Professional Documents

Culture Documents

Bolt & Gasket Sets - Spec Sheet: Non-Asbestos Red Rubber

Bolt & Gasket Sets - Spec Sheet: Non-Asbestos Red Rubber

Uploaded by

Patel Mehul0 ratings0% found this document useful (0 votes)

19 views3 pagesThe document provides specifications for two types of gaskets - style CNA-750 and style 0700. CNA-750 is constructed of aramid and synthetic fibers with an NBR binder and rated to 750F continuous. Style 0700 is a red rubber gasket rated to 170F continuous. Both use ASTM A307 bolts and A563 nuts. Dimensions and specifications are provided for fittings and flanges from 1/2" to 24" pipe sizes. Tightening torque values in lb-ft are also included for various bolt sizes.

Original Description:

nut bolt size

Original Title

Bolts Gaskets (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides specifications for two types of gaskets - style CNA-750 and style 0700. CNA-750 is constructed of aramid and synthetic fibers with an NBR binder and rated to 750F continuous. Style 0700 is a red rubber gasket rated to 170F continuous. Both use ASTM A307 bolts and A563 nuts. Dimensions and specifications are provided for fittings and flanges from 1/2" to 24" pipe sizes. Tightening torque values in lb-ft are also included for various bolt sizes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

19 views3 pagesBolt & Gasket Sets - Spec Sheet: Non-Asbestos Red Rubber

Bolt & Gasket Sets - Spec Sheet: Non-Asbestos Red Rubber

Uploaded by

Patel MehulThe document provides specifications for two types of gaskets - style CNA-750 and style 0700. CNA-750 is constructed of aramid and synthetic fibers with an NBR binder and rated to 750F continuous. Style 0700 is a red rubber gasket rated to 170F continuous. Both use ASTM A307 bolts and A563 nuts. Dimensions and specifications are provided for fittings and flanges from 1/2" to 24" pipe sizes. Tightening torque values in lb-ft are also included for various bolt sizes.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

Bolt & Gasket Sets • Spec Sheet

Non-Asbestos Red Rubber

Gasket: APG style 0700

Gasket: APG style CNA-750 • Constructed of SBR (Styrene Butadiene Rubber)

• Constructed of aramid and other synthetic fibers and • “Smooth” red rubber finish as opposed to rough

bonded with nitrile rubber (NBR). “cloth” finish

• Max temperature rating: 750 degrees F • Max temperature rating: -20 to 170 degrees F, 210

• (Continuous temp max: 460 degrees F) degrees F intermittent

• Max pressure limit: 1595 PSI • Tensile Strength: 500 PSI

• (Continuous pressure max: 725 PSI) • Suitable for: hot & cold water, air, and neutral fluids

• Suitable for: Water, air, and a variety of industrial gases • Meets ASTM D-1330

and fluids; suitable for steam depending on operating Bolts: ASTM A307 Grade A zinc plated carbon steel

conditions • Minimum tensile strength: 60,000 PSI

• Meets ASTM F152 Nuts: ASTM A563, Grade A, zinc plated carbon steel

• Comparable products: Klinger C-4401, Garlock 3000 Finished Hex Nut (Standard Factory furnished)

Bolts: ASTM A307 Grade A zinc plated carbon steel ASTM A563, Grade A, zinc plated carbon steel

• Minimum tensile strength: 60,000 PSI HEAVY HEX NUT(Available upon request)

Nuts: ASTM A563, Grade A, zinc plated carbon steel Packaging:

Finished Hex Nut (Standard Factory furnished) • Box: Folding tab white mottled boxes

ASTM A563, Grade A, zinc plated carbon steel • Bolts are packaged in sealed poly bags

HEAVY HEX NUT (Available upon request) • Nuts are packaged in sealed poly bags

Packaging:

• Box: Folding tab white mottled boxes

• Bolts are packaged in sealed poly bags

• Nuts are packaged in sealed poly bags

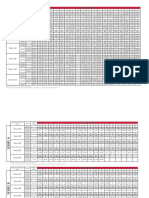

Flange Compatibility Chart • Spec Sheet

A.S.A Flanged Fittings

Class 125 Cast Iron Flanges and Fittings

Dimensions of Cast Iron Flanges, Bolts, and Ring Gaskets

Diam. Thickness¹ Diam. of Diam.² of Size of Full

Nominal of of Flanges Bolt Number² Diam. of Bolt Length3,4 Size of Flat Face Ring

Pipe Size Flange (Min.) Circle of Bolts Bolts Holes of Bolts Ring Gasket Gasket

1/2 4 1/2 27/32 x 3-1/2

3/4 4 1/2 1-1/6 x 3-7/8

1 4 1/4 7/16 3 1/8 4 1/2 5/8 1 3/4 1 x 2-5/8 1-5/16 x 4-1/4

1 1/4 4 5/8 1/2 3 1/2 4 1/2 5/8 2 1-1/4 x 3

1 1/2 5 9/16 3 7/8 4 1/2 5/8 2 1-1/2 x 3-3/8 1-29/32 x 5

2 6 5/8 4 3/4 4 5/8 3/4 2 1/4 2 x 4-1/8 2-3/8 x 6

2 1/2 7 11/16 5 1/2 4 5/8 3/4 3 2-1/2 x 4-7/8 2-7/8 x 7

3 7 1/2 3/4 6 4 5/8 3/4 3 3 x 5-3/8 3-1/2 x 7-1/2

3 1/2 8 1/2 13/16 7 8 5/8 3/4 3 3-1/2 x 6-3/8

4 9 15/16 7 1/2 8 5/8 3/4 3 4 x 6-7/8 4-1/2 x 9

5 10 15/16 8 1/2 8 3/4 7/8 3 5 x 7-3/4 5-9/16 x 10

6 11 1 9 1/2 8 3/4 7/8 3 1/2 6 x 8-3/4 6-5/8 x 11

8 13 1/2 1 1/3 11 3/4 8 3/4 7/8 3 1/2 8 x 11 5-5/8 x 13-1/2

10 16 1 3/16 14 1/4 12 7/8 1 4 10 x 13-3/8 10-3/4 x 16

12 19 1 1/4 17 12 7/8 1 4 12 x 16-1/8 12-3/4 x 19

14 OD 21 1 3/8 18 3/4 12 1 1 1/8 4 1/2 14 x 17-3/4 14 x 21

16 OD 23 1/2 1 7/16 21 1/4 16 1 1 1/8 4 1/2 16 x 20-1/4 16 x 23-1/2

18 OD 25 1 9/16 22 3/4 16 1 1/8 1 1/4 5 18 x 21-5/8 18 x 25

20 OD 27 1/2 1 11/16 25 20 1 1/8 1 1/4 5 20 x 23-7/8 20 x 27-1/2

24 OD 32 1 7/8 29 1/2 20 1 1/4 1 3/8 5 1/2 24 x 28-1/4 24 x 32

All dimensions given in inches.

Flange Compatibility Chart • Spec Sheet

A.S.A Flanged Fittings

Class 300 Cast Iron Flanges

Dimensions of Cast Iron Flanges, and Bolts

Nominal Diam. of Thickness of Diam. of Bolt Number Diam. of Diam. of Length of

Pipe Size Flange Flanges (Min.) Circle of Bolts Bolts Bolt Holes Bolts

1/2 3 3/4 - 2.62 4 0.50 0.62 -

3/4 4 5/8 - 3.25 4 0.62 0.75 -

1 4 7/8 - 3.50 4 0.62 0.75 -

1 1/4 - - 3.88 4 0.62 0.75 -

1 1/2 6 1/8 - 4.50 4 0.75 0.88 -

2 6 1/2 5/8 5.00 8 0.62 0.75 3

2 1/2 7 1/2 3/4 5.88 8 0.75 0.88 3 1/4

3 8 1/4 3/4 6.62 8 0.75 0.88 3 1/2

3 1/2 - - 7.25 8 0.75 0.88 -

4 10 3/4 7.88 8 0.75 0.88 3 3/4

5 11 3/4 9.25 8 0.75 0.88 4

6 12 1/2 3/4 10.62 12 0.75 0.88 4 1/4

8 15 7/8 13.00 12 0.88 1.00 4 3/4

10 17 1/2 - 15.25 16 1.00 1.12 -

12 20 1/2 - 17.75 16 1.12 1.25 -

14 23 - 20.25 20 1.12 1.25 -

16 25 1/2 - 22.50 20 1.25 1.38 -

18 28 - 24.75 24 1.25 1.38 -

20 30 1/2 - 27.00 24 1.25 1.38 -

24 36 - 32.00 24 1.50 1.62 -

*All dimensions given in inches

Tightening Torque Values

ASTM A307 Grade A

Clamp

Nominal Dia Threads Tightening Torque

Load

(in) per inch

(Lbs) K = 0.15 K = 0.17 K = 0.20

(Lubricated) (Plated) (Plain)

1/2" 13 3831 24 27 32

5/8" 11 6102 48 54 64

3/4" 10 9030 85 96 113

7/8" 9 12467 136 155 182

You might also like

- Mckinsey - Style Practice Case #8: Ronald ChocolatesDocument12 pagesMckinsey - Style Practice Case #8: Ronald ChocolatesHiếu LươngNo ratings yet

- OptiBlend System Operation and Installation ManualDocument9 pagesOptiBlend System Operation and Installation ManualVijendra PanwarNo ratings yet

- ASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Document11 pagesASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Isaac IglesiasNo ratings yet

- Wind Tunnel Lab SafetyDocument2 pagesWind Tunnel Lab SafetyZ-B67% (3)

- Bronze Flanges - ASME/ANSI 150 LB: (Inches)Document6 pagesBronze Flanges - ASME/ANSI 150 LB: (Inches)Karim ShamsNo ratings yet

- ASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Document7 pagesASME - ANSI B16.5 - Flanges and Bolt Dimensions Class 150 To 2500Amer FiqriNo ratings yet

- Dimension Flange AsmeDocument10 pagesDimension Flange AsmeHanif SaidonNo ratings yet

- Flanges and Bolt Dimensions ASME/ANSI B16.5 - Class 150 To 2500Document9 pagesFlanges and Bolt Dimensions ASME/ANSI B16.5 - Class 150 To 2500daveNo ratings yet

- ASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500Document8 pagesASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500Swaminathan ThayumanavanNo ratings yet

- ASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500Document8 pagesASME and ANSI B16.5 Flanges and Bolt Dimensions Class 150 To 2500elias2505No ratings yet

- ANSI Flange DimensionDocument8 pagesANSI Flange DimensionGalaco EngineeringNo ratings yet

- (Inches) (Inches) (Inches) (Inches) (Inches) : Nominal Pipe Size NPS Class 150Document10 pages(Inches) (Inches) (Inches) (Inches) (Inches) : Nominal Pipe Size NPS Class 150Brilliant Adi SjahranieNo ratings yet

- Flanges - ASME - ANSI B16.5 Flanges and Bolt Dimensions - Class 150 To 2500Document11 pagesFlanges - ASME - ANSI B16.5 Flanges and Bolt Dimensions - Class 150 To 2500ABDELKADER BENABDALLAHNo ratings yet

- Https WWW Engineeringtoolbox Com Flanges-Bolts-Dimensions-D 464 HTMLDocument13 pagesHttps WWW Engineeringtoolbox Com Flanges-Bolts-Dimensions-D 464 HTMLMashudi FikriNo ratings yet

- Flanges and Bolt Dimensions - Class 150 To 2500 - ASME - ANSI B16 (Mat Bich)Document4 pagesFlanges and Bolt Dimensions - Class 150 To 2500 - ASME - ANSI B16 (Mat Bich)Duong ThanhNo ratings yet

- ANSI B16.5 Flanges: Class 150Document17 pagesANSI B16.5 Flanges: Class 150Djoko Dwi IrwantoNo ratings yet

- Asme b16.5 Class 300 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerDocument1 pageAsme b16.5 Class 300 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerRyan SolomonNo ratings yet

- 1221 Standard Pipe NipplesDocument1 page1221 Standard Pipe NipplesmvinuNo ratings yet

- 002 Steel StructuralDocument16 pages002 Steel Structuraljalv.mendoza25No ratings yet

- TexasFlange - Bolt and Stud Dimensions ASME B16.5Document2 pagesTexasFlange - Bolt and Stud Dimensions ASME B16.5cristinelbNo ratings yet

- Gasket DimensionsDocument41 pagesGasket DimensionsGrimmo1979100% (1)

- Standard Dimensions of Spectacle Blind ThicknessDocument10 pagesStandard Dimensions of Spectacle Blind ThicknessSubrata MukherjeeNo ratings yet

- Sch80ctech SDL80C TDocument9 pagesSch80ctech SDL80C Thumberto.aranguiz2715No ratings yet

- Loucon MetalDocument43 pagesLoucon MetalHitzfitsNo ratings yet

- ASME/ANSI B16.5: (Inches) (Inches) (Inches) (Inches)Document19 pagesASME/ANSI B16.5: (Inches) (Inches) (Inches) (Inches)Harish PothepalliNo ratings yet

- Watersec16pg18 PDFDocument1 pageWatersec16pg18 PDFVincent PaulrajNo ratings yet

- Flanges and Bolt Dimensions ASME - ANSI B16Document3 pagesFlanges and Bolt Dimensions ASME - ANSI B16A.YOGAGURUNo ratings yet

- Flange - Weld Neck, ANSI Class 150, B16.5 (In)Document8 pagesFlange - Weld Neck, ANSI Class 150, B16.5 (In)Roni FirmansyahNo ratings yet

- Number & Size of Bolts For Flanged Joints-Asme B16.5: Call Us First For All Your Pipe, Valves Fittings!Document1 pageNumber & Size of Bolts For Flanged Joints-Asme B16.5: Call Us First For All Your Pipe, Valves Fittings!Venki TekkaliNo ratings yet

- Bolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronDocument1 pageBolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronGiorgi KOGOSHVILINo ratings yet

- 20b Bolt Torque PCC-1 CalculationDocument25 pages20b Bolt Torque PCC-1 CalculationRiyan EsapermanaNo ratings yet

- Astm f4844Document2 pagesAstm f4844Miguel AngelNo ratings yet

- Asme b16.5 Class 150 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerDocument1 pageAsme b16.5 Class 150 Flanges Bolting Pattern and Dimensions Chart Northwest FastenerRyan SolomonNo ratings yet

- Flange Size TableDocument1 pageFlange Size Tablediana.isbalNo ratings yet

- Stud Bolt Sizes For ANSI ASME API FlangesDocument2 pagesStud Bolt Sizes For ANSI ASME API FlangesviralNo ratings yet

- Stud Bolt For Oil and Gas PipelineDocument2 pagesStud Bolt For Oil and Gas PipelineTg TarroNo ratings yet

- Bridas Slip On Grandes b16.47Document1 pageBridas Slip On Grandes b16.47Nilton Inca TitoNo ratings yet

- Fire Dampers: Construction and SpecificationsDocument7 pagesFire Dampers: Construction and SpecificationsAmr Adeeb Abd-ElaahNo ratings yet

- Flange Data Chart: Mactech Portable Machining SolutionsDocument2 pagesFlange Data Chart: Mactech Portable Machining SolutionsJalal NorriNo ratings yet

- Jack Screw Sizes For Ring Joint Face Orifice FlangesDocument1 pageJack Screw Sizes For Ring Joint Face Orifice FlangeswahyoesoemantriNo ratings yet

- Flange Data Chart: Mactech Portable Machining SolutionsDocument2 pagesFlange Data Chart: Mactech Portable Machining SolutionsSinojKumarMalipronNo ratings yet

- TorqueDocument6 pagesTorquelucianaNo ratings yet

- Flange Data ChartDocument2 pagesFlange Data ChartDaryl DelimanNo ratings yet

- TorqueDocument6 pagesTorquelucianaNo ratings yet

- Flange Data Chart: Mactech Portable Machining SolutionsDocument2 pagesFlange Data Chart: Mactech Portable Machining SolutionsOktayKulNo ratings yet

- Slip On Flange RTJ GasketDocument2 pagesSlip On Flange RTJ GasketEDAC RFCLNo ratings yet

- Studbolt Size ChartDocument3 pagesStudbolt Size ChartRenalyn TorioNo ratings yet

- Gasket Dimensions For ANSI Flanges 01012021Document1 pageGasket Dimensions For ANSI Flanges 01012021Sachin HolkarNo ratings yet

- Flange Bolting ChartDocument2 pagesFlange Bolting ChartOlarotimi OlaleyeNo ratings yet

- Stud Bolt ChartDocument2 pagesStud Bolt ChartDI DI100% (1)

- Reference For Orifice SelectionDocument1 pageReference For Orifice Selectiondeepak_313No ratings yet

- 4 12sampleDocument1 page4 12sampleSilvia MassottoNo ratings yet

- CU AL Ampacity Chart FinalDocument1 pageCU AL Ampacity Chart FinalRobertoHerediaJacoboNo ratings yet

- Temporary Cone & Basket Strainers: 2089 Ninth Avenue, New York 11779Document1 pageTemporary Cone & Basket Strainers: 2089 Ninth Avenue, New York 11779Anonymous FH8OunZrXNo ratings yet

- Roller Hanger: Material: Service: How To Size: OrderingDocument1 pageRoller Hanger: Material: Service: How To Size: OrderingAsif HaqNo ratings yet

- Ficha Tecnica EsparragosDocument2 pagesFicha Tecnica EsparragosYahayra PadillaNo ratings yet

- Bleed RingDocument3 pagesBleed RingXxavierNo ratings yet

- Standard Stud SizeDocument4 pagesStandard Stud Sizeranjith_p7No ratings yet

- Flange Data: Bolt Reference Charts For ASME B16.5 FlangesDocument4 pagesFlange Data: Bolt Reference Charts For ASME B16.5 FlangesMilena Lemus FonsecaNo ratings yet

- Container Quantities: All Standard Bolts Except Lag ScrewsDocument1 pageContainer Quantities: All Standard Bolts Except Lag ScrewsDarwin LimNo ratings yet

- 10.flange Bolts, STD TeesDocument7 pages10.flange Bolts, STD TeesNIRMAL SINGHNo ratings yet

- Instruction Manual: E48W13A-AUDocument2 pagesInstruction Manual: E48W13A-AUDanilo100% (1)

- Ved Vyas FinalDocument20 pagesVed Vyas FinalSunandaNo ratings yet

- Feel The Difference Owner'S Handbook: FordrangerDocument156 pagesFeel The Difference Owner'S Handbook: FordrangerGammy ZhammyNo ratings yet

- Indoor Breaktimes ArgumentDocument2 pagesIndoor Breaktimes ArgumentPrasojo MpjNo ratings yet

- d000523 Doseuse RemplisseuseDocument2 pagesd000523 Doseuse RemplisseuseEnzo QuatremareNo ratings yet

- Christina H. Parks: Magna Cum Laude, Chemistry HonorsDocument2 pagesChristina H. Parks: Magna Cum Laude, Chemistry HonorsTim BrownNo ratings yet

- Text WinnicottDocument44 pagesText WinnicottCharlotte Betti100% (1)

- What Are Alfalfa SproutsDocument4 pagesWhat Are Alfalfa SproutsPaul SagunNo ratings yet

- Repair Processes of Experimental Root Fractures in Rat Molars Examined by Histopathological Techniques and 3D Micro-CT ImagingDocument8 pagesRepair Processes of Experimental Root Fractures in Rat Molars Examined by Histopathological Techniques and 3D Micro-CT ImagingAhmad Ulil AlbabNo ratings yet

- Planning Considerations For Ice PlantsDocument5 pagesPlanning Considerations For Ice PlantsribozymesNo ratings yet

- Final ReportDocument8 pagesFinal ReportZack GroothouseNo ratings yet

- AEG JSA 107 Angle GrinderDocument3 pagesAEG JSA 107 Angle GrinderSai PrasathNo ratings yet

- ClauseDocument25 pagesClauseHanida Rahmah TaminNo ratings yet

- Compact Ct-Based Explosives Detection: Technical InformationDocument2 pagesCompact Ct-Based Explosives Detection: Technical InformationraviNo ratings yet

- Declaration Good Health Form PDFDocument2 pagesDeclaration Good Health Form PDFMurali SiddarthNo ratings yet

- Competitors Analysis 1Document2 pagesCompetitors Analysis 1rajaroma45No ratings yet

- The Nature of DreamsDocument2 pagesThe Nature of DreamsWesternLNo ratings yet

- Desain Pengembangan Karir FTDocument39 pagesDesain Pengembangan Karir FTasma hayatiNo ratings yet

- TVA Interview Chatral RinpocheDocument2 pagesTVA Interview Chatral RinpocheDzogJomoNo ratings yet

- Orif ReportDocument5 pagesOrif ReportduypalaNo ratings yet

- 38 Fault Codes Tachograph MID 220Document34 pages38 Fault Codes Tachograph MID 220Lazuardhitya oktananda100% (1)

- Igneous RocksDocument7 pagesIgneous RocksHamzaBaigNo ratings yet

- Death Valley NP Historic Resource Study of Mining Vols 1 and 2Document982 pagesDeath Valley NP Historic Resource Study of Mining Vols 1 and 2Russell HartillNo ratings yet

- Hazard Assessment Report Legaspi AlbayDocument7 pagesHazard Assessment Report Legaspi AlbayJosh 施志勇 HarderNo ratings yet

- PRC Ready ReckonerDocument2 pagesPRC Ready Reckonersparthan300No ratings yet

- May 2014Document48 pagesMay 2014debtwiggNo ratings yet

- Egg Cookery PowerpointDocument43 pagesEgg Cookery PowerpointBossy Thing'sNo ratings yet