Professional Documents

Culture Documents

OEE Calculation For Year Apr 16-Mar 2017: Pulp Machine System (OEE Calculation Point Based On The Theory of Constraint)

OEE Calculation For Year Apr 16-Mar 2017: Pulp Machine System (OEE Calculation Point Based On The Theory of Constraint)

Uploaded by

andicha0 ratings0% found this document useful (0 votes)

9 views1 pageThe document summarizes the OEE (Overall Equipment Effectiveness) calculation for a pulp machine system from April 2016 to March 2017. It finds the availability index was 91.8%, the production performance index was 95.9%, and the quality performance index was 97.41%. Multiplying these indexes together results in an OEE of 85.8%, indicating good performance within the world class category range of 85-95%.

Original Description:

How to calculate OEE

Original Title

OEE Calculation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document summarizes the OEE (Overall Equipment Effectiveness) calculation for a pulp machine system from April 2016 to March 2017. It finds the availability index was 91.8%, the production performance index was 95.9%, and the quality performance index was 97.41%. Multiplying these indexes together results in an OEE of 85.8%, indicating good performance within the world class category range of 85-95%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

9 views1 pageOEE Calculation For Year Apr 16-Mar 2017: Pulp Machine System (OEE Calculation Point Based On The Theory of Constraint)

OEE Calculation For Year Apr 16-Mar 2017: Pulp Machine System (OEE Calculation Point Based On The Theory of Constraint)

Uploaded by

andichaThe document summarizes the OEE (Overall Equipment Effectiveness) calculation for a pulp machine system from April 2016 to March 2017. It finds the availability index was 91.8%, the production performance index was 95.9%, and the quality performance index was 97.41%. Multiplying these indexes together results in an OEE of 85.8%, indicating good performance within the world class category range of 85-95%.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

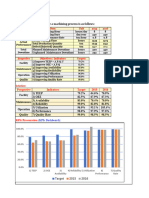

OEE calculation for year Apr 16-Mar 2017

Pulp Machine System (OEE Calculation Point based on the Theory of constraint)

1 Total calendar days 365 days

2 Major Shutdown 12 days

3 Minor Shutdown 6 days

Operating days 347 days

4 Planned operating days 347 days

5 Unplanned Down time 28.43 days (data from Down Time Pulp machine 2016)

6 Actual operating day 319 days

6 Availability index = Actual Operating days = 318.57 = 91.8%

Planned Operating days 347

7 Final Product 421,796.65 Adt

8 Ideal Run rate 1380 Adt/d (data from Pulp machine design capacity)

9 Production Performance index = Final Product/Act.Op.days = 95.9%

Capacity

10 Total Product 421,796.7 Adt

11 Total Off Grade 549.7 Adt

12 Total Repulping 7.88 Adt

13 Total good pieces 410,854.4 Adt

14 Quality Performance index = Good Product = 97.41%

Total Product

15 Calculation of Overall Equipment Effectiveness (OEE) 2016

= Availability Index x Performance Production Index x Quality Performance Index x 100%

= 91.8% x 95.9% x 97.41%

= 85.8%

Based on literature, the value of OEE beetwen 85% to 95%, it's mean our performance

was good (world class categories)

You might also like

- ISO 22400 Standard Presentation - KPIsDocument11 pagesISO 22400 Standard Presentation - KPIsTaheni Amara100% (1)

- Bergerac System Case Analysis-Group 1Document11 pagesBergerac System Case Analysis-Group 1Karan Trivedi100% (1)

- Managing OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryDocument26 pagesManaging OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryMohammad QureshiNo ratings yet

- Production KPIsDocument29 pagesProduction KPIsNovalonNo ratings yet

- Metric 2.1.1 OEEDocument7 pagesMetric 2.1.1 OEEAbdelaziz RagabNo ratings yet

- Calculate TEEP - Measure Utilization and Capacity - OEEDocument4 pagesCalculate TEEP - Measure Utilization and Capacity - OEEahmed nawaz100% (1)

- FerryDocument9 pagesFerryFrederico TariganNo ratings yet

- Whitepaper Understanding TEEP Vs OEE DigitalDocument9 pagesWhitepaper Understanding TEEP Vs OEE DigitalNguyen TranNo ratings yet

- OeeDocument6 pagesOeesingh1984_09No ratings yet

- Industrial Engineering Basics - Pharma - OEEDocument5 pagesIndustrial Engineering Basics - Pharma - OEEMelvin MarsNo ratings yet

- Metric 2.1.2 TEEPDocument8 pagesMetric 2.1.2 TEEPAbdelaziz RagabNo ratings yet

- Batangas State University: Group IiDocument9 pagesBatangas State University: Group IinoelNo ratings yet

- Lec.03 Advanced Manufacturing SystemsDocument17 pagesLec.03 Advanced Manufacturing SystemsAmer Abd EL-hkimNo ratings yet

- Total Productive Maintenance (TPM)Document17 pagesTotal Productive Maintenance (TPM)Fgj JhgNo ratings yet

- Lean ReviewDocument11 pagesLean Reviewhong thaoNo ratings yet

- Calculation of Overall Equipment Effectiveness Total Productive Maintenance in Improving Productivity of Casting MachinesDocument5 pagesCalculation of Overall Equipment Effectiveness Total Productive Maintenance in Improving Productivity of Casting MachinesAnonymous izrFWiQNo ratings yet

- 8 - Minimizing Product Defects Based On Labor Performance Using Linear Regression and Six Sigma ApproachDocument11 pages8 - Minimizing Product Defects Based On Labor Performance Using Linear Regression and Six Sigma Approachleylagale27No ratings yet

- OEE CalculatorDocument7 pagesOEE CalculatorAbdelaziz RagabNo ratings yet

- Calculating OEEDocument3 pagesCalculating OEETuấn Trần ĐứcNo ratings yet

- QC2 Paper 06 David Sungkono 2014Document5 pagesQC2 Paper 06 David Sungkono 2014camp bali demakNo ratings yet

- 73 Essential Manufacturing KPIsDocument16 pages73 Essential Manufacturing KPIsjvanandhNo ratings yet

- CFM ROss SolutionsDocument5 pagesCFM ROss SolutionsHai HaNo ratings yet

- DHL B2be CommerceDocument13 pagesDHL B2be CommerceShreyansh SagareNo ratings yet

- Analysis of Total Productive MaintenanceDocument7 pagesAnalysis of Total Productive MaintenancehuynhthimytienbkNo ratings yet

- 3 KPIs Every Facility Should Be Tracking - Vector SolutionsDocument7 pages3 KPIs Every Facility Should Be Tracking - Vector Solutionssatya krishna chagantiNo ratings yet

- Process Capability BaselineDocument19 pagesProcess Capability BaselinecamilaskishoreNo ratings yet

- Overall Equipment EffectivenessDocument43 pagesOverall Equipment EffectivenessKailas Sree Chandran100% (4)

- 09 Casewhere SelectionDocument3 pages09 Casewhere SelectionKiran SEEROONo ratings yet

- For Feedback / Further Assistance Please Email or Via Facebook @growth ImprovementsDocument15 pagesFor Feedback / Further Assistance Please Email or Via Facebook @growth Improvementsmiss_almasNo ratings yet

- OEE CalculationDocument7 pagesOEE Calculationirrosel46500% (1)

- OEE PresentationDocument15 pagesOEE PresentationIbrahim FaragNo ratings yet

- What Is OEEDocument4 pagesWhat Is OEEmarcovsouzaNo ratings yet

- Understanding OEEDocument5 pagesUnderstanding OEECristian Ramirez AmayaNo ratings yet

- Analisis TPM Pada Mesin Press Fine Blanking 1100 Ton Dengan Metode OEE Di Perusahaan Manufacturing Press PartDocument6 pagesAnalisis TPM Pada Mesin Press Fine Blanking 1100 Ton Dengan Metode OEE Di Perusahaan Manufacturing Press PartAdiinNo ratings yet

- CMRP CertificationDocument25 pagesCMRP Certificationjhonatan lorenzoNo ratings yet

- 288653_driving-efficiences-6-steps-to-improving-asset-performance-in-manufacturingDocument24 pages288653_driving-efficiences-6-steps-to-improving-asset-performance-in-manufacturingTamour Habib KhanNo ratings yet

- Coconut Dehusking MachineDocument11 pagesCoconut Dehusking Machineryeue100% (1)

- OEE - LeanDocument8 pagesOEE - LeanNick VoNo ratings yet

- Availability: Example OEE CalculationDocument2 pagesAvailability: Example OEE CalculationVaibhav Sharma100% (1)

- Aerospace Lean Manufacturing MetricsDocument2 pagesAerospace Lean Manufacturing MetricsMani Rathinam RajamaniNo ratings yet

- OEE Analysis - Assignment 2-1Document1 pageOEE Analysis - Assignment 2-1ʆƠƘЄƦ 6No ratings yet

- Capacity Concept PresentationDocument9 pagesCapacity Concept PresentationJeerawatNo ratings yet

- World Class OEEDocument22 pagesWorld Class OEESinggihNo ratings yet

- CII - AVANTHA Centre For CompetitivenessDocument31 pagesCII - AVANTHA Centre For CompetitivenessRohit TripathiNo ratings yet

- Talk 09. Lean & Six SigmaDocument19 pagesTalk 09. Lean & Six SigmaPhuc Linh100% (1)

- Model Celkovej Efektívnosti Procesu (OPE) V Priemysle Výroby PneumatíkDocument4 pagesModel Celkovej Efektívnosti Procesu (OPE) V Priemysle Výroby PneumatíkB6D4N0No ratings yet

- HW ch11Document4 pagesHW ch11peizhen luNo ratings yet

- KPIsDocument5 pagesKPIsyousriabdouli10No ratings yet

- 5S Is The Best SytemDocument9 pages5S Is The Best SytemYasser BadrNo ratings yet

- Pom Imp QuestionsDocument7 pagesPom Imp QuestionsramsastryNo ratings yet

- ANALYSIS OF TPM IMPLEMENTATION BY MEASURING OVERALL EQUIPMENT EFFECTIVENESS (OEE) AND EFFORTS TO IMPROVE FURNACE MACHINE PERFORMANCE AT PT XYZDocument11 pagesANALYSIS OF TPM IMPLEMENTATION BY MEASURING OVERALL EQUIPMENT EFFECTIVENESS (OEE) AND EFFORTS TO IMPROVE FURNACE MACHINE PERFORMANCE AT PT XYZIJAR JOURNALNo ratings yet

- A Strategy For Performance ExcellenceDocument25 pagesA Strategy For Performance ExcellenceSahu PraveenNo ratings yet

- Process Improvement Methods and ToolsDocument41 pagesProcess Improvement Methods and ToolsJoseph VindolloNo ratings yet

- A Strategy For Performance ExcellenceDocument32 pagesA Strategy For Performance Excellencesubodh ranjanNo ratings yet

- Oee 1Document1 pageOee 1roysumit8888No ratings yet

- 5S QualityDocument32 pages5S QualityOmkar BapatNo ratings yet

- Understanding OEE in Lean Production: Toyota Production System ConceptsFrom EverandUnderstanding OEE in Lean Production: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- The Performance Management Revolution: Business Results Through Insight and ActionFrom EverandThe Performance Management Revolution: Business Results Through Insight and ActionNo ratings yet

- Chapter 4 Three Phase Uncontrolled Rectifier (Compatibility Mode)Document17 pagesChapter 4 Three Phase Uncontrolled Rectifier (Compatibility Mode)Apry PermatasariNo ratings yet

- The Design of Garment Enterprise Data Warehouse Using TOGAFDocument9 pagesThe Design of Garment Enterprise Data Warehouse Using TOGAFsentyNo ratings yet

- 380 KV Underground Transmission LineDocument15 pages380 KV Underground Transmission LineMohmmad NawabNo ratings yet

- Cable-Catalogue BR enDocument72 pagesCable-Catalogue BR enmuhammedNo ratings yet

- Medium Fonnat CamerasDocument20 pagesMedium Fonnat CamerasavhajNo ratings yet

- Tensores Van GorpDocument17 pagesTensores Van GorpsalematadorNo ratings yet

- User Manual: Global Mapper V21.1Document131 pagesUser Manual: Global Mapper V21.1Dedi SetyawanNo ratings yet

- G500H TXi Pilots Guide 190-01717-10 - FDocument380 pagesG500H TXi Pilots Guide 190-01717-10 - FErik MatomaNo ratings yet

- Automatic Differential Unit Locking SystemDocument19 pagesAutomatic Differential Unit Locking SystemPradeep Gs100% (1)

- 《TypeScript开发实战》课件Document74 pages《TypeScript开发实战》课件Wang WendyNo ratings yet

- B40 45 50X-5 - Sb1085e PDFDocument450 pagesB40 45 50X-5 - Sb1085e PDFGORDNo ratings yet

- FB Test CaseDocument8 pagesFB Test CaseLionKingNo ratings yet

- Ei M Y4Document209 pagesEi M Y4bhadz SabellaNo ratings yet

- ATI FirePro V7800 DatasheetDocument2 pagesATI FirePro V7800 Datasheetjbarboza2236No ratings yet

- RBI Guidelines On Information SecurityDocument171 pagesRBI Guidelines On Information SecurityMubeen MirzaNo ratings yet

- VSX-808RDS: Audio/Video Multi-Channel ReceiverDocument62 pagesVSX-808RDS: Audio/Video Multi-Channel ReceiverDaniel Crespillo BlancoNo ratings yet

- MCQ Artificial Intelligence Class 10 Computer VisionDocument41 pagesMCQ Artificial Intelligence Class 10 Computer VisionpratheeshNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankWawanNo ratings yet

- Improved Particle Swarm Optimization Based MPPT For PV Systems Under Partial Shading ConditionsDocument6 pagesImproved Particle Swarm Optimization Based MPPT For PV Systems Under Partial Shading ConditionsNazrul HaqemNo ratings yet

- Assessing The Environmental Impact of Data Centres Part 1: Background, Energy Use and MetricsDocument10 pagesAssessing The Environmental Impact of Data Centres Part 1: Background, Energy Use and Metricsmarf123No ratings yet

- Simularea Reţelei În Cisco Packet TracerDocument6 pagesSimularea Reţelei În Cisco Packet TracerFlorin AlexandruNo ratings yet

- Scale-S 1209Document28 pagesScale-S 1209NajmalNo ratings yet

- Ai&ml RecordDocument57 pagesAi&ml Recordhemapardeep8No ratings yet

- Site Weekly Observation ReportDocument20 pagesSite Weekly Observation Reportbra9tee9tiniNo ratings yet

- Where and How Does Urban Design Happen Thought CollectionDocument7 pagesWhere and How Does Urban Design Happen Thought Collectionvince baconsNo ratings yet

- VividGraph Learning To Extract and Redesign Network Graphs From Visualization ImagesDocument14 pagesVividGraph Learning To Extract and Redesign Network Graphs From Visualization ImagessasasaNo ratings yet

- Petrel Manual: Vshale CalculationDocument20 pagesPetrel Manual: Vshale CalculationEmira ZrelliNo ratings yet

- Vector Operating Manual RevJ 031920Document81 pagesVector Operating Manual RevJ 031920Myname Is MLKNo ratings yet

- Entertainment and Media Outlook PDFDocument134 pagesEntertainment and Media Outlook PDFEd NjorogeNo ratings yet

- Protection and Relay SchemesDocument44 pagesProtection and Relay SchemesSaeed Mahmood Gul Khan67% (6)