Professional Documents

Culture Documents

Glass Flake Coatings PDF

Glass Flake Coatings PDF

Uploaded by

Dinesh ChouguleCopyright:

Available Formats

You might also like

- New South Wales Code of Practice For Plumbing and Drainage Third Editions 2006Document169 pagesNew South Wales Code of Practice For Plumbing and Drainage Third Editions 2006NourNo ratings yet

- VGB S 021 03 2018 04 enDocument37 pagesVGB S 021 03 2018 04 enCarmen Rodriguez Polo100% (2)

- Essential Ingredients For A Greener World: Home Care Sustainable Product GuideDocument13 pagesEssential Ingredients For A Greener World: Home Care Sustainable Product GuideTinasheNo ratings yet

- Acceptance Criteria For Damaged PFP Info Sheet 12-2007Document9 pagesAcceptance Criteria For Damaged PFP Info Sheet 12-2007Richard HollidayNo ratings yet

- Corrosion Webinar Series - Coatings Maintenance Assessments PDFDocument37 pagesCorrosion Webinar Series - Coatings Maintenance Assessments PDFyaofuzhang100% (1)

- Corrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium PigmentsDocument14 pagesCorrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium Pigmentssmith100% (1)

- JPCL Transpipe EbookDocument82 pagesJPCL Transpipe Ebookvincent.w.stone6724No ratings yet

- The Repair OptionDocument4 pagesThe Repair OptionMAGUNAMNo ratings yet

- As 4822-2008 External Field Joint Coatings For Steel PipelinesDocument8 pagesAs 4822-2008 External Field Joint Coatings For Steel PipelinesSAI Global - APAC0% (1)

- Cathodic Protection Strategies For FPSO's FinalDocument11 pagesCathodic Protection Strategies For FPSO's FinalThaibinh Nguyen100% (1)

- Underground Insulation Specification Data SheetDocument2 pagesUnderground Insulation Specification Data Sheetadoptvn100% (1)

- Pipe CoatingsDocument23 pagesPipe CoatingsIshani Gupta75% (4)

- Glasse FlakeDocument18 pagesGlasse FlakeBoris CardenasNo ratings yet

- Com Su 6095 PDFDocument33 pagesCom Su 6095 PDFresp-ect100% (1)

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Tech Coating SelectionDocument8 pagesTech Coating SelectionKarthikeyan Shanmugavel100% (1)

- Zinc Silicate or Zinc Epoxy As The Preferred High Performance PrimerDocument10 pagesZinc Silicate or Zinc Epoxy As The Preferred High Performance Primerbabis1980100% (1)

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDocument3 pages001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- Underwater Repairs: 18.1 GeneralDocument11 pagesUnderwater Repairs: 18.1 GeneralmigescuNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Pipeline Internal CoatingDocument14 pagesPipeline Internal CoatingMostafa Sharaf100% (1)

- ID-PRC 19 - PE Coating RepairDocument7 pagesID-PRC 19 - PE Coating Repaircloud23No ratings yet

- COM SU 5191 C February 2017Document91 pagesCOM SU 5191 C February 2017suriya100% (1)

- Interspec: Tangguh Expansion ProjectDocument43 pagesInterspec: Tangguh Expansion ProjectZamri Rahmat SikumbangNo ratings yet

- A World of Protection: Arc Advanced Reinforced Coatings For Metal and ConcreteDocument12 pagesA World of Protection: Arc Advanced Reinforced Coatings For Metal and ConcreteMotasem DarwishNo ratings yet

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- CUI: An In-Depth Analysis: Hira S. AhluwaliaDocument6 pagesCUI: An In-Depth Analysis: Hira S. AhluwaliaJithuJohnNo ratings yet

- Pipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge TavesDocument51 pagesPipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge Tavesnathgsurendra100% (2)

- Cathodic Protection Design For Offshore Pipeline and Subsea StructureDocument24 pagesCathodic Protection Design For Offshore Pipeline and Subsea StructurekalaiNo ratings yet

- Trouble With Paint Blistering of Paint On Metal 1Document10 pagesTrouble With Paint Blistering of Paint On Metal 1ravi00098No ratings yet

- Oil and Gas Offshore ProductionDocument9 pagesOil and Gas Offshore ProductionLao ZhuNo ratings yet

- Coatings and Cathodic Disbondment - The True StoryDocument23 pagesCoatings and Cathodic Disbondment - The True StoryCamilo Godoy V100% (1)

- Investigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorDocument6 pagesInvestigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorNsidibe Michael Etim100% (1)

- NclUni Lect1 1103Document49 pagesNclUni Lect1 1103Dino Peduto100% (1)

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 pagesDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Graphite Vademecum E-HDocument27 pagesGraphite Vademecum E-Hdroessaert_stijnNo ratings yet

- CoatingDocument162 pagesCoatingSharafudeen M Mohammedali100% (1)

- Belzona Coating Guide For CUI and Atmospheric CorrosionDocument2 pagesBelzona Coating Guide For CUI and Atmospheric CorrosionfraemddNo ratings yet

- CP Painting Revised SpecsDocument57 pagesCP Painting Revised SpecsanilnwaychalNo ratings yet

- The Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantDocument5 pagesThe Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantSergio Daniel Barea Nuñez100% (1)

- Garnet SpecificationDocument2 pagesGarnet SpecificationskNo ratings yet

- Challenging The Organic "Zinc Rich" Primer StandardDocument9 pagesChallenging The Organic "Zinc Rich" Primer Standardaliabdulhamid100% (2)

- Interseal 670HS+Br+EngDocument2 pagesInterseal 670HS+Br+Engrajauae2008100% (1)

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- New Insights in Repairing Damaged Pipes and Pipelines Using Composite Materials Chris AlexanderDocument41 pagesNew Insights in Repairing Damaged Pipes and Pipelines Using Composite Materials Chris AlexanderAlp Altınok100% (1)

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocument15 pagesA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyNo ratings yet

- Fusion Bond Epoxy (FBE) Coating RepairsDocument4 pagesFusion Bond Epoxy (FBE) Coating Repairsyasi heeru100% (1)

- Section 6 API Publication 2207 - Preparing Tank Bottoms For Hot WorkDocument7 pagesSection 6 API Publication 2207 - Preparing Tank Bottoms For Hot WorkRamyMoustafaNo ratings yet

- The Adhesion Characteristics of Protective Coating Materials For The Containment Structure in Nuclear Power PlantsDocument8 pagesThe Adhesion Characteristics of Protective Coating Materials For The Containment Structure in Nuclear Power PlantsHaidarHussaini100% (1)

- NORSOK M 004 S 738v2021 03 - 18Document1 pageNORSOK M 004 S 738v2021 03 - 18noureldinmohammedNo ratings yet

- Dual-Layer Fusion-Bonded Epoxy (FBE) Coatings Protect Pipelines PDFDocument13 pagesDual-Layer Fusion-Bonded Epoxy (FBE) Coatings Protect Pipelines PDFjeedanNo ratings yet

- Chem ClearDocument5 pagesChem ClearBiju_PottayilNo ratings yet

- Sky Climber SparesDocument7 pagesSky Climber SparesshambhoiNo ratings yet

- ISES CP Report 2Document18 pagesISES CP Report 2Tamer Hesham AhmedNo ratings yet

- Development of DNV F101Document8 pagesDevelopment of DNV F101E.Kannan S.EhambaramNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07250-1 FireproofingDocument4 pagesITCC in Riyadh Residential Complex J10-13300 07250-1 FireproofinguddinnadeemNo ratings yet

- Up Graded Thermal Insulation DCLDocument14 pagesUp Graded Thermal Insulation DCLSubrata NagNo ratings yet

- Polymer Linings For Restoration Corrosion Protection of Steel SurfacesDocument7 pagesPolymer Linings For Restoration Corrosion Protection of Steel Surfacesfrancisco javier rubioNo ratings yet

- Masterprotect 300 Tds For TrestelDocument3 pagesMasterprotect 300 Tds For TrestelrannuNo ratings yet

- Perić Nikola PM 8-2021Document3 pagesPerić Nikola PM 8-2021Nikola PericNo ratings yet

- ITW PSMB Vs Polykraft or PaintDocument2 pagesITW PSMB Vs Polykraft or PaintVishnu DuttaNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Glossary of Financial TermsDocument12 pagesGlossary of Financial TermsDinesh ChouguleNo ratings yet

- Sample Test QuestionsDocument14 pagesSample Test QuestionsDinesh ChouguleNo ratings yet

- 15 FB / # 800 (3PC) Ball ValvesDocument10 pages15 FB / # 800 (3PC) Ball ValvesDinesh ChouguleNo ratings yet

- Letter of Ack. (Alfa Laval)Document1 pageLetter of Ack. (Alfa Laval)Dinesh ChouguleNo ratings yet

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChouguleNo ratings yet

- EIL - Specification SheetDocument1 pageEIL - Specification SheetDinesh ChouguleNo ratings yet

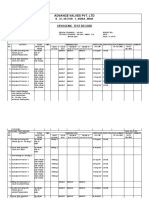

- Advance Valves Pvt. LTD: Cryogenic Test RecordDocument3 pagesAdvance Valves Pvt. LTD: Cryogenic Test RecordDinesh ChouguleNo ratings yet

- M Tork New CatalogueDocument16 pagesM Tork New CatalogueDinesh ChouguleNo ratings yet

- G 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDocument2 pagesG 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDinesh ChouguleNo ratings yet

- Gandhi Special Tubes LTD.: Product ProfileDocument6 pagesGandhi Special Tubes LTD.: Product ProfileDinesh ChouguleNo ratings yet

- Jamesbury 4000Document12 pagesJamesbury 4000Dinesh ChouguleNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- (FLS 1000 (A4) FLS Product Catalog LR1 0Document260 pages(FLS 1000 (A4) FLS Product Catalog LR1 0Dinesh ChouguleNo ratings yet

- DVG CatalogDocument7 pagesDVG CatalogDinesh ChouguleNo ratings yet

- Ameya GearboxDocument1 pageAmeya GearboxDinesh ChouguleNo ratings yet

- Solenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Document10 pagesSolenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Dinesh ChouguleNo ratings yet

- Calorimetry and Conservation of Energy Lab ReportDocument5 pagesCalorimetry and Conservation of Energy Lab ReportKali stringsNo ratings yet

- A 59Document1 pageA 59AnuranjanNo ratings yet

- Data Sheet IGBTDocument12 pagesData Sheet IGBTAndrés David Martínez MarteloNo ratings yet

- BHS Prospekt DKX USA 072014 WebDocument20 pagesBHS Prospekt DKX USA 072014 WebMoaiyadMhtarNo ratings yet

- Cellular RespirationDocument13 pagesCellular Respirationapi-329164492No ratings yet

- Product Line GuideDocument2 pagesProduct Line Guidenicolas yoris marcoglieseNo ratings yet

- WA150-5 SEBM033805 TroubleshootingDocument273 pagesWA150-5 SEBM033805 Troubleshootinghaimay118No ratings yet

- Application Note AN-1164: IR Class D Audio IC, Operation With Single Output Power SupplyDocument11 pagesApplication Note AN-1164: IR Class D Audio IC, Operation With Single Output Power SupplyMárcio FerreiraNo ratings yet

- King Fahd University of Petroleum & Minerals: Mechanical Engineering Dynamics ME 201 BY Dr. Meyassar N. Al-HaddadDocument29 pagesKing Fahd University of Petroleum & Minerals: Mechanical Engineering Dynamics ME 201 BY Dr. Meyassar N. Al-HaddadTommyVercettiNo ratings yet

- 7 Statistical Thermodynamics-IIDocument30 pages7 Statistical Thermodynamics-IICahyarani ParamestiNo ratings yet

- Ferroresonant Configurations in Power Systems: V. Valverde, G. Buigues, A. J. Mazón, I. Zamora, I. AlbizuDocument6 pagesFerroresonant Configurations in Power Systems: V. Valverde, G. Buigues, A. J. Mazón, I. Zamora, I. AlbizuMehdi_Mashayekhi_172No ratings yet

- Sop 002 Copper Strip CorrosionDocument8 pagesSop 002 Copper Strip CorrosionAmnaKamran100% (1)

- Carbo RateDocument3 pagesCarbo RateJeevan Landge PatilNo ratings yet

- The Future of Biofuels and Challenges AheadDocument22 pagesThe Future of Biofuels and Challenges AheadNitishNo ratings yet

- Dispersion Modeling BibliographyDocument1 pageDispersion Modeling BibliographyMilton BeychokNo ratings yet

- AssignmentDocument26 pagesAssignmentAriel GamboaNo ratings yet

- TORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogDocument1 pageTORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogBluish FlameNo ratings yet

- 00 AFWW Corporate BrochureDocument8 pages00 AFWW Corporate BrochureCherif TharwatNo ratings yet

- VNX - Su I20 Brochure PDFDocument12 pagesVNX - Su I20 Brochure PDFruk100% (1)

- Brochure Corporate enDocument9 pagesBrochure Corporate enbizolutionNo ratings yet

- 60601-1 ChecklistDocument47 pages60601-1 Checklistgfgdgfd100% (4)

- Citizen Eco Drive Watch ManualDocument46 pagesCitizen Eco Drive Watch Manualjwha238No ratings yet

- AS Level Physics Revision NotesDocument39 pagesAS Level Physics Revision NotesjoshuaNo ratings yet

- QuestDocument4 pagesQuestKanda VelanNo ratings yet

- Synchro - ManDocument8 pagesSynchro - Manapi-19787379No ratings yet

- Chapter 3 - Electric Current and Direct Current Circuit 1Document8 pagesChapter 3 - Electric Current and Direct Current Circuit 1Fazilah TawasilNo ratings yet

- sm-K1017314E DX210W LowResDocument1,184 pagessm-K1017314E DX210W LowResDavid Apaza Hurtado100% (1)

- Effect of Various Technology On Engine PerformanceDocument89 pagesEffect of Various Technology On Engine PerformanceArya FahimNo ratings yet

Glass Flake Coatings PDF

Glass Flake Coatings PDF

Uploaded by

Dinesh ChouguleOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glass Flake Coatings PDF

Glass Flake Coatings PDF

Uploaded by

Dinesh ChouguleCopyright:

Available Formats

GLASS FLAKE COATING

The principle of Glass Flake coating system lies in

providing laminar glass fillers with tortuous path

through the resin binder so that the corrosive ions

traveling through the binder have to travel a much

longer distance. The distance traveled will depend

upon the thickness of the flakes and the number of

layers of glass flakes in a given coating.

1) KOROGLASS

Koroglass series is a glass flake reinforced system in which

laminar glass fillers are embedded in solvent free matrix of

Epoxy resin. This high performance epoxy coating system are

recommended for enhanced protection to metal and concrete

against erosion, corrosion and attack of chemicals. Its extremely

low permeability with relatively high abrasion and chemical

resistance helps to protect various industrial equipment like

pumps, pipes tanks vessels, structures etc.

Range

Koroglass 100

Koroglass 200

Koroglass 1000

Koroglass FG

Koroguard GF

Applications

Pump castings / impeller

Cooling tower header

Tanks & Vessels

Internal & External surface of pipelines

Condenser Tube plates & Water boxes

Offshore platforms

Penstocks

Typical Properties

Thickness for 2 coats 500-1000 microns

Coverage for single coat 1-1.5 m2 /kg

Temperature Resistance (Dry Condition) 110 0C

Working time for 100 gms at R.T 40-45 minutes

Hardness shore D 85

Chemical Resistance Passes ASTM D 6943

2) CHEMGLASS

Chmeglass series is a matrix of Glass flakes and vinyl ester co-

polymer 100% solventless coating systems which offers

excellent chemical and corrosion resistance properties. This

three component high build system with heavy duty

impermeable chemical resistant barrier is suitable for metal and

concrete surface protection . The cured film is having excellent

corrosion resistance, highly impermeable to protect the

substrate from concentrated Acid/Alkali attacks in immersed

conditions.

Range

Chemglass 150

Chemglass 1000

Chemglass FG

Chemguard GF

Applications

Structures subjected to attack of concentrated Acid/Alkali solutions.

Pressure Vessels.

Brine and Chemical Tank Lining.

Acid/Alkali splash & Spillage

Mineral processing Industries.

Internal Surface of Chimney.

Scrubber lining for Flue Gas.

Acid Tank Lining

Battery room coating

Typical Properties

Thickness for 2 coats 250-500 microns

Coverage for single coat 2-3.0 m2/kg

Temperature Resistance (Dry Condition) 120 0C

Working time for 100 gms at R.T 15-18 minutes

Hardness shore D 80

Chemical Resistance Passes ASTM D 6943

3) SUPERGLASS

SUPERGLASS series is high build coating system in which laminar glass fillers are embedded in solvent

free matrix of polyester resin offering an excellent resistance against atmospheric moisture penetration.

Its extremely low permeability, high abrasion resistance and chemical resistance properties protect

various industrial equipments like pump casings, impellers, pipe bends, stirrers and diffuser drums in

severe conditions.

Range

Superglass 1000

Applications

Splash zones

Decks, Sheet Piles

Jetty Piles and Jacket Legs

Offshore structure

Escape routes

Heavy duty marine application

Lining of waste water fouls & tanks

Typical Properties

Thickness for 2 coats 150-350 microns

Coverage for single coat 2.0-3.0 m2/ kg

Temperature Resistance (Dry Condition) 120 0 C

Working time for 100 gms at R.T 25-30 minutes

Hardness shore D 80

Chemical Resistance Passes ASTM D 6943

You might also like

- New South Wales Code of Practice For Plumbing and Drainage Third Editions 2006Document169 pagesNew South Wales Code of Practice For Plumbing and Drainage Third Editions 2006NourNo ratings yet

- VGB S 021 03 2018 04 enDocument37 pagesVGB S 021 03 2018 04 enCarmen Rodriguez Polo100% (2)

- Essential Ingredients For A Greener World: Home Care Sustainable Product GuideDocument13 pagesEssential Ingredients For A Greener World: Home Care Sustainable Product GuideTinasheNo ratings yet

- Acceptance Criteria For Damaged PFP Info Sheet 12-2007Document9 pagesAcceptance Criteria For Damaged PFP Info Sheet 12-2007Richard HollidayNo ratings yet

- Corrosion Webinar Series - Coatings Maintenance Assessments PDFDocument37 pagesCorrosion Webinar Series - Coatings Maintenance Assessments PDFyaofuzhang100% (1)

- Corrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium PigmentsDocument14 pagesCorrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium Pigmentssmith100% (1)

- JPCL Transpipe EbookDocument82 pagesJPCL Transpipe Ebookvincent.w.stone6724No ratings yet

- The Repair OptionDocument4 pagesThe Repair OptionMAGUNAMNo ratings yet

- As 4822-2008 External Field Joint Coatings For Steel PipelinesDocument8 pagesAs 4822-2008 External Field Joint Coatings For Steel PipelinesSAI Global - APAC0% (1)

- Cathodic Protection Strategies For FPSO's FinalDocument11 pagesCathodic Protection Strategies For FPSO's FinalThaibinh Nguyen100% (1)

- Underground Insulation Specification Data SheetDocument2 pagesUnderground Insulation Specification Data Sheetadoptvn100% (1)

- Pipe CoatingsDocument23 pagesPipe CoatingsIshani Gupta75% (4)

- Glasse FlakeDocument18 pagesGlasse FlakeBoris CardenasNo ratings yet

- Com Su 6095 PDFDocument33 pagesCom Su 6095 PDFresp-ect100% (1)

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Tech Coating SelectionDocument8 pagesTech Coating SelectionKarthikeyan Shanmugavel100% (1)

- Zinc Silicate or Zinc Epoxy As The Preferred High Performance PrimerDocument10 pagesZinc Silicate or Zinc Epoxy As The Preferred High Performance Primerbabis1980100% (1)

- 001CorrosionArticleAntiCorrosionTechWEIQ PDFDocument3 pages001CorrosionArticleAntiCorrosionTechWEIQ PDFJACK100% (1)

- Underwater Repairs: 18.1 GeneralDocument11 pagesUnderwater Repairs: 18.1 GeneralmigescuNo ratings yet

- Phenoline 1205 PDS 9-06 PDFDocument2 pagesPhenoline 1205 PDS 9-06 PDFttr_1947No ratings yet

- Pipeline Internal CoatingDocument14 pagesPipeline Internal CoatingMostafa Sharaf100% (1)

- ID-PRC 19 - PE Coating RepairDocument7 pagesID-PRC 19 - PE Coating Repaircloud23No ratings yet

- COM SU 5191 C February 2017Document91 pagesCOM SU 5191 C February 2017suriya100% (1)

- Interspec: Tangguh Expansion ProjectDocument43 pagesInterspec: Tangguh Expansion ProjectZamri Rahmat SikumbangNo ratings yet

- A World of Protection: Arc Advanced Reinforced Coatings For Metal and ConcreteDocument12 pagesA World of Protection: Arc Advanced Reinforced Coatings For Metal and ConcreteMotasem DarwishNo ratings yet

- Technical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoDocument27 pagesTechnical Proposal: FOR Application of Formashield On Flow Line On-Board Abo FpsoIdung ChristopherNo ratings yet

- CUI: An In-Depth Analysis: Hira S. AhluwaliaDocument6 pagesCUI: An In-Depth Analysis: Hira S. AhluwaliaJithuJohnNo ratings yet

- Pipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge TavesDocument51 pagesPipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge Tavesnathgsurendra100% (2)

- Cathodic Protection Design For Offshore Pipeline and Subsea StructureDocument24 pagesCathodic Protection Design For Offshore Pipeline and Subsea StructurekalaiNo ratings yet

- Trouble With Paint Blistering of Paint On Metal 1Document10 pagesTrouble With Paint Blistering of Paint On Metal 1ravi00098No ratings yet

- Oil and Gas Offshore ProductionDocument9 pagesOil and Gas Offshore ProductionLao ZhuNo ratings yet

- Coatings and Cathodic Disbondment - The True StoryDocument23 pagesCoatings and Cathodic Disbondment - The True StoryCamilo Godoy V100% (1)

- Investigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorDocument6 pagesInvestigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorNsidibe Michael Etim100% (1)

- NclUni Lect1 1103Document49 pagesNclUni Lect1 1103Dino Peduto100% (1)

- Design No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263Document3 pagesDesign No. N854: BXUV.N854 Fire-Resistance Ratings - ANSI/UL 263EngTamerNo ratings yet

- Graphite Vademecum E-HDocument27 pagesGraphite Vademecum E-Hdroessaert_stijnNo ratings yet

- CoatingDocument162 pagesCoatingSharafudeen M Mohammedali100% (1)

- Belzona Coating Guide For CUI and Atmospheric CorrosionDocument2 pagesBelzona Coating Guide For CUI and Atmospheric CorrosionfraemddNo ratings yet

- CP Painting Revised SpecsDocument57 pagesCP Painting Revised SpecsanilnwaychalNo ratings yet

- The Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantDocument5 pagesThe Journal of Protective Coatings & Linings - Why Surface Preparation Is ImportantSergio Daniel Barea Nuñez100% (1)

- Garnet SpecificationDocument2 pagesGarnet SpecificationskNo ratings yet

- Challenging The Organic "Zinc Rich" Primer StandardDocument9 pagesChallenging The Organic "Zinc Rich" Primer Standardaliabdulhamid100% (2)

- Interseal 670HS+Br+EngDocument2 pagesInterseal 670HS+Br+Engrajauae2008100% (1)

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- New Insights in Repairing Damaged Pipes and Pipelines Using Composite Materials Chris AlexanderDocument41 pagesNew Insights in Repairing Damaged Pipes and Pipelines Using Composite Materials Chris AlexanderAlp Altınok100% (1)

- A High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingDocument15 pagesA High Performance, Damage Tolerant Fusion Bonded Epoxy CoatingpaimpillyNo ratings yet

- Fusion Bond Epoxy (FBE) Coating RepairsDocument4 pagesFusion Bond Epoxy (FBE) Coating Repairsyasi heeru100% (1)

- Section 6 API Publication 2207 - Preparing Tank Bottoms For Hot WorkDocument7 pagesSection 6 API Publication 2207 - Preparing Tank Bottoms For Hot WorkRamyMoustafaNo ratings yet

- The Adhesion Characteristics of Protective Coating Materials For The Containment Structure in Nuclear Power PlantsDocument8 pagesThe Adhesion Characteristics of Protective Coating Materials For The Containment Structure in Nuclear Power PlantsHaidarHussaini100% (1)

- NORSOK M 004 S 738v2021 03 - 18Document1 pageNORSOK M 004 S 738v2021 03 - 18noureldinmohammedNo ratings yet

- Dual-Layer Fusion-Bonded Epoxy (FBE) Coatings Protect Pipelines PDFDocument13 pagesDual-Layer Fusion-Bonded Epoxy (FBE) Coatings Protect Pipelines PDFjeedanNo ratings yet

- Chem ClearDocument5 pagesChem ClearBiju_PottayilNo ratings yet

- Sky Climber SparesDocument7 pagesSky Climber SparesshambhoiNo ratings yet

- ISES CP Report 2Document18 pagesISES CP Report 2Tamer Hesham AhmedNo ratings yet

- Development of DNV F101Document8 pagesDevelopment of DNV F101E.Kannan S.EhambaramNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 07250-1 FireproofingDocument4 pagesITCC in Riyadh Residential Complex J10-13300 07250-1 FireproofinguddinnadeemNo ratings yet

- Up Graded Thermal Insulation DCLDocument14 pagesUp Graded Thermal Insulation DCLSubrata NagNo ratings yet

- Polymer Linings For Restoration Corrosion Protection of Steel SurfacesDocument7 pagesPolymer Linings For Restoration Corrosion Protection of Steel Surfacesfrancisco javier rubioNo ratings yet

- Masterprotect 300 Tds For TrestelDocument3 pagesMasterprotect 300 Tds For TrestelrannuNo ratings yet

- Perić Nikola PM 8-2021Document3 pagesPerić Nikola PM 8-2021Nikola PericNo ratings yet

- ITW PSMB Vs Polykraft or PaintDocument2 pagesITW PSMB Vs Polykraft or PaintVishnu DuttaNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Glossary of Financial TermsDocument12 pagesGlossary of Financial TermsDinesh ChouguleNo ratings yet

- Sample Test QuestionsDocument14 pagesSample Test QuestionsDinesh ChouguleNo ratings yet

- 15 FB / # 800 (3PC) Ball ValvesDocument10 pages15 FB / # 800 (3PC) Ball ValvesDinesh ChouguleNo ratings yet

- Letter of Ack. (Alfa Laval)Document1 pageLetter of Ack. (Alfa Laval)Dinesh ChouguleNo ratings yet

- EIL - Specification Sheet123Document1 pageEIL - Specification Sheet123Dinesh ChouguleNo ratings yet

- EIL - Specification SheetDocument1 pageEIL - Specification SheetDinesh ChouguleNo ratings yet

- Advance Valves Pvt. LTD: Cryogenic Test RecordDocument3 pagesAdvance Valves Pvt. LTD: Cryogenic Test RecordDinesh ChouguleNo ratings yet

- M Tork New CatalogueDocument16 pagesM Tork New CatalogueDinesh ChouguleNo ratings yet

- G 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDocument2 pagesG 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDinesh ChouguleNo ratings yet

- Gandhi Special Tubes LTD.: Product ProfileDocument6 pagesGandhi Special Tubes LTD.: Product ProfileDinesh ChouguleNo ratings yet

- Jamesbury 4000Document12 pagesJamesbury 4000Dinesh ChouguleNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- (FLS 1000 (A4) FLS Product Catalog LR1 0Document260 pages(FLS 1000 (A4) FLS Product Catalog LR1 0Dinesh ChouguleNo ratings yet

- DVG CatalogDocument7 pagesDVG CatalogDinesh ChouguleNo ratings yet

- Ameya GearboxDocument1 pageAmeya GearboxDinesh ChouguleNo ratings yet

- Solenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Document10 pagesSolenoid Valves 3/2-5/2 551: Single/dual Solenoid (Mono/bistable Function) 1/4Dinesh ChouguleNo ratings yet

- Calorimetry and Conservation of Energy Lab ReportDocument5 pagesCalorimetry and Conservation of Energy Lab ReportKali stringsNo ratings yet

- A 59Document1 pageA 59AnuranjanNo ratings yet

- Data Sheet IGBTDocument12 pagesData Sheet IGBTAndrés David Martínez MarteloNo ratings yet

- BHS Prospekt DKX USA 072014 WebDocument20 pagesBHS Prospekt DKX USA 072014 WebMoaiyadMhtarNo ratings yet

- Cellular RespirationDocument13 pagesCellular Respirationapi-329164492No ratings yet

- Product Line GuideDocument2 pagesProduct Line Guidenicolas yoris marcoglieseNo ratings yet

- WA150-5 SEBM033805 TroubleshootingDocument273 pagesWA150-5 SEBM033805 Troubleshootinghaimay118No ratings yet

- Application Note AN-1164: IR Class D Audio IC, Operation With Single Output Power SupplyDocument11 pagesApplication Note AN-1164: IR Class D Audio IC, Operation With Single Output Power SupplyMárcio FerreiraNo ratings yet

- King Fahd University of Petroleum & Minerals: Mechanical Engineering Dynamics ME 201 BY Dr. Meyassar N. Al-HaddadDocument29 pagesKing Fahd University of Petroleum & Minerals: Mechanical Engineering Dynamics ME 201 BY Dr. Meyassar N. Al-HaddadTommyVercettiNo ratings yet

- 7 Statistical Thermodynamics-IIDocument30 pages7 Statistical Thermodynamics-IICahyarani ParamestiNo ratings yet

- Ferroresonant Configurations in Power Systems: V. Valverde, G. Buigues, A. J. Mazón, I. Zamora, I. AlbizuDocument6 pagesFerroresonant Configurations in Power Systems: V. Valverde, G. Buigues, A. J. Mazón, I. Zamora, I. AlbizuMehdi_Mashayekhi_172No ratings yet

- Sop 002 Copper Strip CorrosionDocument8 pagesSop 002 Copper Strip CorrosionAmnaKamran100% (1)

- Carbo RateDocument3 pagesCarbo RateJeevan Landge PatilNo ratings yet

- The Future of Biofuels and Challenges AheadDocument22 pagesThe Future of Biofuels and Challenges AheadNitishNo ratings yet

- Dispersion Modeling BibliographyDocument1 pageDispersion Modeling BibliographyMilton BeychokNo ratings yet

- AssignmentDocument26 pagesAssignmentAriel GamboaNo ratings yet

- TORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogDocument1 pageTORQUE CONVERTER 4) TURBINE SHAFT AND STATOR D135A-1 S - N 10001-UP Komatsu Part CatalogBluish FlameNo ratings yet

- 00 AFWW Corporate BrochureDocument8 pages00 AFWW Corporate BrochureCherif TharwatNo ratings yet

- VNX - Su I20 Brochure PDFDocument12 pagesVNX - Su I20 Brochure PDFruk100% (1)

- Brochure Corporate enDocument9 pagesBrochure Corporate enbizolutionNo ratings yet

- 60601-1 ChecklistDocument47 pages60601-1 Checklistgfgdgfd100% (4)

- Citizen Eco Drive Watch ManualDocument46 pagesCitizen Eco Drive Watch Manualjwha238No ratings yet

- AS Level Physics Revision NotesDocument39 pagesAS Level Physics Revision NotesjoshuaNo ratings yet

- QuestDocument4 pagesQuestKanda VelanNo ratings yet

- Synchro - ManDocument8 pagesSynchro - Manapi-19787379No ratings yet

- Chapter 3 - Electric Current and Direct Current Circuit 1Document8 pagesChapter 3 - Electric Current and Direct Current Circuit 1Fazilah TawasilNo ratings yet

- sm-K1017314E DX210W LowResDocument1,184 pagessm-K1017314E DX210W LowResDavid Apaza Hurtado100% (1)

- Effect of Various Technology On Engine PerformanceDocument89 pagesEffect of Various Technology On Engine PerformanceArya FahimNo ratings yet