Professional Documents

Culture Documents

Bolt and Torque Requirement For Sealing Flanges

Bolt and Torque Requirement For Sealing Flanges

Uploaded by

sushil0 ratings0% found this document useful (0 votes)

1 views3 pagesbolt and torque requirement for sealing flanges

Original Title

Bolt and Torque Requirement for Sealing Flanges

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbolt and torque requirement for sealing flanges

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

1 views3 pagesBolt and Torque Requirement For Sealing Flanges

Bolt and Torque Requirement For Sealing Flanges

Uploaded by

sushilbolt and torque requirement for sealing flanges

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 3

General Design 59

PROCEDURE 2-10

BOLT TORQUE REQUIRED FOR SEAL! FLANGES [10-13]

Py =test pressure, psi

Notation Frestorng force of gasket (decreasing compression

; : foro? fron inital bolting strain, tb

Ay Seross-sectional ure of bolts, in

Final tuhtening fre I

Az Sct oi 1h = effetve length of holt, vid na to id atin

fective g W total eightening force, Ih

Wor = 1+ Hy = requited bolt load. operating, Th

pitch diameter of thre i

2 require! ot load, gasket seating, Dy

diameter at location of gasket load reaction, in et unit seating loa, psi

sternal bending snoment,in-lby al ydnostatic end force, Lh

ct actor face compression: load, Th

joe rece, fh

thickness of gasket, in

et width, in

aber of bolls

1) = modulus of clstiity of bolting material at tempera US thickness of putin

ture, pst K = total friction factor between hol¥/nut and nut! Mange

E., =modilis of elastilly of gasket material at face

ture, ps sw width of rng joint gasket, in

P= internal pressure

P, sexuivalent pressure incloding external loads, ps Note: See Procedure 2-7 for salues of €, Noa, be and y

P,=adial load, Th

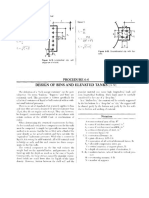

Figure 229. Flange and jot act's

Table 2-6

Beting Oimensiar! Baka

‘in a

vee) ages bos | aa

60

Pressure Vessel Design Manual

Table 27

Modulus of Eistiny, Fa, 10's)

Temperature,

7 mo~*C«SStSSSSCSSCTSCSCSCC

RSF we 277 aS was

Low alloy A-199-87, 616, B7M 299) 205 250 286 28.0 a4 286 287 248

Sualgh come AW8S-BE BEX 20228 a7 a0 260 a8 2a at

Starese AN0G.0 saves a e?rs~SCiSS*«aSC*“‘ CCC

‘Note Vales pe" ASE Gove, Sesion _ - -

‘sue 19 m8 gasket reaxing

i

a Senresson

Figure 224, Typical agram

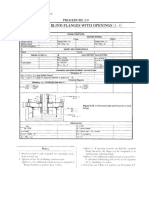

—besn oar gxsner oata ‘BOLTING DATA

Tess, Pr oo. a tC

[Moreen ¥ ~ Te ~

Radel i ~ ~ To

+ + ———|..-sf0 | |

Modulus of Elasticity of Gasket Material, E,

f© Ring joint and lat metal: Select sales hom ASME,

Seation Hor Appendls K-of this book:

© Comp ash = 70 bs

@ Robber = 10 bs

© Gratis! 35 ksi

© Teflon 2 ks

Spiral wontnd = 560 bs

Friction Factor, K

oor

on

615,

p25)

# Lubricued

© Nowlsbricated

Calculations

Fovalbor prose Pop

— 1M Rey

r@ ac

© Hydeostatee end force, HLM

# ital joint contacts

rompression

Hy = 2haGm,

© Minti cequived bull load for gasket wating, Waa, 0

Wyo = abGs

© Actual joint area cout Aen

Ay = 2ahG

© evnoastg eompesston force in grsket, AB, My

ar =

Pa

Initial required tightening farew (tension, Fh th

+P

8 Vota tightening force regard bo seal jomt, WM

W = greater of Py oF

General Design 61

© Required torque, Tf

Kwa,

Notes,

1. Bolted joints im high-pressure systems repre at initial

preload! to prevent the joint fiom leaking, The loads

swlnich toad to open the int ate

1. Internal presse

1 Thermal bending moment

6. Dead load bonding moment

2. Bither stud tensionets oF torque wrenches ate used for

pprestressing bolts tothe resquiedt stress far gasket seat=

ing. Shid tensioners are by far the most acenrate, Stud

tension achieved by torquing the wot is aflected! by

A%

ate the major variables

many variables and may vary drome 10% to

cealeuated values, The following

affecting, tension achieved by torging

1. Chass of ft of stand sb

Burrs

©. Lubrication

4. Grit, chips, ane dit in treads of bolts or nats

© Nicks

[Th

flange against which the mt is rotates

Adequate lubrication shold be used, Nonlubieatedd

bolting has am elfciency of about 304 af a well-lubr:

teated bolt, For standard applications, « heavy graphite

axl oil anistane works well, Bor high temperature ser=

relative condition of the seating surface on the

view (300°F to HARP), a high temperature thread

comporni may be used

Table 2-0

Bal Toraes

“ormus Required in oo Produce te Folowing Ball Sirs

Bot Sze 1Sksi_——_SOk aks! 60Ksi

= 35 0

20 120

80 200

& B20

1 390

185 710

a 1000

1960

1000

000

000

400,

“ e260

- ‘600

- rae

= 580

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bins and Elevated TanksDocument10 pagesBins and Elevated TankssushilNo ratings yet

- Flange Lug DesignDocument11 pagesFlange Lug DesignsushilNo ratings yet

- Summery of Changes ASME DIV 1Document8 pagesSummery of Changes ASME DIV 1sushilNo ratings yet

- Wind Desgin As Per Ubc-97Document2 pagesWind Desgin As Per Ubc-97sushilNo ratings yet

- Chapter 3 Design Methodology: 3.1 IntroductionDocument10 pagesChapter 3 Design Methodology: 3.1 Introductionsushil100% (2)

- Hydraulic Cylinder Side LoadDocument8 pagesHydraulic Cylinder Side LoadsushilNo ratings yet

- Design of TrunionDocument3 pagesDesign of TrunionsushilNo ratings yet

- Blind Flanges With OpeningsDocument1 pageBlind Flanges With OpeningssushilNo ratings yet

- Davits DesignDocument5 pagesDavits DesignsushilNo ratings yet

- Design of Vessels With Refractory LiningsDocument7 pagesDesign of Vessels With Refractory LiningssushilNo ratings yet