Professional Documents

Culture Documents

Shrcttrral: Management Bulk Carrier Structure Appendix 24.1 (' Tuenag6',i?'t

Shrcttrral: Management Bulk Carrier Structure Appendix 24.1 (' Tuenag6',i?'t

Uploaded by

Ocean going master Cpt. batuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shrcttrral: Management Bulk Carrier Structure Appendix 24.1 (' Tuenag6',i?'t

Shrcttrral: Management Bulk Carrier Structure Appendix 24.1 (' Tuenag6',i?'t

Uploaded by

Ocean going master Cpt. batuCopyright:

Available Formats

Management of Bulk Carrier Structure Appendix 24.

1('

This app€ndix contains edtted eLtl€,cts from the excellent pnacucal p€lper tuenag6',i?'t d Bt IE Cuatc

Strncarrc, by Pet€r A Bryson pr€sent€d at the RINA Mt* a!]d Opc,fafrf'a d ErrIE Cata'l3r:' Seminar'

Iondon, October eOO5. These exbra,cts focus on infom.ation Ukely to be most useful to shiTs' perso-nne

but tlre paper is w"itten frcm tJle per€pective of a Fleet MaJra€er - HUI and aDJ/one wentin{l that level

of detail is w€[ advised to r€8d the ori€Fr€,I paper.

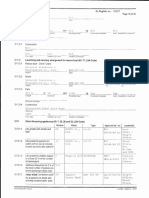

lt€ lrlss ol a tulk ca}?lds stnrotural €I@€ots

3ulkheaC uppor stool

Comrgated hold

bulkhead Bailast

lr(ln(

Bulkhead

BulKlead lower stool

(internal mernbers - d'aphragms or stitfeners)

Tiipp,rrg \ frarnes /-

brAcket Side

-Eidshelframe \

'l\. #j;i"a Blse welt

Doubh txrtlom

tank

Longitudinal sde

Bottorn shell

grrdsr of dwl ke{,

plating

Transwrse

web

Non-watertlght :

transverse floor

Fig. 24E Bulk carrier hold showing the names of structural parts.

Drawing courtesy of Peter Brys'

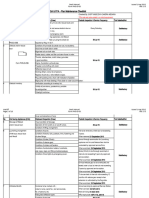

Shrcttrral defec'ts

Structr:ral defects: Th,ese are caused by poor desilfl detail, poor detailed desi$n, Iocal stress

concentration, poor repair workmanship, comosion, bperational incident and wear a,rld tear.

Wrere to look for stnrctural defects:

In Eleneral:

a Note the condition of the access ladder

o Always check both sides - poft and starboard

a IIIIa€e spaces - a ver5r comosive envForlment

o Common br:tkhead.s b-etween water ballast t€nks and heated fuel tanks/warm machinerT/ spaces

o Excessive a,rrrounts of accr:mr:lated loose scale and/or residual ballast mud lying at the bottom of

a tarik entraps water ballast, creates a da,mp and comosive environment, that results in coating

breakd.olrm and subsequent, structural diminution. Excessive a.mounts of loose scale also sug$est

diminution has occurred at some location(s) within the tank.

o Bottom plating in way of suction bell mouth and sor:ndingi pipe strildng pfate.

a Bottom plate pittrn€ ie microbial water ballast cont€,Inination.

o TArtrere iiternat members fail, platin€ becomes unsuppofied. Thris leads to flrrther det€chment of

adjacent internal members and subsequent failure of the platin€.

. Areas of stress concentration, usua$r with associated local coating breakdovtm.

. Both sid.es of internal structural elements in water ballast tanks are subjected to comosion. The

bor:ndary platingi only one side.

474 THE NAUTICAL INSTITUTE

You might also like

- Audi A4 Quattro 2.0L 4-Cyl. 4V Turbo EngineDocument203 pagesAudi A4 Quattro 2.0L 4-Cyl. 4V Turbo EngineNP0% (1)

- Design Notes On Articulated Tug-Barge Connections PDFDocument25 pagesDesign Notes On Articulated Tug-Barge Connections PDFJonatas SilvaNo ratings yet

- Stowage FactorsDocument64 pagesStowage FactorsOcean going master Cpt. batuNo ratings yet

- Water Pump Manual 1Document12 pagesWater Pump Manual 1Baharudin BujangNo ratings yet

- NCB LC FormDocument2 pagesNCB LC FormMohsin KhanNo ratings yet

- Pavement Deflection Measurements: Standard Method of Test ForDocument11 pagesPavement Deflection Measurements: Standard Method of Test Forsidiq7100% (2)

- Compiled QADocument17 pagesCompiled QAAudreyNo ratings yet

- International Standard: Truck and Bus Tyres and Rims (Metric Series) - RimsDocument8 pagesInternational Standard: Truck and Bus Tyres and Rims (Metric Series) - RimsAndres ValdezNo ratings yet

- Banglore To Delhi Flight InvoiceDocument2 pagesBanglore To Delhi Flight InvoiceNikhil AgrawalNo ratings yet

- Bidder Name:: Total Amount With TaxesDocument32 pagesBidder Name:: Total Amount With Taxesbolsamir100% (1)

- Ship Construction Notes For Pre Sea Deck CadetsDocument23 pagesShip Construction Notes For Pre Sea Deck CadetsgeorgesagunaNo ratings yet

- FundamentalDocument1 pageFundamentalAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- 82848211-TREX-05106 Equipmenl Alerl ReviewDocument10 pages82848211-TREX-05106 Equipmenl Alerl ReviewHKHKBOOKSNo ratings yet

- Llo!rs) MSRK !qud Mrrki,: LltrrincDocument17 pagesLlo!rs) MSRK !qud Mrrki,: Lltrrincbhaswath2000No ratings yet

- 8 ReportingDocument17 pages8 ReportingG.O.D 7No ratings yet

- Kim Lighting Concept 5000 Series Brochure 1991Document24 pagesKim Lighting Concept 5000 Series Brochure 1991Alan MastersNo ratings yet

- Brosur Vaccine Refrigerator - Bblo-102-VrDocument1 pageBrosur Vaccine Refrigerator - Bblo-102-VrPPRA RSU Kab. TangerangNo ratings yet

- Unit 3 Ship StructuresDocument21 pagesUnit 3 Ship StructuresRodrigo LimaNo ratings yet

- Chaper Three 1Document22 pagesChaper Three 1natiz addisNo ratings yet

- Saratoga MArketingDocument7 pagesSaratoga MArketingSan JivNo ratings yet

- Ductile Detailing & Its Important CLPIU EduDocument73 pagesDuctile Detailing & Its Important CLPIU EduSankalp LamaNo ratings yet

- Ship Structural ComponentsDocument15 pagesShip Structural ComponentshumbertoNo ratings yet

- D Cap 03 PDFDocument47 pagesD Cap 03 PDFelena lopez albaNo ratings yet

- Inverse Chill in Ductile Iron CastingsDocument2 pagesInverse Chill in Ductile Iron Castingsdemiancito06No ratings yet

- Fiberfrac Usado No TCCDocument3 pagesFiberfrac Usado No TCCGleidson LimaNo ratings yet

- PSC PDFDocument1 pagePSC PDFigortfernandesNo ratings yet

- The Answers: Condition of AssignmentDocument2 pagesThe Answers: Condition of Assignmentadam shaneNo ratings yet

- CFD Modelling of Planing Hulls With PartDocument18 pagesCFD Modelling of Planing Hulls With PartGe XuNo ratings yet

- I N I'It: - Casl-Le Fr. I34 Fo: Laddcr Is A: Nocided RopeDocument1 pageI N I'It: - Casl-Le Fr. I34 Fo: Laddcr Is A: Nocided RopeAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Academy Ah-64d LongbowDocument8 pagesAcademy Ah-64d LongbowGreg RossNo ratings yet

- Advanced Dam Engineering 05 (124-164)Document41 pagesAdvanced Dam Engineering 05 (124-164)chandra adriawanNo ratings yet

- Plumbing Practice (180937126)Document4 pagesPlumbing Practice (180937126)Sauveer SinhaNo ratings yet

- Galletly 1986Document6 pagesGalletly 1986Danish ShaikhNo ratings yet

- Ultrasonic Thickness Measurement Report: Mt. Raka Surya 2.0Document105 pagesUltrasonic Thickness Measurement Report: Mt. Raka Surya 2.0DHABRI -No ratings yet

- M Ii,/a N/A: R.R.J KGDocument1 pageM Ii,/a N/A: R.R.J KGAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- A Frame & Tie BoltsDocument6 pagesA Frame & Tie BoltsCadet Aviral Jha [9335]No ratings yet

- Kim Lighting Concept 5000 Series Brochure 1986Document24 pagesKim Lighting Concept 5000 Series Brochure 1986Alan MastersNo ratings yet

- 15.1.1d Bulkheads 2Document14 pages15.1.1d Bulkheads 2vickyNo ratings yet

- 2 Ebook - Star Wars d6 - Blueprints - Incredible Cross Section (1) (Comprimido)Document16 pages2 Ebook - Star Wars d6 - Blueprints - Incredible Cross Section (1) (Comprimido)bardwolfNo ratings yet

- CHAPTER 10 - Structural Steel Works, Sheet Roofing and Safety CanopyDocument6 pagesCHAPTER 10 - Structural Steel Works, Sheet Roofing and Safety CanopyMd.Rezaul IslamNo ratings yet

- Em 202 Selected FormulaeDocument22 pagesEm 202 Selected FormulaeRajesh NambiarNo ratings yet

- Sliding Contact Bearings Sliding Contact Bearings: r c μ n p r c μ n pDocument4 pagesSliding Contact Bearings Sliding Contact Bearings: r c μ n p r c μ n pAditya Varma YalamanchiliNo ratings yet

- 132 KV Grid StationDocument14 pages132 KV Grid StationWaqas AhmedNo ratings yet

- FP03Document29 pagesFP03api-3738147100% (2)

- BBR VT CONA CMFS1 Flyer Rev3 0420Document2 pagesBBR VT CONA CMFS1 Flyer Rev3 0420wenix oniralcoNo ratings yet

- Delivery Note - Crown Plaza-No 1Document11 pagesDelivery Note - Crown Plaza-No 1Sameer KhanNo ratings yet

- 196122006 Doc 10 Dry Tank CertificateDocument1 page196122006 Doc 10 Dry Tank CertificateRiaz AhmedNo ratings yet

- Astm D 6386 99 PDFDocument4 pagesAstm D 6386 99 PDFIya Nicole LoNo ratings yet

- McKinlay Ch7Document28 pagesMcKinlay Ch7matthew kobulnickNo ratings yet

- 184-193 Hindi Provision of Re-Sealable Plastic Bags For PassengDocument2 pages184-193 Hindi Provision of Re-Sealable Plastic Bags For PassengsrpvickyNo ratings yet

- Sem2 SC 1Document78 pagesSem2 SC 1Jais100% (1)

- Plantrat3 Traveling ScreensDocument19 pagesPlantrat3 Traveling ScreensLuis E.SNo ratings yet

- Brosur Pompa Submersible EbaraDocument4 pagesBrosur Pompa Submersible EbaraBudi RahmadiNo ratings yet

- Pavement Tutorial 3Document13 pagesPavement Tutorial 3mies6996aNo ratings yet

- Inelastic Behavior of Orthotropic Steel Deck Stiffened by U-Shaped StiffenersDocument17 pagesInelastic Behavior of Orthotropic Steel Deck Stiffened by U-Shaped Stiffenersjuan carlos molano toroNo ratings yet

- Basic Principles of Control Valves and Actuators: ObjectivesDocument14 pagesBasic Principles of Control Valves and Actuators: ObjectivesNur Irfansyah SNo ratings yet

- 17238Document37 pages17238tasmiahoque489No ratings yet

- Análisis de API 5C3 PDFDocument9 pagesAnálisis de API 5C3 PDFcomar85No ratings yet

- Veronica PLL8Document8 pagesVeronica PLL8carlos ruiz p.No ratings yet

- Bulkhead ConstructionDocument8 pagesBulkhead ConstructionarmanimamsNo ratings yet

- JointDocument1 pageJointFikri AkhdanNo ratings yet

- Packing ListDocument1 pagePacking ListS DasNo ratings yet

- Asmouk11proceedings - PP 143 152Document10 pagesAsmouk11proceedings - PP 143 152JDESXNo ratings yet

- DIY ModelDocument1 pageDIY ModelAlok KumarNo ratings yet

- Generating Optimal Stowage Plans For Container Vessel BaysDocument15 pagesGenerating Optimal Stowage Plans For Container Vessel BaysKjetil Aleksander Aasen HaaheimNo ratings yet

- Boiler Flow Diagram With Drain and Vent HeaderDocument3 pagesBoiler Flow Diagram With Drain and Vent HeaderRAJKUMARNo ratings yet

- 6sample of Hire Survey ReportDocument16 pages6sample of Hire Survey ReportToufik BensariNo ratings yet

- Pap 0474Document45 pagesPap 0474rotimi olalekan fataiNo ratings yet

- Near Miss Pilot CarmihDocument4 pagesNear Miss Pilot CarmihOcean going master Cpt. batuNo ratings yet

- Çöp Bi̇donlarinin Yerleri̇Document1 pageÇöp Bi̇donlarinin Yerleri̇Ocean going master Cpt. batuNo ratings yet

- Fresh Water Daily Monitoring: Date Time Port STBDDocument2 pagesFresh Water Daily Monitoring: Date Time Port STBDOcean going master Cpt. batuNo ratings yet

- Product Refrigerator (4 °C) Freezer (-18 °C)Document6 pagesProduct Refrigerator (4 °C) Freezer (-18 °C)Ocean going master Cpt. batuNo ratings yet

- Çöp Bi̇donlarinin Yerleri̇Document1 pageÇöp Bi̇donlarinin Yerleri̇Ocean going master Cpt. batuNo ratings yet

- FSS Code - Fire Safety Systems PDFDocument73 pagesFSS Code - Fire Safety Systems PDFOcean going master Cpt. batuNo ratings yet

- MV Esra C Tally Sheet Port: Date C/HNO1 Date Total SignatureDocument1 pageMV Esra C Tally Sheet Port: Date C/HNO1 Date Total SignatureOcean going master Cpt. batuNo ratings yet

- Esra C Muster List UpdatedDocument30 pagesEsra C Muster List UpdatedOcean going master Cpt. batu0% (1)

- PMS 10.2018Document17 pagesPMS 10.2018Ocean going master Cpt. batuNo ratings yet

- Australian Safe LoadingDocument125 pagesAustralian Safe LoadingOcean going master Cpt. batu100% (1)

- Garbage Management Plan (Amendments 2017) Edition 1 + AppendixesDocument36 pagesGarbage Management Plan (Amendments 2017) Edition 1 + AppendixesOcean going master Cpt. batuNo ratings yet

- Soviet Jet Train. Some More History.: Homeaboutfeedbacksubmit!ForumsubscribebookmarkDocument29 pagesSoviet Jet Train. Some More History.: Homeaboutfeedbacksubmit!Forumsubscribebookmarkkjh7903No ratings yet

- 7 Speed DSG VW 0AM - 0CW - DQ200 and Repair Measures - Sheng Hai Au182338Document12 pages7 Speed DSG VW 0AM - 0CW - DQ200 and Repair Measures - Sheng Hai Au182338Nitin Patil100% (2)

- Mort&H, NH Division, (PWD), Maharashtra Schedules To Concession AgreementDocument5 pagesMort&H, NH Division, (PWD), Maharashtra Schedules To Concession AgreementAkshay PendurkarNo ratings yet

- 60TPH Tomato Paste Processing 2Document19 pages60TPH Tomato Paste Processing 2Nick Kim67% (3)

- 04h On The Water ContinuedDocument4 pages04h On The Water ContinuedNgaire TaylorNo ratings yet

- Cmta 2016 LitovelascoDocument114 pagesCmta 2016 Litovelascolito77No ratings yet

- Cargo Handling & StowageDocument56 pagesCargo Handling & Stowagesamar jeetNo ratings yet

- RPM CalculatorDocument2 pagesRPM CalculatorPablo DpNo ratings yet

- 2015 Rookie Tri Participant GuideDocument28 pages2015 Rookie Tri Participant GuideHigh Five EventsNo ratings yet

- Flying Empires Book DocumentsDocument201 pagesFlying Empires Book Documentsjohncrusoe100% (1)

- 8.Pms Monthly July 15 Lsa&FfaDocument10 pages8.Pms Monthly July 15 Lsa&FfaMuhammad Abdul WahidNo ratings yet

- Guidelines On Pavement Markings: 1.0 Dimensions of Longitudinal Lines For Rural and Urban StandardsDocument5 pagesGuidelines On Pavement Markings: 1.0 Dimensions of Longitudinal Lines For Rural and Urban StandardsIsabelle FGNo ratings yet

- PIA Quantitative and Quality AnalysisDocument62 pagesPIA Quantitative and Quality Analysismadnansajid876525% (4)

- The PhaetonDocument76 pagesThe PhaetonAbd DecNo ratings yet

- The Account of PigafettaDocument4 pagesThe Account of Pigafettajanellajoyce.malloNo ratings yet

- Tshwane and Spaces of Power in South Africa - MabinDocument12 pagesTshwane and Spaces of Power in South Africa - MabinTanika SwartNo ratings yet

- Airtransport 2000 eDocument312 pagesAirtransport 2000 eDr. Aleksandar SimicNo ratings yet

- (Wiring Harness Dash - KC6C1)Document1 page(Wiring Harness Dash - KC6C1)Thiên NguyễnNo ratings yet

- Ivory Coast: Customs Regulations and Information For ImportsDocument2 pagesIvory Coast: Customs Regulations and Information For ImportsAziz SghayerNo ratings yet

- MEG - References RailwayDocument12 pagesMEG - References Railwayvoltus88No ratings yet

- Catalogo de Tanque Diario de CombustibleDocument8 pagesCatalogo de Tanque Diario de CombustibleJavier Gaspar Lee RomeroNo ratings yet