Professional Documents

Culture Documents

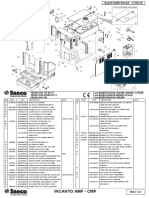

S 1 Engine

S 1 Engine

Uploaded by

PSCopyright:

Available Formats

You might also like

- Saeco Incanto HD8911 HD8912 Part DiagramDocument7 pagesSaeco Incanto HD8911 HD8912 Part DiagramJuso100% (1)

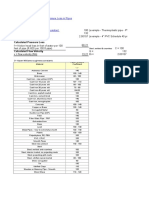

- SpreadSheet Centrifugal PumpDocument2 pagesSpreadSheet Centrifugal PumpengenheiroalencarNo ratings yet

- PMI Error CodesDocument1 pagePMI Error CodesLaurian Chirtop100% (1)

- Equipment Confi Guration Diagram at The Time of The De-Ballasting Operation (Neutralizer Transfer)Document19 pagesEquipment Confi Guration Diagram at The Time of The De-Ballasting Operation (Neutralizer Transfer)Mark Dominic FedericoNo ratings yet

- Machinery Luna Maersk PDFDocument386 pagesMachinery Luna Maersk PDFRafael Da Rosa Siqueira100% (1)

- Maersk Boston Machinery Manual PDFDocument412 pagesMaersk Boston Machinery Manual PDFCeban Eugeniu100% (1)

- Maersk Seletar MachineryDocument387 pagesMaersk Seletar MachineryVinay Kumar Neelam100% (1)

- Machinery MaerskDocument370 pagesMachinery Maerskgopu thalikunnath100% (6)

- Maersk Laberinto HN4224 Machinery Operating Manual Issue 1 October 2012 PDFDocument411 pagesMaersk Laberinto HN4224 Machinery Operating Manual Issue 1 October 2012 PDFShikhar SwaroopNo ratings yet

- LNGC Q-MAX BU SAMRA - IMO 9388833 - Machinery Operating ManualDocument552 pagesLNGC Q-MAX BU SAMRA - IMO 9388833 - Machinery Operating Manualseawolf50No ratings yet

- LNGC Q-Max Lijmiliya - Imo 9388819 - Machinery Operating ManualDocument588 pagesLNGC Q-Max Lijmiliya - Imo 9388819 - Machinery Operating Manualseawolf50100% (1)

- LNGC Q-MAX ZARGA - IMO 9431214 - Machinery Operating ManualDocument564 pagesLNGC Q-MAX ZARGA - IMO 9431214 - Machinery Operating Manualseawolf50No ratings yet

- Jens Maersk Machinery ManualDocument349 pagesJens Maersk Machinery ManualVlad Ştefan100% (1)

- LNGC Golar Frost - IMO 9253284 - Machinery Operating ManualDocument421 pagesLNGC Golar Frost - IMO 9253284 - Machinery Operating Manualseawolf50No ratings yet

- OPT - Yuri Senkevich - Machinery Systems Manual PDFDocument352 pagesOPT - Yuri Senkevich - Machinery Systems Manual PDFpNo ratings yet

- MT" ROBERT MAERSK" IMO #9237008 - Machinery Operating ManualDocument245 pagesMT" ROBERT MAERSK" IMO #9237008 - Machinery Operating Manualseawolf50No ratings yet

- Maersk Wave Machinery Operating Manual: Main MenuDocument272 pagesMaersk Wave Machinery Operating Manual: Main MenuLaurentiu DumitracheNo ratings yet

- LNG RIVERS Machinery Issue 1Document434 pagesLNG RIVERS Machinery Issue 1martinasgeorgeNo ratings yet

- Maersk Seletar Machinery Operating Manual: Section 1: Operational Overview and Engine Room ArrangementDocument387 pagesMaersk Seletar Machinery Operating Manual: Section 1: Operational Overview and Engine Room ArrangementvasyaNo ratings yet

- ELISABETH Maersk - Machinery PDFDocument274 pagesELISABETH Maersk - Machinery PDFpNo ratings yet

- Ship Machinery Operation PDFDocument199 pagesShip Machinery Operation PDFFred GoicocheaNo ratings yet

- LNGC AL DAFNA - IMO 9443683 - Machinery Operating ManualDocument566 pagesLNGC AL DAFNA - IMO 9443683 - Machinery Operating Manualseawolf50No ratings yet

- VLCC Effie Maersk - Imo 9682978 - Machinery Operating ManualDocument274 pagesVLCC Effie Maersk - Imo 9682978 - Machinery Operating Manualseawolf50No ratings yet

- British Ensign Machinery Manual Issue 2 Nov 2010Document309 pagesBritish Ensign Machinery Manual Issue 2 Nov 2010CristiUzuneaNo ratings yet

- British Endurance Machinery ManualDocument288 pagesBritish Endurance Machinery ManualCarlos Henrique SouzaNo ratings yet

- LNGC - Inigo Tapias - Machinery Systems Manual PDFDocument383 pagesLNGC - Inigo Tapias - Machinery Systems Manual PDFpNo ratings yet

- OPT - Maersk Kiera - Machinery Systems Manual PDFDocument334 pagesOPT - Maersk Kiera - Machinery Systems Manual PDFpNo ratings yet

- BP British Purpose Machinery PDFDocument262 pagesBP British Purpose Machinery PDFpNo ratings yet

- Crude Oil Carrier ALBA - IMO 9297345 - Machinery Operating ManualDocument325 pagesCrude Oil Carrier ALBA - IMO 9297345 - Machinery Operating Manualseawolf50No ratings yet

- Container MV Maersk Altair - IMO 9342499 - Machinery Operating ManualDocument387 pagesContainer MV Maersk Altair - IMO 9342499 - Machinery Operating Manualseawolf50No ratings yet

- LNGC Al Ghashamiya - Imo 9397286 - Machinery Operating ManualDocument537 pagesLNGC Al Ghashamiya - Imo 9397286 - Machinery Operating Manualseawolf50No ratings yet

- LNGC Methane Kari Elin - Imo 9256793 - Machinery Operating Manual - 2005Document388 pagesLNGC Methane Kari Elin - Imo 9256793 - Machinery Operating Manual - 2005seawolf50No ratings yet

- CPT Maersk Ramsey - IMO 9275268 - Machinery Operating ManualDocument204 pagesCPT Maersk Ramsey - IMO 9275268 - Machinery Operating Manualseawolf50No ratings yet

- Machinery UNLOCKED PDFDocument238 pagesMachinery UNLOCKED PDFAll AllNo ratings yet

- Aurora Technical Operating ManualDocument574 pagesAurora Technical Operating ManualПетко ПетковNo ratings yet

- P260 MachineryA PDFDocument349 pagesP260 MachineryA PDFmariodalNo ratings yet

- LNGC AAMIRA - IMO 9443401 - Machinery Operating ManualDocument563 pagesLNGC AAMIRA - IMO 9443401 - Machinery Operating Manualseawolf50No ratings yet

- Container MV Maersk Lima - IMO 9526875 - Machinery Operating ManualDocument364 pagesContainer MV Maersk Lima - IMO 9526875 - Machinery Operating Manualseawolf50No ratings yet

- Container Ship Maersk Boston - IMO 9313905 - Machinery Operating Manual-2006Document413 pagesContainer Ship Maersk Boston - IMO 9313905 - Machinery Operating Manual-2006seawolf50No ratings yet

- LNGC Singapore Energy - IMO 9238040 - Marine Operations ManualDocument300 pagesLNGC Singapore Energy - IMO 9238040 - Marine Operations Manualseawolf50No ratings yet

- 2013.12-Emma Maersk ER FloodingDocument58 pages2013.12-Emma Maersk ER FloodingLokesh RavichandiranNo ratings yet

- 709b-2009 Jinling JLZ070405 - 425 FO JPN PDFDocument64 pages709b-2009 Jinling JLZ070405 - 425 FO JPN PDFЮрий ЕфимовNo ratings yet

- Ramsey Machinery Diesel Super PowerDocument203 pagesRamsey Machinery Diesel Super PowerRobert Mihai Răducică100% (1)

- Westfalia Separator Mineraloil Systems GMBH:, Running Mode To Be Pre-Selected: Wms-01Document10 pagesWestfalia Separator Mineraloil Systems GMBH:, Running Mode To Be Pre-Selected: Wms-01Андрей АндреевичNo ratings yet

- Deck Manual PDFDocument217 pagesDeck Manual PDFBozidar TomasevicNo ratings yet

- NAVIGARE PARS Electrical SpecificationDocument813 pagesNAVIGARE PARS Electrical SpecificationElectrical Learn BDNo ratings yet

- Guangzhou Hangtong Shipbuilding and Shipping Co., Ltd. 5600DWT Oil Tanker 6Document105 pagesGuangzhou Hangtong Shipbuilding and Shipping Co., Ltd. 5600DWT Oil Tanker 6ABDUL GHAFOORNo ratings yet

- LNGC Methane Kari Elin - Imo 9256793 - Bridge Operating Manual - 2005Document263 pagesLNGC Methane Kari Elin - Imo 9256793 - Bridge Operating Manual - 2005seawolf50No ratings yet

- MT Iran Dena - IMO 9218480 - Cargo Systems Operating ManualDocument197 pagesMT Iran Dena - IMO 9218480 - Cargo Systems Operating Manualseawolf50No ratings yet

- DBAB602760 A DBAB602760Document75 pagesDBAB602760 A DBAB602760Diego CardenasNo ratings yet

- ENSCO 8501: General InformationDocument1 pageENSCO 8501: General InformationtphsbNo ratings yet

- 污水处理器Document78 pages污水处理器Vikas SinghNo ratings yet

- P960 Section 4 Propulsion SystemsDocument43 pagesP960 Section 4 Propulsion SystemsLaurentiu DumitracheNo ratings yet

- Centricone WestfaliaDocument4 pagesCentricone WestfaliaLTE002No ratings yet

- Rita MachineryDocument203 pagesRita MachineryGheorghe CristianNo ratings yet

- P-42 - Tank Monitoring SystemDocument118 pagesP-42 - Tank Monitoring SystemCengiz İyiceNo ratings yet

- Wire Handling MaintenanceDocument24 pagesWire Handling MaintenanceSamoila ConstantinNo ratings yet

- 72271-410-001-F Topology Drawing MOL 928 - As Built - With CloudsDocument20 pages72271-410-001-F Topology Drawing MOL 928 - As Built - With CloudsTseng EthanNo ratings yet

- Chapter 4 Tunnel Thruster As Built DrawingsDocument47 pagesChapter 4 Tunnel Thruster As Built DrawingsSergei KurpishNo ratings yet

- Machinery Operating Manual Maersk GatesheadDocument358 pagesMachinery Operating Manual Maersk GatesheadСергей ЯковлевNo ratings yet

- LNGC Singapore Energy - IMO 9238040 - Machinery Operating ManualDocument420 pagesLNGC Singapore Energy - IMO 9238040 - Machinery Operating Manualseawolf50No ratings yet

- LNGC Q-Flex Al Thumama - Imo 9360843 - Machinery Operating ManualDocument510 pagesLNGC Q-Flex Al Thumama - Imo 9360843 - Machinery Operating Manualseawolf50100% (1)

- RAB KLASIS OFFICE 2017-TOTAL FINAL-okeDocument191 pagesRAB KLASIS OFFICE 2017-TOTAL FINAL-okeRAKYAT JELATAHNo ratings yet

- Revision Index Description and / or Revised SheetsDocument244 pagesRevision Index Description and / or Revised SheetsneivaprojetosNo ratings yet

- Renr5514renr5514-01 SisDocument9 pagesRenr5514renr5514-01 SisHelar W. Cutipa MachacaNo ratings yet

- Site Visit ReportDocument5 pagesSite Visit ReportSharad KulkarniNo ratings yet

- Restriction Orifice RO Flow Control Instrument PDFDocument8 pagesRestriction Orifice RO Flow Control Instrument PDFRaphael212219No ratings yet

- 428C-System Operation-Piston Pump (Implement and Steering)Document10 pages428C-System Operation-Piston Pump (Implement and Steering)yoga_jpbmbm100% (1)

- My CalculationsDocument39 pagesMy CalculationsWaqas Khan ChannarNo ratings yet

- Technical Data Sheet: Model MA4 Air Pressure Maintenance DeviceDocument4 pagesTechnical Data Sheet: Model MA4 Air Pressure Maintenance DeviceDjapaNo ratings yet

- Centrifugal Pump Performance TestDocument6 pagesCentrifugal Pump Performance TestVirneDalisayNo ratings yet

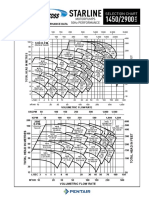

- Isostarlineperformancedata50hz PDFDocument122 pagesIsostarlineperformancedata50hz PDFThomas KamongNo ratings yet

- Class 11 Project For Hydraulic LiftDocument8 pagesClass 11 Project For Hydraulic LiftHritam Sharma53% (17)

- SCX180 Catalog REV 01-08Document32 pagesSCX180 Catalog REV 01-08Horea CordunianuNo ratings yet

- T115 Vega-Zr CarburetorDocument2 pagesT115 Vega-Zr CarburetorDadung setyaNo ratings yet

- Trolley Jack ProposalDocument8 pagesTrolley Jack Proposaladebayo gabriel100% (1)

- Product Specifications: EatonDocument2 pagesProduct Specifications: EatonAdrian MartinNo ratings yet

- Melon Baturaden-Model - PDF REV 1 PDFDocument1 pageMelon Baturaden-Model - PDF REV 1 PDFFaiz KarmaniNo ratings yet

- Van Nap LT06Document3 pagesVan Nap LT06hoiNo ratings yet

- Instructions For Installation, Operation, Care and MaintenanceDocument18 pagesInstructions For Installation, Operation, Care and MaintenanceDANIEL CADENANo ratings yet

- MOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationDocument27 pagesMOTS 44 - Rev. 2.0 - MOG FP PRO STD 0044 Valving and IsolationKingston RivingtonNo ratings yet

- Urzs - D - Ulzs - DB - wk422980 - en - 01-2020-1VALVULAS LOGICASDocument10 pagesUrzs - D - Ulzs - DB - wk422980 - en - 01-2020-1VALVULAS LOGICAS13177566No ratings yet

- List Stok Barang GudangDocument113 pagesList Stok Barang Gudanganangga felixNo ratings yet

- Planos 721FDocument6 pagesPlanos 721FAsistente MantenimientoNo ratings yet

- Centrifugal PumpDocument38 pagesCentrifugal PumpAbdullah Azzam100% (2)

- Lift, Displacement, and Gravity PumpsDocument22 pagesLift, Displacement, and Gravity PumpskerezsigyorgyNo ratings yet

- Company Profile - PT - KDTDocument28 pagesCompany Profile - PT - KDTmediakreasionlineNo ratings yet

- Final BUILDING Report T1&T2 DormitaryDocument27 pagesFinal BUILDING Report T1&T2 DormitaryFreedom Love NabalNo ratings yet

- Module-07: Fluidics and Fluid Logic Lecture - 28: Automation and Principle of Circuit DesignDocument7 pagesModule-07: Fluidics and Fluid Logic Lecture - 28: Automation and Principle of Circuit DesignDhamu DhamodharanNo ratings yet

- Partlist: Design Date: Designed By: Unit No.: Unit DescriptionDocument2 pagesPartlist: Design Date: Designed By: Unit No.: Unit DescriptionRASOUL KHADIBINo ratings yet

S 1 Engine

S 1 Engine

Uploaded by

PSOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S 1 Engine

S 1 Engine

Uploaded by

PSCopyright:

Available Formats

Peter Mærsk Machinery Operating Manual

1: Machinery Operating Manual 2.3 Condensate and Feed Systems 2.13 Electrical Power Distribution

2.3.1 Condensate System 2.13.1 Distribution and Loading

List of Contents: 2.3.2 Drains Systems 2.13.2 Shore Power

2.3.3 Boiler Feed System 2.13.3 Main Alternators

Issues and Updates 2.3.4 Boiler Water Sampling and Treatment System 2.13.4 Emergency Alternator

Mechanical Symbols 2.13.5 Preferential Tripping and Sequencial Restart

Electrical and Instrument Symbols 2.4 Sea Water Systems 2.13.6 Uninterruptible Power Supplies (UPS)

Colour Scheme 2.4 1 Main and Auxiliary Sea Water Systems 2.13.7 Batteries, Transformers, Rectifiers and Chargers

Introduction 2.4.2 Sea Water General Service System 2.13.8 Cathodic Protection System

2.4.3 Engine Room Ballast System

Part 1: Operational Overview 2.4.4 Evaporator 2.14 Accommodation Systems

2.4.5 Distilled Water Transfer and Distribution 2.14.1 Domestic Fresh Water System

1.1 To Bring Vessel into Live Condition 2.14.2 Domestic Refrigeration System

2.5 Fresh Water Cooling Systems 2.14.3 Accommodation Air Conditioning Plant

1.2 To Prepare Main Plant for Operation 2.5.1 Main Engine Jacket Cooling Fresh Water System 2.14.4 Miscellaneous Air Conditioning Units

2.5.2 Central Fresh Water Cooling System 2.14.5 Sewage Treatment

1.3 To Prepare Main Plant for Manoeuvring from 'In Port' Condition 2.14.6 Incinerator and Garbage Disposal

2.6 Fuel Oil and Diesel Oil Service Systems

1.4 To Change Main Plant from Manoeuvring to Full Away 2.6.1 Main Engine Fuel Oil Service System 2.15 Inert Gas (Top-up System) Generators

2.6.2 Auxiliary Engines Fuel Oil Service System 2.15.1 Main Inert Gas System

1,5 To Prepare for UMS Operation 2.6.3 Auxiliary Boilers Fuel Oil System 2.15.2 Topping Up System

2.6.4 Incinerator Fuel Oil System 2.15.3 Maintenance (Routine Maintenance in Operation

1.6 To Change from UMS to Manned Operation only)

2.7 Fuel Oil and Diesel Oil Transfer Systems

1.7 To Change Main Plant from Full Away to Manoeuvring 2.7.1 Fuel Oil and Diesel Oil Bunkering and Transfer Illustrations

System 2.1.1a Main Engine

1.8 To Secure Main Plant at Finished With Engines 2.7.2 Fuel Oil and Diesel Oil Purifying System 2.1.2a Main Engine Control - Manoeuvring

2.1.2b Main Engine Bridge Control System

1.9 To Secure Plant for Dry Dock 2.8 Lubricating Oil Systems 2.1.3a Main Engine Safety System

2 8.1 Main Engine Lubricating Oil System 2.2.1a Auxiliary Boiler

Illustrations 2.8.2 Stern Tube Lubricating Oil System 2.2.2a Boiler Control Panel

2.8.3 Lubricating Oil Purifying Systems 2.2.3a Sootblowers

Location Plan of Engine Room - 2nd and 3rd Platforms 2.8.4 Lubricating Oil Filling and Transfer System 2.2.4a Medium Pressure Steam System

Location Plan of Engine Room - 4th Platforms and Floor 2.2.5a 6kg/cm2 Steam System

2.9 Bilge Systems 2.2.6a Exhaust Gas Boiler

Part 2: Main Engine and Auxiliary Systems 2.9.1 Engine Room Bilge System 2.3.1a Condensate System

2.9.2 Pump Room Bilge System 2.3.2a Heating Drains / Contaminated Water System

2.1 Main Engine 2.9.3 Bosun's Store, Fore Hydraulic Oil Pump Room 2.3.3a Boiler Feed Water System

2.1.1 Main Engine Details and Chain Locker Bilge System 2.3.4a Water Sampling and Treatment System

2.1.2 Main Engine Manoeuvring Control 2.4.1a Main and Auxiliary Sea Water Cooling System

2.1.3 DPS 2100 Main Engine Safety System 2.10 Air Systems 2.4.2a Sea Water General Service System

2.10.1 Starting Air System 2.4.3a Engine Room Ballast System

2.2 Boilers and Steam Systems 2.10.2 General Service Air System 2.4.4a Evaporator

2.2.1 General Description 2.10.3 Control Air System 2.4.5a Distilled Water Transfer and Distribution System

2.2.2 Boiler Control Systems 2.5.2a Central Fresh Water Cooling System

2.2.3 Sootblowers 2.11 Steering Gear 2.6.1a Main Engine Fuel Oil Service System

2.2.4 Medium Pressure Steam System 2.6.1b Viscosity - Temperature Graph

2.2.5 Low Pressure Steam System 2.12 Electrical Power Generators 2.6.2a Auxiliary Engine Fuel Oil Service System

2.2.6 Exhaust Gas Boiler 2.12.1 Diesel Generators 2.6.3a Auxiliary Boiler Fuel Oil Service System

2.12.2 Emergency Diesel Generator 2.6.4a Incinerator Fuel Oil Service System

Issue: 1 List of Contents - Page 1

PREVIOUS PAGE MAIN MENU EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

2.7.1a Fuel Oil and Diesel Oil Bunkering and Transfer Illustrations Part 6: Communications

System 3.1.1a IMS System Overview

2.7.2a Fuel Oil and Diesel Oil Purifying System 3.1.2a Operator Stations 6.1 UMS 2100 System

2.8.1a Main Engine Lubricating Oil System 3.1.3a Screen Displays 6.2 Sound Powered Telephone System

2.8.2a Stern Tube Lubricating Oil System 3.1.5a Trending Display 6.3 Automatic Telephone and Public Address System

2.8.3a Lubricating Oil Purifying System 3.1.6a UMS Layout 6.4 Public Address and Talkback System

2.8.4a Lubricating Oil Filling and Transfer System 3.2a Engine Control Room Console

2.9.1a Engine Room Bilge System Illustrations

2.9.3a Forward Bilge System Part 4: Emergency Systems 6.1a UMS 2100 System Layout

2.10.1a Starting Air System 6.1b UMS 2100 Operator Panels

2.10.2a General Service Air System 4.1 Fire Hydrant System 6.2a Sound Powered Telephone System

2.10.3a Control Air System 4.2 CO2 Flooding System 6.4a Public Address and Talkback System

2.11a Steering Gear 4.3 Quick Closing and Remote Closing Valve System

2.12.1a Diesel Generators 4.4 Fresh Water Spray Extinguishing System

2.12.2a Emergency Diesel Generator. 4.5 Safety Systems

2.13.1a Distribution and Loading

Illustrations

2.13.1b Power Management System

4.1a Engine Room Fire Hydrant System

2.13.2a Shore Power

4.2a CO2 Flooding System

2.13.4a Emergency Alternator Electrical/Automation

2.13.7a Emergency Battery Charging and 24V Distribution 4.3a Quick Closing and Remote Closing Valve System

2.13.8a Cathodic Protection System 4.4a Fresh Water Spray Extinguishing System

2.14.1a Domestic Fresh Water System 4.5a Safety Systems

2.14.2a Domestic Refrigeration System

2.14.3a Accommodation Air Conditioning Plant Part 5: Emergency Procedures

2.14.5a Sewage Treatment System

2.14.6a Incinerator and Operating Panel 5.1 Flooding in Engine Room

2.15.1a Inert Gas System in Engine Room 5.2 Emergency Operation of Main Engine

5.3 Emergency Steering

Part 3: Main Machinery Control 5.4 Emergency Fire Pump Operation

3.1 Integrated Management System 5.5 Fire in Engine Room

3.1.1 System Overview 5.6 Escape Systems and Fire doors

3.1.2 Operator Stations

Illustrations

3.1.3 Screen Displays

3.1.4 Alarm List

5.2a Emergency Operation of Main Engine

3.1.5 Trending

5.3a Emergency Steering

3.1.6 UMS - Manned Hand-over

5.4a Emergency Fire Pump

3.2 Engine Control Room, Console and Panels 5.5a Fire Control Station

5.6a Escape System and Fire Doors

Issue: 1 List of Contents - Page 2

PREVIOUS PAGE MAIN MENU EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Issue and Update Control This manual was produced by:

Issue 1 Issue 2 Issue 3 Issue 4

This manual is provided with a system of issue and update

control. Controlling documents ensures that: WORLDWIDE MARINE TECHNOLOGY LTD. List of Contents January 2000

Issues and Updates January 2000

• Documents conform to a standard format;

Machinery Symbols January 2000

For any new issue or update contact:

• Amendments are carried out by relevant personnel; Electrical and Instrument Symbols January 2000

Colour Scheme January 2000

The Technical Director

• Each document or update to a document is approved Introduction January 2000

WMT Technical Office

before issue;

The Court House

Text

• A history of updates is maintained; 15 Glynne Way

1.1 January 2000

Hawarden

1.2 January 2000

• Updates are issued to all registered holders of Deeside, Flintshire

1.3 January 2000

documents; CH5 3NS, UK

1.4 January 2000

• Sections are removed from circulation when obsolete. 1.5 January 2000

E-Mail: manuals@wmtmarine.com

1.6 January 2000

Document control is achieved by the use of the footer 1.7 January 2000

provided on every page and the issue and update table 1.8 January 2000

below. 1.9 January 2000

In the right hand corner of each footer are details of the

Illustrations

pages section number and title followed by the page

Loc’n Plan of E.R - 2nd & 3rd Platforms January 2000

number of the section. In the left hand corner of each

Loc’n Plan of E.R - 4th Platform & Floor January 2000

footer is the issue number.

Details of each section are given in the first column of the Text

issue and update control table. The table thus forms a 2.1 January 2000

matrix into which the dates of issue of the original 2.1.1 January 2000

document and any subsequent updated sections are 2.1.2 January 2000

located. 2.1.3 January 2000

2.2 January 2000

The information and guidance contained herein is 2.2.1 January 2000

produced for the assistance of certificated officers who by 2.2.2 January 2000

virtue of such certification are deemed competent to 2.2.3 January 2000

operate the vessel to which such information and 2.2.4 January 2000

guidance refers. Any conflict arising between the 2.2.5 January 2000

information and guidance provided herein and the profes- 2.2.6 January 2000

sional judgement of such competent officers must be 2.3 January 2000

immediately resolved by reference to Maersk Technical 2.3.1 January 2000

Operations Office. 2.3.2 January 2000

2.3.3 January 2000

2.3.4 January 2000

2.4 January 2000

2.4.1 January 2000

2.4.2 January 2000

2.4.3 January 2000

2.4.4 January 2000

2.4.5 January 2000

2.5 January 2000

Issue: 1 Issues and Updates - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Issue 1 Issue 2 Issue 3 Issue 4 Issue 1 Issue 2 Issue 3 Issue 4

Text

2.5.1 January 2000 Illustrations

2.5.2 January 2000 2.1.1a January 2000

2.6 January 2000 2.1.2a January 2000

2.6.1 January 2000 2.1.2b January 2000

2.6.2 January 2000 2.1.3a January 2000

2.6.3 January 2000 2.2.1a January 2000

2.6.4 January 2000 2.2.2a January 2000

2.7 January 2000 2.2.3a January 2000

2.7.1 January 2000 2.2.4a January 2000

2.7.2 January 2000 2.2.5a January 2000

2.8 January 2000 2.2.6a January 2000

2.8.1 January 2000 2.3.1a January 2000

2.8.2 January 2000 2.3.2a January 2000

2.8.3 January 2000 2.3.3a January 2000

2.8.4 January 2000 2.3.4a January 2000

2.9 January 2000 2.4.1a January 2000

2.9.1 January 2000 2.4.2a January 2000

2.9.2 January 2000 2.4.3a January 2000

2.9.3 January 2000 2.4.4a January 2000

2.10 January 2000 2.4.5a January 2000

2.10.1 January 2000 2.5.2a January 2000

2.10.2 January 2000 2.6.1a January 2000

2.10.3 January 2000 2.6.1b January 2000

2.11 January 2000 2.6.2a January 2000

2.12 January 2000 2.6.3a January 2000

2.12.1 January 2000 2.6.4a January 2000

2.12.2 January 2000 2.7.1a January 2000

2.13 January 2000 2.7.2a January 2000

2.13.1 January 2000 2.8.1a January 2000

2.13.2 January 2000 2.8.2a January 2000

2.13.3 January 2000 2.8.3a January 2000

2.13.4 January 2000 2.8.4a January 2000

2.13.5 January 2000 2.9.1a January 2000

2.13.6 January 2000 2.9.3a January 2000

2.13.7 January 2000 2.10.1a January 2000

2.13.8 January 2000 2.10.2a January 2000

2.14 January 2000 2.10.3a January 2000

2.14.1 January 2000 2.11a January 2000

2.14.2 January 2000 2.12.1a January 2000

2.14.3 January 2000 2.12.2a January 2000

2.14.4 January 2000 2.13.1a January 2000

2.14.5 January 2000 2.13.1b January 2000

2.14.6 January 2000 2.13.2a January 2000

2.15 January 2000 2.13.4a January 2000

2.15.1 January 2000 2.13.7a January 2000

2.15.2 January 2000 2.13.8a January 2000

2.15.3 January 2000 2.14.1a January 2000

2.5.2 January 2000 2.14.2a January 2000

Issue: 1 Issues and Updates - Page 2

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Issue 1 Issue 2 Issue 3 Issue 4 Issue 1 Issue 2 Issue 3 Issue 4

Illustrations Illustrations

2.14.3a January 2000 5.2a January 2000

2.14.5a January 2000 5.3a January 2000

2.14.6a January 2000 5.4a January 2000

2.15.1a January 2000 5.5a January 2000

5.6a January 2000

Text

3.1 January 2000 Text

3.1.1 January 2000 6.1 January 2000

3.1.2 January 2000 6.2 January 2000

3.1.3 January 2000 6.3 January 2000

3.1.4 January 2000 6.4 January 2000

3.1.5 January 2000

3.1.6 January 2000 Illustrations

3.2 January 2000 6.1a January 2000

6.1b January 2000

Illustrations 6.2a January 2000

3.1.1a January 2000 6.4a January 2000

3.1.2a January 2000

3.1.3a January 2000

3.1.5a January 2000

3.1.6a January 2000

3.2a January 2000

Text

4.1 January 2000

4.2 January 2000

4.3 January 2000

4.4 January 2000

4.5 January 2000

Illustrations

4.1a January 2000

4.2a January 2000

4.3a January 2000

4.4a January 2000

4.5a January 2000

Text

5.1 January 2000

5.2 January 2000

5.3 January 2000

5.4 January 2000

5.5 January 2000

5.6 January 2000

Issue: 1 Issues and Updates - Page 3

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Mechanical Symbols

Stop Valve Storm Valve With Hand Wheel Flexible Hose Observation Glass Overboard Discharge

Screw Down Non-Return Water Separator Spool Piece

Flow Control Valve Expansion Bend Pipe

Valve

P1 P2

Angle Stop Valve Pressure Reducing Valve Hopper Without Cover Air Trap / Deaerating Valve Discharge/Drain

Normally Open

Angle Screw Down Non- Gear or Screw Type Pump N.O or N.C or

Solenoid Valve Orifice

Return Valve Normally Closed

Air Control

Lift Check Non-Return Valve Blind (Blank) Flange Centrifugal Pump Tank Penetration

Valve

Swing Check Non-Return Temperature Control Spectacle Flange

Mono Screw Pump Air Horn

Valve Valve (With Hand Wheel) ( Open, Shut)

3-Way Temperature Control Sounding Head with Dresser Type

Gate Valve Eductor (Ejector)

Valve (With Hand Wheel) Filling Cap Expansion Joint

Sounding Head with Self

Wax Expansion Temperature Not Connected

Butterfly Valve Closing Cap and Sampling Hand Pump

Control Valve Crossing Pipe

Cock (Self Closing)

3-Way Wax Expansion Liquid Level Gauge

Ball Valve Suction Bell Mouth Connected Crossing Pipe

Temperature Control Valve

2-Way Cock Water Transducer Vent Pipe Cylinder Piston Actuator T Pipe

A Butterfly Valve With Vent Pipe with Filter Regulating Valve

3-Way Cock (L-Type) Hose Valve

Air Actuator Flame Screen With Strainer

3-Way Cock (T-Type) Suction Non-Return Valve Simplex Strainer Flow Meter Non-Return Ball Valve

Safety / Relief Valve Float Valve Duplex Strainer Hydraulic Operated Valve

Reciprocating Type Pump (Open/Shut)

Angle Safety / Relief Valve Deck Stand (Manual) Mud Box Manometer

Regulating Valve Spark Arrester Rose Box Filter

Self Closing Valve Valve Locked Closed Y-Type Strainer HB Fire Hose Box

Quick-Closing Valve

Valve Locked Open Steam Trap Without Strainer FB Foam Box

(Pneumatic Operated)

Quick-Closing Valve Bellows Type

Steam Trap With Strainer Accumulator

(Wire Operated) Expansion Joint

Issue: 1 Mechanical Symbols

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Electrical and Instrumentation Symbols

CP Compound Gauge

Trip Automatic Trip DPI Differential Pressure Indicator

DPS Differential Pressure Switch

DPT Differential Pressure Transmitter

I Interlock FD Flow Detector

FS Flow Switch

FT Flow Transmitter

Locally Mounted IL Indication Lamps

XX

Instrument (2 letters) LAH Level Alarm High

LAL Level Alarm Low

Locally Mounted LI Level Indicator

XXX LIC Level Indicating Controller

Instrument (3 letters)

LS Level Switch

LT Level Transmitter

XXX Remotely Mounted

PAH Pressure Alarm High

XXXX Instrument

PAL Pressure Alarm Low

PI Pressure Indicator

Letters outside the circle

XXX PIC Pressure Indicating Controller

of an instrument symbol

XXXX

HH indicate whether high (H), PIAH Pressure Indicator Alarm High

high-high (HH), low (L) PIAL Pressure Indicator Alarm Low

or low-low (LL) function

is involved PIAHL Pressure Indicator Alarm High Low

O = Open PS Pressure Switch

C = Closed PT Pressure Transmitter

SAH Salinity Alarm High

TAH Temperature Alarm High

TAL Temperature Alarm Low

TI Temperature Indicator

TIC Temperature Indicating Controller

TIAH Temperature Indicator Alarm High

TIAL Temperature Indicator Alarm Low

TIAHL Temperature Indicator Alarm High Low

TS Temperature Switch

TT Temperature Transmitter

VAH Viscosity Alarm High

VAL Viscosity Alarm Low

VCA Vacuum Alarm

VCI Vacuum Indicator

VCT Vacuum Transmitter

VI Viscosity Indicator

VT Viscosity Transmitter

XS Auxillary Unspecified Switch

ZI Position Indicator

ZS Limit Switch

Issue: 1 Electrical and Instrumentation Symbols

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Maersk Machinery Colour Scheme

Dom. Fresh Water

H.T. Cooling Water

L.T. Cooling Water

Sea Water

Hydraulic Oil

Lubricating Oil

Saturated Steam

Condensate

Feed Water

Fire/Deck Water

CO2

Fuel Oil

Marine Diesel Oil

Air

Bilges

Electrical Signal

Instrumentation

Issue: 1 Illustration Machinery Colour Scheme

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Introduction 1 Never continue to operate any machine or equipment which appears to be Part five gives operational emergency procedures for the use of essential

potentially unsafe or dangerous and always report such a condition machinery.

General immediately.

Part six deals with the ships internal communication systems.

Although the ship is supplied with shipbuilder's plans and manufacturer’s 2 Make a point of testing all safety equipment and devices regularly. Always

instruction books, there is no single handbook which gives guidance on test safety trips before starting any equipment. In particular, over-speed trips The valves and fittings identifications used in this manual are the same as those

operating complete systems as installed on board, as distinct from individual on auxiliary turbines must be tested before putting the unit to work. used by the shipbuilder.

items of machinery.

3 Never ignore any unusual or suspicious circumstances, no matter how trivial. Illustrations

The purpose of this manual is to fill some of the gaps and to provide the ship’s Small symptoms often appear before a major failure occurs.

officers with additional information not otherwise available on board. It is All illustrations are referred to in the text and are located either in-text where

intended to be used in conjunction with the other plans and instruction books 4 Never underestimate the fire hazard of petroleum products, whether fuel oil sufficiently small or above the text, so that both the text and illustration are

already on board and in no way replaces or supersedes them. or cargo vapour. accessible when the manual is laid face up.

Information relevant to the operation of the Peter Mærsk has been carefully 5 Never start a machine remotely from the control room without checking When text concerning an illustration covers several pages the illustration is

collated in relation to the systems of the vessel and is presented in two on board visually to see if the machine is operating satisfactorily. duplicated above each page of text.

volumes consisting of DECK OPERATING MANUAL and MACHINERY

OPERATING MANUAL. In the design of equipment and machinery, devices are included to ensure that, Where flows are detailed in an illustration these are shown in colour. A key of

as far as possible, in the event of a fault occurring, whether on the part of the all colours and line styles used in an illustration is provided on the illustration.

The Deck Operating Manual is designed to complement Marpol 73/78, equipment or the operator, the equipment concerned will cease to function Details of colour coding used in the illustrations are given in the following

ISGOTT and Company Regulations. without danger to personnel or damage to the machine. If these safety devices colour scheme.

are neglected, the operation of any machine is potentially dangerous.

The vessel is constructed to comply with Marpol 73/78. These regulations can Symbols given in the manual adhere to international standards and keys to the

be found in the Consolidated Edition, 1991 and in the Amendments dated Description symbols used throughout the manual are given on the following pages.

1992, 1994 and 1995.

The concept of this Machinery Operating Manual is to provide information to Notices

Officers should familiarise themselves with the contents of the International technically competent ship’s officers, unfamiliar to the vessel, in a form that is

Convention for the Prevention of Pollution from Ships, such that they are readily comprehensible. Thus, aiding their understanding and knowledge of The following notices occur throughout this manual:

aware of the category of the cargo being carried and the requirements for the specific vessel. Special attention is drawn to emergency procedures and fire

cleaning of cargo tanks and the disposal of tank washings / ballast containing fighting systems. WARNING

residues. Warnings are given to draw the reader’s attention to operation where

The manual consists of a number of parts and sections which describe the DANGER TO LIFE OR LIMB MAY OCCUR.

Particular attention is drawn to Appendix IV of Marpol 73/78, the form of systems and equipment fitted and their method of operation related to a

Cargo Record Book. It is essential that a record of relevant cargo/ballast schematic diagram where applicable. ! CAUTION

operations are kept in the Cargo Record Book and duly signed. Cautions are given to draw the reader’s attention to operations where

Part one details the machinery commissioning procedures required to bring the DAMAGE TO EQUIPMENT MAY OCCUR.

In many cases the best operating practice can only be learned by experience. vessel into varying states of readiness, from bringing the vessel to a live

Where the information in this manual is found to be inadequate or incorrect, condition through to securing plant for dry dock. (Note ! Notes are given to draw the reader’s attention to points of interest or to

details should be sent to the Maersk Technical Operations Office so that supply supplementary information.)

revisions may be made to manuals of other ships of the same class. The second part of the manual details ships systems, providing a technical

description, system capacities and ratings, control and alarm settings and

Safe Operation operating details.

The safety of the ship depends on the care and attention of all on board. Most Part three provides similar details for the vessels main machinery control

safety precautions are a matter of common sense and good housekeeping and system.

are detailed in the various manuals available onboard. However, records show

that even experienced operators sometimes neglect safety precautions through Part four details the emergency fire fighting system incorporated on the vessel,

over-familiarity and the following basic rules must be remembered at all times. providing information on their operation and system capacities.

Issue: 1 Introduction

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Part 1

Operational Overview

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Part 1: Operational Overview

1.1 To Bring Vessel Into Live Condition

Dead Ship Condition

Supply Power to 440V & 220V Emerg.Switchboards 2.13

Shore SupplyAvailable

Shore Supply Available No Shore Supply Available

Prepare Central F.W. Cooling Systems.

2.5.2

Establish Shore Supply. Start Central C.W. Pumps.

Ensure Emergency

Tank Level Generator Fuel

is Adequate. 2.13..4

Check Phase Sequence, 2.13.2

Voltage and Frequency.

Start up Instrumentation Air System. 2.10.3

Supply Main Switchboard. 2.13.4 Start Emergency Generator. 2.13.4

Disconnect Shore Supply. 2.13.2

Stop Emergency Generator and

2.12.2

place on Standby.

Place Emergency Generator

2.12.2

on Standby.

Isolate Sequential Restart System.

All Ancillary Equipment set to Manual to avoid

Low Pressure Auto Start. 2.13

Reset Preference Trips. 2.13.5

Supply Emergency 440V Switchboard.

Supply Emergency 220V Switchboard.

Prepare S.W. Cooling System. 2.4.1

Start Emergency Air Compressor and Top Up

2.10.1

Auxiliary Air Reservoir if required. Start S.W. Cooling Water Pump. 2.4.1

Start a Generator Engine L.O. Priming Pump. 2.13.3 Start Engine Room and Accommodation

2.14.3

Ventilation Fans. Start Air Conditioning.

Start Generator Engine Air Driven D.O. Pump. 2.6.2 Ensure the CO2 Systems are

4.2

Ready for Use.

Prepare an Auxiliary Engine for Starting. 4.2

2.12.1 Ensure Foam System is Ready for Use.

Start Auxiliary Generator. Cargo

Start I.G.S. Deck Seal Supply Pump. 2.15.2

Supply Power to Main 440V & 220V Switchboards. 2.13 Pressurise Fire Main. 4.1

Issue: 1 1.1 To Bring Vessel Into Live Condition - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.1 To Bring Vessel

Into Live Condition

Start Domestic Water System with Electric Heater. 2.14.1

Put Refrigeration System into Operation. 2.14.2

Put G.S. Air System into Operation. 2.10.2

Pump Bilges to Bilge Holding Tank as Required. 2.9.1

Put all Ancillary Equipment on Standby.

Restore Sequential Restart System.

Put remaining Auxiliary Diesel Generators

on Standby.

PLANT IS NOW IN LIVE CONDITION

One Diesel Generator in Use,

Other Diesel Generators on Standby.

Emergency Generator on Standby.

Boiler and Steam System Shut Down.

S.W. and C.F.W. Systems in Use.

Domestic Services in Use.

Start Fire Pump on Standby. 4.1

Start Sewage Treatment Plant. 2.14.5

Issue: 1 1.1 To Bring Vessel Into Live Condition - Page 2

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.2 To Prepare Main Plant

For Operation

Plant is in Live Condition

One Diesel Generator in Use,

Other Diesel Generators on Standby.

Emergency Generator on Standby.

Boiler and Steam System Shut Down.

S.W. and C.F.W. Systems in Use.

Domestic Services in Use.

Prepare and Flash Up Aux Boiler, using

2.2.1

Diesel Oil and Air Atomising.

Supply Steam to M.E. F.O. Heater.

Start M.E. F.O. Supply and Circulating Pumps.

2.6.1

Start Viscosity Controller.

.

Supply Steam to Low Pressure Steam System. 2.2.5 Circulate F.O. until the D.O. has been Expelled.

Start Feed Pump. Maintain Standby Generators in Warm

2.3.3 2.5.1

Line up Distilled Water Make Up System. Condition using G/E Preheater.

2.2.5 Plant in 'In Port' Condition

Supply Steam to F.O. Tanks and Trace Heating

Supply Steam to Boiler Fuel Oil Heaters. 2.2.5

Start Boiler F.O. Pump and Circulate Fuel. 2.6.3

One Diesel Generator in Use,

Other Diesel Generators on Standby.

Emergency Generator on Standby.

Change Boiler to Operate on F.O. and Boiler and Steam System in Use.

2.6.3

Atomising Steam. Diesel Generator Running on HFO.

M.E. JCW System in Warm Condition.

M.E. Circulating with Hot F.O.

Put Boiler on Automatic Operation. Prepare other

2.2.2

Boiler and Set to Automatic Operations.

Start F.O. Purifier System. 2.7.2

Change Diesel Generator to Run on H.F.O. 2.6.2

Start M.E. Jacket C.W. Pumps. 2.5.1

Supply Steam to Jacket C.W. Heaters. 2.2.5

Issue: 1 1.2 To Prepare Main Plant For Operation - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.3 To Prepare Main Plant For Manoeuvring

From 'In Port' Condition

Plant in 'In Port' Condition

2.10.1

Supply Starting Air and Control Air to the M.E.

One Diesel Generator in Use,

Other Diesel Generators on Standby.

Emergency Generator on Standby. Start Aux Blowers and Switch to Auto. 2.1.1

Boiler and Steam System in Use.

Diesel Generator Running on H.F.O.

M.E. JCW System in Warm Condition.

M.E Circulating with Hot F.O. Obtain Clearance from the Bridge, Turn M.E.

5.2

Over on Starting Air from Local Control Stand.

Start L.O. Purifier System. 2.8.3

Close Indicator Cocks.

From the Local Control Stand Start the M.E.

5.2

in the Ahead and Astern Directions.

Start M.E. L.O. Pump. Close Turbo Blower Drains.

2.8.1

Heat Sump if Required.

Change Control to the Engine Control Room. 2.1.2

Start Crosshead L.O Pump. 2.9.1

Change Control to Bridge Control. 2.1.2

Ensure Cylinder Oil Measuring Tank is Full. 2.8.1

Check Telegraph, Bridge/E.R. Clocks and

2.1.2

Start another Diesel Generator and Communications.

2.12.1

Run In Parallel.

Ensure all Standby Pumps are On Auto. 2.13

Start both Steering Motors.

2.11

Carry out Steering Tests.

1.6

Prepare Deck Machinery for Use.

Cargo

.

Obtain Clearance from the Bridge and Turn the

Engines Two or Three Revolutions while Manually

2.1.1 Plant in Manoeuvring Condition

Operating Cylinder Oil Pumps.

Take Out the Turning Gear.

Two Diesel Generators in Use,

Remaining Diesel Generator on Standby.

Put Starting Air System into Use. 2.10.1 Emergency Generator on Standby.

Boilers and Steam System in Use.

Diesel Generators Running on H.F.O.

M.E. Heated and Ready for Use on Bridge Control.

M.E. Circulating with Hot F.O.

Both Steering Gear in Use.

Deck Machinery Ready for Use.

Issue: 1 1.3 To Prepare Main Plant For Manoeuvring From ‘In Port’ Conditions - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.4 To Change Main Plant From Manoeuvring To Full Away

Plant in Manoeuvring Condition

Shut down Deck Machinery. 1.6.2

Cargo

Two

TwoDiesel

DieselGenerators

Generatorsininuse,

Use,

Stop one Steering Gear Motor. 2.11

remaining Diesel Generator on Standby.

Emergency Generator on Standby.

Boilers and Steam System in Use.

Diesel Generators Running on H.F.O. Put Dump Steam System into Operation. 2.2.4

M.E. Heated and Ready for Use on Bridge Control.

M.E. Circulating with Hot F.O.

Both Steering Gear in Use.

Deck Machinery Ready for Use. Operate Turbo Blower Cleaning System

Vessel Manoeuvring on Bridge Control. 2.1.1

if Required.

Ensure Boiler Stops as the Economiser takes over

Put Main Engine on Automatic Run Up Programme. 2.1.2 Steam Generation. Secure Standby Boiler and

2.2.1

Supply Heating to Maintain Pressure above

0.5 kg/cm2 or put in Wet Lay Up Condition.

Shut Down M.E. Jacket Heating Systems. 2.5.1

Start up F.W. generator System.

Do not fill Fresh Water Tanks while in 2.4.2

Operate Auxiliary Boiler Sootblowers while Boiler 2.2.3 Coastal Waters.

is on load.

Transfer and Purify F.O. as Required. 2.7.1

Operate Exhaust Gas Economiser Sootblowers. 2.2.3

When Run Up Program completes, Check that

2.1.2

Pressures and Temperatures Stabilise.

When Bridge notifies Engine Control Room

of Full Away, record the following:

Time.

M.E. Revolution Counter. Reduce the Bilge Water Holding Tank Level

F.O. and D.O. Tank levels. 2.10

through the O.W.S. if vessel is not in Restricted

F.O. and D.O. Counters. Area.

Fresh Water Tank levels.

Shut Down Generators until only One is in Use.

2.12

Ensure Auxiliary Blowers Stop Automatically. 2.1.2 Put Remaining Two Generators on Standby.

Vessel is Full Away on Bridge Control.

Issue: 1 1.4 To Change Main Plant From Manoeuvring To Full Away - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.5 To Prepare For UMS Operation

Plant 'Manned' Condition

All Standby Pumps and Machinery Systems

2.13.5

are on Auto Start, Sequential Restart System

Operational.

All F.O., L.O. and Fresh Water Tanks/Sumps Acetylene and Oxygen Cylinder and pipeline

are Adequately Full. Valves are closed.

All Ventilation Fans Running.

Bilges are Dry and High Level Alarms are 2.9.1

Operational. All Combustable Material Stored in a Safe Place. 2.14.6 Main Engine on Bridge Control. 2.1.2

4.1 All Strainers and Filters of Running and Stand By

Smoke and Fire Sensors are Operational. Machinery are in a Clean Condition. Data Logger is programmed to print Parameters

Cargo 3.1

at 0800hrs, 1200hrs and 1730 hrs.

All Piping Systems are Tight and not Temporarily E.R. and Steering Gear Compartment W.T.

Repaired. Doors, Sky Lights and Funnel Dampers are Shut.

Control is on the Bridge and Duty Officer is

3.1

informed of Commencement Time of UMS.

All Alarms and Safety Cut Outs are Operational. 3.1 All Parameters are within Normal Range. 3.1

Duty Officer should be aware of location of

Duty Engineer.

All Drain Tanks are Empty.

E.C.R. Air Conditioning Operating Correctly. 2.14.4

Compressed Air Bottles are Fully Charged. 2.10 Watchkeeper Control switched to

Duty Engineer's Cabin.

Loose Items are Secured.

Purifier Feed Inlets are Suitably Adjusted. 2.7.2

Electric Kettle Plugs Removed in E.C.R. E.R. not to be Unmanned for more than 8hrs.

Emergency Diesel Generator is on Standby. 2.12.2

Workshop Welding Machine Plug is Removed.

Stopped Diesel Generators are on Standby. 2.12.1

Plant in 'UMS' Condition

Issue: 1 1.5 To Prepare For UMS Operation - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.6 To Change From UMS To Manned Operation

Plant in 'UMS' Condition

Activate Patrol Man Alarm on Entry into the Engine

Room.

Notify Bridge of Manned Condition.

Inform Bridge why E.R. is Manned if Outside

Normal Hours.

Switch Watchkeeping Control to the E.C.R.

Reset Patrol Man Alarm every 27 minutes when

Duty Engineer only is Manning the E.R.

Examine latest Parameter Print Out.

Handover to on coming Duty Engineer and

inform him of any Abnormalities.

Discuss any Defects with the Senior Engineer,

who will decide if they warrant inclusion in the

Work List. The Duty Engineer should be aware of

all Maintenance Work being carried out, and

informed of any changes that occur during the

day.

Plant in 'Manned' Condition.

Issue: 1 1.6 To Change From UMS To Manned Operation - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.7 To Change Main Plant From Full Away To Manoeuvring Condition

Vessel is Full Away on Bridge Control. Test Fire the Boiler in Use. 2.2.1

Operate E.G.B. Sootblowers and Isolate System. 2.2.6

Ensure that the E.R. Bilges and Bilge Holding

2.9.1

Tank are Empty.

Bridge Informs Engine Control Room of E.O.P.

Prepare Sewage Treatment System for

2.14.5

Port Operation. Record the Following:

Time.

M.E. Revolution Counter.

F.O. & D.O. Tank Levels.

Shut Down F.W.Evaporator Plant. 2.4.4

F.O. & D.O. Counters.

Fresh Water Tank Levels.

Start another Diesel Generator and Place

2.12.1

in Parallel with Running Generator.

Prepare Standby Boiler for Operation. 2.2.1

Supply Steam to J.C.W. Heaters. 2.5.1 1.6.2

Prepare Deck Machinery for Use.

Cargo

Prepare Main Starting Air Compressors for Use.

2.10.1 Check Bridge/E.R. Clocks and Communications. 2.1.2

Check Starting Air System Drains for Water.

If Required to Manoeuvre on D.O. Begin Change Operated Turbo Charger Washing System 2.1.1

2.6.1 if Required.

Over 1 Hour Before E.O.P.

Plant in Manoeuvring Condition

30 mins Before E.O.P. Bridge Begins to

2.1.1

Reduce Speed.

Two Diesel Generators in Use,

remaining Diesel Generator on Standby.

Emergency Generator on Standby.

Start Second Steering Motor. Boiler in Use.

2.11

Carry Out Steering Tests. Diesel Generators Running on H.F.O.

Both Steering Gears in Use.

Deck Machinery Ready for Use.

Issue: 1 1.7 To Change Main Plant From Full Away To Manoeuvring Condition - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.8 To Secure Main Plant At Finished

With Engines

Plant in Manoeuvring Condition

Two Diesel Generators in Use,

remaining Diesel Generator on Standby.

Emergency Generator on Standby. After a Minimum of 15 mins Stop Main L.O. Pumps.

Boiler and Economiser in Use. Stop Crosshead L.O. Pumps. 2.8.1

Diesel Generators Running on H.F.O. Maintain L.O. Sump Temperature with L.O. Purifier.

Both Steering Gears in Use.

Deck Machinery Ready for Use.

If M.E. was Manoeuvred on D.O. 2.6.1

Bridge notifies Engine Control Room of F.W.E.

Two Diesel Generators will Remain in Use if

Cargo or Ballast Pumps are Required. 2.12.1

Switch Over to Engine Control Room Control. 2.1.2

Prepare Plant for Cargo Operations if Required. 2.2.4

Stop Auxiliary Blowers. 2.1.1

Isolate Starting Air. Prepare Plant for I.G.S. Operations if Required. 2.15.1

Open Indicator Cocks.

Open Turbo Blower Drains. 2.1.1

Vent M.E. Starting Air and Control Air Systems.

Engage Turning Gear. Plant in 'In Port' Condition

Stop Steering Gear. 2.11

Maintain J.C.W Temperature for Normal Port Stay. 2.5.1

Issue: 1 1.8 To Secure Main Plant At Finished With Engines - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

1.9 To Secure Main Plant For Dry Dock

Plant in 'In Port' Condition

Change Diesel Generator to Run on D.O. 2.6.2 Establish Shore Power.

2.13.2

Check Phase Sequence, Voltage and Frequency.

Shut down Diesel Generators until only One is

in Use.

Shut Down Auxiliary Boilers.

Allow to Cool Naturally, Drain if required for 2.2.1 Stop Diesel Generator. 2.12.1

Ensure all Tanks are at the Required Levels to Maintenance OR put in Wet Lay Up Condition.

give the Vessel the Necessary Trim, Draft and

Stability for Entering Dry Dock. Connect Shore Supply.

Connect Shore Supply to Main Switchboard.

Shut Down Feed Pumps and Condensate System. 2.12

2.3 Establish Lighting and Ventilation and any other

Shut Steam Off the J.C.W. Heaters. Allow J.C.W. Isolate Distilled Water Tanks. Essential Services.

2.5.1

Pumps to Run until M.E. has Cooled Down.

Circulate Boiler F.O. System with D.O.

2.6.3 Shut Down S.W. and F. W. Cooling Systems. 2.4&2.5

Transfer the Main Engine L.O. Sump to the Shut Down Boiler F.O. Pumps.

2.8.3

L.O. Settling Tank via the Purifier.

Shut Down Stern Tube L.O. System. 2.8.2

Shut Down Control and G.S. Air Systems. 2.10

Shut Down L.O. Purifier. 2.8.3

Change Domestic Water Heating to Electric. 2.14.1

Restart F.W. Cooling Pump and Circulate

Shut Down F.O. Purifier. 2.7.1 2.5.2

Diesel Generator until Cool.

Shut Down Air Conditioning and Refrigeration

2.5.2

M.E. should have been Manoeuvred on D.O. Plants until Shore C.W. Supply is Established.

Secure CO2 System. 4.2

If not, Change Over to D.O. and Circulate F.O.

Back to H.F.O. Tank, until the Line has been 2.6.1

Flushed with D.O. Shut Down Fire Pumps.

4.1

Stop M.E.F.O. Pumps and Viscosity Controller. Pressurise Fire Main from Shore Supply. The Dry Dock can now be Emptied.

2.6.2

Shut Down Deck Machinery System. Isolate Sequential Restart System. 2.13.5

Deck Plant Secured for Dry Dock

Issue: 1 1.9 To Secure Main Plant For Dry Dock - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

2nd Platform

3rd Platform

No.3 H.F.O. No.2 H.F.O. H.F.O. Bunker

Bunker Tank (P) Bunker Tank (P)

Tank No.2 (P)

H.F.O. Bunker

Tank No.3 (P)

No.1 H.F.O.

Elect. Bunker Tank (P)

H.F.O. Bunker

Fresh Water Wkshop Tank No.1 (P)

Tank &

Store Engine

Control

Room Engine Store

DN UP

UP

Lift Space

UP

Turbine Oil Tank

DN

Cyl. Oil Tank No.1

Cyl. Oil Tank No.2

Pump

DN Workshop Room

M/E L.O. Storage Tank

Pipe Trunk UP

Distil. Water Tank

M/E L.O. Settling Tank

Purifiers and Heaters

F.O. Pumps

H.F.O. Bunker Tank No.1 (S)

and Heaters

H.F.O. Bunker

H.F.O. Settling Tank Tank No.1 (S)

D.O. Service H.F.O. Bunker

Fresh Water Tank H.F.O.

Tank Service Tank Tank No.2 (S)

A/E L.O. Storage Tank

Refrig. & Aircon. A/E L.O. Settling Tank Cascade

Compressor Space No.3 H.F.O. Tank

Bunker Tank (P)

D.O.

Service Tank H.F.O

Service Tank H.F.O.

Settling Tank

Issue: 1 Location Plan Of Engine Room - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

4th Platform

H.F.O. Bunker H.F.O. Bunker

Tank No.3 (P) Tank No.2 (P)

Floor Level

Bilge Well

H.F.O. Bunker High Sea Chest

Tank No.1 (P)

L.O Drain

Tank

Diesel Oil

Tank (Port)

UP DN Clean Bilge F.O

Water Tank Bilge Well Overflow F.O Overflow

Tank Tank

UP DN Bilge Well

L.O Sump Tank Pump

Room

DN Dirty Bilge UP

Water Tank

Bilge Well

UP DN

Bilge Well

Cofferdam

Diesel Oil

Tank (Starboard)

H.F.O. Bunker Low Sea Chest

Tank No.1 (S) Bilge Well

H.F.O. Bunker

Tank No.2 (S)

Issue: 1 Location Plan Of Engine Room - Page 2

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Part 2

Main Engine and Auxiliary Systems

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Illustration 2.1.1a Sulzer 7RTA62U Hydraulic Exhaust Exhaust Manifold

Valve Actuator

Cylinder Head

Turbo' Blower

Air Cooler

Camshaft

Scavenger Port

Piston Rod

Crosshead Guide

Crosshead Lub. Shoe

Oil Pipe

Lubricating Oil

Scavenge Air

Combustion Gas

Fresh Water

Main Bearing Bolts

Issue: 1 Illustration 2.1.1a Main Engine

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

2.1. Main Engine The pistons are cooled by bearing lubricating oil. The thrust bearing and Cooling water system description

turning gear are situated at the engine-driving end. The camshaft is driven by The cooling water supplied by the jacket cooling water pump is divided in two

2.1.1 Main Engine Details gear wheels from the crankshaft. part streams, after the heater. One part stream, of a basic setting of about 15%

water flow, by-passes the cooler. This is led via the jacket cooling water cooler

Maker: Dalian - Sulzer The engine is started by compressed air, which is controlled by a starting air by-pass to provide a minimum water flow to the primary cooling piping, where

Model: 7RTA62U distributor. it joins cooling water allotted by the 3-way diverting valve.

Type: Two stroke, single acting direct reversible,

In case of failure of the pneumatic control system, the engine can be controlled The main water flow of about 85% flows through the main jacket cooling

cross head diesel engine with two constant

from an emergency control stand. water cooler line, through the automatic temperature control valve to the 3-way

pressure turbo chargers and air coolers.

Number of cylinders: 7 diverting valve at the engine inlet. The automatic temperature control valve

Lubricating Oil System regulates the water flow through the cooler in order to keep the water outlet

Cylinder bore: 620 mm

The engine lubrication system, (with the exception of cylinder and exhaust temperature constant in the return piping at about 85°C.

Stroke: 2,150 mm

valve spindle lubrication), is supplied by one of two main pumps, which take

Output (M.C.R.): 15540 bhp at 113 rpm

suction from the sump tank and supply the main bearings. Two cross-head The cooling water flowing back from the air separator and turbo-charger is led

Direction of rotation: Clockwise looking from aft

pumps take suction from the main pump discharge after the automatic back- again back to the cooling water pump suction, where it joins the outlet from the

Specific fuel oil consumption: 124.3 g/bhp per hour

flush filter and supply the cross-head bearings. buffer tank.

Firing order: 1-6-3-4-5-2-7

Main bearing oil system From the 3-way diverting valve, the cooling flow for the turbo-chargers is

Turbocharger

Main bearing oil, at an operating pressure of 2.5 to 3.5 kg/cm2 is also supplied branched off. The 3-way diverting valve distributes the water flow in corre-

Maker: A.B.B. via an articulated lever to cool the working piston crown. Main bearing and spondence with the control command, on one side via connecting piping to the

No.of sets: 2 cross-head oil systems are interconnected through a non-return valve. The primary cooling water piping, on the other side to the secondary cooling water

Type: VTR564-3 integrated damper (axial de-tuner) and the balancer are also cooled with piping.

bearing oil.

General Description The cooling water which has been branched off the inlet piping flows through

If the cross-head bearing oil pump should fail, then the cross-head oil system the turbo-charger turbine casing via a common return piping and back to the

The RTA-engine is a single acting, two-stroke, reversible, Diesel engine of is supplied with oil from the main L.O. pumps. Under such conditions, the cooling water outlet. The water flow through the turbo-charger is set by

cross-head design with exhaust gas turbo-charging and uniflow scavenging. engine can only be operated at reduced load (Load Indicator Position, max. orifices in the water inlets.

Tie rods bind the bed-plate, columns and cylinder jacket together. Crankcase 4.5).

and cylinder jackets are separated from each other by a partition, which incor-

porates the sealing gland boxes for the piston rods. The cylinders and cylinder Cross-head bearing oil system

heads are fresh water-cooled. The operating pressure of the cross-head bearing oil is 10 - 12 kg/cm2. This

pressure is reduced via a pressure-retaining valve to 4.5 - 6 kg/cm2 for the

The exhaust gases flow from the cylinders through the hydraulically operated operation of the flexible coupling which is arranged in the balancer casing at

exhaust valves into an exhaust gas manifold. The exhaust gas turbo-chargers the free end.

work on the constant pressure charging principle.

The oil for the exhaust-valve actuator pumps passes from the cross-head

The engine is provided with two electrically-driven blowers. The suction side bearing oil system through an air separator. For actuating the exhaust valves,

of the blowers are connected to the scavenge air space after the air cooler. the oil pressure is raised by the actuator pumps to about 160 kg/cm2.

Between the air cooler and the scavenge air receiver, non-return valves are

fitted, which automatically close when the auxiliary blowers supply the air. The lubrication of cross-heads and connecting rod bottom end bearings is

The auxiliary blowers will start operating before the engine is started and will through articulated levers. The reversing servomotors are actuated by cross-

ensure sufficient scavenge air to obtain a safe start. head bearing oil.

During operation of the engine, the auxiliary blowers will start automatically Cylinder lubrication system

each time the engine load is reduced to about 30-40%, and they will continue The power dependent lubrication of the pistons, cylinders and exhaust valve

operating until the load again exceeds approximately 40-50%. spindles is performed by a separate cylinder lubrication system.

The charge air delivered by the turbo-chargers, flows through air coolers and Cooling Water System

water separators into the air receiver. It enters the cylinders via air flaps The cooling water must be treated with an approved cooling water inhibitor to

through the scavenge ports when the pistons are nearly at their B.D.C. At low prevent corrosive attack, sludge formation and scale deposits in the system.

loads independently driven auxiliary blowers supply additional air to the

scavenging air space.

Issue: 1 2.1.1 Main Engine Details - Page 1

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Fuel Oil System e) Start up the pumps for cylinder cooling water, bearing and cross- p) Set the switch at the control panel for the auxiliary blower to

The fuel oil is delivered via a supply pipe to the injectors. The delivered fuel head bearing lubricating oil and set the pressures to their normal AUTOMATIC.

quantity is considerably greater than that actually required by the engine. The values.

specified booster pressure is adjusted by a pressure-retaining valve. The q) Bring the safety cut-out to operating position.

surplus fuel is led via a return pipe back to the system. f) Check to ensure that all system vents are open. r) Press the EMERGENCY STOP button on the control panel and

observe if the safety cut-out on the fuel injection pumps reacts,

The main engine is designed to operate on fuel oil during manoeuvring. All g) Open each cylinder head indicator cock. Using the turning gear, i.e. their suction valves are lifted. After this check, press the

pipes to the fuel distributors on the cylinder heads are provided with trace turn the engine through a minimum of one full revolution to check EMERGENCY STOP RESET button.

heating and are insulated. Fuel distributors and injection valves are kept hot by that all the running gear is in order. Check if any large quantities

a separate circulation system. For reasons of safety, all high-pressure pipes are of water, oil or fuel has collected on the piston crown. Operate the s) Check whether the pressure gauge on the supply unit for cylinder

encased by a metallic hose. Any leakage is contained and led to an alarm tank cylinder pre-lubrication system. lubrication indicates 40 kg/cm2.

circulation system.

h) Shut the indicator valves. t) Take out the turning gear and secure the lever.

Injection valves and fuel distributors are kept hot by circulation of heated fuel.

u) Open the check cock 2.06 of the main automatic starting air shut-

For this a supply circulating line is led from the supply pipe to each cylinder i) Check to ensure that all the crankcase doors are closed with all the

off valve 2.04 for a short time and listen for the valve opening

head. After flowing through the three injection valves and distributor, the fuel latches tight. (can be heard distinctly). Close the cock again.

enters via a return circulating line into a common return collector main. The

circulation return is led again to a spill pipe via an orifice after the pressure- j) Check to ensure that cutting out devices for all the fuel injection v) Check hydraulic system of exhaust valve drive for tightness.

retaining valve. pumps are correctly positioned.

w) The levers on the local manoeuvring stand must be put into the

Procedure for Preparing the Engine for Starting k) Check that the fuel regulating linkage moves freely: correct position the corresponding to where the engine will be

started, (the bridge, the control room or the auxiliary local stand).

Before starting the engine, the below mentioned checks and procedures must Disengage the fuel control lever at the auxiliary manoeuvring stand from the The changeover buttons of the remote control must be activated.

be followed: position REMOTE CONTROL and engage it into the regulating linkage lever.

Loosen the fuel control lever lock, pull the handgrip up and move the fuel x) Check again to ensure that no personnel are near the flywheel.

All components that have been overhauled should have been correctly re- control lever backwards and forwards between the range '0' and '10'. After

assembled and fitted and their function checked. carrying out this check, put the fuel control lever back to the position y) Inform the bridge.

REMOTE CONTROL and lock it by tightening the wing nuts of the hand

All devices and tools, which were used, have been removed from the engine wheel. Procedure for the Operation of the Main Engine

and that no cleaning rags or other items have been left behind.

l) Check the pressure in the starting air receivers and open their Slow Turning

! CAUTION drains until any condensate has been drained.

Up until point ‘n’ the shut-off valves AE003 and AE004 of the starting air a) Turn by the turning gear. The crankshaft can be turned at a slow

receivers to the main automatic starting air shut-off valve must be closed m) Open the drain and test valves AE035 and AE036 until all water rate using the turning gear.

and the venting valve AE007 must be open (see illustration 2.10.1a) has been drained.

b) Slow turning with starting air. The running gear can be turned at

a) Check the fluid levels of all the tanks in the engine systems n) Close venting valve AE007 and open the main shut-off valves about 12 rpm by releasing the starting air by a measured amount.

(including the leakage drain tanks). AE003V and AE004 on the starting air receivers. This is initiated from the control room.

b) Check that all the shut-offs for the engine cooling water and o) The pressure gauges should now indicate the following pressures: The following conditions must be fulfiled before activating the slow turning

lubricating oil systems are in the correct position. operation:

Safety control air and stand by supply for air spring air on

Turning gear is disengaged.

c) Open the air supply to the shipboard system and from the starting the pressure reducing valve 23HA (6 kg/cm2)

air receivers to the control air supply. Oil pumps are operating (bearing oil and cross-head oil).

Air spring air supply on the pressure reducing valve 19HA

(7.5 kg/cm2) Fuel interlock not released. Reversing lever is set on REMOTE

d) Prepare the fuel. CONTROL.

Control air stand by supply on the pressure reducing valve

Speed control on minimum (Pos. ‘0’).

19HB (7 kg/cm2)

Issue: 1 2.1.1 Main Engine Details - Page 2

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

Indicator valves closed. d) When abnormally high or low temperatures are detected at a p) Check the charge air receiver drain manifolds sight glass to see if

water outlet, the temperature must be brought to the prescribed any water is draining away and if so, how much.

Shut-off valves on the starting air receivers open.

normal value very gradually. Abrupt temperature changes may

Air pressure for air spring correctly set. cause damage. q) Drain the scavenge spaces. To do this, open the drain cock of the

leakage manifold daily and look to see if any liquid flows out

During slow turning, the cylinder lubrication must be switched on.

e) The maximum permissible exhaust temperature at turbine inlet along with the charge air.

must not be exceeded.

Slow turning function r) Check the pressure drop across the oil filters. Clean them if

f) Check combustion by observing the colour of the exhaust gases. necessary.

The procedure is similar to starting the engine.

g) Maintain the correct charge air temperature after the air cooler s) The temperature of the running gear should be checked by feeling

The shut-off valve for starting air is opened by the control valve and starting with the normal water flow. In principle, higher charge air the crankcase doors. Bearings, which have been overhauled or

air reaches starting cut-off valve 215HA on the starting air distributor as well temperature will result in poorer filling of the cylinder, which in replaced, must be given special attention for some time after

as the starting air valves in the cylinder heads. return will result in a higher fuel consumption and higher exhaust being put into service.

gas temperatures.

Via the starting cut-off valve, a measured amount of starting air reaches the t) Listening to the noise of the engine will reveal any irregularities.

starting air distributor. This valve transmits the pneumatic signal to the h) Check the charge air pressure-drop through the air filter and air

respective cylinders. cooler. Excessive resistance will lead to a lack of air to the engine. u) Hand drawn indicator diagrams and Premet XL data provide

information on the combustion process and pressures within the

By this signal the valves 134HA-M before the starting valves are controlled in i) The fuel oil has to be carefully cleaned before being used. Open cylinder. When the quality of the fuel used changes the maximum

such a way that the starting valves are opened and shut for only short intervals. the drain cocks of all fuel tanks and fuel oil filters regularly for a pressure in the cylinder at service power must be determined at

short period to drain off any water or sludge, which may have the earliest opportunity and compared with the pressure measured

Procedure for Operating the Main Engine collected there. Maintain the correct fuel oil pressure at the inlet during the corresponding ship trial (speed, power).

to the fuel injection pumps. Adjust the pressure at the injection

It is preferable to operate the engine at constant power. When the speed / load pump inlet with the pressure-regulating valve in the fuel oil return v) Centrifuge the lubricating oil. Samples should be taken at regular

has to be altered, it should be done as slowly as possible. pipe so that the fuel oil circulates within the system at the normal intervals.

delivery capacity of the booster pump.

During normal running, regular checks have to be made and precautions taken w) Replenish the air cushion in damping vessels of fuel oil system.

which contribute towards trouble free operation. The most important of these j) The heavy fuel oil has to be sufficiently heated to ensure that its

are: viscosity before inlet to the fuel injection pumps lies within the x) Check the inspection glasses in the upper casing of the exhaust

prescribed limits. valve periodically and note if the air spring cylinder of each

a) Regular checks of pressures and temperatures. exhaust valve is rotating. If not, the offending valve must be

k) Determine the cylinder lubricating oil consumption. Extended overhauled at the next opportunity.

b) The values read off the instruments compared with those given in service experience will determine the optimum cylinder

the acceptance records and taking into account engine speed lubricating oil consumption. Manoeuvring

and/or engine power, provide an excellent yardstick for the engine

performance. Compare temperatures by feeling the pipes. l) The cooling water pumps should be run at their normal operating Correct manoeuvring and the resulting increase in engine load up to service

-point, i.e. the actual delivery head corresponds with the designed power, as well as decrease in load from the service power, is very important

The essential readings are: The load indicator position, turbo-charger speed, value. If the temperature difference between inlet and outlet with the usual high engine powers of today. Changing the load too quickly in

charge air pressure, exhaust gas temperature before the turbine. A valuable exceeds the desired value, pump overhaul should be considered. the upper power ranges can result in increased wear and fouling, especially of

criterion is also the daily fuel consumption, considering the lower calorific the piston rings and cylinder liners.

value. m) The vents at the uppermost points of the cooling water spaces

must be kept closed. Slow load changes allow the piston rings to adapt themselves to the new

c) Check all shut-off valves in the cooling and lubricating system for running conditions and therefore ensure optimum sealing.

their correct position. The shut-offs for the cooling inlets and n) Check the level in all water and oil tanks, as well as all the

outlets on the engine must always be fully open in service. These drainage tanks of the leakage piping. Investigate any abnormal

serve only to cut off individual cylinders from the cooling water changes.

circuit during overhauls.

o) Observe the condition of the cooling water. Check for oil contamination.

Issue: 1 2.1.1 Main Engine Details - Page 3

PREVIOUS PAGE CONTENTS LIST EXIT NEXT PAGE

Peter Mærsk Machinery Operating Manual

On the other hand, there must always be sufficient power available within a The cylinder lubricating oil quantity is automatically adapted to the lower load. Fouling and fires in the scavenge air spaces.

short time to ensure safe manoeuvring in ports and waterways. The lubricating oil quantities are regulated in accordance with engine load or

position of intermediate regulating shaft. The principle cause of fouling is blow-by of combustion products between

Manoeuvring is the operation of leaving port until ‘Full Away on Passage’ and piston and cylinder into the scavenge air spaces. The fouling will be greater if

from the port approach until ‘Finished With Engines’. Procedures after Shutting Down the Engine there is incomplete combustion of the fuel injected (smokey exhaust).

The manoeuvring range is the speed range up to and including the After the engine has been stopped, the cooling water and lubricating oil pumps Causes of poor combustion:

manoeuvring speeds FULL AHEAD and FULL ASTERN. This range is should be left running for at least a further 20 minutes in order to allow the

The fuel injectors are not working correctly.

usually divided into four manoeuvring stages with correspondingly allocated temperatures to equalise. These systems should not be cooled down below

speeds. their normal inlet temperatures. The fuel is at too low a temperature.

Poorly adjusted injection pump timing.

Possible critical barred speed ranges have to be taken into account. The starting air supply has to be closed as soon as possible after stopping the

engine i.e. shut the valves AE004V and AE005V on the starting air receivers Operation with a temporary shortage of air during extreme variations

Normally the FULL manoeuvring speed for engines driving fixed pitch and open the venting valve AE007V. in engine loading and with the charge air pressure dependent fuel

propellers corresponds to about 70% of the nominal speed, which in turn limiter in the governor set too high.