Professional Documents

Culture Documents

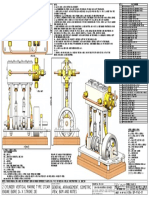

Jpb2cvse A3 Sheet 01

Jpb2cvse A3 Sheet 01

Uploaded by

Juan PastorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jpb2cvse A3 Sheet 01

Jpb2cvse A3 Sheet 01

Uploaded by

Juan PastorCopyright:

Available Formats

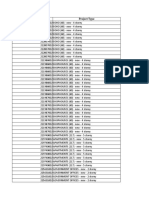

QTY.

PART NUMBER

A SMALL VIDEO CLIP CAN BE 1 JPB2CVSE-01-BASE PLATE NOTES:

FOUND ON YOUTUBE WEBSITE 6 JPB2CVSE-02-PILLAR STUD 0. ALL DRAWINGS ARE IN METRIC MEASUREMENTS

6 JPB2CVSE-03-PILLAR TUBE 1. ALL ENGINEERING PRACTICES SHALL BE APPLIED WITH REGARDS TO HOLE AND SHAFT TOLERANCES.

1 JPB2CVSE-04-CYLINDER SUPPORT PLATE 2. WHERE SCREWS OR BOLTS ARE USED THE CLEARANCE HOLES SHALL BE APPROXIMATELY 5% TO 8% LARGER THAN THE

1 JPB2CVSE-05-CYLINDER BLOCK MATCHING TAPPED HOLE.

2 JPB2CVSE-06-CRANKSHAFT BEARING BLOCK 3. PREFERABLY ALL TAPPED HOLES AND MATCHING SCREWS AND/OR BOLTS TO BE METRIC FINE (MF)

2 JPB2CVSE-07-10x25x8 BALL BEARING 4. MATERIALS SPECIFIED ON THE DRAWINGS ARE INDICATIVE ONLY. THE BUILDER CAN MAKE HIS/HER OWN MATERIAL CHOICE.

104 4.09

1 JPB2CVSE-08-VALVE PUSHER GUIDE 5. ALL CONNECTIONS/JOINTS WHICH HAVE STEAM PRESSURE APPLIED TO IT SHALL BE SILVER/HARD SOLDERED.

2 JPB2CVSE-09-STEAM PIPE CONNECTOR 6. COMPRESSION SPRINGS ARE DRAWN IN COMPRESSED STATE (CP), UNCOMPRESSED STATE IS APPROX 40% TO 60%

1 JPB2CVSE-10-CYLINDER TOP PORT PLATE LONGER THEN COMPRESSED STATE.

THE OFF SET ANGLE OF THE 1 JPB2CVSE-11-PIVOT ANGLE BRACKET 7. WHERE PREFERRED SCREW OR RIVETED CONNECTIONS CAN BE OMITTED AND PARTS CAN BE BONDED TOGETHER BY USING

ECCENTRIC IN RELATION TO THE 1 JPB2CVSE-11-PIVOT ANGLE BRACKET EITHER HIGH STRENGTH GLUE, EPOXY RESIN, OR SOLDER.

CRANK AXIS TO BE 1 JPB2CVSE-12-SLIDE VALVE PORT PLATE 8. PARTS WHICH ARE DIRECTLY EXPOSED TO STEAM AND/OR WATER SHOULD BE CONSTRUCTED USING NON-FERROUS OR

EXPERIMENTALLY DETERMINED 1 JPB2CVSE-13-ANGLE BRACKET PIVOT PIN NON CORROSIVE MATERIAL SUCH AS BRASS, BRONZE, GUNMETAL, STAINLESS STEEL, COPPER OR MONEL.

FOR THE SMOOTH RUNNING OF 1 JPB2CVSE-14-VALVE CHEST 9. THE ORDER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED AND THE MODEL IS ASSEMBLED IS ENTIRELY LEFT

THE ENGINE AND TO THE 1 JPB2CVSE-15-VALVE CHEST COVER TO THE BUILDER/MODEL MAKER.

SATISFACTION OF THE BUILDER 1 JPB2CVSE-16-VALVE ROD GUIDE 10. A COLOUR SCHEME FOR THIS PROJECT IS ENTIRELY LEFT UP TO THE MODEL MAKER.

1 JPB2CVSE-17-VALVE ROD GLAND 11. THE MANNER IN WHICH THE PARTS/COMPONENTS ARE MANUFACTURED IS ENTIRELY LEFT UP TO THE BUILDER.

2 JPB2CVSE-21-CRANKSHAFT END 12. USE LOCTITE, ON SCREW OR PRESS FIT CONNECTIONS OR SURFACES, WERE DEEMED NECESSARY TO PREVENT PARTS

2 JPB2CVSE-22-OUTER CRANK WEB FROM LOOSENING.

1 JPB2CVSE-23-INNER CRANK WEB XX. ERRORS AND/OR OMISSIONS MAY OCCUR IN THE DRAWINGS, DO NOT HESITATE TO CONTACT ME SO THAT THE

2 JPB2CVSE-24-CRANKPIN ERRORS/OMISSIONS CAN BE RECTIFIED. OTHER ABBREVIATIONS

1 JPB2CVSE-25-ECCENTRIC SHEAVE MATERIAL ABBREVIATIONS: DP = DEEP

1 JPB2CVSE-26-ECCENTRIC SHEAVE COVER ALU = ALUMINIUM DAA= DRILL AFTER ASSEMBLY

1 JPB2CVSE-27-ECCENTRIC SHEAVE SPACER BRS = BRASS D&TAA= DRILL AND TAP AFTER ASSEMBLY

2 JPB2CVSE-28-PISTON BRZ = BRONZE OR GUNMETAL (BRZ/GM) CF = CLOSE FIT (SIZE FOR SIZE)

2 JPB2CVSE-29-PISTON GUDGEON PIN CI = CAST IRON PF = PRESS FIT

2 JPB2CVSE-30-CON-ROD CU = COPPER PFAA= PRESS FIT AFTER ASSEMBLY

1 JPB2CVSE-31-ECCENTRIC STRAP GRA = GRAPHITE PCD = PITCH CIRCLE DIAMETER

161 6.34 1 JPB2CVSE-32-PUSHER GUIDE SLIDER RM = REAM

MS = MILD STEEL/BRIGHT MILD STEEL

1 JPB2CVSE-33-SLIDER PIVOT PIN S/S = SILVER STEEL OR STAINLESS STEEL HEX = HEXACON, 6SIDED

1 JPB2CVSE-34-SLIDER LINKAGE SPS = SPRING STEEL CP = COMPRESSED

1 JPB2CVSE-35-SLIDE VALVE PEEK= POLYETHER ETHER KETONE KNL = KNURLED

1 JPB2CVSE-36-SLIDE VALVE NUT SYN = SYNTHETIC MATERIAL SUCH AS VETON, NYLON, TEFLON OR RUBBER CSK = COUNTERSINK

1 JPB2CVSE-37-SLIDE VALVE STEM IN GENERAL SYNTHETIC MATERIALS SOULD BE ABLE TO WITHSTAND PL = PLACES

1 JPB2CVSE-38-VALVE STEM CONNNECTOR THE HEAT AND PRESSURE(S) APPLIED TO THEM. DWL= DOWEL

8 JPB2CVSE-M4 DOME NUT nnn/nnn MEANS THAT EITHER MATERIAL CAN BE USED HESOP=HOLES EQUALLY SPACED ON PCD

6 JPB2CVSE-M4 NUT SA-xxx = SUB ASSEMBLY-xxx

1 JPB2CVSE-M4x3.5 GRUB SREW

16 JPB2CVSE-M4x13 HEX BOLT 6-6PL R8-6PL M4 13-8PL 20 31

4 JPB2CVSE-M4x24HEX BOLT 22 22

32PF 32PF 15 28

4 JPB2CVSE-M4x32 STUD

4 JPB2CVSE-M4x45 STUD 30RM 30RM 6 5

186 7.32 10 JPB2CVSE-M6 DOME NUT 4-6PL

4 JPB2CVSE-M6x16 HEX BOLT

10

M10

M10

40

35

6-8PL M6-6PL ALU

25

0

20

20

R1 F F

P P 12 12

32 32

(96)

12

20

20

20

25

18

01

35

40

R4

ALU

10

M6 TUBE R5-8PL

8x6 16 16 SECTION A-A

18 96 12 16 22 22 16 12 SCALE 1 : 2

44

64

50

38 38 A

04 42 42

6 6 (100)

70

4mm THICK SCALE 1:2

18

8 BRZ M4 10-4PL

03

60

BRZ

64

12

8

SCALE 1:2 ALU

02

20

10 14 42 42 14 10 22 22

06

SCALE 1:2 25PF

6

12

R8 12

7

A M4 10-6PL 14 14

C'BORE 12-4PL SCALE 1:2 R8 05

4 8.5 5 8.5 09

16

R5 HIDDEN LINES REMOVED

5 5

FOR CLARITY

14HEX

20

13 13

6

M10

M10

8 6 8 ALU

10 07 10

18

5

8.5 4 BRS

M3

6

4RM

20

4

14HEX

5CF

10

25PF

M12

28 28

13

1

14

1 SCALE 1:1.5

13 18 4 12 5 38 38

16 R2 11A 11B

MS SCALE 1:1.5 ALU M3 ALU SCALE 1:2 PROPRIETY ITEM 8mm THICK

NOTES: FOUND THE ORIGINAL SET OF DRAWINGS ON THE INTERNET. THE ORIGINAL DRAWINGS WERE DESIGNED AND DRAWN BY J.P.BOURDILLAT IN FRENCH. (THIS DESIGN IS VERY SIMILAR TO THAT OF ELMER VERBURG PROJECT CHAPTER 44)

TITLE DRAWING CONTENTS PROJECT No 09C-21-00 PROJECTION

MODEL SCALE: 1:1

2 CYLINDER VERTICAL STEAM ENGINE WITH G.A., ISOMETRIC VIEW, BOM, NOTES, JDW DRAUGHTING SERVICES DATE

JDWDS DWG SCALE: 1:1 @A3 OR AS SHOWN

J.A.M. DE WAAL. 12 BRIGHTWELL STREET PAPAKURA 2110. JULY-2016 J.A.M. DE WAAL PAPAKURA NZ Copyright ©

SINGLE VALVE. PARTS AND ASSEMBLIES. NEW ZEALAND. PHONE: OO64 09 2988815. MOB: 0211791000

E-MAIL: dewaal@xtra.co.nz. SHEET: 01 OF 02 A3 No: JPB2CVSE-01

You might also like

- Technical Manual (Part A) Tatuus-Msv 023: Release 1.03 (27/02/2023)Document80 pagesTechnical Manual (Part A) Tatuus-Msv 023: Release 1.03 (27/02/2023)Nelson Piquet Souto Maior100% (1)

- Python SyllabusDocument3 pagesPython SyllabusAnonymous FJZFrEKONo ratings yet

- BP9763 A3 Sheet 01 PDFDocument1 pageBP9763 A3 Sheet 01 PDFjuan pedro pastor garciaNo ratings yet

- 2 Cylinder Vertical Marine Type Steam Engine (Bore 24 X Stroke 28) General Arrangement, Isometric View, Bom and NotesDocument1 page2 Cylinder Vertical Marine Type Steam Engine (Bore 24 X Stroke 28) General Arrangement, Isometric View, Bom and NotesMiguel MotaNo ratings yet

- 09C-40-00-A3-SHEET-01 - Sheet1Document1 page09C-40-00-A3-SHEET-01 - Sheet1Nam HoangNo ratings yet

- Plano en AutocadDocument1 pagePlano en AutocadJuan PastorNo ratings yet

- General Arrangement, Sections Bom, Parts and Assemblies Steam Operated Water Pump/InjectorDocument2 pagesGeneral Arrangement, Sections Bom, Parts and Assemblies Steam Operated Water Pump/InjectorJuan Manuel Arguello EspinosaNo ratings yet

- Lanz A3 Sheet 05 PDFDocument1 pageLanz A3 Sheet 05 PDFsrihariNo ratings yet

- NX Sheet MetalDocument2 pagesNX Sheet MetalSathish KumarNo ratings yet

- Muncaster 11 A3 Sheet 02Document1 pageMuncaster 11 A3 Sheet 02Juan PastorNo ratings yet

- Datasheet - M542H Stepper Motor DriverDocument10 pagesDatasheet - M542H Stepper Motor DriversthollanderNo ratings yet

- Adafruit Cc3000 WifiDocument56 pagesAdafruit Cc3000 Wifilojain centerNo ratings yet

- Camless Engine: Working of Push Rod EngineDocument14 pagesCamless Engine: Working of Push Rod EngineAkshay Kumar pn AkshayNo ratings yet

- Zen Toolworks CNC Carving Machine DIY Kit User Installation ManualDocument47 pagesZen Toolworks CNC Carving Machine DIY Kit User Installation ManualMartin SilisqueNo ratings yet

- A3 Tcose Sheet 01 PDFDocument1 pageA3 Tcose Sheet 01 PDFसचिन पटेलNo ratings yet

- User Guide - Air Quality Sensor Kit PDFDocument45 pagesUser Guide - Air Quality Sensor Kit PDFMR. TNo ratings yet

- Engine2 Pm63-Sheet-2 PDFDocument1 pageEngine2 Pm63-Sheet-2 PDFShridhar ZambareNo ratings yet

- Using Servo Motors With RPI PDFDocument11 pagesUsing Servo Motors With RPI PDFVictor Alexandru BusnitaNo ratings yet

- Cloud Connected Weather Station With The Arduino Yun and TembooDocument12 pagesCloud Connected Weather Station With The Arduino Yun and TembooMiguel Augusto Gutierrez MaldonadoNo ratings yet

- Arduino-TempHumidity-with-LCD-And-Web-Interface ALLSTEPSDocument12 pagesArduino-TempHumidity-with-LCD-And-Web-Interface ALLSTEPSKurniawan SusiloNo ratings yet

- CNC Router: Digital Fabrication WorkshopDocument4 pagesCNC Router: Digital Fabrication Workshopandri maulanaNo ratings yet

- Adafruit Io Basics Temperature and HumidityDocument29 pagesAdafruit Io Basics Temperature and HumiditysyncasterNo ratings yet

- Adafruit CatalogDocument53 pagesAdafruit CatalogCsaba LangerNo ratings yet

- CNC Interface Board CM101 ManualDocument17 pagesCNC Interface Board CM101 ManualZorica SolunacNo ratings yet

- Ose 53cyl Etoile Ose 3 Sisters OkDocument2 pagesOse 53cyl Etoile Ose 3 Sisters OkJulio Almanza100% (1)

- 6 CylinderDocument5 pages6 CylinderCường TrọngNo ratings yet

- Single Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Document3 pagesSingle Cylinder Oscillating Steam Engine Named "Lucy" General Arrangement and Components A3Jhon Fredy MartinNo ratings yet

- Adafruits Raspberry Pi Lesson 4 Gpio SetupDocument17 pagesAdafruits Raspberry Pi Lesson 4 Gpio SetupJuan BuitragoNo ratings yet

- Weatherstatiohhhn ThesisDocument49 pagesWeatherstatiohhhn ThesisAmparo RomnickNo ratings yet

- VEXTA PK Motor Only OverviewDocument21 pagesVEXTA PK Motor Only OverviewHerbert RodriguezNo ratings yet

- Exp Pistons Oppos S 09 04 04 PDFDocument4 pagesExp Pistons Oppos S 09 04 04 PDFHerbertCampanaSoteloNo ratings yet

- Spring Loaded GraverDocument1 pageSpring Loaded GraverGeo CpNo ratings yet

- 5 Axis ManualDocument6 pages5 Axis Manualpfonsecap0% (1)

- Stepper Motors CatalogDocument35 pagesStepper Motors Catalogapi-3700604100% (1)

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesStojan Pece CmarNo ratings yet

- A Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesDocument1 pageA Simple Oscillating Steam Engine by H.Muncaster. G.A., B.O.M., Notes, Isometric View, Parts and AssembliesSARGEN YOHAN LOZANO ARIASNo ratings yet

- Adafruit GFX Graphics LibraryDocument20 pagesAdafruit GFX Graphics LibraryfelixdobrescuNo ratings yet

- Engineering Vol 56 1893-12-15Document33 pagesEngineering Vol 56 1893-12-15ian_newNo ratings yet

- Adafruit CatalogDocument46 pagesAdafruit CataloggregguerreroNo ratings yet

- Convertible Cabriolet: Classic Car Series: 02Document5 pagesConvertible Cabriolet: Classic Car Series: 02Jesus DencheNo ratings yet

- Cilindro Horizontal PequeñoDocument1 pageCilindro Horizontal PequeñoNMM100% (1)

- 4 Cylindres Oscillant en Ligne PDFDocument3 pages4 Cylindres Oscillant en Ligne PDFJose Guadalupe AntonioNo ratings yet

- JVL Quickstep BrochureDocument8 pagesJVL Quickstep BrochureElectromate100% (1)

- Notes, Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam EngineDocument1 pageNotes, Parts and Assemblies A Model of A Maudslay Marine Type Vertical Steam EngineJayaramakrishna YakambariNo ratings yet

- Moto 360 Smartwatch Teardown PDFDocument14 pagesMoto 360 Smartwatch Teardown PDFPhone 4uNo ratings yet

- 0903 Taylor TitchDocument3 pages0903 Taylor Titchpor930sche100% (1)

- 080544R - Stepper Motor and DriversDocument8 pages080544R - Stepper Motor and DriversAnuruddha WijerathneNo ratings yet

- Arduino Your Home & Environment - USB - FTDIDocument8 pagesArduino Your Home & Environment - USB - FTDINusa TemyNo ratings yet

- TB6600 Toshiba Datasheet PDFDocument8 pagesTB6600 Toshiba Datasheet PDFArmin SelimovicNo ratings yet

- Iot Based Smart Irrigation System Using Nodemcu Esp8266 & Adafruit IoDocument6 pagesIot Based Smart Irrigation System Using Nodemcu Esp8266 & Adafruit IoSanthosh Kumar100% (1)

- EA230 Manual Voltage RegulatorDocument4 pagesEA230 Manual Voltage Regulatorhenryvargas238565No ratings yet

- General Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Document12 pagesGeneral Arrangement. Complete Steam Plant Including Two Steam Engines (1cyl + 2cyl Vertical)Trung NguyenNo ratings yet

- 09C-40-00-A3-SHEET-03 - Sheet1Document1 page09C-40-00-A3-SHEET-03 - Sheet1Abdul MannanNo ratings yet

- Maudslay Marine Type Vertical Steam EngineDocument3 pagesMaudslay Marine Type Vertical Steam EngineAxel DominiqueNo ratings yet

- Pidora Running On Raspberry PiDocument5 pagesPidora Running On Raspberry PiPraveen Kumar RNo ratings yet

- 2cwse PDFDocument2 pages2cwse PDFOrlando Rojas PintoNo ratings yet

- 09B 26 00 A3 Sheet 02Document1 page09B 26 00 A3 Sheet 02Leonardo PereiraNo ratings yet

- Manual Panasonic NV-GS 6 EE PDFDocument107 pagesManual Panasonic NV-GS 6 EE PDFQwerNo ratings yet

- Service Manual: XB-2, XB-SNDocument46 pagesService Manual: XB-2, XB-SNChristophe HomandNo ratings yet

- G1000 Mooney Installation, PitchServoGFC700AFCS PDFDocument5 pagesG1000 Mooney Installation, PitchServoGFC700AFCS PDFAndres GuerreroNo ratings yet

- CRS-VD-0301-ZML-MAR-0005-001B ResDocument3 pagesCRS-VD-0301-ZML-MAR-0005-001B Resshrikanth5singhNo ratings yet

- Bem VCB 27-29th Oct 2021 Presentation ADocument59 pagesBem VCB 27-29th Oct 2021 Presentation AScalperNo ratings yet

- Muncaster 11 A3 Sheet 04Document1 pageMuncaster 11 A3 Sheet 04Juan PastorNo ratings yet

- Muncaster 11 A3 Sheet 02Document1 pageMuncaster 11 A3 Sheet 02Juan PastorNo ratings yet

- Plano en AutocadDocument1 pagePlano en AutocadJuan PastorNo ratings yet

- R134a Pressure Enthalpy SiDocument2 pagesR134a Pressure Enthalpy SiCornelius YudhaNo ratings yet

- R134a Pressure Enthalpy SiDocument2 pagesR134a Pressure Enthalpy SiCornelius YudhaNo ratings yet

- Usted: PXNDX Sangre FríaDocument9 pagesUsted: PXNDX Sangre FríaJuan PastorNo ratings yet

- Rhythm GuitarDocument9 pagesRhythm GuitarJuan PastorNo ratings yet

- Usted: PXNDX Sangre FríaDocument5 pagesUsted: PXNDX Sangre FríaJuan PastorNo ratings yet

- SOP FOR STIFFNESS Tester (09.6.17)Document2 pagesSOP FOR STIFFNESS Tester (09.6.17)Q ANo ratings yet

- Data Base Proyek KonstruksiDocument913 pagesData Base Proyek KonstruksiZefanyaNo ratings yet

- Docker Management Design Patterns: Swarm Mode On Amazon Web ServicesDocument1 pageDocker Management Design Patterns: Swarm Mode On Amazon Web ServicesAli AhmadNo ratings yet

- CH 5 Membrane Dynamics TestDocument42 pagesCH 5 Membrane Dynamics TestDani Anyika100% (1)

- Apurba MazumdarDocument2 pagesApurba MazumdarDRIVECURENo ratings yet

- Battery Soc Prediction JournalDocument12 pagesBattery Soc Prediction JournalketamencoNo ratings yet

- The Head and The Heart National Identity and Urban Planning in A Devolved ScotlandDocument23 pagesThe Head and The Heart National Identity and Urban Planning in A Devolved ScotlandMarkNo ratings yet

- Kobelco Sk200 8 Excavator Parts Catalog ManualDocument5 pagesKobelco Sk200 8 Excavator Parts Catalog ManualWahyu Yudi100% (2)

- Gospel Steel TrussDocument18 pagesGospel Steel TrussJoseph Cloyd L. LamberteNo ratings yet

- 10 DM Commandments EbookDocument9 pages10 DM Commandments EbookLily KimNo ratings yet

- AVCN1 Full BDocument395 pagesAVCN1 Full BPhương TrungNo ratings yet

- Introduction To Mineral Processing 2010Document24 pagesIntroduction To Mineral Processing 2010elmonemNo ratings yet

- Research Paper Example in Citation Guide PDFDocument6 pagesResearch Paper Example in Citation Guide PDFDm Wivinny JesonNo ratings yet

- Adjusting Entries, Worksheet and FSDocument26 pagesAdjusting Entries, Worksheet and FSBianca RoswellNo ratings yet

- NDT Basics GuideDocument29 pagesNDT Basics Guideravindra_jivaniNo ratings yet

- Basic Modules of Instruction Agriculture NC IIDocument13 pagesBasic Modules of Instruction Agriculture NC IIMEAMALLORCANo ratings yet

- Lesson 11 Payroll Calculation SolutionDocument6 pagesLesson 11 Payroll Calculation SolutionashrithssNo ratings yet

- 4045tf270 Power Unit For Gen Set (12 24v 1800rpm) Sdmo EngineDocument3 pages4045tf270 Power Unit For Gen Set (12 24v 1800rpm) Sdmo EngineRoberto MoraNo ratings yet

- University of PeradeniyaDocument6 pagesUniversity of PeradeniyaAmila SampathNo ratings yet

- Chapter 15 - Designing and Managing Integrating Marketing CommunicationsDocument28 pagesChapter 15 - Designing and Managing Integrating Marketing CommunicationsArmanNo ratings yet

- Energy Research Institute - Wang SichengDocument17 pagesEnergy Research Institute - Wang SichengADB_SAEN_ProjectsNo ratings yet

- Media Preparation and Uses in Medical MicrobiologyDocument20 pagesMedia Preparation and Uses in Medical MicrobiologyPrincewill SeiyefaNo ratings yet

- Osy MPDocument16 pagesOsy MPPratiksha JadhavNo ratings yet

- Nutanix: NCP-MCI-5.15 ExamDocument7 pagesNutanix: NCP-MCI-5.15 ExamAlvin BosqueNo ratings yet

- Srikanth ImJDocument2 pagesSrikanth ImJTEJA unixNo ratings yet

- 144 Daftar P2P Ilegal AprilDocument12 pages144 Daftar P2P Ilegal AprilSumiatiNo ratings yet

- PEH Pre-Finals ReviewerDocument1 pagePEH Pre-Finals ReviewerMaribeth Alyssa GoNo ratings yet

- English Unit 9 - Ni Putu Angelika RistyaDocument3 pagesEnglish Unit 9 - Ni Putu Angelika RistyaAngel LikaNo ratings yet