Professional Documents

Culture Documents

Welding Procedure Specification

Welding Procedure Specification

Uploaded by

Godwin A.udo-akanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification

Welding Procedure Specification

Uploaded by

Godwin A.udo-akanCopyright:

Available Formats

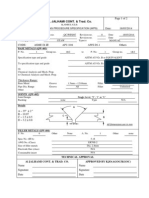

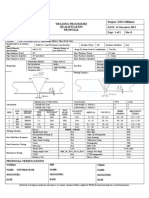

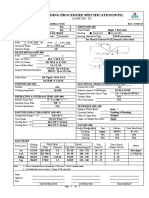

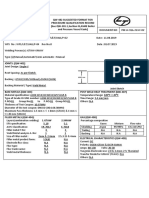

Welding Procedure Specification- WPS NO.

NWA/PHC/TSCH/0001

Weld Procedure Number NWA/PHC/TSCH/0001

Qualifying Welding Procedure (WPAR) WPAR/PHC/TSCH/0001

Establishment:

Nigerian Welders Method Of Preparation

Association. Port and Cleaning: Machine and Degrease

harcourt. Parent Metal Specification: Grade 304L Stainless

Steel

Parent Metal Thickness 3 to 12mm

Wall Pipe Outside Diameter 25 to 100mm

Location: Workshop

Welding Process: Manual TIG Welding Position: All Positions

Joint Type: Single Sided Butt Weld Welding Progression: Upwards

Joint Design Welding Sequences

70

1-2mm

1-2mm 1G

3-12mm

45

1F

Size Of Current Voltage Type Of Wire Feed Travel

Run Process Heat Input

Filler Metal A V Current/Polarity Speed Speed

1 TIG 1.2mm 70 - 90 DC-

N/A N/A N/A N/A

2 And Subs TIG 1.6mm 80 - 140 DC-

Welding Consumables:- Production Sequence

Type, Designation Trade Name: BS 2901 Part 2 : 308S92

Any Special Baking or Drying: No 1. Clean weld and 25mm borders to

bright metal using approved solvent.

Gas Flux: Argon 99.99% Purity

Gas Flow Rate - Shield: 8 - 12 LPM 2. Position items to be welded ensuring

- Backing: 5 LPM good fit up and apply purge

3. Tack weld parts together using TIG,

Tungsten Electrode Type/ Size: 2% Thoriated 2.4mm Dia tacks to at least 5mm min length

Details of Back Gouging/Backing: Gas Backing

Preheat Temperature: 5°C Min 4. Deposit root run using 1.2mm dia.

Interpass temperature: 200°C Max wire.

5. Inspect root run internally

Post Weld Heat Treatment Not Required

Time, temperature, method: 6. Complete weld using 1.6mm dia wire

Heating and Cooling Rates*: using stringer beads as required.

7. 100% Visual inspection of completed

weld

Revision History

Date Issue Changes Authorization

26/11/2000 A First Issue Jack Straw Jack Straw

You might also like

- TMX SupremoDocument90 pagesTMX Supremomotorcentral balayan78% (23)

- Annex A - NON CONFORMITY RESOLUTION REPORT-BridsiteDocument8 pagesAnnex A - NON CONFORMITY RESOLUTION REPORT-BridsiteGodwin A.udo-akanNo ratings yet

- Epcm Insulation Project Execution PlanDocument41 pagesEpcm Insulation Project Execution PlanGodwin A.udo-akan100% (2)

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS GF170 As 1554.6Document1 pageWPS GF170 As 1554.6Syed Mahmud Habibur Rahman100% (1)

- WPS Sitelca S002Document2 pagesWPS Sitelca S002Jose Antonio GomezNo ratings yet

- Welding Procedure SpecificationsDocument2 pagesWelding Procedure SpecificationsGerhard Kemp0% (1)

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- PQR Asme Template EDITABLEDocument6 pagesPQR Asme Template EDITABLErcpretoriusNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Proposed Welding Procedure Specification (PWPS) : REV:A3Document1 pageProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakNo ratings yet

- Welding Specification ChartDocument189 pagesWelding Specification ChartVivek SatapathyNo ratings yet

- Asme WPS Demo PWHT PDFDocument3 pagesAsme WPS Demo PWHT PDFGanesh rohitNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- 1662 15Document117 pages1662 15RajamanikkamNo ratings yet

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- Preliminary Welding Procedure Specification Pwps PDF FreeDocument1 pagePreliminary Welding Procedure Specification Pwps PDF FreeFirozNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- PWPS WPS CAP 039 PQR 035Document15 pagesPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRNo ratings yet

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- PQRDocument3 pagesPQRnazirulhakimNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- Limak - Sawaed WpsDocument1 pageLimak - Sawaed WpsAlam MD SazidNo ratings yet

- WPS-Nozzle With Reinforcement Pad (CS-CS) .Document1 pageWPS-Nozzle With Reinforcement Pad (CS-CS) .suria qaqcNo ratings yet

- WPS-PQR - PipingDocument14 pagesWPS-PQR - PipingCharwin PicaoNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 pageWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Welding Procedure Specification (WPS)Document1 pageWelding Procedure Specification (WPS)Daniel ChewNo ratings yet

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan Ahmed100% (1)

- QC - Consumables Colour Coding and IdentificationDocument3 pagesQC - Consumables Colour Coding and IdentificationfizanlaminNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- WPS List For Piping: (Asme Section Ix)Document2 pagesWPS List For Piping: (Asme Section Ix)Ali MoosaviNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Welder IdentificationDocument9 pagesWelder Identificationdandiar1No ratings yet

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedNo ratings yet

- Welding Procedure Specification: Wps NoDocument1 pageWelding Procedure Specification: Wps NoLipika Gayen100% (1)

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Document2 pagesLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidNo ratings yet

- APSM WPS 008R Rev. 0Document3 pagesAPSM WPS 008R Rev. 0Amir NorNo ratings yet

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Welding Procedure Specification ExampleDocument2 pagesWelding Procedure Specification ExampleShajahan ShagulNo ratings yet

- Toaz - Info Welding Procedure Specification Sample PRDocument2 pagesToaz - Info Welding Procedure Specification Sample PRKarim ZahranNo ratings yet

- Welding Procedure Specifications-BsenDocument2 pagesWelding Procedure Specifications-BsenAbraham AbyNo ratings yet

- Quality Awareness TBT Presentation - 20032024Document9 pagesQuality Awareness TBT Presentation - 20032024Godwin A.udo-akanNo ratings yet

- 2 Alpha and GodmanDocument1 page2 Alpha and GodmanGodwin A.udo-akanNo ratings yet

- Eptech Answers Additional Questions Regarding Field Trials 12 11 2020 (262425)Document6 pagesEptech Answers Additional Questions Regarding Field Trials 12 11 2020 (262425)Godwin A.udo-akanNo ratings yet

- Acme Corporation Strategic Plan 2014-2016Document1 pageAcme Corporation Strategic Plan 2014-2016Godwin A.udo-akanNo ratings yet

- 3.8 - List of Procurement ExperienceDocument3 pages3.8 - List of Procurement ExperienceGodwin A.udo-akanNo ratings yet

- New Vendor Information FormDocument1 pageNew Vendor Information FormGodwin A.udo-akanNo ratings yet

- 0.1 - Table of ContentsDocument4 pages0.1 - Table of ContentsGodwin A.udo-akanNo ratings yet

- 3.3 - List of Equipment ListDocument8 pages3.3 - List of Equipment ListGodwin A.udo-akanNo ratings yet

- 1.0 - Form of TenderDocument3 pages1.0 - Form of TenderGodwin A.udo-akanNo ratings yet

- Accident Incident Investigation Form NewDocument2 pagesAccident Incident Investigation Form NewGodwin A.udo-akanNo ratings yet

- Fortune Energy Internal ScheduleDocument1 pageFortune Energy Internal ScheduleGodwin A.udo-akanNo ratings yet

- Rev.1 CIVIL SITE PREPARATION WORKS FOR TURN AROUND MAINT. of THE OIL SECTION OF OBOB GAS PLANTDocument1 pageRev.1 CIVIL SITE PREPARATION WORKS FOR TURN AROUND MAINT. of THE OIL SECTION OF OBOB GAS PLANTGodwin A.udo-akanNo ratings yet

- Rev 00 - NLNG Project Execution Plan - Minor Electrical WorksDocument35 pagesRev 00 - NLNG Project Execution Plan - Minor Electrical WorksGodwin A.udo-akanNo ratings yet

- ITT Document - B210081TPI - Minor Electrical Works and Related Services (Call-Off)Document67 pagesITT Document - B210081TPI - Minor Electrical Works and Related Services (Call-Off)Godwin A.udo-akanNo ratings yet

- Technical Data Sheet - Glasswool SPIDocument2 pagesTechnical Data Sheet - Glasswool SPIGodwin A.udo-akanNo ratings yet

- S/N Mandatory Requirements Bridgsite Response A Mandatory RequirementsDocument2 pagesS/N Mandatory Requirements Bridgsite Response A Mandatory RequirementsGodwin A.udo-akanNo ratings yet

- Bladder AccumulatorsDocument7 pagesBladder AccumulatorsMaciej KostenckiNo ratings yet

- TEST 1 - Answer Scheme - Complete GeotechDocument10 pagesTEST 1 - Answer Scheme - Complete Geotechfaraeiin57No ratings yet

- Kelas 7 SOAL ASESMEN AKHIR SEMESTER 1Document6 pagesKelas 7 SOAL ASESMEN AKHIR SEMESTER 1binta azkiyaNo ratings yet

- Astm A961-21Document9 pagesAstm A961-21bdr85100% (1)

- Limbo Analysis by Edward KamauDocument5 pagesLimbo Analysis by Edward KamauVincent Tan Ying Zheng100% (5)

- Community Technology Development Trust: Our VisionDocument2 pagesCommunity Technology Development Trust: Our VisiondanielNo ratings yet

- Prim Maths 6 2ed TR Unit 11 TestDocument3 pagesPrim Maths 6 2ed TR Unit 11 TestKabagambe HamimNo ratings yet

- 2013 A Simple Carrier-Based Modulation For The SVM of The Matrix ConverterDocument10 pages2013 A Simple Carrier-Based Modulation For The SVM of The Matrix ConverterTran Quoc HoanNo ratings yet

- Cdin-5-Reviewer 3Document19 pagesCdin-5-Reviewer 3shaina mae mojicaNo ratings yet

- Data Sheets: For Hfc/Hfo/Hcfc Refrigerants Standard and Ecoinside SeriesDocument3 pagesData Sheets: For Hfc/Hfo/Hcfc Refrigerants Standard and Ecoinside Seriessilverblade123192No ratings yet

- Product Data Sheet: Tesys Vario - Emergency Stop Switch Disconnector - 63 A - On DoorDocument3 pagesProduct Data Sheet: Tesys Vario - Emergency Stop Switch Disconnector - 63 A - On DoorBNCHNo ratings yet

- SMD 357Document6 pagesSMD 357Marcoantonio AntonioNo ratings yet

- German AssignmentDocument6 pagesGerman AssignmentArna BiswasNo ratings yet

- Relay OmronDocument2 pagesRelay Omronmuhammad fajri JuliansyahNo ratings yet

- Organic Farming and Medicinal PlantDocument43 pagesOrganic Farming and Medicinal PlantAbraham100% (4)

- B S T Year 5Document9 pagesB S T Year 5INCREASE & ABUNDANT SCHOOLSNo ratings yet

- Hydraulic Conductivity Empirical FormulaeDocument7 pagesHydraulic Conductivity Empirical FormulaeFaizan AnwarNo ratings yet

- JOB GMBH - Thermo BulbsDocument6 pagesJOB GMBH - Thermo BulbsFrancoisNo ratings yet

- Manual For StreetsDocument108 pagesManual For StreetstachmidNo ratings yet

- Wijs-Cyclohexane MethodDocument4 pagesWijs-Cyclohexane Methodnuur iffahNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/22Document12 pagesCambridge IGCSE: MATHEMATICS 0580/22radima ArbievaNo ratings yet

- Syringe PumpDocument84 pagesSyringe PumpAlia Popa100% (1)

- Getting Started Guide: Model Predictive Control Toolbox™Document174 pagesGetting Started Guide: Model Predictive Control Toolbox™porco gesuNo ratings yet

- The Heychris DramaDocument14 pagesThe Heychris DramaAnnNo ratings yet

- SLM Q2 M2 Cookery 9 ArcisoDocument17 pagesSLM Q2 M2 Cookery 9 ArcisoShien Zan SouNo ratings yet

- Dendrocalamus Asper PDFDocument7 pagesDendrocalamus Asper PDFVictor Eduardo Barraza SalgueroNo ratings yet

- Yogesh Aghav 2Document7 pagesYogesh Aghav 2pranjalbaruah8No ratings yet

- High Displacement in Installed PipingDocument4 pagesHigh Displacement in Installed PipingSharun SureshNo ratings yet