Professional Documents

Culture Documents

Tray Revamp Restores Crude Column Performance

Tray Revamp Restores Crude Column Performance

Uploaded by

asdasdasdasdasdasdasdCopyright:

Available Formats

You might also like

- Improving Hydrotreater OperationsDocument5 pagesImproving Hydrotreater Operationssaleh4060No ratings yet

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitDocument5 pagesRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavNo ratings yet

- Special Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDDocument6 pagesSpecial Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDGhasem Bashiri100% (1)

- Recent Developments in Urea Plant Design: Pan OrphanidesDocument17 pagesRecent Developments in Urea Plant Design: Pan OrphanidesMagdy SalehNo ratings yet

- KRES TechnologyDocument10 pagesKRES TechnologyabubakarNo ratings yet

- Alternative Routes To Paraxylene ProductionDocument7 pagesAlternative Routes To Paraxylene ProductionArash AbbasiNo ratings yet

- StripingDocument7 pagesStripingVia Utami PutriNo ratings yet

- Catalytic Reforming Options and PracticesDocument5 pagesCatalytic Reforming Options and PracticesanshumanNo ratings yet

- Mo Krys 1993Document16 pagesMo Krys 1993wsanchez_soteloNo ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower Revampniladri_paulNo ratings yet

- Efficiency and Optimization of Fired HeaterDocument4 pagesEfficiency and Optimization of Fired Heatermms2007No ratings yet

- Parallel-Flow Drum-Mix Plants: SectionDocument33 pagesParallel-Flow Drum-Mix Plants: SectionTayyabah ZafarNo ratings yet

- Trouble Shooting Compendium 2022-23Document142 pagesTrouble Shooting Compendium 2022-2300083583rfNo ratings yet

- ENERGY STAR Guide Petroleum Refineries 20150330Document7 pagesENERGY STAR Guide Petroleum Refineries 20150330rameshkarthik810No ratings yet

- Purge Gas Purification and Recovery in Ammonia Plants: Process DescriptionDocument5 pagesPurge Gas Purification and Recovery in Ammonia Plants: Process DescriptionFerdian AziziNo ratings yet

- Retrofits Applications Worth ConsideringDocument7 pagesRetrofits Applications Worth ConsideringBharti FamilyNo ratings yet

- Increased Margin From Updated Internals and CatalystDocument7 pagesIncreased Margin From Updated Internals and CatalystBamrung SungnoenNo ratings yet

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- Kempster 1995Document6 pagesKempster 1995Hiwa KhalediNo ratings yet

- Benton 2007Document14 pagesBenton 2007aminardakaniNo ratings yet

- TRB0521-TB-Steam-Turbines-Modernize-Aging-REPRINT-pdf - Original FileDocument2 pagesTRB0521-TB-Steam-Turbines-Modernize-Aging-REPRINT-pdf - Original FileCaio AmorimNo ratings yet

- 014 PDFDocument12 pages014 PDFGrootNo ratings yet

- Prereforming: Based On High Activity Catalyst To Meet Market DemandsDocument8 pagesPrereforming: Based On High Activity Catalyst To Meet Market Demandsvaratharajan g rNo ratings yet

- Innovation For Refinery With ModellingDocument5 pagesInnovation For Refinery With ModellingJulio Adolfo López PortocarreroNo ratings yet

- 073Document5 pages073api-3822562No ratings yet

- Hydroprocessing Upgrades To Meet Changing Fuels RequirementsDocument4 pagesHydroprocessing Upgrades To Meet Changing Fuels RequirementsBilal KhashanNo ratings yet

- Optimising Preflash For Light Tight Oil ProcessingDocument8 pagesOptimising Preflash For Light Tight Oil Processingmathew8No ratings yet

- Revamping The PCS Nitrogen 02 Plant in TrinidadDocument12 pagesRevamping The PCS Nitrogen 02 Plant in TrinidadGaurav GuptaNo ratings yet

- Maximisation of VGO Through Deep-Cut Distillation For Refinery MarginsDocument6 pagesMaximisation of VGO Through Deep-Cut Distillation For Refinery Marginsahmed MohamedNo ratings yet

- PCS#176, Low-Capital Crude Unit Revamp Increases Product YieldDocument4 pagesPCS#176, Low-Capital Crude Unit Revamp Increases Product YieldJeffrey Ryan LindmarkNo ratings yet

- Xenon Propellant Tank DatasheetDocument1 pageXenon Propellant Tank Datasheethectoriasulemareyna19No ratings yet

- Casale Chemicals Pure Oxygen Autothermal Reformer BurnersDocument12 pagesCasale Chemicals Pure Oxygen Autothermal Reformer BurnersGaurav GuptaNo ratings yet

- Honeywell Uop FCC Related Processes DatasheetDocument4 pagesHoneywell Uop FCC Related Processes Datasheetduraid ahmadNo ratings yet

- Turboexpander Compressors 2Document5 pagesTurboexpander Compressors 2Lidia JaraNo ratings yet

- 17chap18 PDFDocument9 pages17chap18 PDFmick.pride81No ratings yet

- Achieve Success in Gasoline HydrotreatingDocument6 pagesAchieve Success in Gasoline Hydrotreatingdonald55555No ratings yet

- Conventional Ammonia Plant Revamp With Purifier: Rajesh AggarwalDocument12 pagesConventional Ammonia Plant Revamp With Purifier: Rajesh AggarwalGrootNo ratings yet

- Correct FCC Tower RevampDocument8 pagesCorrect FCC Tower RevampAlessio ScarabelliNo ratings yet

- Revamping of The PCS Nitrogen 03 Plant in Trinidad: Elizabeth West-ToolseeDocument7 pagesRevamping of The PCS Nitrogen 03 Plant in Trinidad: Elizabeth West-Toolseevaratharajan g rNo ratings yet

- Recovered Hydrogen As Quench in CO Conversion Section: P. Ravichandran, Hussain A. Al-Hajari, and Yousif A. Al-NassarDocument8 pagesRecovered Hydrogen As Quench in CO Conversion Section: P. Ravichandran, Hussain A. Al-Hajari, and Yousif A. Al-Nassarvaratharajan g rNo ratings yet

- Effect of The Operating Pressure On Residual Oil HydroprocessingDocument6 pagesEffect of The Operating Pressure On Residual Oil HydroprocessingOwais AhmedNo ratings yet

- Gas Turbines - Design and Operating ConsiderationsDocument5 pagesGas Turbines - Design and Operating ConsiderationsaliNo ratings yet

- Casale Strategies For Complete Ammonia Plant Revamping, The Example of Al BayroniDocument8 pagesCasale Strategies For Complete Ammonia Plant Revamping, The Example of Al BayroniGaurav GuptaNo ratings yet

- 1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFDocument14 pages1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFnghiNo ratings yet

- A Complete Range of Solutions For Sulfur Recovery: Christian STREICHER, ProsernatDocument28 pagesA Complete Range of Solutions For Sulfur Recovery: Christian STREICHER, ProsernatpratikkapseNo ratings yet

- Balanced Distill Eqp Des PDFDocument8 pagesBalanced Distill Eqp Des PDFB rgNo ratings yet

- Aiche-36-005Simple, Safe and Reliable KRESDocument14 pagesAiche-36-005Simple, Safe and Reliable KRESHsein WangNo ratings yet

- Sliding Vs Constant PRDocument6 pagesSliding Vs Constant PRswatkoolNo ratings yet

- Octanizing Reformer Options-English 2 1Document2 pagesOctanizing Reformer Options-English 2 1vahid0% (1)

- Optimisation of Product Yield and Coke Formation in A RFCC UnitDocument5 pagesOptimisation of Product Yield and Coke Formation in A RFCC UnitCHE.ENG1734No ratings yet

- FETMA A Simple Code For Thermo Mechanical Analysis On BWR Fuel RodsDocument7 pagesFETMA A Simple Code For Thermo Mechanical Analysis On BWR Fuel RodstinatrntnNo ratings yet

- Comparison of RR and GE Civil Turbofan Engines: Zhenyu SunDocument9 pagesComparison of RR and GE Civil Turbofan Engines: Zhenyu SunVishnu RamNo ratings yet

- Equipment Upgrade, Power Enhancement: Pan American Energy SL Sucursal ArgentinaDocument2 pagesEquipment Upgrade, Power Enhancement: Pan American Energy SL Sucursal ArgentinaAntonio MendesNo ratings yet

- Reduce Emissions and Save Energy With An Unconventional Flare Gas Recovery SystemDocument2 pagesReduce Emissions and Save Energy With An Unconventional Flare Gas Recovery System김형진No ratings yet

- Fuel Flexibility in Conventional and Dry Low Emissions Industrial Gas TurbinesDocument30 pagesFuel Flexibility in Conventional and Dry Low Emissions Industrial Gas TurbinesHenrik13No ratings yet

- GasificationDocument6 pagesGasificationVivek YadavNo ratings yet

- ZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsDocument6 pagesZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsSiroos Yousefi100% (1)

- Chemical Engineering Journal: Abarasi Hart, Malcolm Greaves, Joseph WoodDocument11 pagesChemical Engineering Journal: Abarasi Hart, Malcolm Greaves, Joseph WoodFarah Talib Al-sudaniNo ratings yet

- New Recycle Process Scheme For High Ethane RecoveryDocument7 pagesNew Recycle Process Scheme For High Ethane RecoveryAnonymous ZPV7AKaBANo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- New Resid Fluid Catalytic Cracking (FCC) Catalyst Technology For Maximum Distillates Yield Demonstrated in Big West Oil's Salt Lake City RefineryDocument12 pagesNew Resid Fluid Catalytic Cracking (FCC) Catalyst Technology For Maximum Distillates Yield Demonstrated in Big West Oil's Salt Lake City RefineryasdasdasdasdasdasdasdNo ratings yet

- Lessons From FCC HistoryDocument10 pagesLessons From FCC HistoryasdasdasdasdasdasdasdNo ratings yet

- Acid Gas TreatmentDocument10 pagesAcid Gas TreatmentasdasdasdasdasdasdasdNo ratings yet

- C&M Basics 17 Feb 2015Document56 pagesC&M Basics 17 Feb 2015asdasdasdasdasdasdasdNo ratings yet

- Power Industry EHT Update 2'23'2015Document28 pagesPower Industry EHT Update 2'23'2015asdasdasdasdasdasdasdNo ratings yet

- EHT Maintenance & Troubleshooting Guide PDFDocument7 pagesEHT Maintenance & Troubleshooting Guide PDFasdasdasdasdasdasdasdNo ratings yet

- HAC Training Course - 1st Part - PPT (ModDocument150 pagesHAC Training Course - 1st Part - PPT (ModasdasdasdasdasdasdasdNo ratings yet

- GK GS Study PlanDocument14 pagesGK GS Study Planpavankumar4791No ratings yet

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersDocument29 pages04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaANo ratings yet

- Acid Base Equilibrium Multiple ChoiceDocument4 pagesAcid Base Equilibrium Multiple ChoiceMarcus LeeNo ratings yet

- End of Course Chemistry: Form S0119, CORE 1Document24 pagesEnd of Course Chemistry: Form S0119, CORE 1kristymadimikeNo ratings yet

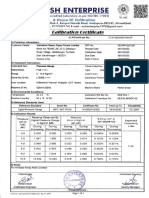

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- Digital Magnetometer: Xtrinsic MAG3110 Three-AxisDocument30 pagesDigital Magnetometer: Xtrinsic MAG3110 Three-Axislevietphong100% (1)

- Transformer Practice - Manufacture, Assembling, Connections, Operation and Testing.Document296 pagesTransformer Practice - Manufacture, Assembling, Connections, Operation and Testing.TaliaNaraNo ratings yet

- As 4310-2004 DN80 Piston Type Vacuum Interface Valves For Municipal Sewer SystemsDocument7 pagesAs 4310-2004 DN80 Piston Type Vacuum Interface Valves For Municipal Sewer SystemsSAI Global - APACNo ratings yet

- QCM Chapter 2Document16 pagesQCM Chapter 2Wiam Baalla0% (1)

- How To Factorize The Quadratic Equation E CientlyDocument2 pagesHow To Factorize The Quadratic Equation E CientlyNikola Pacek-VetnićNo ratings yet

- 2k15-ES Lec-5 3D Forces SystemDocument31 pages2k15-ES Lec-5 3D Forces SystemUsama KhanNo ratings yet

- Typhoon User's Manual For The Yamaha TX16W SamplerDocument74 pagesTyphoon User's Manual For The Yamaha TX16W SamplernamderluapNo ratings yet

- Astm A111 PDFDocument3 pagesAstm A111 PDFbanglvhNo ratings yet

- Jones1988 Two Point DeterminationDocument7 pagesJones1988 Two Point DeterminationJulian De BedoutNo ratings yet

- Salmonella Surrogate Reduction Using Industrial Peanut Dry Roasting ParametersDocument13 pagesSalmonella Surrogate Reduction Using Industrial Peanut Dry Roasting ParametersRodd PintoNo ratings yet

- Weir PDFDocument85 pagesWeir PDFMOHAMMED RAYYAN NNo ratings yet

- DEVICE Reference GuideDocument302 pagesDEVICE Reference GuidesreevatsakurudiNo ratings yet

- The Meaning of ColorsDocument10 pagesThe Meaning of ColorsceltiftNo ratings yet

- CE6505-Design of RC ElementsDocument15 pagesCE6505-Design of RC ElementsManikandanNo ratings yet

- 2d TransformationsDocument38 pages2d TransformationsPoonam GholapNo ratings yet

- Review The Article Unified Model For Gas-Liquid Pipe Flow Via Slug DynamicsDocument11 pagesReview The Article Unified Model For Gas-Liquid Pipe Flow Via Slug Dynamicsdimatteoc dimatteocNo ratings yet

- Altermundus PgfornamentDocument6 pagesAltermundus PgfornamentFrank GNo ratings yet

- 9 Beam DeflectionDocument34 pages9 Beam DeflectionBharat JajoriaNo ratings yet

- OD - New Method For Reduce Polymerization ShrinkageDocument52 pagesOD - New Method For Reduce Polymerization ShrinkageLn ShenNo ratings yet

- Betalight Tritium Illumination DevicesDocument28 pagesBetalight Tritium Illumination DevicesGautam NatrajanNo ratings yet

- Neuromeasure 5 User'S ManualDocument14 pagesNeuromeasure 5 User'S ManualGokulNo ratings yet

- Tubo CarcasaDocument20 pagesTubo CarcasaFranko Edgar Martinez ReateguiNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsDanut RusNo ratings yet

- Aristotle On TimeDocument7 pagesAristotle On Timebenan celikelNo ratings yet

Tray Revamp Restores Crude Column Performance

Tray Revamp Restores Crude Column Performance

Uploaded by

asdasdasdasdasdasdasdOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tray Revamp Restores Crude Column Performance

Tray Revamp Restores Crude Column Performance

Uploaded by

asdasdasdasdasdasdasdCopyright:

Available Formats

Tray revamp restores crude column

performance

Retrofitting the packed top section of a crude atmospheric tower with high

capacity trays improved separation efficiency

M JAGANNATHA RAO and K SRI GANESH Hindustan Petroleum Corporation Limited

R MADHAVAN and SANDEEP YADAV Koch-Glitsch India

T

he existing crude distil-

Results after first installation of

lation unit at Hindustan

24 Superfrac trays in top section

Petroleum Corporation Off-gas

Limited’s (HPCL) Mumbai 24 trays in ASTM D-86, 5%, 95%, Gap/(overlap),

refinery is designed to pro- top section vol% °C °C °C

Light naphtha 111

cess Bombay High and Arab 14

Mix crudes. During an earlier Unstabilised Heavy naphtha 125 148

naphtha

capacity revamp of the crude

20

Kerosene 168

atmospheric tower, 24 conven-

tional trays with moving valves Table 1

located in the top fractionat-

ing sections that separated light cess study to evaluate the feasi-

naphtha, heavy naphtha, and bility of achieving the 20% extra

Heavy

kerosene were replaced with naphtha capacity needed to process

PA

an equal number of Superfrac lighter crudes. The engineering

trays equipped with fixed company recommended replac-

valves. The tower configuration ing the top section of high

Kerosene

after the first revamp is shown capacity trays with two beds

PA

in Figure 1. With Superfrac of structured packing in addi-

trays, capacity and separation tion to other modifications in

Feed

between naphtha, heavy naph- the tower. With agreement to

Light

tha, and kerosene cuts were gasoil implement the recommended

Steam

satisfactory with a good gap changes, the engineering com-

between the 95% ASTM D-86 Heavy pany designed the structured

gasoil

distillation point of one product packing and internals, which

and the 5% ASTM D-86 distilla- were purchased from a local

Reduced

tion point of the next product. crude oil fabricator. During installation,

Table 1 shows the product qual- the tray tower attachments

ity of naphtha to kerosene fol- Figure 1 Original configuration after were removed to accommodate

lowing the first installation first revamp the structured packing. The

of Superfrac trays in the top tower configuration with pack-

section. overcome capacity limitations ing revamp is shown in Figure

To take advantage of the in the top fractionating sections. 2. The crude capacity after

opportunity to process lighter Plant personnel contacted an the modifications could be

crudes, the refinery needed to engineering company for a pro- increased by 20%, but the sep-

www.digitalrefining.com/article/1002248 Revamps 2018 1

Results after packing installation

in top section Off-gas

ASTM D-86, 5%, 95%, Gap/(overlap), Structured

vol% °C °C °C packing

Light naphtha 147

(28)

Heavy naphtha 119 193 Unstabilised

(26) naphtha

Kerosene 167

Table 2

aration between the three cuts

(light naphtha, heavy naph- Heavy

naphtha

tha, and kerosene) was very PA

poor with a significant overlap

in the ASTM D-86 cut points

as compared to the gaps that Kerosene

were being obtained prior to PA

the revamp. Table 2 shows the

product quality of naphtha to Feed

kerosene after the replacement Light Figure 3 Typical stack of structured

gasoil

of trays with packing in the top Steam packing layers

section.

Heavy

gasoil crimp angle of 60° from hori-

Analysis of the existing tower zontal with an approximate

configuration Reduced surface area of 110-115 m2/m3

crude oil

Three different evaluations was used in the fractionation

were conducted: gamma scan, section. This type of packing is

physical inspection of packing Figure 2 Tower configuration after more typically applied in heat

and internals, and a process packing installation in top section transfer and absorption services

simulation to understand the and may have been selected to

possible causes for the under- Physical inspection of the meet capacity requirements.

performance of the packed packing and internals The packing and internals

bed. Two possibilities for the mald- were inspected during a sched-

istribution were considered: the uled shutdown. The packing

Gamma scan structured packing layers were layers were found to be rotated

The refinery conducted a not rotated at 90° angles during properly, and the internals

gamma scan of the top sec- installation, and the tower inter- were intact. Photographs taken

tion of the tower. The results nals may have been damaged during shutdown indicated cor-

pointed to liquid maldistribu- during operation. rosion on the packing (Figure

tion wherein one side of the Structured packing layers 4), but severe damage was

tower received a larger pro- are installed with each layer absent in the sections that were

portion of the liquid flow com- rotated 90° with respect to accessed.

pared to the other. Critical the layer below. The rotation The packed beds occupied

sections, such as the equipment mixes and spreads both liquid most of the tower height, and

between two packed beds, had and vapour phases in all hori- the distribution systems for liq-

significant external obstruc- zontal directions to avoid local uid and vapour were fitted into

tions interfering with the scan concentration variations at the a smaller vertical space. The

results, and consequently the same elevation. Figure 3 shows need to maximise the packed

data were not sufficient to accu- a properly rotated stack of bed height may have restricted

rately determine the origin of structured packing layers. the available space for the dis-

the maldistribution. Structured packing with a tribution systems. The dis-

2 Revamps 2018 www.digitalrefining.com/article/1002248

tributor type selected by the

engineering company was dif-

ficult to level and was designed

to operate with a low liquid

head in a multi-stage configu-

ration. Using low liquid heads

makes the distributor prone to

the maleffects of liquid gradi-

ents formed by the flow and

more sensitive to the levelness.

In this case, the reflux feed

pipe feeding the distributor

of the top bed was designed

in a sub-optimal way without

any significant flow restriction

and could have additionally

contributed to the non-uni- Figure 4 Structured packing after a few months of operations

formity of liquid distribution

observed in the gamma scan. cant pressure drop, packing has distribution. The overall result

Feed pipes or pre-distribution much lower pressure drop and of the constrained arrangement

systems are equally critical to is not able to correct for vapour of risers beneath the packed bed

the performance of the packed maldistribution. Therefore, ini- is increased vapour maldistri-

column as the liquid distrib- tial distribution of vapour to bution and reduced separation

utor. Obtaining the desired the packed bed is very impor- efficiency.

performance from a tower tant. In this case, the chim-

requires appropriate distribu- ney collector below the top bed Process simulation

tion devices for the column was installed with little space HPCL requested Koch-Glitsch

feeds. When designing feed or between the top of the riser to assist in improving the col-

pre-distribution devices, con- to the packed bed above (see umn performance in the packed

sideration must be given to Figure 5), possibly due to the section. Koch-Glitsch devel-

their spacing and orientation desire to maximise the packed oped a steady state process

with respect to the type of liq- height. It is necessary to provide model of the tower using a

uid distributor below, expected sufficient3 distance between steady state simulation soft-

distributor performance, flow the top of the risers to the bed ware. Ten theoretical stages

rate, operating range, thermal above to create uniformity in were expected from the 12m of

condition (for instance, degree the vapour flow into the packed packing installed, based on effi-

of sub-cooling), and whether bed. The distance between the ciency data from similar size

mixing with overhead liquid is riser hats was also restrictive, packings. However, the sim-

required. To achieve uniform creating higher velocities that ulation results that matched

liquid distribution, feed pipes would hamper good vapour the test run indicated that the

should have a reasonable3 pres- number of stages achieved was

sure drop. Restriction orifices actually less than half of the

within the pipe may be used expected number.

to balance flow distribution in

situations where fluid equali- Inside-Out revamp approach

sation is non-ideal and it is dif- To optimise the tower’s effi-

ficult for the internals to correct ciency and capacity, Koch-

for flow variations. Glitsch adopted the Inside-Out

Vapour distribution is design approach.2 This is an

another important aspect in iterative method that combines

packed tower performance. Figure 5 Chimney tray with low process simulation with equip-

Unlike trays that have signifi- clearance to the packed bed above ment selection, design, and

www.digitalrefining.com/article/1002248 Revamps 2018 3

well. Koch-Glitsch has patented

Comparison of options

several downcomer arrange-

Replace with Flexipac Restore to original Replace with Superfrac

ments for the Superfrac tray.

structured packing configuration with trays with increased For the light naphtha section, a

and Intalox high Superfrac trays and tray spacing vapour tunnel downcomer was

performance internals original tray spacing (fewer trays)

Capacity No change Reduction No change used. For the slightly higher liq-

Efficiency Better Significantly better Better uid loaded heavy naphtha sec-

tion, a truncated vapour tunnel

Fouling resistance Low High High

Cost High Low Lowest

downcomer was used.

HPCL had experienced

Table 3 improved separation and

capacity with the previ-

hydraulic evaluation. The ben- flow path and contacting area. ous revamp from conven-

efit of this approach is that The efficiency of a Superfrac tional trays to Superfrac trays.

it eliminates the guesswork tray is maximised by eliminat- Replacing the packing with

needed to fit the equipment ing stagnant zones and retro- redesigned Superfrac trays was

design to the original simula- grade flow on the deck. This considered more reliable even if

tion. For improving the packed is done by strategically plac- the retrofit used fewer trays. As

bed performance, significant ing proprietary push valves hydraulic loads were different

changes were envisaged for and other directional devices for different sections, different

the feed pre-distribution, liq- on the tray deck. This feature tray spacings were employed

uid distribution, packing selec- was employed in this case as to get optimal capacity and to

tion, and vapour distribution. maximise the number of trays;

For the equipment design, dif- Off-gas 17 trays could thus be accom-

ferent options were evaluated, modated in the available space.

which also included trayed 17 trays in

top section It was expected that the separa-

options. The pros and cons of tions would not be as good as

each option were identified and the original Superfrac tray con-

Unstabilised

compared (see Table 3). Because naphtha figuration which had 24 trays,

the capacity requirement was but it would be significantly

now 20% higher than the ear- better than the separation pro-

lier configuration of Superfrac vided by the existing packing

trays, retrofitting with the orig- (see Figure 6). Process simula-

inal number of trays would tions were refined to reflect the

reduce the capacity unless the Heavy expected number of stages with

naphtha

tray spacing could be increased. PA this configuration. The calcu-

Using higher spacing reduces lated product qualities were

the number of trays and, there- significantly better than what

fore, the number of contacting Kerosene was achieved with the existing

stages. PA packing.

For the trayed option, After discussion between

Superfrac trays were selected Feed Koch-Glitsch and HPCL, the

because they offer the best Light Superfrac tray option was

gasoil

combination of capacity and Steam selected. New tower attach-

efficiency. Depending on the ments – support rings and bolt

Heavy

performance requirements, gasoil bars – were welded to the col-

the Superfrac tray offers var- umn shell to support the trays,

ious design options.1 This Reduced and the tower was retrofitted

crude oil

includes high capacity VG-0 with Superfrac trays (see Figure

type Minivalve valves in com- 7).

bination with specially shaped Figure 6 Configuration after second After tower start-up, the

downcomers that maximise the revamp (top section only) required capacity was achieved

4 Revamps 2018 www.digitalrefining.com/article/1002248

Results post-revamp with 17

Superfrac trays in top section

ASTM D-86, 5%, 95%, Gap/(overlap),

vol% °C °C °C

Light naphtha 118

5

Heavy naphtha 123 157

8

Kerosene 165

Figure 7 Superfrac tray deck with push valves Table 4

with very good separation Superfrac trays, with their com- of experience in refinery process plants,

between the cuts. Gaps in bination of high capacity and he is a graduate in chemical engineering

ASTM D-86 curves rather than efficiency, offered the most reli- from Indian Institute of Technology,

overlaps were observed. Table able high capacity option and Mumbai.

R Madhavan is Vice President – Process

4 shows the details of the sepa- improved product qualities

with Koch Chemical Technology Group

ration between lighter products significantly. India Private Limited in the Koch-Glitsch

achieved post-revamp with the division. He has over two decades of

trays. SUPERFRAC, MINIVALVE, INTALOX and experience in mass transfer technology

FLEXIPAC are marks of Koch-Glitsch, LP. and holds an MTech in chemical

Conclusion engineering from Indian Institute of

References

When revamping towers from 1 Nieuwoudt I, Penciak J, Best of both,

Technology, Mumbai.

Sandeep Yadav is Senior Manager –

trays to packing, considera- Hydrocarbon Engineering, Jul 2007, 85-

Process with Koch Chemical Technology

tion must be given to the suit- 89.

Group India Private Limited in the Koch-

ability of the packing to the 2 Remesat D, Krela M, Customised tower Glitsch division. He has over 10 years of

service and to the liquid and design, PTQ Q2 2013. experience in mass transfer technology

vapour distribution. In gen- 3 Kister H Z, Distillation Operation, and holds a bachelor’s degree in chemical

eral, it is considered that pack- McGraw Hill Publishing Company. engineering from Shivaji University,

ing provides higher capacity M Jagannatha Rao is Senior Manager

Maharashtra.

compared to trays and thus –Technical Services with Hindustan

is a good option for revamps. Petroleum Corporation Limited. With

Although the high open area 23 years’ experience in refinery process LINKS

of packing allows it to handle plants, he holds a bachelor’s degree

in chemical engineering from Andhra

higher hydraulic loads com- More articles from the following

University, Visakhapatnam, Andhra categories:

pared to trays, packing is also Pradesh. Crude and Vacuum Units

more sensitive to liquid and K Sri Ganesh is Chief Manager – Technical Mass Transfer

vapour distribution because of Services with Hindustan Petroleum Process Modelling and Simulation

a lower resistance to fluid flow. Corporation Limited. With over 24 years

www.digitalrefining.com/article/1002248 Revamps 2018 5

You might also like

- Improving Hydrotreater OperationsDocument5 pagesImproving Hydrotreater Operationssaleh4060No ratings yet

- Revamping An Integrated Hydrocracker and Lube Base Oil UnitDocument5 pagesRevamping An Integrated Hydrocracker and Lube Base Oil UnitVyacheslavNo ratings yet

- Special Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDDocument6 pagesSpecial Focus: Reboiler Pinch: An Approach To Optimize Flare System Design During FEEDGhasem Bashiri100% (1)

- Recent Developments in Urea Plant Design: Pan OrphanidesDocument17 pagesRecent Developments in Urea Plant Design: Pan OrphanidesMagdy SalehNo ratings yet

- KRES TechnologyDocument10 pagesKRES TechnologyabubakarNo ratings yet

- Alternative Routes To Paraxylene ProductionDocument7 pagesAlternative Routes To Paraxylene ProductionArash AbbasiNo ratings yet

- StripingDocument7 pagesStripingVia Utami PutriNo ratings yet

- Catalytic Reforming Options and PracticesDocument5 pagesCatalytic Reforming Options and PracticesanshumanNo ratings yet

- Mo Krys 1993Document16 pagesMo Krys 1993wsanchez_soteloNo ratings yet

- An Atmospheric Crude Tower RevampDocument6 pagesAn Atmospheric Crude Tower Revampniladri_paulNo ratings yet

- Efficiency and Optimization of Fired HeaterDocument4 pagesEfficiency and Optimization of Fired Heatermms2007No ratings yet

- Parallel-Flow Drum-Mix Plants: SectionDocument33 pagesParallel-Flow Drum-Mix Plants: SectionTayyabah ZafarNo ratings yet

- Trouble Shooting Compendium 2022-23Document142 pagesTrouble Shooting Compendium 2022-2300083583rfNo ratings yet

- ENERGY STAR Guide Petroleum Refineries 20150330Document7 pagesENERGY STAR Guide Petroleum Refineries 20150330rameshkarthik810No ratings yet

- Purge Gas Purification and Recovery in Ammonia Plants: Process DescriptionDocument5 pagesPurge Gas Purification and Recovery in Ammonia Plants: Process DescriptionFerdian AziziNo ratings yet

- Retrofits Applications Worth ConsideringDocument7 pagesRetrofits Applications Worth ConsideringBharti FamilyNo ratings yet

- Increased Margin From Updated Internals and CatalystDocument7 pagesIncreased Margin From Updated Internals and CatalystBamrung SungnoenNo ratings yet

- Designing Atmospheric Crude Distillation For Bitumen Service PDFDocument6 pagesDesigning Atmospheric Crude Distillation For Bitumen Service PDFfawmer61No ratings yet

- Kempster 1995Document6 pagesKempster 1995Hiwa KhalediNo ratings yet

- Benton 2007Document14 pagesBenton 2007aminardakaniNo ratings yet

- TRB0521-TB-Steam-Turbines-Modernize-Aging-REPRINT-pdf - Original FileDocument2 pagesTRB0521-TB-Steam-Turbines-Modernize-Aging-REPRINT-pdf - Original FileCaio AmorimNo ratings yet

- 014 PDFDocument12 pages014 PDFGrootNo ratings yet

- Prereforming: Based On High Activity Catalyst To Meet Market DemandsDocument8 pagesPrereforming: Based On High Activity Catalyst To Meet Market Demandsvaratharajan g rNo ratings yet

- Innovation For Refinery With ModellingDocument5 pagesInnovation For Refinery With ModellingJulio Adolfo López PortocarreroNo ratings yet

- 073Document5 pages073api-3822562No ratings yet

- Hydroprocessing Upgrades To Meet Changing Fuels RequirementsDocument4 pagesHydroprocessing Upgrades To Meet Changing Fuels RequirementsBilal KhashanNo ratings yet

- Optimising Preflash For Light Tight Oil ProcessingDocument8 pagesOptimising Preflash For Light Tight Oil Processingmathew8No ratings yet

- Revamping The PCS Nitrogen 02 Plant in TrinidadDocument12 pagesRevamping The PCS Nitrogen 02 Plant in TrinidadGaurav GuptaNo ratings yet

- Maximisation of VGO Through Deep-Cut Distillation For Refinery MarginsDocument6 pagesMaximisation of VGO Through Deep-Cut Distillation For Refinery Marginsahmed MohamedNo ratings yet

- PCS#176, Low-Capital Crude Unit Revamp Increases Product YieldDocument4 pagesPCS#176, Low-Capital Crude Unit Revamp Increases Product YieldJeffrey Ryan LindmarkNo ratings yet

- Xenon Propellant Tank DatasheetDocument1 pageXenon Propellant Tank Datasheethectoriasulemareyna19No ratings yet

- Casale Chemicals Pure Oxygen Autothermal Reformer BurnersDocument12 pagesCasale Chemicals Pure Oxygen Autothermal Reformer BurnersGaurav GuptaNo ratings yet

- Honeywell Uop FCC Related Processes DatasheetDocument4 pagesHoneywell Uop FCC Related Processes Datasheetduraid ahmadNo ratings yet

- Turboexpander Compressors 2Document5 pagesTurboexpander Compressors 2Lidia JaraNo ratings yet

- 17chap18 PDFDocument9 pages17chap18 PDFmick.pride81No ratings yet

- Achieve Success in Gasoline HydrotreatingDocument6 pagesAchieve Success in Gasoline Hydrotreatingdonald55555No ratings yet

- Conventional Ammonia Plant Revamp With Purifier: Rajesh AggarwalDocument12 pagesConventional Ammonia Plant Revamp With Purifier: Rajesh AggarwalGrootNo ratings yet

- Correct FCC Tower RevampDocument8 pagesCorrect FCC Tower RevampAlessio ScarabelliNo ratings yet

- Revamping of The PCS Nitrogen 03 Plant in Trinidad: Elizabeth West-ToolseeDocument7 pagesRevamping of The PCS Nitrogen 03 Plant in Trinidad: Elizabeth West-Toolseevaratharajan g rNo ratings yet

- Recovered Hydrogen As Quench in CO Conversion Section: P. Ravichandran, Hussain A. Al-Hajari, and Yousif A. Al-NassarDocument8 pagesRecovered Hydrogen As Quench in CO Conversion Section: P. Ravichandran, Hussain A. Al-Hajari, and Yousif A. Al-Nassarvaratharajan g rNo ratings yet

- Effect of The Operating Pressure On Residual Oil HydroprocessingDocument6 pagesEffect of The Operating Pressure On Residual Oil HydroprocessingOwais AhmedNo ratings yet

- Gas Turbines - Design and Operating ConsiderationsDocument5 pagesGas Turbines - Design and Operating ConsiderationsaliNo ratings yet

- Casale Strategies For Complete Ammonia Plant Revamping, The Example of Al BayroniDocument8 pagesCasale Strategies For Complete Ammonia Plant Revamping, The Example of Al BayroniGaurav GuptaNo ratings yet

- 1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFDocument14 pages1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFnghiNo ratings yet

- A Complete Range of Solutions For Sulfur Recovery: Christian STREICHER, ProsernatDocument28 pagesA Complete Range of Solutions For Sulfur Recovery: Christian STREICHER, ProsernatpratikkapseNo ratings yet

- Balanced Distill Eqp Des PDFDocument8 pagesBalanced Distill Eqp Des PDFB rgNo ratings yet

- Aiche-36-005Simple, Safe and Reliable KRESDocument14 pagesAiche-36-005Simple, Safe and Reliable KRESHsein WangNo ratings yet

- Sliding Vs Constant PRDocument6 pagesSliding Vs Constant PRswatkoolNo ratings yet

- Octanizing Reformer Options-English 2 1Document2 pagesOctanizing Reformer Options-English 2 1vahid0% (1)

- Optimisation of Product Yield and Coke Formation in A RFCC UnitDocument5 pagesOptimisation of Product Yield and Coke Formation in A RFCC UnitCHE.ENG1734No ratings yet

- FETMA A Simple Code For Thermo Mechanical Analysis On BWR Fuel RodsDocument7 pagesFETMA A Simple Code For Thermo Mechanical Analysis On BWR Fuel RodstinatrntnNo ratings yet

- Comparison of RR and GE Civil Turbofan Engines: Zhenyu SunDocument9 pagesComparison of RR and GE Civil Turbofan Engines: Zhenyu SunVishnu RamNo ratings yet

- Equipment Upgrade, Power Enhancement: Pan American Energy SL Sucursal ArgentinaDocument2 pagesEquipment Upgrade, Power Enhancement: Pan American Energy SL Sucursal ArgentinaAntonio MendesNo ratings yet

- Reduce Emissions and Save Energy With An Unconventional Flare Gas Recovery SystemDocument2 pagesReduce Emissions and Save Energy With An Unconventional Flare Gas Recovery System김형진No ratings yet

- Fuel Flexibility in Conventional and Dry Low Emissions Industrial Gas TurbinesDocument30 pagesFuel Flexibility in Conventional and Dry Low Emissions Industrial Gas TurbinesHenrik13No ratings yet

- GasificationDocument6 pagesGasificationVivek YadavNo ratings yet

- ZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsDocument6 pagesZKG4-2022 How To Save Electric Energy in Maerz PFR Lime KilnsSiroos Yousefi100% (1)

- Chemical Engineering Journal: Abarasi Hart, Malcolm Greaves, Joseph WoodDocument11 pagesChemical Engineering Journal: Abarasi Hart, Malcolm Greaves, Joseph WoodFarah Talib Al-sudaniNo ratings yet

- New Recycle Process Scheme For High Ethane RecoveryDocument7 pagesNew Recycle Process Scheme For High Ethane RecoveryAnonymous ZPV7AKaBANo ratings yet

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesFrom EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- New Resid Fluid Catalytic Cracking (FCC) Catalyst Technology For Maximum Distillates Yield Demonstrated in Big West Oil's Salt Lake City RefineryDocument12 pagesNew Resid Fluid Catalytic Cracking (FCC) Catalyst Technology For Maximum Distillates Yield Demonstrated in Big West Oil's Salt Lake City RefineryasdasdasdasdasdasdasdNo ratings yet

- Lessons From FCC HistoryDocument10 pagesLessons From FCC HistoryasdasdasdasdasdasdasdNo ratings yet

- Acid Gas TreatmentDocument10 pagesAcid Gas TreatmentasdasdasdasdasdasdasdNo ratings yet

- C&M Basics 17 Feb 2015Document56 pagesC&M Basics 17 Feb 2015asdasdasdasdasdasdasdNo ratings yet

- Power Industry EHT Update 2'23'2015Document28 pagesPower Industry EHT Update 2'23'2015asdasdasdasdasdasdasdNo ratings yet

- EHT Maintenance & Troubleshooting Guide PDFDocument7 pagesEHT Maintenance & Troubleshooting Guide PDFasdasdasdasdasdasdasdNo ratings yet

- HAC Training Course - 1st Part - PPT (ModDocument150 pagesHAC Training Course - 1st Part - PPT (ModasdasdasdasdasdasdasdNo ratings yet

- GK GS Study PlanDocument14 pagesGK GS Study Planpavankumar4791No ratings yet

- 04-400. Sub-Bases, (Non-Bituminous) and ShouldersDocument29 pages04-400. Sub-Bases, (Non-Bituminous) and ShouldersAnonymous g1LSaANo ratings yet

- Acid Base Equilibrium Multiple ChoiceDocument4 pagesAcid Base Equilibrium Multiple ChoiceMarcus LeeNo ratings yet

- End of Course Chemistry: Form S0119, CORE 1Document24 pagesEnd of Course Chemistry: Form S0119, CORE 1kristymadimikeNo ratings yet

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- Digital Magnetometer: Xtrinsic MAG3110 Three-AxisDocument30 pagesDigital Magnetometer: Xtrinsic MAG3110 Three-Axislevietphong100% (1)

- Transformer Practice - Manufacture, Assembling, Connections, Operation and Testing.Document296 pagesTransformer Practice - Manufacture, Assembling, Connections, Operation and Testing.TaliaNaraNo ratings yet

- As 4310-2004 DN80 Piston Type Vacuum Interface Valves For Municipal Sewer SystemsDocument7 pagesAs 4310-2004 DN80 Piston Type Vacuum Interface Valves For Municipal Sewer SystemsSAI Global - APACNo ratings yet

- QCM Chapter 2Document16 pagesQCM Chapter 2Wiam Baalla0% (1)

- How To Factorize The Quadratic Equation E CientlyDocument2 pagesHow To Factorize The Quadratic Equation E CientlyNikola Pacek-VetnićNo ratings yet

- 2k15-ES Lec-5 3D Forces SystemDocument31 pages2k15-ES Lec-5 3D Forces SystemUsama KhanNo ratings yet

- Typhoon User's Manual For The Yamaha TX16W SamplerDocument74 pagesTyphoon User's Manual For The Yamaha TX16W SamplernamderluapNo ratings yet

- Astm A111 PDFDocument3 pagesAstm A111 PDFbanglvhNo ratings yet

- Jones1988 Two Point DeterminationDocument7 pagesJones1988 Two Point DeterminationJulian De BedoutNo ratings yet

- Salmonella Surrogate Reduction Using Industrial Peanut Dry Roasting ParametersDocument13 pagesSalmonella Surrogate Reduction Using Industrial Peanut Dry Roasting ParametersRodd PintoNo ratings yet

- Weir PDFDocument85 pagesWeir PDFMOHAMMED RAYYAN NNo ratings yet

- DEVICE Reference GuideDocument302 pagesDEVICE Reference GuidesreevatsakurudiNo ratings yet

- The Meaning of ColorsDocument10 pagesThe Meaning of ColorsceltiftNo ratings yet

- CE6505-Design of RC ElementsDocument15 pagesCE6505-Design of RC ElementsManikandanNo ratings yet

- 2d TransformationsDocument38 pages2d TransformationsPoonam GholapNo ratings yet

- Review The Article Unified Model For Gas-Liquid Pipe Flow Via Slug DynamicsDocument11 pagesReview The Article Unified Model For Gas-Liquid Pipe Flow Via Slug Dynamicsdimatteoc dimatteocNo ratings yet

- Altermundus PgfornamentDocument6 pagesAltermundus PgfornamentFrank GNo ratings yet

- 9 Beam DeflectionDocument34 pages9 Beam DeflectionBharat JajoriaNo ratings yet

- OD - New Method For Reduce Polymerization ShrinkageDocument52 pagesOD - New Method For Reduce Polymerization ShrinkageLn ShenNo ratings yet

- Betalight Tritium Illumination DevicesDocument28 pagesBetalight Tritium Illumination DevicesGautam NatrajanNo ratings yet

- Neuromeasure 5 User'S ManualDocument14 pagesNeuromeasure 5 User'S ManualGokulNo ratings yet

- Tubo CarcasaDocument20 pagesTubo CarcasaFranko Edgar Martinez ReateguiNo ratings yet

- Geomembrane Technical DataDocument1 pageGeomembrane Technical DataYusufAliMuktiNo ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsDanut RusNo ratings yet

- Aristotle On TimeDocument7 pagesAristotle On Timebenan celikelNo ratings yet