Professional Documents

Culture Documents

Klinger - Gasket Factors

Klinger - Gasket Factors

Uploaded by

Anonymous q2HC0zyfa2Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Klinger - Gasket Factors

Klinger - Gasket Factors

Uploaded by

Anonymous q2HC0zyfa2Copyright:

Available Formats

Gasket factors

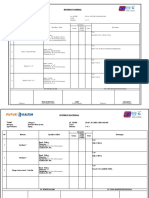

KLINGERSIL® DIN 28090/DIN 28091 DIN 2505 ASTM

Type thick- σVO σVu 0,1 σBO (7.2.2)

ness MPa MPa MPa MPa MPa MPa k1 KO x KD ”m” ”y”Stress

mm 25°C 25°C 50°C 100°C 200°C 300°C mm (N/mm) factor MPa

KLINGERSIL® C-4300/ C-4324 1 158 15 120 63 39 1.1 x bD 22 x bD 2.7 15.0

2 120 18 80 52 33 1.1 x bD 22 x bD 3.0 15.0

3 48 20 40 29 18 1.1 x bD 22 x bD 3.3 15.0

KLINGERSIL® C-4400 1 240 18 195 95 50 38 1.1 x bD 22 x bD 3.2 20.0

2 240 23 110 80 42 30 1.1 x bD 22 x bD 3.5 20.0

3 63 24 53 41 24 1.1 x bD 22 x bD 3.9 20.0

KLINGERSIL® C-4409 1 240 39 215 176 120 80 1.1 x bD 28 x bD 3.2 30.0

2 240 43 110 80 42 30 1.1 x bD 28 x bD 3.5 30.0

KLINGERSIL® C-4430 1 >240 22 260 145 81 65 1.1 x bD 22 x bD 4.5 25.0

2 >240 29 240 120 73 56 1.1 x bD 22 x bD 5.0 25.0

3 133 29 97 65 40 31 1.1 x bD 22 x bD 5.5 25.0

KLINGERSIL® C-4500 1 220 23 195 120 68 51 1.1 x bD 22 x bD 3.5 25.0

2 180 26 110 110 59 43 1.1 x bD 22 x bD 4.0 25.0

3 100 28 80 55 33 23 1.1 x bD 22 x bD 4.5 25.0

KLINGERSIL® C-4509 1 280 24 195 140 120 97 1.1 x bD 28 x bD 3.5 30.0

2 180 28 110 110 59 43 1.1 x bD 28 x bD 4.0 30.0

KLINGERSIL® C-8200 1 225 17 160 70 44 1.1 x bD 22 x bD 3.5 22.5

2 150 19 110 53 34 1.1 x bD 22 x bD 4.0 22.5

3 75 21 55 26 17 1.1 x bD 22 x bD 4.5 22.5

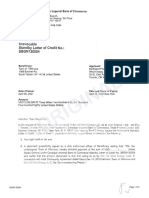

KLINGERtop-chem and top-graph DIN 28090/DIN 28091 DIN 2505 ASTM

Type thick- σVO σVu 0,1 σBO (7.2.2)

ness MPa MPa MPa MPa MPa MPa k1 KO x KD ”m” ”y”Stress

mm 25°C 25°C 50°C 100°C 200°C 250°C mm (N/mm) factor MPa

KLINGERtop-chem 2000 1 253 21 214 150 125 75 1.1 x bD 25 x bD 4.7 10.0

2 210 21 185 150 125 75 1.1 x bD 25 x bD 5.0 10.0

3 100 21 87 60 50 33 1.1 x bD 25 x bD 5.2 10.0

KLINGERtop-chem 2003 2 >110 13 110 28 15 10 1.1 x bD 22 x bD 2.8 5.0

KLINGERtop-chem 2005 2 >110 28 50 35 22 15 1.1 x bv 22 x bD 10.0 10.0

KLINGERtop-graph 2000 2 >160 25 120 80 70 60 * 4.0 25.0

* 300°C

The evaluation of these characteristic The design factors ”m” and ”y” Subject to technical alterations.

datas are based on the rules of DIN according to the ASME Code are Status: June 2004

28090. The use of this values will not based on a maximum leakage rate of

guarantee the performance of the 1 ml/min. approx. 0.1 mg/sec x m Certified according to

gasket. Application conditions not in measured according to DIN 28090 at DIN EN ISO 9001:2000

the control of the gasket material different gas pressures and different

manufacturer can influence the gasket stresses.

operation of the gasket. A deducation The DIN 2505 and the ”y” and ”m”

of liability claims of any nature is concept itself now being questioned

therefore not possible. As further as a valid design tool.

investigations are continuosely

carried out we reserve the right of

appropriate updates.

You might also like

- IRC-SP-135-2022-Manual For The Design of Hot Bituminous MixesDocument63 pagesIRC-SP-135-2022-Manual For The Design of Hot Bituminous MixesSundara Nayakan100% (8)

- Sullair Diesel Compressors - Sullair S115Document2 pagesSullair Diesel Compressors - Sullair S115=IceBurn=No ratings yet

- ATC - Automatic Air Conditioner PDFDocument134 pagesATC - Automatic Air Conditioner PDFbenNo ratings yet

- Extreme-Range RFID Hacking by Chris (Now Kristin) PagetDocument10 pagesExtreme-Range RFID Hacking by Chris (Now Kristin) PagetPacketerror100% (1)

- Tightening Torques For Imperial (U.S.) Bolts of Yield Strength (Sy) 80%Document2 pagesTightening Torques For Imperial (U.S.) Bolts of Yield Strength (Sy) 80%Serj DavidNo ratings yet

- ACW Booster Pump CalculationDocument7 pagesACW Booster Pump CalculationgreenenergykolkataNo ratings yet

- Motorcycle Gearing Worksheet: Primary Drive Ratio 20 67 14 34 19 31 21 26 22 23Document2 pagesMotorcycle Gearing Worksheet: Primary Drive Ratio 20 67 14 34 19 31 21 26 22 23Rizki RiandiNo ratings yet

- Torque CalculationDocument11 pagesTorque CalculationNur JamiludinNo ratings yet

- Calculation Book Cathodic Protection Input ParametersDocument4 pagesCalculation Book Cathodic Protection Input ParametersLuis SuarezNo ratings yet

- Worm Gear Efficiency and Motor Stall Torque Relation CalculationDocument8 pagesWorm Gear Efficiency and Motor Stall Torque Relation CalculationVenkateswaran venkateswaranNo ratings yet

- Motor Gearbox LeadscrewDocument1 pageMotor Gearbox LeadscrewS C GaurNo ratings yet

- Fittings Catalogue 2010Document218 pagesFittings Catalogue 2010sixuletNo ratings yet

- EDG-Motor Starting Calculation-Define PreloadDocument2 pagesEDG-Motor Starting Calculation-Define PreloadJacob PhilipNo ratings yet

- Electric Motor Torque Calculation 20140507Document1 pageElectric Motor Torque Calculation 20140507nvkjayanthNo ratings yet

- Tabel Pipa HDPEDocument2 pagesTabel Pipa HDPEIftikar Rizkia NugrahaNo ratings yet

- Design Calculation of Gearbox: ST ND RD TH THDocument50 pagesDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNo ratings yet

- Data Sheet Kabel NA2XSEYDocument5 pagesData Sheet Kabel NA2XSEYGansar KharismawanNo ratings yet

- Wall Thickness CalcDocument2 pagesWall Thickness Calcpbao_12No ratings yet

- Size of Capacitor For Power Factor Improvement (1.1.17)Document9 pagesSize of Capacitor For Power Factor Improvement (1.1.17)Reza PahlepiNo ratings yet

- OpeningCalculator v1 0Document4 pagesOpeningCalculator v1 0PROYECTOMSNo ratings yet

- Spare Parts Listing 1622544Document32 pagesSpare Parts Listing 1622544Mara OrdinaryNo ratings yet

- Unalloyed Carbon-Steels: Product DescriptionDocument4 pagesUnalloyed Carbon-Steels: Product DescriptionSute IntNo ratings yet

- Form HDPE Pipe Inspection-2Document2 pagesForm HDPE Pipe Inspection-2Angga Dwi PutrantoNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetZineddine ALICHENo ratings yet

- User Guide: Pipeflow Is A Trading Name of Daxesoft LTDDocument205 pagesUser Guide: Pipeflow Is A Trading Name of Daxesoft LTDAhmad Salim Muttaqin100% (1)

- Kitz GraphiteDocument48 pagesKitz GraphitejjdNo ratings yet

- NYY 1 X (1.5-500) MM 0.6/1 KVDocument5 pagesNYY 1 X (1.5-500) MM 0.6/1 KVFebi HerdianaNo ratings yet

- Hardness ConversionDocument11 pagesHardness ConversionSimon RisteskiNo ratings yet

- ST 60-2Document1 pageST 60-2AmiNo ratings yet

- Power Factor Correction Calculator V.02Document2 pagesPower Factor Correction Calculator V.02NM GroupNo ratings yet

- Klenger GasketDocument23 pagesKlenger Gasketjayhuacat7743No ratings yet

- CPM S Curve BroilerDocument4 pagesCPM S Curve BroilerBert EngNo ratings yet

- Price Kitazawa ValveDocument9 pagesPrice Kitazawa ValveAhmad Syaifudin ZNo ratings yet

- Sri Shakthi Institute of Engg and Technology: Two Marks Questions and AnswersDocument12 pagesSri Shakthi Institute of Engg and Technology: Two Marks Questions and AnswersdhivyadevinNo ratings yet

- Crane Sany STC250HDocument9 pagesCrane Sany STC250HAlfin ListioNo ratings yet

- Klingersil: Optimum Flange SecurityDocument7 pagesKlingersil: Optimum Flange SecurityjbertralNo ratings yet

- EZ Water Calculator 3.0.2Document4 pagesEZ Water Calculator 3.0.2adriano70No ratings yet

- Metal Table-2865 - 2866Document1 pageMetal Table-2865 - 2866kastelaninNo ratings yet

- Hvac Condensate Calculator: Difference in Specific Humidity gr/ft3Document4 pagesHvac Condensate Calculator: Difference in Specific Humidity gr/ft3Ruby AbionNo ratings yet

- 04-000-R1 Impressed Current Anodes SummaryDocument14 pages04-000-R1 Impressed Current Anodes SummaryGustavo OliveiraNo ratings yet

- Caustic Soda Flake MSDS PDFDocument3 pagesCaustic Soda Flake MSDS PDFFajar RamadhanNo ratings yet

- Stress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanDocument9 pagesStress Analysis of Silo Hopper: by G. Sangareeswari U. GanesanGANESANMECH05No ratings yet

- Daftar Biaya Sewa Peralatan Per Jam Kerja: No. Uraian KO Ket. DEDocument2 pagesDaftar Biaya Sewa Peralatan Per Jam Kerja: No. Uraian KO Ket. DEGuntur PolontaloNo ratings yet

- Toez C736 70.1Document27 pagesToez C736 70.1Marius BarNo ratings yet

- STP Wall Working MethodsDocument7 pagesSTP Wall Working MethodsReza AndrianaNo ratings yet

- Gate Valve (Z45X)Document1 pageGate Valve (Z45X)lnacerNo ratings yet

- Design Project - 1 (Autosaved) FinalDocument45 pagesDesign Project - 1 (Autosaved) FinalMilion dugumaNo ratings yet

- Pt. Indexim Coalindo Pt. Jakarta Prima CranesDocument1 pagePt. Indexim Coalindo Pt. Jakarta Prima Cranesfajar kristantiNo ratings yet

- Piping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0Document44 pagesPiping Specifications - Sn10 1 Pipe: Doc No: JKPM/DOC/M/001 Page 1 of 44 R0josphinvalarNo ratings yet

- Centrifugal Pump Data SheetDocument8 pagesCentrifugal Pump Data SheetCarlos GomezNo ratings yet

- Pump Calc ExampleDocument21 pagesPump Calc ExampleMohammad Usman HabibNo ratings yet

- LS G100 Quick SettingDocument8 pagesLS G100 Quick SettingtrunghieutcNo ratings yet

- Kontur Pipeflow BaruDocument33 pagesKontur Pipeflow BaruAngga Lionix ManullangNo ratings yet

- Hopper Calculation-9Document1 pageHopper Calculation-9Ujwal KhandokarNo ratings yet

- Hydrophore Sequencing Relay: Connection Diagram For HSR-03Document1 pageHydrophore Sequencing Relay: Connection Diagram For HSR-03Pa'd Edy Sustiyono0% (1)

- Upvc Price ChartDocument4 pagesUpvc Price ChartbewithkiranNo ratings yet

- Gasket Factors: KlingersilDocument3 pagesGasket Factors: KlingersilsNo ratings yet

- Dichtungskennwerte e PDFDocument3 pagesDichtungskennwerte e PDFАндрей ИнгельбергNo ratings yet

- Frenzelit - Gasket Characteristics DIN 28090-1 Novatec PREMIUM IIDocument1 pageFrenzelit - Gasket Characteristics DIN 28090-1 Novatec PREMIUM IIRuben PauwelsNo ratings yet

- Klinger Gasket FactorsDocument3 pagesKlinger Gasket FactorsGeorge TanasescuNo ratings yet

- Medium Voltage FusesDocument92 pagesMedium Voltage FusesEliasNo ratings yet

- Cable ELEXOR BT-MTDocument4 pagesCable ELEXOR BT-MTespiripitiberto espiripitiflauticoNo ratings yet

- Vent StackDocument6 pagesVent Stackiuiuiooiu0% (1)

- Lrrrevocabos Standby Letter of Credh: Sbgn130554: Canadian Gmperiai Bank of CommerceDocument3 pagesLrrrevocabos Standby Letter of Credh: Sbgn130554: Canadian Gmperiai Bank of CommerceAhmed LaajiliNo ratings yet

- PLC-XU86 PLC-XU83: Multimedia ProjectorDocument72 pagesPLC-XU86 PLC-XU83: Multimedia ProjectorAmarjeet.SinghNo ratings yet

- 02 Laboratory Experiment 1Document2 pages02 Laboratory Experiment 1J Paradise100% (1)

- 6 High Efficiency Boiler Technology Sugar Industry Suwat enDocument29 pages6 High Efficiency Boiler Technology Sugar Industry Suwat enctomeyNo ratings yet

- Wvsucat Application Form: (To Be Personally Accomplished by The Student Applicant Only)Document2 pagesWvsucat Application Form: (To Be Personally Accomplished by The Student Applicant Only)Marissa Altarejos BrionesNo ratings yet

- Engine Technology International - June 2019 PDFDocument76 pagesEngine Technology International - June 2019 PDFebt555No ratings yet

- 1st Year, 1st Semester: Subject Description Lec Lab Pre-RequisiteDocument4 pages1st Year, 1st Semester: Subject Description Lec Lab Pre-RequisiteAUDREY MUGASNo ratings yet

- Irf13n50 Data SheetDocument7 pagesIrf13n50 Data SheetMuhammad IchsanNo ratings yet

- PNC00004 PDFDocument9 pagesPNC00004 PDFRaymundo Maldonado AlvarezNo ratings yet

- Curriculum Area: Science Title: Light Up My Life Unit OutlineDocument19 pagesCurriculum Area: Science Title: Light Up My Life Unit Outlineapi-327519956No ratings yet

- Load Schedule and Single Line Engr GorospeDocument1 pageLoad Schedule and Single Line Engr GorospeMichael Pepz DatuinNo ratings yet

- L1 Feebdack - Persistent - Akash Karhale Akash KarhaleDocument2 pagesL1 Feebdack - Persistent - Akash Karhale Akash KarhalerameshraodNo ratings yet

- Piping Specification SheetDocument63 pagesPiping Specification SheetNilesh Gohel100% (1)

- An Examination of The Effects of Globalization On Contemporary Art PDFDocument3 pagesAn Examination of The Effects of Globalization On Contemporary Art PDFMarilou Chalanao EstebanNo ratings yet

- 00-23 Maret 2022 Data Stok FLDocument70 pages00-23 Maret 2022 Data Stok FLGudang FarmasiNo ratings yet

- Plex For Samsung App Manual v2 002 PDFDocument69 pagesPlex For Samsung App Manual v2 002 PDFmarco antonio martinez andradeNo ratings yet

- Gas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Document91 pagesGas Turbine Performance Acceptance Test Specification (Version 5) (TSMKO-00TG-T-30-TG0-321-A)Anonymous kVwp7D67% (3)

- Semiconductor 101Document79 pagesSemiconductor 101jamalur.lNo ratings yet

- Hydraulic Oils 1Document1 pageHydraulic Oils 1sifuszNo ratings yet

- MED808 Course InformationDocument4 pagesMED808 Course InformationJaine TanNo ratings yet

- X11SNI&ODocument23 pagesX11SNI&Oprihartono_diasNo ratings yet

- MicroStation Basic Macros...Document4 pagesMicroStation Basic Macros...Anoop SV100% (1)

- Nurture International SchoolDocument5 pagesNurture International SchoolRahul GuptaNo ratings yet

- Tme 601Document14 pagesTme 601dearsaswatNo ratings yet

- A Warm Welcome To Centre of Excellence Biopharmaceutical Technology!Document11 pagesA Warm Welcome To Centre of Excellence Biopharmaceutical Technology!shreyaNo ratings yet

- Amazon EC2 Instance ComparisonDocument3 pagesAmazon EC2 Instance ComparisonxuanvNo ratings yet

- 7SG14 - Duobias M Complete Technical Manual PDFDocument142 pages7SG14 - Duobias M Complete Technical Manual PDFsteve_osullivanNo ratings yet