Professional Documents

Culture Documents

We Create Chemistry For A Sustainable Future

We Create Chemistry For A Sustainable Future

Uploaded by

Stephan NiedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

We Create Chemistry For A Sustainable Future

We Create Chemistry For A Sustainable Future

Uploaded by

Stephan NiedCopyright:

Available Formats

We create chemistry

for a sustainable future

Stephan Nied, BASF SE, Germany

WETEX 2017 Dubai, October 23-25, 2017

Our purpose

We create chemistry for a sustainable future

This means that we contribute to a world that provides a viable future with

enhanced quality of life for everyone. We do so by creating chemistry for our

customers and society and by making the best use of available resources.

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 2

Water Resource

Megatrends And Water Availability

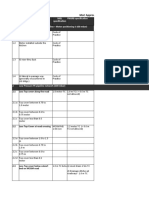

Water Supply & Demand Balance 2030

~10bn 70% Km³, based on 154 basins/regions

… people by 2050 … of the world population

will live in cities by 2050

50% 30%

… more primary energy … more food needed

consumption by 2050 by 2050

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 3

We create chemistry for a sustainable

future

At BASF, we are addressing the need for innovative

desalination with sustainable solutions

Superior foam Multifunctional Advanced scale Advanced scale

control in thermal reverse osmosis control by wetting control by Real-

desalination plants antiscalants for agent for time monitoring of

water reuse and thermal MED antiscalant

RO desalination desalination concentration

Sokalan® AF-X Sokalan® RO 3500 Bascal® HP 100 Bascal® e-DC

Latest product innovations from BASF

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 4

Reverse Osmosis as a solution to reuse

wastewater and minimize water scarcity

“The success of a reverse osmosis system depends upon membrane life

and performance which is directly impacted by the efficiency of the

applied antiscalant.”

Sujandi – Application scientist BASF Water Chemicals

Sokalan® RO 3500, as multifunctional antiscalant for reverse osmosis (RO) membrane

treatment keeps the membrane surface free from any scale deposition and helps to

maximize production capacity while enhancing the energy footprint of the RO plant.

Modified polycarboxylate Outstanding scale-inhibiting

Very low phosphorous performance allowing high recovery

rates

No eutrophication of waterbodies

Excellent prevention against iron fouling

NSF/ANSI 60 Standard certified

Effective for high pH and high recovery

Ideal for water reuse applications RO operation for Boron removal in

Reduced dosage rate and higher SWRO

output

A multifunctional antiscalant to handle multiple scale potentials

AQUATECH 2017 - Amsterdam 5

Sokalan® RO sustainability performance

Phosphorus comparison of Sokalan® RO with market standard products

Value at 5 ppm dose rate and 75% recovery

Durability

Phosphonates Sokalan® RO 100 Sokalan® RO 3500 Sokalan® RO 400

e.g. ATMP 33%

Water

~ 1,5 mg P/L ~ 0,2 mg P/L < 0,005 mg P/L* 0 mg P/L

Costs Savings

high low very low

phosphorus phosphorus phosphorus no phosphorus

content content content content

Resource

ATMP = Amino tri (methylene phosphonic acid) *calculated, below detection limit Efficiency

Sokalan® RO antiscalants show a superior performance compared to phosphonate-based

WETEX 2017 – Water, Energy, Technology and Environment Exhibition

Innovative antifoam for sustainable

operation of thermal desalination plants

“Current state of the art foam control agents are not soluble in water

and thus require continuous stirring during dissolution to avoid phase

separation. In contrast, Sokalan® AF-X is the first fully water soluble and

readily biodegradable antifoam; setting a new market standard.”

Stephan Nied – Application scientist BASF Water Chemicals

Uncontrolled foaming in thermal desalination plants can lead to an increase of salt-

contaminated distillate and therefore a decrease in the operational efficiency.

Sokala® AF-X, is a readily biodegradable, cost effective and universal foam control

agent working in MSF and MED desalination plants.

Readily biodegradable (OECD 301b) No agitation needed to prepare

Fully soluble in water dose solution

Free of solvents and hydrocarbons Very low dose rate

Foam prevention and control in thermal desalination Sokalan® AF-X

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 7

Sokalan® AF-X from BASF

Highly Water Soluble Biodegradable Antifoam

Solubility in water: Sokalan® AF-X vs. Conventional Antifoam

Sokalan®AF-X Conventional Antifoam

in water (2% w/w) in water (2% w/w)

Clear stable solution Phase separation / undisolved

droplets

Homogenous dosing

Risk of inhomogenous dosing

Does not require

continues agitation Requires continues agitation

Sokalan® AF-X offers following benefits:

Excellent foam control performance for Pure organic anti-foam

MSF & MED desalination plants Solvent-free formulation

Easy preparation and application Readily Biodegradable

Complete solubility in water: Compatible with known Antiscalant

No agitation required chemistries

Reduced CapEx and OpEx Certified by Kiwa®

Sokalan® AF-X – our next generation antifoam for thermal desalination!

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 8

Advanced scale control by wetting agent

for thermal MED desalination

“The wetting agent offers the possibility to design and operate future MED plants

at reduced wetting rates without the risk of surface dryout and of severe scale

formation. Thus, better heat transfer and thermal performance as well as reduced

electrical energy consumption may be achieved.

Dr. Heike Glade – Senior Researcher - University of Bremen

The dosage of Bascal® HP 100 affects the seawater film flow characteristics to prevent

film breakdown in the events of liquid maldistribution and the declining liquid flow rate.

Eco-friendly product and safe to handle Inhibit the prevention of scale formation on

tube surface

Ensure complete tube wetting over a wide

range of MED plant operation conditions Improve heat transfer and thermal

performance

More flexibility in design of future MED plants

higher throughput of existing plant

Helps horizontal evaporators to fulfill the

Zero-Liquid-Discharge requirements Minimize down-time for cleaning

higher plant availability

Ensures best operation of a MED seawater desalination plants

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 9

Bascal® HP 100

Combined use of wetting agent and antiscalant

Without additive Antiscalant (1.5 ppm) Antiscalant (2.5 ppm) Antiscalant (1.5 ppm) +

wetting agent (1.0 ppm)

Al brass, tV = 70°C, tH = 65°C, S = 65 g/kg, Γ = 0,015 kg/(s m), τ = 50 h

Combination of antiscalant and wetting agent most effective solution even at

critical process conditions

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 10

Summary

BASF offers innovative chemistry solutions for desalinations

Superior foam Multifunctional Advanced scale

control in thermal reverse osmosis control by wetting

desalination plants antiscalants for agent for

water reuse and thermal MED

RO desalination desalination

Sokalan® AF-X Sokalan® RO 3500 Bascal® HP 100

We create chemistry for a sustainable future

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 11

Follow us: Focus Topics in October are

Sokalan® AF-X and Thermal Desalination

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 12

Meet our water experts in Amsterdam

WETEX 2017 – Water, Energy, Technology and Environment Exhibition 13

14

You might also like

- BMP LLC Marine Survey - Cargo Container Damage Survey ReportDocument4 pagesBMP LLC Marine Survey - Cargo Container Damage Survey ReportCharity Gibson100% (2)

- Proposal On Construction and Installation of Water Treatment PlantDocument6 pagesProposal On Construction and Installation of Water Treatment PlantDolce Ncube100% (1)

- Water Treatment Solutions For Municipalities and Drinking-Water PlantsDocument8 pagesWater Treatment Solutions For Municipalities and Drinking-Water PlantsbimbremboNo ratings yet

- Product Brochure With Industrial ApplicationDocument9 pagesProduct Brochure With Industrial Applicationanon_159986285No ratings yet

- Nanotechnology For Water TreatmentDocument19 pagesNanotechnology For Water TreatmentCHIEF VISHAAL 45100% (1)

- C18-Andrew LiewDocument24 pagesC18-Andrew LiewCheong Wen YuanNo ratings yet

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- AFM Application in - Marine Mammal & Bird Systems - FinalDocument12 pagesAFM Application in - Marine Mammal & Bird Systems - Finalsergio.huete.hernandezNo ratings yet

- Reverse Osmosis Membrane AntiscalantDocument2 pagesReverse Osmosis Membrane AntiscalantsinughoshNo ratings yet

- Aqua Reslin SuperDocument4 pagesAqua Reslin SuperSyed Sajid KamalNo ratings yet

- Optimizing The Industrial Wastewater TreatmentDocument53 pagesOptimizing The Industrial Wastewater TreatmentOscar MezaNo ratings yet

- COD Reduction Through NFDocument4 pagesCOD Reduction Through NFPraveen KhatriNo ratings yet

- 15 IMPROVING PRODUCTIVITY IN SHRIMP FARMING TOWARDS INTENSIVE FARMING Didier LeclerrqDocument30 pages15 IMPROVING PRODUCTIVITY IN SHRIMP FARMING TOWARDS INTENSIVE FARMING Didier LeclerrqVũ TrựcNo ratings yet

- Membrane ProcessesDocument18 pagesMembrane Processestatchanok1525No ratings yet

- Water Stills Brochure GFLDocument19 pagesWater Stills Brochure GFLCorina StanculescuNo ratings yet

- Water Stills Brochure GFL PDFDocument19 pagesWater Stills Brochure GFL PDFCorina StanculescuNo ratings yet

- Ahlstrom Disruptor Sell SheetDocument2 pagesAhlstrom Disruptor Sell SheetJayan PrajapatiNo ratings yet

- Hydrogen Peroxide Application To A CommeDocument7 pagesHydrogen Peroxide Application To A CommeJuan José Bonilla ReinosoNo ratings yet

- Kurita Water Treatment Chemicals-ChemicalsDocument1 pageKurita Water Treatment Chemicals-Chemicalss.lakeb19No ratings yet

- Brochure AFM NG - ENDocument4 pagesBrochure AFM NG - ENMehdi AcilNo ratings yet

- Brochure DE NORA TETRA ABF 650 0316Document4 pagesBrochure DE NORA TETRA ABF 650 0316Khang TrầnNo ratings yet

- For Cs PDFDocument16 pagesFor Cs PDFmoon338No ratings yet

- Membrane Processes: Reverse Osmosis Ultrafiltration MicrofiltrationDocument18 pagesMembrane Processes: Reverse Osmosis Ultrafiltration MicrofiltrationssgentisNo ratings yet

- REDO - Product Information 05.05-Engl PDFDocument22 pagesREDO - Product Information 05.05-Engl PDFAlberto DiazNo ratings yet

- Innovative Food Science and Emerging TechnologiesDocument9 pagesInnovative Food Science and Emerging TechnologiesWaheed ZebNo ratings yet

- Membrane SeparationDocument18 pagesMembrane SeparationIteoluwakiishi AberuagbaNo ratings yet

- Groundwater Treatment by Reverse Osmosis 2007 Belkacem Desalination 206Document8 pagesGroundwater Treatment by Reverse Osmosis 2007 Belkacem Desalination 206Ayyaz ButtNo ratings yet

- Global Oilfield Solutions: Performance Chemicals For ProductionDocument6 pagesGlobal Oilfield Solutions: Performance Chemicals For ProductionLê CôngNo ratings yet

- Arkema MP Water Market PresentationDocument25 pagesArkema MP Water Market Presentationj4leschelNo ratings yet

- PET Recycle Case StudyDocument5 pagesPET Recycle Case StudyIndustria ProyectosNo ratings yet

- Aquaculture Industry: Creating Water SolutionsDocument6 pagesAquaculture Industry: Creating Water SolutionsQuân Nguyễn ĐứcNo ratings yet

- Tackling Difficult Effluent - A GuideDocument3 pagesTackling Difficult Effluent - A GuideSam MurrayNo ratings yet

- FAQs LEVAPORDocument16 pagesFAQs LEVAPORAmit ChristianNo ratings yet

- TSB110Document7 pagesTSB110touseefdada241No ratings yet

- Nanotechnology For Water Treatment: K.M.Hundekar 1SI10HCE07Document20 pagesNanotechnology For Water Treatment: K.M.Hundekar 1SI10HCE07CHIEF VISHAAL 45No ratings yet

- Invent Hyperclassic Mixer Evo 7Document16 pagesInvent Hyperclassic Mixer Evo 7Cristhian Carranza CortesNo ratings yet

- Nalco PermaTreat PC-191: RO Membrane AntiscalantDocument2 pagesNalco PermaTreat PC-191: RO Membrane AntiscalantChemEqual100% (2)

- Imp Distillery Industry Wastewater TreatmentDocument21 pagesImp Distillery Industry Wastewater Treatmentteddybir100% (1)

- Ijpab 2017 5 2 379 386Document8 pagesIjpab 2017 5 2 379 386Harsha Vardhan ReddyNo ratings yet

- Improvements in Spiral Wound RO and NF Membrane & Element Construction For High Fouling Feed Water ApplicationsDocument8 pagesImprovements in Spiral Wound RO and NF Membrane & Element Construction For High Fouling Feed Water Applicationszerocool86No ratings yet

- Oasis Literature (New)Document5 pagesOasis Literature (New)Sherif Sabri SobhyNo ratings yet

- Survey of Materials and Technologies Developed byDocument18 pagesSurvey of Materials and Technologies Developed bySredha BabyNo ratings yet

- Membrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationDocument66 pagesMembrane Technology: Reverse Osmosis Ultrafiltration MicrofiltrationShivani MunishwarNo ratings yet

- Clean Ganga ProjectDocument15 pagesClean Ganga ProjectRahul Ravi Singh100% (1)

- Desalination by Forward Osmosis Paper Presented at Amta 2007Document10 pagesDesalination by Forward Osmosis Paper Presented at Amta 2007sop sopNo ratings yet

- Report of Ro For DesalinationDocument25 pagesReport of Ro For DesalinationDeep ShahNo ratings yet

- Aluminium ChlorohydrateDocument2 pagesAluminium ChlorohydrateAnandNo ratings yet

- Levapor Presentation ChinaDocument21 pagesLevapor Presentation ChinaAmit ChristianNo ratings yet

- CpataDocument2 pagesCpataidanfriNo ratings yet

- IX News: Water Demineralisation. Ion Exchange and Reverse Osmosis: Competitors or Associates ?Document8 pagesIX News: Water Demineralisation. Ion Exchange and Reverse Osmosis: Competitors or Associates ?nermeen ahmed100% (1)

- Sintex - STP FullDocument25 pagesSintex - STP FullPooja Kamal GargNo ratings yet

- Chemical Engineering JournalDocument11 pagesChemical Engineering JournalAgrimart IndonesiaNo ratings yet

- Genesys - Application GuideDocument2 pagesGenesys - Application GuideNetFriendNo ratings yet

- Biocides For Disinfection and Storage of Hydranautics Membrane ElementsDocument6 pagesBiocides For Disinfection and Storage of Hydranautics Membrane Elementstata_77No ratings yet

- EL-1200 BrochureDocument8 pagesEL-1200 BrochureRawaz MstafaNo ratings yet

- Statiflo Brochure - EN-USADocument12 pagesStatiflo Brochure - EN-USARyan DuhonNo ratings yet

- Reverse OsmosisDocument37 pagesReverse OsmosislightsonsNo ratings yet

- Why Is Post Treatment Necessary in Commercial RO PlantsDocument5 pagesWhy Is Post Treatment Necessary in Commercial RO PlantsbhardwajmayankNo ratings yet

- Hydranautics TSB110 LDocument7 pagesHydranautics TSB110 Ldpahomi1No ratings yet

- Biopak Filter MilliporeDocument4 pagesBiopak Filter Milliporef148355 Hassan Tariq MajeedNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Report On Salia Sahi Slum Study: Sustainability Marketing ProjectDocument10 pagesReport On Salia Sahi Slum Study: Sustainability Marketing ProjectVino100% (1)

- Horizontal Wells: Technology Overview ReportDocument17 pagesHorizontal Wells: Technology Overview Reportmohammad teimuriNo ratings yet

- Self Cleaning Hydro ScreensDocument4 pagesSelf Cleaning Hydro ScreenssavuNo ratings yet

- Mid Term Test 1Document4 pagesMid Term Test 1Hanh An Nguyen HoangNo ratings yet

- 26 Hydrology2Document7 pages26 Hydrology2himanshiNo ratings yet

- Activity 10 Quality Assessment of Drinking Water Through Coliform IsolationDocument2 pagesActivity 10 Quality Assessment of Drinking Water Through Coliform IsolationAloha Mae SarabiaNo ratings yet

- Els 2ND QTR ExamDocument2 pagesEls 2ND QTR ExamMary Jane Tamondong BaniquedNo ratings yet

- MOC Approval Matrix (Revised)Document14 pagesMOC Approval Matrix (Revised)Omkar JadhavNo ratings yet

- Manual Autotrol Performa 263-268 Logix740-760 enDocument78 pagesManual Autotrol Performa 263-268 Logix740-760 enJuan Pablo Arango SolanoNo ratings yet

- Republic of The Philippines Municipality of DiffunDocument3 pagesRepublic of The Philippines Municipality of DiffunKrisna Criselda SimbreNo ratings yet

- P1, P2 Pile Cap Construction MethodDocument42 pagesP1, P2 Pile Cap Construction MethodtomahNo ratings yet

- Environmental Law Final ProjectDocument30 pagesEnvironmental Law Final Projectpraharshitha100% (1)

- Charbel NahasDocument64 pagesCharbel NahasmoudshahineNo ratings yet

- 9-3-19 - A Case Study of Impacts of Flooding in Espana Boulevard, Sampaloc District City of ManilaDocument75 pages9-3-19 - A Case Study of Impacts of Flooding in Espana Boulevard, Sampaloc District City of ManilaPercibal felicesNo ratings yet

- Marine Biology Unit-4 LectureDocument10 pagesMarine Biology Unit-4 LectureYashNo ratings yet

- Reading SkillsDocument1 pageReading SkillsHhffcjfc UyftylNo ratings yet

- Navarrete Et Al 9marzoDocument47 pagesNavarrete Et Al 9marzoMario PrinceNo ratings yet

- Midea Mdf3 20den3Document14 pagesMidea Mdf3 20den3Vladimir StakićNo ratings yet

- Available MN in Salt Affected Soils: ArticleDocument7 pagesAvailable MN in Salt Affected Soils: ArticleMahidul IslamNo ratings yet

- 2020 California Checklist Rev 1Document11 pages2020 California Checklist Rev 1DeepakpanarkandyNo ratings yet

- Chap 4Document50 pagesChap 4Ziyad Qazi 104-FET/BSCCET/F20No ratings yet

- Chapter-5 Geography Natural Vegetation and Wildlife: ReliefDocument2 pagesChapter-5 Geography Natural Vegetation and Wildlife: ReliefMANUKONDA RAJUNo ratings yet

- HepworthDocument147 pagesHepworthldbautista2005No ratings yet

- Estericlean Agroalimentaria Registro NSFDocument1 pageEstericlean Agroalimentaria Registro NSFwilber jovany monzon uriasNo ratings yet

- Internal Cleaness ProcedureDocument26 pagesInternal Cleaness Procedureqamar qateebNo ratings yet

- Concrete Pipe Sewerlines by Negative Air Pressure (Vacuum) Test Method (Metric)Document3 pagesConcrete Pipe Sewerlines by Negative Air Pressure (Vacuum) Test Method (Metric)Bianca GuevarraNo ratings yet

- Private Housing Project Land Development Rule'2004Document23 pagesPrivate Housing Project Land Development Rule'2004Sheikh Ahnaf HasanNo ratings yet

- FC PWPDocument1 pageFC PWPkueensy martirNo ratings yet

- BS 7874Document11 pagesBS 7874Fenner ElectromechanicalNo ratings yet