Professional Documents

Culture Documents

WEB When A Sif Is Off PDF

WEB When A Sif Is Off PDF

Uploaded by

ozkanhasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WEB When A Sif Is Off PDF

WEB When A Sif Is Off PDF

Uploaded by

ozkanhasanCopyright:

Available Formats

When a SIF is Not Accurate

What if the SIF is Not Accurate?

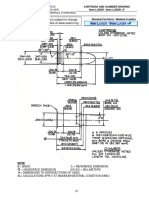

The figure below shows an X at 100% of a typical allowable stress and a Z at the mean of

the failure data. The ratio between Z and X is the “safety” when the design is at 100% of

the allowable stress. For fatigue, the ratio between Z and X is about 2.0.

If the SIF is off by 2.0 and the ratio between design and mean failure is 2.0, then at 100%

of the Code allowable stress there is no safety factor.

The design stress is a product of the calculated load and the SIF.

If the calculated load is off by more than 2.0 and the ratio between design and mean failure

is 2.0, then at 100% of the allowable stress, there is more than a 50% probability the

component will develop a crack during its lifetime.

Copyright© 2008 - Paulin Research Group

When a SIF is Not Accurate

Some Calculated SIFs are compared below to B31 Code SIFs from Appendix D for large

diameter 90 and 60 degree large diameter intersections with d/D = 1 and 0.4. Differences

can be seen to be both conservative and non-conservative by a factor of about 2.0

Unreinforced Fabricated Tee

Description Angle ii (B31.3) io (B31.3) ii (FEA) ii (FEA)

30x30x0.375 90 8.079 10.439 10.63 13.75

30x12x0.375 90 8.079 10.439 4.56 13.22

30x30x0.375 60 8.079 10.439 9.23 10.9

30x12x0.375 60 8.079 10.439 4.64 11.07

Fabricated Tee With 0.25 inch Reinforcing Pad

Description Angle ii (B31.3) io (B31.3) ii (FEA) ii (FEA)

30x30x0.375 90 5.1 6.46 6.82 12.32

30x12x0.375 90 5.1 6.46 3.98 11.09

30x30x0.375 60 5.1 6.46 6.22 10.87

30x12x0.375 60 5.1 6.46 4.07 9.54

Note that for laterals and hillside junctions torsional moments may

interact with inplane and outplane moments to produce situations

where the calculated and B31 SIF factors are different by much

greater than 2.0.

In these situations users are urged to use additional caution.

Copyright© 2008 - Paulin Research Group

You might also like

- Spreader BeamDocument2 pagesSpreader Beamwisnu_bayusakti80% (5)

- The Golden Turkey AwardsDocument5 pagesThe Golden Turkey AwardsMIDNITECAMPZ0% (2)

- Beam Design To BS 8110Document14 pagesBeam Design To BS 8110Gihan Chathuranga60% (5)

- Mechanical Properties of Tension MemberDocument77 pagesMechanical Properties of Tension MemberSky Fire100% (1)

- Reference CalcDocument15 pagesReference CalcPoulomi BiswasNo ratings yet

- Solutions Manual to accompany Introduction to Linear Regression AnalysisFrom EverandSolutions Manual to accompany Introduction to Linear Regression AnalysisRating: 1 out of 5 stars1/5 (1)

- Aruba 5400R Switch Series Technical Product GuideDocument25 pagesAruba 5400R Switch Series Technical Product GuideWK OngNo ratings yet

- Course CatalogDocument495 pagesCourse Catalogzbouzgha100% (2)

- ADS Project (1 To 3)Document43 pagesADS Project (1 To 3)damanNo ratings yet

- 2.0 Theory: 1.0 ObjectiveDocument5 pages2.0 Theory: 1.0 ObjectiveSyafiq AimanNo ratings yet

- Printed in GermanyDocument8 pagesPrinted in Germanyengine wangNo ratings yet

- Calc SheetDocument69 pagesCalc SheetElda Adriani SimarmataNo ratings yet

- Deflection and StiffnessDocument8 pagesDeflection and Stiffnesserish FolienteNo ratings yet

- DWGB106Document6 pagesDWGB106LucaNo ratings yet

- Appendix A Thickness of Base MetalDocument24 pagesAppendix A Thickness of Base MetalSaylittle PrayerNo ratings yet

- Elements of RC Design1Document12 pagesElements of RC Design1kimkov119No ratings yet

- Punching Shear Design A Detailed DiscussionDocument9 pagesPunching Shear Design A Detailed DiscussionAnil kumar RNo ratings yet

- Beam Splitter Output Coupler Coatings (Materiais para Laser)Document1 pageBeam Splitter Output Coupler Coatings (Materiais para Laser)AndréNo ratings yet

- Model Number Part Number Description M5307 100 Kip Deadline Anchor 53070000 100-DEADLINEDocument29 pagesModel Number Part Number Description M5307 100 Kip Deadline Anchor 53070000 100-DEADLINEc.valderrabano81No ratings yet

- Practice 3 Multiple Regression 2023 03-16-09!06!38Document5 pagesPractice 3 Multiple Regression 2023 03-16-09!06!38PavonisNo ratings yet

- Tuesday-2 Tensile Arko Basak 210184Document6 pagesTuesday-2 Tensile Arko Basak 210184Dewanshu JaiswalNo ratings yet

- Sem220182019 Test Set A (Answer Scheme)Document5 pagesSem220182019 Test Set A (Answer Scheme)ThiruNo ratings yet

- 9 Regular Machining Dimension Tolerance 01Document1 page9 Regular Machining Dimension Tolerance 01OllenkNo ratings yet

- To Das Muni CoesDocument15 pagesTo Das Muni CoesAlexandre FonsecaNo ratings yet

- C CCCC CCCCCC CCCCCC C C !C "# $%&C&C&'" (C %" (#) " " (C + ,-C C ,-, C - , CCC..CCC/C C CDocument20 pagesC CCCC CCCCCC CCCCCC C C !C "# $%&C&C&'" (C %" (#) " " (C + ,-C C ,-, C - , CCC..CCC/C C CVikas VermaNo ratings yet

- Understanding Machinery Fits and TolerancesDocument11 pagesUnderstanding Machinery Fits and TolerancesManojkumar ThilagamNo ratings yet

- General Tolerance ISO2768 For CNC MachiningDocument5 pagesGeneral Tolerance ISO2768 For CNC Machiningsogaworks2015No ratings yet

- StressDocument1 pageStressmukesh ambaniNo ratings yet

- Printed in GermanyDocument22 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Component Fragility GenDocument19 pagesComponent Fragility GenAbhishek ChaurasiyaNo ratings yet

- Deflections of BeamsDocument5 pagesDeflections of Beamsromesaali23No ratings yet

- My - Spreadsheet - SlabDocument26 pagesMy - Spreadsheet - SlabBilal Ahmed Barbhuiya50% (2)

- Rafi - PDF Base PlateDocument3 pagesRafi - PDF Base PlatemohamedNo ratings yet

- Critical Load On StrutDocument5 pagesCritical Load On StrutelhammeNo ratings yet

- PM Curve For ColumnDocument5 pagesPM Curve For Columnyedida v r aviswanadhNo ratings yet

- Deep BeamDocument7 pagesDeep BeamasdNo ratings yet

- NZS 3101-06 RC-BM-001Document7 pagesNZS 3101-06 RC-BM-001renzo1221No ratings yet

- Simply Supported Reinforced Concrete Beam Analysis and DesignDocument31 pagesSimply Supported Reinforced Concrete Beam Analysis and DesignAdil ShugayNo ratings yet

- Ground Mount Dashboard Reference ManualDocument5 pagesGround Mount Dashboard Reference ManualAbdul AleemNo ratings yet

- Calculating Cylinder Liner Projection For 3500, 3500B, 3500C, and G3500 EnginesDocument6 pagesCalculating Cylinder Liner Projection For 3500, 3500B, 3500C, and G3500 EnginesmkNo ratings yet

- Assignment # 6 Solution: MS MS y T y T N NDocument6 pagesAssignment # 6 Solution: MS MS y T y T N Nsulaiman_GNo ratings yet

- CIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2Document7 pagesCIS SAFE د ماجد البنا مقارنة الحل اليدوي والحل في برنامج 2bassam1911992No ratings yet

- Timber Truss Design: ProjectDocument8 pagesTimber Truss Design: ProjectEvello MercanoNo ratings yet

- Experiment 3: Strut BucklingDocument8 pagesExperiment 3: Strut BucklingEdmund TiewNo ratings yet

- 3D Effects in Slope Stability AnalysesDocument18 pages3D Effects in Slope Stability AnalysesJOSE LUIS SIERRA PEREZNo ratings yet

- Lab Report Template - PHYS 194-3Document9 pagesLab Report Template - PHYS 194-3bebsybiswezNo ratings yet

- Lab Report Instability of StrutDocument13 pagesLab Report Instability of StrutepolNo ratings yet

- Tension Members - Notes Mohit JaiswalDocument5 pagesTension Members - Notes Mohit JaiswalPiyush GuptaNo ratings yet

- Customer DocumentsDocument56 pagesCustomer DocumentsYana AbdurrahmanNo ratings yet

- Typical Civil BOQDocument11 pagesTypical Civil BOQMuhammad Wazim AkramNo ratings yet

- Customer DocumentsDocument76 pagesCustomer Documentsgabriel andres sepulveda ramirezNo ratings yet

- Timber Work Specs CPWDDocument6 pagesTimber Work Specs CPWDThilak BalakrishnanNo ratings yet

- Allowable Nozzle Loads Pressure VesselDocument3 pagesAllowable Nozzle Loads Pressure Vesselvenkatrangan2003No ratings yet

- Application: Slip-On Outdoor TerminationDocument2 pagesApplication: Slip-On Outdoor Terminationlatif100% (1)

- Case 9: Four Edges DiscontinuousDocument2 pagesCase 9: Four Edges DiscontinuousEvonne LeeNo ratings yet

- ToleranceDocument7 pagesTolerancemohdmaazkhan025No ratings yet

- Shear On Slab Close To SupportDocument19 pagesShear On Slab Close To SupportthinnaiNo ratings yet

- Sampling and Analysis ExamplesDocument53 pagesSampling and Analysis ExamplesyromeroNo ratings yet

- Torsional Vibrations and Torsion Modulus: (Item No.: P2133000)Document6 pagesTorsional Vibrations and Torsion Modulus: (Item No.: P2133000)Masood ImtiazNo ratings yet

- Filter ANOVADocument6 pagesFilter ANOVAVinayak TevarannavarNo ratings yet

- Point Fixing WLDocument7 pagesPoint Fixing WLmuralidharan10901No ratings yet

- Beam Crack PDFDocument1 pageBeam Crack PDFAnonymous koR9VtfNo ratings yet

- Point Fixing LL-0.89kNDocument8 pagesPoint Fixing LL-0.89kNmuralidharan10901No ratings yet

- EN 1337-2 (6.9.3) Backing Plate StiffnessDocument1 pageEN 1337-2 (6.9.3) Backing Plate StiffnessMarijanaNo ratings yet

- Forming of Ellipse Heads of Large Scale Austenitic Stainless Steel Pressure VesselDocument6 pagesForming of Ellipse Heads of Large Scale Austenitic Stainless Steel Pressure VesselozkanhasanNo ratings yet

- Untia Duunit: (12) United States PatentDocument11 pagesUntia Duunit: (12) United States PatentozkanhasanNo ratings yet

- Determination of Modal Properties of The Coffee Fruit-Stem System Using High Speed Digital Video and Digital Image ProcessingDocument8 pagesDetermination of Modal Properties of The Coffee Fruit-Stem System Using High Speed Digital Video and Digital Image ProcessingozkanhasanNo ratings yet

- 2 PostprocessingUsingAPI Mairs Cardinal PDFDocument21 pages2 PostprocessingUsingAPI Mairs Cardinal PDFozkanhasanNo ratings yet

- Astm-A992 PDFDocument3 pagesAstm-A992 PDFOsvaldo MoralesNo ratings yet

- Us Lisega Catalog 2020 PDFDocument289 pagesUs Lisega Catalog 2020 PDFozkanhasan100% (1)

- Reviews: Instability and Plastic Collapse of SteelDocument1 pageReviews: Instability and Plastic Collapse of SteelozkanhasanNo ratings yet

- Technical Data Sheet Bolt Diameter Tolerances For Crosby® S/G-2130/2140 ShacklesDocument1 pageTechnical Data Sheet Bolt Diameter Tolerances For Crosby® S/G-2130/2140 ShacklesozkanhasanNo ratings yet

- Classification of Shell Stresses Resulting From Piping Nozzle LoadsDocument4 pagesClassification of Shell Stresses Resulting From Piping Nozzle LoadsozkanhasanNo ratings yet

- Bending of Thin Circular RingsDocument14 pagesBending of Thin Circular RingsozkanhasanNo ratings yet

- Hilti HKV DatasheetDocument5 pagesHilti HKV DatasheetozkanhasanNo ratings yet

- How To Use Abaqus2MatlabDocument4 pagesHow To Use Abaqus2MatlabozkanhasanNo ratings yet

- How To Use Abaqus2MatlabDocument4 pagesHow To Use Abaqus2MatlabozkanhasanNo ratings yet

- Diabetes Mellitus Diagnosis Using Optical Ring Resonators-758Document7 pagesDiabetes Mellitus Diagnosis Using Optical Ring Resonators-758Darshan rajNo ratings yet

- Acer Aspire x1400 X1420, Emachines EL1358 Wistron Eboxer MANALODocument45 pagesAcer Aspire x1400 X1420, Emachines EL1358 Wistron Eboxer MANALOHoàng Chương DươngNo ratings yet

- Andal BEED3B HomeLearningSupport&ReadingPerformance C1-3Document30 pagesAndal BEED3B HomeLearningSupport&ReadingPerformance C1-3Arcel SorianoNo ratings yet

- Module 5Document27 pagesModule 5Labour lawNo ratings yet

- EHS Learnshare Database V1Document53 pagesEHS Learnshare Database V1Rajeev VarmaNo ratings yet

- BEC ChemDocument7 pagesBEC ChemSka dooshNo ratings yet

- Oando For Jevlink2Document4 pagesOando For Jevlink2Steve Bassey100% (2)

- Module 1, Graph Theory 1Document133 pagesModule 1, Graph Theory 1Ayush Kumar 20BTRIS004No ratings yet

- LM140/LM340A/LM340/LM7800C Series 3-Terminal Positive RegulatorsDocument15 pagesLM140/LM340A/LM340/LM7800C Series 3-Terminal Positive Regulatorsvmm mNo ratings yet

- Fifi SpeechDocument2 pagesFifi SpeechDesi NovitaNo ratings yet

- West Bengal Forest Directorate - Eco-Tourism FacilitiesDocument5 pagesWest Bengal Forest Directorate - Eco-Tourism FacilitiesSamarendu BaulNo ratings yet

- Topology and Its TypeDocument4 pagesTopology and Its TypeNEHA CHAHARNo ratings yet

- High Speed Rail in IndiaDocument36 pagesHigh Speed Rail in IndiaNamesh Killemsetty100% (1)

- English ReportDocument10 pagesEnglish Reportsherpanawang41No ratings yet

- Market Plan of Lucky Cement FActoryDocument20 pagesMarket Plan of Lucky Cement FActoryRehman RehoNo ratings yet

- Chico Resume 2015 For WebsiteDocument2 pagesChico Resume 2015 For Websiteapi-87866586No ratings yet

- Policy Guideliness For Community Radio in KenyaDocument36 pagesPolicy Guideliness For Community Radio in KenyaAmos Ochieng100% (1)

- PROCESS AND ART. OSKAR HANSEN AND HIS CONCEPT OF VARIABLE ARCHITECTURE - Contemporary Lynx - Promoting Polish Art in The WorldDocument13 pagesPROCESS AND ART. OSKAR HANSEN AND HIS CONCEPT OF VARIABLE ARCHITECTURE - Contemporary Lynx - Promoting Polish Art in The WorldBen GreenNo ratings yet

- PA - StocksDocument36 pagesPA - Stocksikolev57No ratings yet

- Fast Food Nation Book ThesisDocument7 pagesFast Food Nation Book Thesistfwysnikd100% (2)

- Book Review-Teach Like A Champion-Hussein Haj AhmadDocument2 pagesBook Review-Teach Like A Champion-Hussein Haj Ahmadapi-286467538No ratings yet

- MBA 6104 - Research-LectureDocument5 pagesMBA 6104 - Research-LectureTanvir RahmanNo ratings yet

- Infection Control Questions For StaffDocument3 pagesInfection Control Questions For StaffManisha maharaNo ratings yet

- CS9i Low Mount Suspension Assembly Parts ListDocument3 pagesCS9i Low Mount Suspension Assembly Parts ListВЛАДИМИРNo ratings yet

- Mahmoud GshashDocument1 pageMahmoud Gshashapi-402002428No ratings yet

- Access Grammar 2Document20 pagesAccess Grammar 2Agostina Calienno PazNo ratings yet

- The Westing Game Characters InformationDocument12 pagesThe Westing Game Characters Informationapi-355786379No ratings yet