002 Eth VL2020210101718 Cat-1 QP Key Cat I PedesubramanianNo ratings yet

- A Comparison of An Organic Biofilter and An Inorganic Biofilter For The Treatment of Residual Odors Emanating From A Biosolids de Watering FacilityDocument19 pagesA Comparison of An Organic Biofilter and An Inorganic Biofilter For The Treatment of Residual Odors Emanating From A Biosolids de Watering FacilityRahmi ArslanNo ratings yet

- A. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesDocument7 pagesA. Standard Membrane Bioreactor Computations: 2.1. Design Flowrates and Maximum Monthly Loading RatesshekharshindeNo ratings yet

- High Pressure Knock Out Drum (ALF)Document12 pagesHigh Pressure Knock Out Drum (ALF)Eng AlfNo ratings yet

- Aerobic Calculation WWTP TataDocument1 pageAerobic Calculation WWTP TataAchmad Rizky Hardi AdhariNo ratings yet

- 4MLD TSSEZL Process CalculationDocument23 pages4MLD TSSEZL Process CalculationNishantNo ratings yet

- Standard Membrane Bioreactor ComputationsDocument8 pagesStandard Membrane Bioreactor ComputationsSwaminathan ThayumanavanNo ratings yet

- Secondary ClarifierDocument29 pagesSecondary ClarifierNoureddine MerahNo ratings yet

- Inco - PDF - Projection Overview With CEB - 0Document1 pageInco - PDF - Projection Overview With CEB - 0Alexis Jara VidalNo ratings yet

- Bewerage Industry RecheckDocument4 pagesBewerage Industry RecheckdishaenvirocareNo ratings yet

- STP Monitoring - Revised Format (April 2024)Document7 pagesSTP Monitoring - Revised Format (April 2024)Rajesh KumarNo ratings yet

- Design of Anaerobic Upflow ReactorDocument6 pagesDesign of Anaerobic Upflow ReactorKanishka WijesekaraNo ratings yet

- CAL-00-P-0005 Rev 0 Vessel SizingDocument10 pagesCAL-00-P-0005 Rev 0 Vessel SizingSyed Zaki HaiderNo ratings yet

- Nagarjuna Construction Company Limited: Design Calculations For Sludge Handling SystemDocument26 pagesNagarjuna Construction Company Limited: Design Calculations For Sludge Handling SystemrammohanNo ratings yet

- STP Design (With MBBR)Document9 pagesSTP Design (With MBBR)Sagar Patel.100% (1)

- Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonDocument29 pagesJae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonSuhas JadhavNo ratings yet

- Super Smelter WTP UFDocument1 pageSuper Smelter WTP UFVijayargavan PasupathinathNo ratings yet

- Group M2 Janjua Report Volume 4Document91 pagesGroup M2 Janjua Report Volume 4Ola Daniel AjayiNo ratings yet

- Calculation Memory TailingsDocument13 pagesCalculation Memory TailingsjordanNo ratings yet

- STP Design PDFDocument151 pagesSTP Design PDFMark Anthony AcangNo ratings yet

- Design FMR HighDensityDocument2 pagesDesign FMR HighDensityPandiaraj Mk100% (1)

- Downloads Ir File v1 1829Document1 pageDownloads Ir File v1 1829Vinoth SenthilNo ratings yet

- Filter CapacityDocument6 pagesFilter CapacityNoopur PancholiNo ratings yet

- Foam Calculation Sample From ForumDocument2 pagesFoam Calculation Sample From Forumika524No ratings yet

- Exposure Assessment and Safety Considerations for Working with Engineered NanoparticlesFrom EverandExposure Assessment and Safety Considerations for Working with Engineered NanoparticlesNo ratings yet

- Kar Yaku: NON Resi DEN Ui TM Shah AlamDocument1 pageKar Yaku: NON Resi DEN Ui TM Shah AlamAzizul HakimNo ratings yet

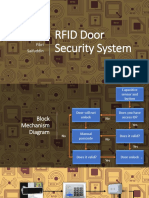

- RFID Door Security System Rev02Document8 pagesRFID Door Security System Rev02Azizul HakimNo ratings yet

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNo ratings yet

- Buzzer Order List: Name Qty. Price Total 2 RM10/qty RM20Document1 pageBuzzer Order List: Name Qty. Price Total 2 RM10/qty RM20Azizul HakimNo ratings yet

- CGE669 - Assigment HYSYS Activity 3Document1 pageCGE669 - Assigment HYSYS Activity 3Azizul HakimNo ratings yet

- Doorknob With Security Access Key Lock AccessDocument3 pagesDoorknob With Security Access Key Lock AccessAzizul HakimNo ratings yet

- Sun Jun 23 03:37:25 2019 Case: Activity 3.hsc Flowsheet: Case (Main)Document1 pageSun Jun 23 03:37:25 2019 Case: Activity 3.hsc Flowsheet: Case (Main)Azizul HakimNo ratings yet

- New Doc 2019-04-16 09.24.29Document1 pageNew Doc 2019-04-16 09.24.29Azizul HakimNo ratings yet

- Wellbore CompletionDocument39 pagesWellbore CompletionAzizul HakimNo ratings yet

- SwotDocument2 pagesSwotAzizul HakimNo ratings yet

- App 1Document1 pageApp 1Azizul HakimNo ratings yet

- 08 Drilling Engineering Part 4 DrillbitsDocument35 pages08 Drilling Engineering Part 4 DrillbitsAzizul HakimNo ratings yet

- Unit 2: Creativity, Innovation and Technology Entrepreneurship Unit 2: Creativity, Innovation and Technology EntrepreneurshipDocument32 pagesUnit 2: Creativity, Innovation and Technology Entrepreneurship Unit 2: Creativity, Innovation and Technology EntrepreneurshipAzizul HakimNo ratings yet

- CGE443: Computer Application in Oil & Gas Engineering: Noraida Amin Binti MD Taib March 2017Document41 pagesCGE443: Computer Application in Oil & Gas Engineering: Noraida Amin Binti MD Taib March 2017Azizul HakimNo ratings yet

- Bus Order Summary: YjrkfhoqDocument7 pagesBus Order Summary: YjrkfhoqAzizul HakimNo ratings yet

- Why Do You Think That Elders Always Ecperienct Any Form of Abuse by The Others?Document2 pagesWhy Do You Think That Elders Always Ecperienct Any Form of Abuse by The Others?Azizul HakimNo ratings yet

- Transient Flow Because of Time Dependent Flow: o o o o o o o o o oDocument5 pagesTransient Flow Because of Time Dependent Flow: o o o o o o o o o oAzizul HakimNo ratings yet

- Event Dota T&CDocument2 pagesEvent Dota T&CAzizul HakimNo ratings yet

- Group StageDocument36 pagesGroup StageAzizul HakimNo ratings yet

- Drillpipe Properties PDFDocument9 pagesDrillpipe Properties PDFAzizul HakimNo ratings yet

- Uitm International Centre (Uic) : Tuanku Syed Sirajuddin Chancellery BuildingDocument1 pageUitm International Centre (Uic) : Tuanku Syed Sirajuddin Chancellery BuildingAzizul HakimNo ratings yet

- Elc590: English For Oral Presentations Portfolio: Persuasive Speech Topic: Extinction of Animal SpeciesDocument6 pagesElc590: English For Oral Presentations Portfolio: Persuasive Speech Topic: Extinction of Animal SpeciesAzizul HakimNo ratings yet

- Full Well LogDocument22 pagesFull Well LogAzizul HakimNo ratings yet

- TopicsDocument2 pagesTopicsAzizul HakimNo ratings yet

- Hilti HvaDocument14 pagesHilti Hvaceca_89No ratings yet

- Condenser Steam Dump Control Valve ServomotorDocument1 pageCondenser Steam Dump Control Valve ServomotorPeter Antony100% (1)

- Porosity and Pore Size Distribution in Recycled ConcreteDocument9 pagesPorosity and Pore Size Distribution in Recycled ConcreteBagus Rizqi KurniawanNo ratings yet

- JMC FORMAT FOR RCC Cable TrenchDocument1 pageJMC FORMAT FOR RCC Cable TrenchKuldeep KumarNo ratings yet

- Recommended Exhaust Dyeing Process For EcoFRESH Yarn V3 00-2015 12 (En)Document5 pagesRecommended Exhaust Dyeing Process For EcoFRESH Yarn V3 00-2015 12 (En)Saidur Rahman SajibNo ratings yet

- Ruanta C-12 TDSDocument1 pageRuanta C-12 TDSm daneshpourNo ratings yet

- Entroy and Shaclock Mix Design For HSCDocument9 pagesEntroy and Shaclock Mix Design For HSCvempadareddyNo ratings yet

- 3604 4157 - 00 - SW Fanuc ManDocument24 pages3604 4157 - 00 - SW Fanuc ManGuillermo RamirezNo ratings yet

- Chen 2015-Membrane Gas Separation Technologies For Biogas UpgradingDocument50 pagesChen 2015-Membrane Gas Separation Technologies For Biogas UpgradingyenNo ratings yet

- ESAB Transportation Catalogue 201181132250 20118916190 PDFDocument68 pagesESAB Transportation Catalogue 201181132250 20118916190 PDFcengizarda1979No ratings yet

- Eye Bolt Rating and SpecificationsDocument7 pagesEye Bolt Rating and SpecificationsIlham Adi SusiloNo ratings yet

- Haas VF2 - Preinstall GuideDocument12 pagesHaas VF2 - Preinstall GuideJuana ChivoNo ratings yet

- SloanDocument30 pagesSloanKritika AhujaNo ratings yet

- Mat Sci Engg PresentDocument39 pagesMat Sci Engg PresentH Janardan PrabhuNo ratings yet

- JWB - AAL Engineering - Cabint Quotation - 15JUL22Document5 pagesJWB - AAL Engineering - Cabint Quotation - 15JUL22Alexander LiwanagNo ratings yet

- Megasil M 1763Document2 pagesMegasil M 1763Siddharth SainathNo ratings yet

- Module 2Document60 pagesModule 2harp_p24No ratings yet

- (Solid Mechanics and Its Applications 218) David Wagg, Simon Neild (Auth.) - Nonlinear Vibration With Control - For Flexible and Adaptive Structures-Springer International Publishing (2015)Document461 pages(Solid Mechanics and Its Applications 218) David Wagg, Simon Neild (Auth.) - Nonlinear Vibration With Control - For Flexible and Adaptive Structures-Springer International Publishing (2015)oscar201140No ratings yet

- Yvoire Contour-ImdadDocument3 pagesYvoire Contour-ImdadWaddah Al-magrabiNo ratings yet

- Experiment No. 8: Specific Heat of MetalsDocument2 pagesExperiment No. 8: Specific Heat of MetalsTiny100% (1)

- 3M Scotch 23 TDSDocument2 pages3M Scotch 23 TDSVivek JayswalNo ratings yet

- Asphalt Road RepairDocument49 pagesAsphalt Road Repairhalil_dogan4806100% (2)

- A Paper On Ground Improvement TechniquesDocument18 pagesA Paper On Ground Improvement TechniquesDhyanom GalaNo ratings yet

- Overview of Beam Pump OperationsDocument16 pagesOverview of Beam Pump OperationsLEONARDO ARZUZA100% (1)

- 4 Sealing & Bonding PDFDocument35 pages4 Sealing & Bonding PDFdilian bikovNo ratings yet

- Date Area Equipment Mech. Elect. C&I IsolationsDocument1 pageDate Area Equipment Mech. Elect. C&I IsolationsbhaskarNo ratings yet

- Deep Foundation Practice - BarrettesDocument9 pagesDeep Foundation Practice - Barrettesssi3k100% (1)