Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

134 viewsDesign of Stair Case

Design of Stair Case

Uploaded by

pathan is khanThe document provides the steps to design a stair case with the following key details:

Step 1 provides the room dimensions and floor to floor height of 3m.

Step 2 calculates the number of risers and treads needed based on a riser height of 160mm and tread depth of 250mm.

Step 6 checks that the calculated bending moment of 12.76kN-m results in a required depth of 69.13mm which is safe.

Step 8 determines that 8mm diameter bars spaced at 200mm centers is sufficient to reinforce the waist slab based on the required steel reinforcement area of 236.49mm2.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- Ipc J-Std-030a-2014Document48 pagesIpc J-Std-030a-2014vahid hajihasaniNo ratings yet

- Allstate/McKinsey Bates H000001010Document495 pagesAllstate/McKinsey Bates H0000010104207west59th100% (3)

- Jack Well - Well FoundationDocument3 pagesJack Well - Well FoundationRamakanth PuttyNo ratings yet

- Pile Retaining Wall - With Wind..Document6 pagesPile Retaining Wall - With Wind..epe civilNo ratings yet

- All Footing DesignDocument16 pagesAll Footing Designer.praveenraj30No ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument27 pagesEngineering Calculation Sheet Consulting Engineersazhar ahmadNo ratings yet

- 4 - Hydro Jetting and Sludge RemovalDocument18 pages4 - Hydro Jetting and Sludge RemovalPerwez21100% (2)

- Design of Strip Footing at Grid C-C: U U, LimDocument3 pagesDesign of Strip Footing at Grid C-C: U U, LimSujal MaharjanNo ratings yet

- CANTILEVER SLAB DESIGN Latest CorrectedDocument6 pagesCANTILEVER SLAB DESIGN Latest CorrectedBijendra PradhanNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Combined FootingDocument4 pagesCombined FootingSakar ShresthaNo ratings yet

- Parapet CapacityDocument4 pagesParapet CapacityJemicah YumenaNo ratings yet

- Staircase ExcelDocument5 pagesStaircase ExcelvishnuNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Masonry Compound WallDocument4 pagesMasonry Compound Wallasingh4000% (1)

- Shear Wall DesignDocument9 pagesShear Wall DesignJai ThakkarNo ratings yet

- Design of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000Document4 pagesDesign of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000MaheshNo ratings yet

- Wind Load Calculation On Wall and Monoslope RoofDocument4 pagesWind Load Calculation On Wall and Monoslope RoofajatNo ratings yet

- Precast Column Design - Boundary WallDocument21 pagesPrecast Column Design - Boundary WallAnonymous cG5MyHMNo ratings yet

- Crack Width Calculation For Rectangular RC BeamDocument1 pageCrack Width Calculation For Rectangular RC BeamRomyMohanNo ratings yet

- Structure Report of Manahari GaupalikaDocument41 pagesStructure Report of Manahari GaupalikaPraveen Bhandari100% (1)

- Compound Wall DesignDocument31 pagesCompound Wall Designnikki naidu50% (2)

- Dynamic Analysis and Design of UG WATER TANK TWOWAYDocument35 pagesDynamic Analysis and Design of UG WATER TANK TWOWAYsaiNo ratings yet

- RCC Box Bridge DesignDocument20 pagesRCC Box Bridge DesignAnu PathakNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Isolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CDocument2 pagesIsolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CMark JosephNo ratings yet

- Retaining WallDocument41 pagesRetaining Wallp_ignatiusNo ratings yet

- Design of Grid Floor SlabDocument3 pagesDesign of Grid Floor SlabHarini Ramesh100% (1)

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Purlins & GirtsDocument10 pagesPurlins & GirtsRaviKiranNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Design of StaircaseDocument4 pagesDesign of StaircaseAnish NeupaneNo ratings yet

- Bouddha HotelDocument62 pagesBouddha HotelMilan KarkiNo ratings yet

- RCC - Design Excel SheetDocument10 pagesRCC - Design Excel SheetYashas KatugamNo ratings yet

- Raft Footing DesignDocument7 pagesRaft Footing DesignPrakash ShresthaNo ratings yet

- Asmita SchoolDocument19 pagesAsmita Schoolformwork companyNo ratings yet

- Junior Design Engineer: Satyavani Projects and Consultants Pvt. LTDDocument30 pagesJunior Design Engineer: Satyavani Projects and Consultants Pvt. LTDyedida viswanadhNo ratings yet

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Basement Wall DesignDocument2 pagesBasement Wall DesignArindam RoyNo ratings yet

- Boundary Wall Design - Final For RFCDocument10 pagesBoundary Wall Design - Final For RFCShubham Khare100% (1)

- Beam Design References Calculations Output 1. General DetailsDocument7 pagesBeam Design References Calculations Output 1. General Detailsswargadwari consultancyNo ratings yet

- DESIGN OF SLAB-CantileverDocument10 pagesDESIGN OF SLAB-CantilevermeenuNo ratings yet

- Water Tank (WSM) With Is 3370 Moment CoefficientDocument5 pagesWater Tank (WSM) With Is 3370 Moment Coefficientprasanth bhadranNo ratings yet

- Design of Simply Supported One Way SlabDocument15 pagesDesign of Simply Supported One Way SlabNikhil100% (2)

- Flat Slab Design:: General ParameterDocument6 pagesFlat Slab Design:: General ParameterKwan Hau LeeNo ratings yet

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- Ductile Design of Column For Multistorey Building.Document4 pagesDuctile Design of Column For Multistorey Building.NikhilNo ratings yet

- Wind Load Calculation of Gable As Per Is 875Document1 pageWind Load Calculation of Gable As Per Is 875kapil075No ratings yet

- Crack WidthDocument4 pagesCrack Widthnavneet3bawaNo ratings yet

- Shear WallDocument10 pagesShear WallStructural SpreadsheetsNo ratings yet

- Pool Calculation SheetDocument6 pagesPool Calculation SheetSuman Resolved NeupaneNo ratings yet

- Annular Raft Under 1250 Cum OHRDocument1 pageAnnular Raft Under 1250 Cum OHRanirban dasNo ratings yet

- Steel Staircase DesignDocument6 pagesSteel Staircase DesignMario FeghaliNo ratings yet

- Circular Column Design Excel SheetDocument7 pagesCircular Column Design Excel SheetDhananjay ShindeNo ratings yet

- Design of Slab - Wo Way Slab Design As Per Is - 456 - 2000Document25 pagesDesign of Slab - Wo Way Slab Design As Per Is - 456 - 2000rupesh417No ratings yet

- Design of One Way SlabDocument2 pagesDesign of One Way Slabpathan is khanNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Grid Slab WITH BBSDocument11 pagesGrid Slab WITH BBSJyoti PatilNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- Wbcviii PDFDocument1,192 pagesWbcviii PDFDaniel PinheiroNo ratings yet

- CO2 Supply Agreement - A-ZDocument13 pagesCO2 Supply Agreement - A-ZEslam A. FahmyNo ratings yet

- Marketing Plan of AirconDocument16 pagesMarketing Plan of AirconJewel Virata100% (1)

- PRELIM Fire Technology and Arson InvestigationDocument6 pagesPRELIM Fire Technology and Arson InvestigationIgnacio Burog RazonaNo ratings yet

- CV Examples Uk StudentDocument8 pagesCV Examples Uk Studente7648d37100% (1)

- Surface WarfareDocument65 pagesSurface WarfareLobbyist_Myo100% (5)

- Short Version Bio Based Building Blocks and Polymers 2018 2023Document16 pagesShort Version Bio Based Building Blocks and Polymers 2018 2023phaniraj_c100% (1)

- Portfolio AnswersDocument4 pagesPortfolio Answersa73609No ratings yet

- 001 2012 4 b-3Document114 pages001 2012 4 b-3dikahunguNo ratings yet

- AdvertisingDocument16 pagesAdvertisingSun KambojNo ratings yet

- Shah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfDocument311 pagesShah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfTri4alNo ratings yet

- Coll. v. Henderson, 1 SCRA 649Document2 pagesColl. v. Henderson, 1 SCRA 649Homer SimpsonNo ratings yet

- Pilz PNOZ Sigma PDFDocument16 pagesPilz PNOZ Sigma PDFCristopher Entena100% (1)

- MDSW TamilNadu06Document14 pagesMDSW TamilNadu06miningnova1No ratings yet

- Carbon Dioxide Portable Storage UnitsDocument2 pagesCarbon Dioxide Portable Storage UnitsDiego AnayaNo ratings yet

- Myanmar Companies Law 2017Document188 pagesMyanmar Companies Law 2017Let's Save Myanmar100% (1)

- AralPan9 q2 Mod10 Ang-Pamilihan-V5Document29 pagesAralPan9 q2 Mod10 Ang-Pamilihan-V5Wizly Von Ledesma TanduyanNo ratings yet

- Amendment of Information, Formal Vs SubstantialDocument2 pagesAmendment of Information, Formal Vs SubstantialNikkoCataquiz100% (3)

- Yoseph ShiferawDocument72 pagesYoseph Shiferawmaheder wegayehuNo ratings yet

- Training LV PanelDocument108 pagesTraining LV PanelruslanNo ratings yet

- Wireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010Document21 pagesWireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010ahmed alshamliNo ratings yet

- Niengo Outsep North Papua 5 - 06 - 07rev2Document20 pagesNiengo Outsep North Papua 5 - 06 - 07rev2Prince DenhaagNo ratings yet

- Ed 807 Economics of Education MODULE-14 Activity-AnswerDocument3 pagesEd 807 Economics of Education MODULE-14 Activity-Answerjustfer johnNo ratings yet

- KickStart 19Document2 pagesKickStart 19Venu GopalNo ratings yet

- A 200 Word Essay OnDocument9 pagesA 200 Word Essay OnANANDRAJ HARIHARANNo ratings yet

- (CHIP IC) w25x20cl - A02Document51 pages(CHIP IC) w25x20cl - A02Felipe de san anicetoNo ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet

Design of Stair Case

Design of Stair Case

Uploaded by

pathan is khan0 ratings0% found this document useful (0 votes)

134 views2 pagesThe document provides the steps to design a stair case with the following key details:

Step 1 provides the room dimensions and floor to floor height of 3m.

Step 2 calculates the number of risers and treads needed based on a riser height of 160mm and tread depth of 250mm.

Step 6 checks that the calculated bending moment of 12.76kN-m results in a required depth of 69.13mm which is safe.

Step 8 determines that 8mm diameter bars spaced at 200mm centers is sufficient to reinforce the waist slab based on the required steel reinforcement area of 236.49mm2.

Original Description:

it is design of dog legged stair case

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides the steps to design a stair case with the following key details:

Step 1 provides the room dimensions and floor to floor height of 3m.

Step 2 calculates the number of risers and treads needed based on a riser height of 160mm and tread depth of 250mm.

Step 6 checks that the calculated bending moment of 12.76kN-m results in a required depth of 69.13mm which is safe.

Step 8 determines that 8mm diameter bars spaced at 200mm centers is sufficient to reinforce the waist slab based on the required steel reinforcement area of 236.49mm2.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

134 views2 pagesDesign of Stair Case

Design of Stair Case

Uploaded by

pathan is khanThe document provides the steps to design a stair case with the following key details:

Step 1 provides the room dimensions and floor to floor height of 3m.

Step 2 calculates the number of risers and treads needed based on a riser height of 160mm and tread depth of 250mm.

Step 6 checks that the calculated bending moment of 12.76kN-m results in a required depth of 69.13mm which is safe.

Step 8 determines that 8mm diameter bars spaced at 200mm centers is sufficient to reinforce the waist slab based on the required steel reinforcement area of 236.49mm2.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 2

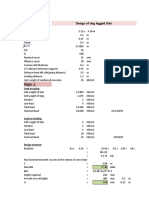

DESIGN OF STAIR CASE

Step 1 Preliminary Data

Stair case room dimensions = 3m x 4m

Floor to floor height= 3.2 m 3200 mm

Width of landing= 1m

Step 2 Riser, Tread & Span

Let Riser (R)= 160 mm

Tread (T)= 250 mm

No. of risers req= 20 no.s

No. of risers per flight= 10

No. of treads= 9

Going= 2250 mm

Width available at start of flight= 750 mm

Span (L)= 3125 mm

3.125 M

Step 3 Depth of Waist Slab

Assuming overall thickness of waist slab as D = 150 mm

Clear cover = 15 mm

Diameter of bar = 10 mm (assumed)

Therefore, Effective Depth of Slab = 130 mm

Step 4 Load Calculations

Self weight of slab = 25 x D secφ where secφ= (√R2+T2)/T

4.452247 KN/m2 secφ= 1.187266

Weight of steps= 2 KN/m 2

Floor finishes = 1 KN/m2

Total Dead Load = 7.452247 KN/m2

Live Load = 3 KN/m2 (Acc. to IS 875 - Part 2)

Total Load = 10.45225 KN/m 2

Factored Load = 15.67837 KN/m2

Step 5 Bending Moment Calculations

When stair case is supported on both ends of flight, then B.M= WLx2/12

Therefore, Bending Moment is given by M= 12.75909 KN-m

Step 6 Check for depth

d= √M/R*b

M in N.mm

R= 2.67 for M20 & Fe 500

b= 1000 mm

d= 69.12804 mm

Hence Safe

Step 7 Area of Steel Reinforcement

Ast= 0.5 x fck/fy (1- √1- 4.6 x M/fck b d2)b*d

fck = M 20

fy = Fe 500

Ast= 236.4933 mm2

Min Ast = 0.12% of gross c/s area

0.12%*b*D

Ast Min= 180 mm2 Ast Req= 236.4933 mm2

Step 8 Calculation of Spacing

Spacing S= Aφ/Ast x 1000

Assuming 8 mm φ bars, Aφ= π/4 x φ2

Aφ= 50.24 mm2

Therefore S= 212.4373 mm

Max spacing should not be greater than 3d or 300 mm which ever is less.

3d= 390 mm or 300 mm

Hence provide 8mm dia at 200 mm c/c.

Distribution Reinforcement= Ast Min.= 180 mm2

Spacing of 8 mm dia bars = 279.1111 mm

Hence provide 8mm φ @ 275 mm c/c at distribution steel.

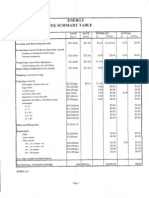

Step 9 Check for Deflection

lx/α*d <=32

α is the modification factor obtained from Fig. 4 of IS 456-2000 Pg. No. 38

Fs= 0.58*fy*Ast required/ Astprovided

Ast prov= Aφ/S provided x 1000

Ast prov= 251.2 mm2

fs= 273.0218 N/mm2 say 290 N/mm2

Percentage of reinforcement provided Pt= Ast prov/bxd *100

0.193231 say 0.2

For fs= 290 N/mm2 & Pt= 0.2

α= 1.3

Therefore, Lx/αxd 18.49112 < 32

HENCE SAFE

You might also like

- Ipc J-Std-030a-2014Document48 pagesIpc J-Std-030a-2014vahid hajihasaniNo ratings yet

- Allstate/McKinsey Bates H000001010Document495 pagesAllstate/McKinsey Bates H0000010104207west59th100% (3)

- Jack Well - Well FoundationDocument3 pagesJack Well - Well FoundationRamakanth PuttyNo ratings yet

- Pile Retaining Wall - With Wind..Document6 pagesPile Retaining Wall - With Wind..epe civilNo ratings yet

- All Footing DesignDocument16 pagesAll Footing Designer.praveenraj30No ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument27 pagesEngineering Calculation Sheet Consulting Engineersazhar ahmadNo ratings yet

- 4 - Hydro Jetting and Sludge RemovalDocument18 pages4 - Hydro Jetting and Sludge RemovalPerwez21100% (2)

- Design of Strip Footing at Grid C-C: U U, LimDocument3 pagesDesign of Strip Footing at Grid C-C: U U, LimSujal MaharjanNo ratings yet

- CANTILEVER SLAB DESIGN Latest CorrectedDocument6 pagesCANTILEVER SLAB DESIGN Latest CorrectedBijendra PradhanNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Sloped FootingDocument19 pagesSloped FootingBala ChandarNo ratings yet

- Combined FootingDocument4 pagesCombined FootingSakar ShresthaNo ratings yet

- Parapet CapacityDocument4 pagesParapet CapacityJemicah YumenaNo ratings yet

- Staircase ExcelDocument5 pagesStaircase ExcelvishnuNo ratings yet

- Reference Output Calculations & FormulasDocument4 pagesReference Output Calculations & FormulasAddrien DanielNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Masonry Compound WallDocument4 pagesMasonry Compound Wallasingh4000% (1)

- Shear Wall DesignDocument9 pagesShear Wall DesignJai ThakkarNo ratings yet

- Design of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000Document4 pagesDesign of Chajja (Sun Shade) Input:: Limit State Method Confirming To IS: 456-2000MaheshNo ratings yet

- Wind Load Calculation On Wall and Monoslope RoofDocument4 pagesWind Load Calculation On Wall and Monoslope RoofajatNo ratings yet

- Precast Column Design - Boundary WallDocument21 pagesPrecast Column Design - Boundary WallAnonymous cG5MyHMNo ratings yet

- Crack Width Calculation For Rectangular RC BeamDocument1 pageCrack Width Calculation For Rectangular RC BeamRomyMohanNo ratings yet

- Structure Report of Manahari GaupalikaDocument41 pagesStructure Report of Manahari GaupalikaPraveen Bhandari100% (1)

- Compound Wall DesignDocument31 pagesCompound Wall Designnikki naidu50% (2)

- Dynamic Analysis and Design of UG WATER TANK TWOWAYDocument35 pagesDynamic Analysis and Design of UG WATER TANK TWOWAYsaiNo ratings yet

- RCC Box Bridge DesignDocument20 pagesRCC Box Bridge DesignAnu PathakNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- Isolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CDocument2 pagesIsolated Footing: BY: Albaytar, Mark Joseph A. Billones, Joyce Anne CMark JosephNo ratings yet

- Retaining WallDocument41 pagesRetaining Wallp_ignatiusNo ratings yet

- Design of Grid Floor SlabDocument3 pagesDesign of Grid Floor SlabHarini Ramesh100% (1)

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Purlins & GirtsDocument10 pagesPurlins & GirtsRaviKiranNo ratings yet

- Composite Slab DesignDocument6 pagesComposite Slab DesignFranklyn GenoveNo ratings yet

- Design of StaircaseDocument4 pagesDesign of StaircaseAnish NeupaneNo ratings yet

- Bouddha HotelDocument62 pagesBouddha HotelMilan KarkiNo ratings yet

- RCC - Design Excel SheetDocument10 pagesRCC - Design Excel SheetYashas KatugamNo ratings yet

- Raft Footing DesignDocument7 pagesRaft Footing DesignPrakash ShresthaNo ratings yet

- Asmita SchoolDocument19 pagesAsmita Schoolformwork companyNo ratings yet

- Junior Design Engineer: Satyavani Projects and Consultants Pvt. LTDDocument30 pagesJunior Design Engineer: Satyavani Projects and Consultants Pvt. LTDyedida viswanadhNo ratings yet

- DEEP BEAM DesignDocument2 pagesDEEP BEAM DesignmangeshNo ratings yet

- Basement Wall DesignDocument2 pagesBasement Wall DesignArindam RoyNo ratings yet

- Boundary Wall Design - Final For RFCDocument10 pagesBoundary Wall Design - Final For RFCShubham Khare100% (1)

- Beam Design References Calculations Output 1. General DetailsDocument7 pagesBeam Design References Calculations Output 1. General Detailsswargadwari consultancyNo ratings yet

- DESIGN OF SLAB-CantileverDocument10 pagesDESIGN OF SLAB-CantilevermeenuNo ratings yet

- Water Tank (WSM) With Is 3370 Moment CoefficientDocument5 pagesWater Tank (WSM) With Is 3370 Moment Coefficientprasanth bhadranNo ratings yet

- Design of Simply Supported One Way SlabDocument15 pagesDesign of Simply Supported One Way SlabNikhil100% (2)

- Flat Slab Design:: General ParameterDocument6 pagesFlat Slab Design:: General ParameterKwan Hau LeeNo ratings yet

- Beam Design ExcelDocument3 pagesBeam Design Excelprashanth palaniNo ratings yet

- Strap Footing Sample PDFDocument6 pagesStrap Footing Sample PDFRegan Tandukar44% (9)

- Ductile Design of Column For Multistorey Building.Document4 pagesDuctile Design of Column For Multistorey Building.NikhilNo ratings yet

- Wind Load Calculation of Gable As Per Is 875Document1 pageWind Load Calculation of Gable As Per Is 875kapil075No ratings yet

- Crack WidthDocument4 pagesCrack Widthnavneet3bawaNo ratings yet

- Shear WallDocument10 pagesShear WallStructural SpreadsheetsNo ratings yet

- Pool Calculation SheetDocument6 pagesPool Calculation SheetSuman Resolved NeupaneNo ratings yet

- Annular Raft Under 1250 Cum OHRDocument1 pageAnnular Raft Under 1250 Cum OHRanirban dasNo ratings yet

- Steel Staircase DesignDocument6 pagesSteel Staircase DesignMario FeghaliNo ratings yet

- Circular Column Design Excel SheetDocument7 pagesCircular Column Design Excel SheetDhananjay ShindeNo ratings yet

- Design of Slab - Wo Way Slab Design As Per Is - 456 - 2000Document25 pagesDesign of Slab - Wo Way Slab Design As Per Is - 456 - 2000rupesh417No ratings yet

- Design of One Way SlabDocument2 pagesDesign of One Way Slabpathan is khanNo ratings yet

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelNo ratings yet

- Grid Slab WITH BBSDocument11 pagesGrid Slab WITH BBSJyoti PatilNo ratings yet

- Design of Bank Building in MSECDocument82 pagesDesign of Bank Building in MSECjahanger ali SNo ratings yet

- Wbcviii PDFDocument1,192 pagesWbcviii PDFDaniel PinheiroNo ratings yet

- CO2 Supply Agreement - A-ZDocument13 pagesCO2 Supply Agreement - A-ZEslam A. FahmyNo ratings yet

- Marketing Plan of AirconDocument16 pagesMarketing Plan of AirconJewel Virata100% (1)

- PRELIM Fire Technology and Arson InvestigationDocument6 pagesPRELIM Fire Technology and Arson InvestigationIgnacio Burog RazonaNo ratings yet

- CV Examples Uk StudentDocument8 pagesCV Examples Uk Studente7648d37100% (1)

- Surface WarfareDocument65 pagesSurface WarfareLobbyist_Myo100% (5)

- Short Version Bio Based Building Blocks and Polymers 2018 2023Document16 pagesShort Version Bio Based Building Blocks and Polymers 2018 2023phaniraj_c100% (1)

- Portfolio AnswersDocument4 pagesPortfolio Answersa73609No ratings yet

- 001 2012 4 b-3Document114 pages001 2012 4 b-3dikahunguNo ratings yet

- AdvertisingDocument16 pagesAdvertisingSun KambojNo ratings yet

- Shah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfDocument311 pagesShah Fahad (editor), Osman Sönmez (editor), Shah Saud (editor), Depeng Wang (editor), Chao Wu (editor), Muhammad Adnan (editor), Muhammad Arif (editor), Amanullah (editor) - Engineering Tolerance in C.pdfTri4alNo ratings yet

- Coll. v. Henderson, 1 SCRA 649Document2 pagesColl. v. Henderson, 1 SCRA 649Homer SimpsonNo ratings yet

- Pilz PNOZ Sigma PDFDocument16 pagesPilz PNOZ Sigma PDFCristopher Entena100% (1)

- MDSW TamilNadu06Document14 pagesMDSW TamilNadu06miningnova1No ratings yet

- Carbon Dioxide Portable Storage UnitsDocument2 pagesCarbon Dioxide Portable Storage UnitsDiego AnayaNo ratings yet

- Myanmar Companies Law 2017Document188 pagesMyanmar Companies Law 2017Let's Save Myanmar100% (1)

- AralPan9 q2 Mod10 Ang-Pamilihan-V5Document29 pagesAralPan9 q2 Mod10 Ang-Pamilihan-V5Wizly Von Ledesma TanduyanNo ratings yet

- Amendment of Information, Formal Vs SubstantialDocument2 pagesAmendment of Information, Formal Vs SubstantialNikkoCataquiz100% (3)

- Yoseph ShiferawDocument72 pagesYoseph Shiferawmaheder wegayehuNo ratings yet

- Training LV PanelDocument108 pagesTraining LV PanelruslanNo ratings yet

- Wireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010Document21 pagesWireless Communication Using Wimax Technology: Journal of Engineering and Sustainable Development September 2010ahmed alshamliNo ratings yet

- Niengo Outsep North Papua 5 - 06 - 07rev2Document20 pagesNiengo Outsep North Papua 5 - 06 - 07rev2Prince DenhaagNo ratings yet

- Ed 807 Economics of Education MODULE-14 Activity-AnswerDocument3 pagesEd 807 Economics of Education MODULE-14 Activity-Answerjustfer johnNo ratings yet

- KickStart 19Document2 pagesKickStart 19Venu GopalNo ratings yet

- A 200 Word Essay OnDocument9 pagesA 200 Word Essay OnANANDRAJ HARIHARANNo ratings yet

- (CHIP IC) w25x20cl - A02Document51 pages(CHIP IC) w25x20cl - A02Felipe de san anicetoNo ratings yet

- Jumping Through HoopsDocument4 pagesJumping Through HoopsCharles RusnellNo ratings yet