Professional Documents

Culture Documents

Compression Testing Machine

Compression Testing Machine

Uploaded by

Sandeep ChoudharyOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compression Testing Machine

Compression Testing Machine

Uploaded by

Sandeep ChoudharyCopyright:

Available Formats

COMPRESSION TESTING MACHINES

Mastering the fine art of testing

COMPRESSION TESTING MACHINES

SALIENT FEATURES

• Loading Accuracy ± 1% confirming to IS-1828-1991.

• Simplified design for ease of operation and maintenance.

• Safety provisions against over load and over travel.

• Highly rigid loading frame.

• FSA’s guarantee of quality.

• Motor driven crosshead for easy adjustment facilities rapid fixing of test specimen.

• Wide range of accessories available.

• Straining at variable speeds to suit wide range of materials.

APPLICATION

Compression Testing Machine have a wide range of applications. It is designed to check materials

under compression, ending, Transverse, Brinell Hardness & Shear testing etc.

CONSTRUCTION

The machine consists of 2 units viz. loading unit and control panel.

A. Loading Unit

It consists of base at its center, hydraulic cylinder, piston and two screws. A crosshead is mounted

on the screws and is driven by a motor for rapid adjustment of test height. A table is mounted on

the piston with a bell joint in between. The precisely ground piston and the individually lapped

cylinder piston assembly ensure smooth transfer of them force with minimum friction losses.

B. Control Panel

It consists of hydraulic system with power pack, load measuring & indicating system and

electrical system.

a. Hydraulic System

It consists of hydraulic power pack with directly driven radial plunger pump. Power pack consist

of oil filter, oil strainer, air breather, drain plug, oil level indicator etc. It can generate an oil

pressure up to 250 bar. A pressure compensated flow control valve is provided for controlling the

oil flow to cylinder thereby achiving a desire piston speed.

b. Load Measuring & Indicating system

For dial type machine

The oil pressure in the main cylinder is transferred to the small dynamometer cylinder. The

dynamometer piston is kept rotating at slow speed to ensure dynamic friction condition

condition. The force defects the pendulum. A damping system is provided to ensure slow

return of pendulum. The Pendulum lever pushes a rack which slides over two pulleys a rack

movement is proportional to the load. A Pinion engaged with a rack rotates and moves the

pointer. A window type dial is provided for easy and clear indication. A continuous roll type

recorder is provided for plotting a load verse deformation graph.

For Electronic & Computerised Machines

The oil pressure in the main cyclinder is transferred to an electronic pressure transducer

which gives proportional electronic signal. Displacement measurement is carries out by a

rotary encoder mounted on the base. The linear motion of piston is. Converted in rotary

motion and the encoder undergoes angular displacement. This gives proportional electronic

signal for deflection. The pressure transducer and encoder signals are given to electronic panel

/ computer.

C. Electrical System

A separate switch box and electrical panel is provided. Both hydraulic pump motor and cross head

motor have interlocks. Limit switch is provide for over travel safety. A push button station is

provided on the control panel with UP, DOWN push buttons for cross head motor and ON, OFF

push buttons for pump motor.

OPERATION

The specimen to be tested is to be kept on the machine table. The position of the cross head can be

adjusted by operating, UP, DOWN push buttons. The Compression test can be conducted by

positioning the positioning the specimen between the compression plates. The Bend / Transverse

tests can be conducted by positioning the specimen over the bending supports. The load is applied

by operating the hand operated valves ergonomically placed for ease of control.

ACCURACY AND CALIBRATION

Every machine is calibrated in accordance with the procedure laid down is BS 1610:1964 and IS

1828:1991 with an accuracy of ±1%.

Electronic Version

EXTRA ACCESSORIES STANDARD ACCESSORIES

1) Load stabilizer Compression platens 2 Pair

2) Shear test attachment

3) Transverse test attachment

4) Brinell Hardness test attachment

( with 10mm ball )

5) Brinell Microscope

6) 180º bend test attachment

7) Bend-Rebend test attachment

8) Printer (Only for Electronic & Computerised Versions )

Combined Analogue & Computerised Version is available

TECHNICAL SPECIFICATIONS

Dial Type Machines

Model FCT-500 kN FCT-1000kN FCT-2000 kN FCT-3000 kN FCT-5000 kN

Maximum capacity (kN) 500 1000 2000 3000 5000

Ist Measuring Range (kN) 0-500 0-1000 0-2000 0-3000 0-5000

Least count (kN) 1 2 4 5 10

2nd Measuring Range (kN) 0-250 0-500 0-1000 0-1500 0-2500

Least count (kN) 0.5 1 2 2.5 5

3rd Measuring Range (kN) 0-100 0-250 0-500 0-600 0-1000

Least count (kN) 0.2 0.5 1 1 2

4th Measuring Range (kN) 0-50 0-100 0-250 0-300 0-500

Least count (kN) 0.1 0.2 0.5 0.5 1

Number of division on load 500 500 500 600 500

measuring dial

Electronic Machines

MODEL FCT-E-500kN FCT-E-1000kN FCT-E-2000kN FCT-E-3000kN FCT-E-5000kN

Maximum capacity (kN) 500 1000 2000 3000 5000

Measuring capacity (kN) 0-500 0-1000 0-2000 0-3000 0-5000

Least count (kN) 0.05 0.1 0.2 0.3 0.5

Resolution of Piston 0.1 0.1 0.1 0.1 0.1

Movement(mm)

Computerised Machines

MODEL FCT-E-500kN FCT-E-1000kN FCT-E-2000kN FCT-E-3000kN FCT-E-5000kN

Maximum capacity (kN) 500 1000 2000 3000 5000

Measuring Range (kN) 0-500 0-1000 0-2000 0-3000 0-5000

Least count (kN) 0.05 0.1 0.2 0.3 0.5

Resolution of Piston 0.1 0.1 0.1 0.1 0.1

Movement(mm)

General Common Specifications (for all version)

Maximum capacity (kN) 500 1000 2000 3000 5000

Max. clearance for [[[[

compression test at fully 500 700 700 1000

500

decended piston position

(mm)

Piston Stroke (mm) 100 100 150 150 250

Power Supply 3ph 415V 50Hz A.C.

HP (Total) 1.5 2 3 6 6

Weight in tons (approx) 2 2.5 3.5 9 12

Sold & Serviced By :

Rockwell Testing Aids

C-76A, Jyoti Colony, St. No.7, 100Ft. Road, Shahdara, Delhi-110032

Ph: 011-22832463 , 65292646, Web: www.hardnesstesters.in

E-mail: info@hardness.in , rockwellindia@gmail.com

You might also like

- Yanan: PowerDocument6 pagesYanan: Powergreenbest777No ratings yet

- CTMDocument2 pagesCTMkumar.phanindraNo ratings yet

- Universal Testing Machine: Model: TUF-C-1000 KN (SERVO)Document4 pagesUniversal Testing Machine: Model: TUF-C-1000 KN (SERVO)Intan PuspitariniNo ratings yet

- Cat - UTMDocument4 pagesCat - UTMDeb RoyNo ratings yet

- Aaff Mue Idm Test A4 - en LowDocument20 pagesAaff Mue Idm Test A4 - en LowAfzal SarfarazNo ratings yet

- Universal Testing Machines - Model: UTE: FeaturesDocument6 pagesUniversal Testing Machines - Model: UTE: FeaturesEr Hemant Kumar SahNo ratings yet

- Waw 1000e 111Document18 pagesWaw 1000e 111ShemelsNo ratings yet

- TEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineDocument3 pagesTEST-E Series Computer Controlled Electro-Hydraulic Servo Universal Testing MachineCirclesOnSandNo ratings yet

- UtesDocument4 pagesUtesPaviter SinghNo ratings yet

- Cement & ConcreteDocument12 pagesCement & ConcretePatricia PalmerNo ratings yet

- Positioner Technical Specification: Welding/Cutting Expert For Over 20 YearsDocument3 pagesPositioner Technical Specification: Welding/Cutting Expert For Over 20 YearsdinescNo ratings yet

- Compact Line Compression MachineDocument44 pagesCompact Line Compression Machinejean-pierre dalyNo ratings yet

- Vertical Vessel (Surge drum V-17-102) Foundation CalcDocument10 pagesVertical Vessel (Surge drum V-17-102) Foundation CalcNazeer NNo ratings yet

- Model: UTN: GroupDocument4 pagesModel: UTN: GrouppoongodiskNo ratings yet

- Astm C109 (2005)Document5 pagesAstm C109 (2005)kimberly solisNo ratings yet

- Software Verification: NTC 2008 Example 004Document12 pagesSoftware Verification: NTC 2008 Example 004yudhi putraNo ratings yet

- Compression Testing Machine CTMDocument2 pagesCompression Testing Machine CTMmalaya tripathyNo ratings yet

- Bondek 300 BP-BT150Document5 pagesBondek 300 BP-BT150trung1983No ratings yet

- EN 2-2004 Ex004Document12 pagesEN 2-2004 Ex004yudhi putraNo ratings yet

- Automatic Compression Testers For Cylinders: SeriesDocument4 pagesAutomatic Compression Testers For Cylinders: SeriesJosé Fco. Cerda M.No ratings yet

- 63 CalibrationEquipment E EmailDocument14 pages63 CalibrationEquipment E Emailطه اللوذعيNo ratings yet

- IitpaveDocument10 pagesIitpaveKanishka SarkarNo ratings yet

- WEW-300D Computer Display Hydraulic Unviersal Testing Machine Four ColumnsDocument12 pagesWEW-300D Computer Display Hydraulic Unviersal Testing Machine Four Columnsedo dwi guntoroNo ratings yet

- Compression Testing MachinesDocument4 pagesCompression Testing MachinesPrabhakar RoyNo ratings yet

- UTES HGFLDocument4 pagesUTES HGFLAnand KumarNo ratings yet

- Daewoo Manuals 1021Document39 pagesDaewoo Manuals 1021Anes BelNo ratings yet

- Injection Pump Test Specifications 093000-573#: ApproxDocument3 pagesInjection Pump Test Specifications 093000-573#: ApproxBaytolgaNo ratings yet

- Torsion Testing SystemDocument3 pagesTorsion Testing Systemsrinath.gajapathy5478No ratings yet

- EL Topic1 - APSDocument4 pagesEL Topic1 - APSSrinivasan SNo ratings yet

- Eco Smart Compression Testing Machine PDFDocument2 pagesEco Smart Compression Testing Machine PDFsyed sulemanNo ratings yet

- Member Reinforced Concrete Column Design Report (AS-3600) PDFDocument13 pagesMember Reinforced Concrete Column Design Report (AS-3600) PDFdongshengNo ratings yet

- Torque Systems Bnl2300 SpecsheetDocument4 pagesTorque Systems Bnl2300 SpecsheetElectromateNo ratings yet

- Fer 52 01 037 2006Document5 pagesFer 52 01 037 2006Danielle SasongkoNo ratings yet

- Pulldown Beside The Copy Button in The Clipboard Section of The Ribbon's Home Tab.)Document6 pagesPulldown Beside The Copy Button in The Clipboard Section of The Ribbon's Home Tab.)vkNo ratings yet

- CBR-Test 50 Machine: ASTM D-1883 AASHTO T-193Document1 pageCBR-Test 50 Machine: ASTM D-1883 AASHTO T-193ninaNo ratings yet

- Model 65023: SensortronicsDocument3 pagesModel 65023: SensortronicsReinaldo Castillo RivasNo ratings yet

- Inj. Pump Calibration Data: 1. Test ConditionsDocument4 pagesInj. Pump Calibration Data: 1. Test ConditionsEdinson Ariel Chavarro Quintero100% (2)

- ENG_DS_XFC200R_A6Document4 pagesENG_DS_XFC200R_A6Adrian RangelNo ratings yet

- C1 SubstructureDocument6 pagesC1 SubstructureEdan John HernandezNo ratings yet

- Anexa 19Document2 pagesAnexa 19pokemon69No ratings yet

- AsincroniDocument18 pagesAsincronikimberly lataNo ratings yet

- Expert 1000 Series Servo Hydraulic Test System BrochureDocument4 pagesExpert 1000 Series Servo Hydraulic Test System BrochureAde DjatnikaNo ratings yet

- Practical No. 9 (CBR)Document5 pagesPractical No. 9 (CBR)slawek780303No ratings yet

- Strength of Materials Lab EquipmentsDocument12 pagesStrength of Materials Lab EquipmentslabtekindiaNo ratings yet

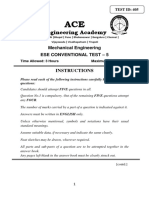

- Engineering Academy: Mechanical Engineering Ese Conventional Test - 5Document8 pagesEngineering Academy: Mechanical Engineering Ese Conventional Test - 5vidya chakitwarNo ratings yet

- Universal Calibrating Machines UCM Datasheet PD 5201Document4 pagesUniversal Calibrating Machines UCM Datasheet PD 5201Rocky TongiaNo ratings yet

- 2021 CatalogueDocument27 pages2021 CatalogueGMAR ComercializadoraNo ratings yet

- Torsion Testing MachineDocument5 pagesTorsion Testing Machinegosaye desalegnNo ratings yet

- SACD (RCDC) - Release Notes - 09.03.00 PDFDocument11 pagesSACD (RCDC) - Release Notes - 09.03.00 PDFErik PerezNo ratings yet

- TSS-TS-TATA 0..996 EDC: For Field Service OnlyDocument2 pagesTSS-TS-TATA 0..996 EDC: For Field Service OnlyRAVIKANT100% (1)

- UTM CatalogDocument6 pagesUTM CatalogAsmita AcharyaNo ratings yet

- Column Design Ecp203 VS Aci VS BS8110Document37 pagesColumn Design Ecp203 VS Aci VS BS8110MANo ratings yet

- Katalog - Ostenco - 2022Document20 pagesKatalog - Ostenco - 2022EZIO AUDITORENo ratings yet

- Phoenix Artificial Lift Monitoring: Paul DochertyDocument24 pagesPhoenix Artificial Lift Monitoring: Paul DochertyvicblanNo ratings yet

- Safe, Accurate, Service Friendly: Right The First TimeDocument10 pagesSafe, Accurate, Service Friendly: Right The First TimeSiewkuan LeeNo ratings yet

- WDW Single SpaceDocument2 pagesWDW Single SpacemffmadiNo ratings yet

- PVS 10 ManualDocument4 pagesPVS 10 Manualdiegorodriguez1988No ratings yet

- Electrical Steel CoilsDocument16 pagesElectrical Steel CoilsX800XLNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- CamScanner 10-30-2023 15.42.30Document1 pageCamScanner 10-30-2023 15.42.30Sandeep ChoudharyNo ratings yet

- CamScanner 10-30-2023 15.41.49Document1 pageCamScanner 10-30-2023 15.41.49Sandeep ChoudharyNo ratings yet

- CamScanner 08-23-2023 20.39.45Document1 pageCamScanner 08-23-2023 20.39.45Sandeep ChoudharyNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationSandeep ChoudharyNo ratings yet

- BBM - 978 3 030 85424 9 - 1Document15 pagesBBM - 978 3 030 85424 9 - 1George Florin CaraimanNo ratings yet

- Multimedia Networking: A Note On The Use of These PPT SlidesDocument48 pagesMultimedia Networking: A Note On The Use of These PPT SlidesStevan AdjieNo ratings yet

- Gobi 1000 Product SheetDocument2 pagesGobi 1000 Product SheetkindboomerNo ratings yet

- Chapter 1: Business Intelligence and AnalyticDocument41 pagesChapter 1: Business Intelligence and AnalyticNurul Shakirah67% (3)

- Curriculum Vitae RamakrishnaDocument4 pagesCurriculum Vitae RamakrishnaRama KrishnaNo ratings yet

- SH77571Document1 pageSH77571pauloNo ratings yet

- STS6 - Why The Future Doesn't Need UsDocument27 pagesSTS6 - Why The Future Doesn't Need UsFritzzie ManalangNo ratings yet

- Antenna-in-Package Design Considerations For Ka-Band 5G Communication ApplicationsDocument9 pagesAntenna-in-Package Design Considerations For Ka-Band 5G Communication Applicationsvikas chawlaNo ratings yet

- Sony MFS-2000 User GuideDocument251 pagesSony MFS-2000 User GuideBratislav ŽivkovićNo ratings yet

- Imagerunner Advance 8205Document264 pagesImagerunner Advance 8205Gerardo SaucedaNo ratings yet

- Explanation of ISO 14001 2015 Clauses enDocument23 pagesExplanation of ISO 14001 2015 Clauses enTomas Morales100% (8)

- CSE-III - YEAR-Regular - Model & End Semester Practical Schedule - April-2022-StudentsDocument8 pagesCSE-III - YEAR-Regular - Model & End Semester Practical Schedule - April-2022-StudentsSaipriya VempalliNo ratings yet

- UsbFix ReportDocument752 pagesUsbFix ReportClaudiaNo ratings yet

- SwiftUI BasicsDocument57 pagesSwiftUI BasicsIsrael CerónNo ratings yet

- OmicronSKYS4R5HE43.4 50-55degcDocument4 pagesOmicronSKYS4R5HE43.4 50-55degcDuc TuNo ratings yet

- (BookRAR - Net) - Computer NetworkingDocument89 pages(BookRAR - Net) - Computer NetworkingAster Jane ArjonaNo ratings yet

- Gujarat Technological UniversityDocument6 pagesGujarat Technological UniversityQuantumyashNo ratings yet

- Modems Cdm-625-En Advanced Satellite Modem With Doubletalk Carrier-In-CarrierDocument5 pagesModems Cdm-625-En Advanced Satellite Modem With Doubletalk Carrier-In-CarrierarzeszutNo ratings yet

- The New Generation of Rectifiers... : Super Barrier RectifierDocument16 pagesThe New Generation of Rectifiers... : Super Barrier Rectifierfahmy najibNo ratings yet

- Jaw Coupling SelectionDocument4 pagesJaw Coupling SelectionpramodtryNo ratings yet

- An4230 Stm32 Microcontroller Random Number Generation Validation Using The Nist Statistical Test Suite StmicroelectronicsDocument29 pagesAn4230 Stm32 Microcontroller Random Number Generation Validation Using The Nist Statistical Test Suite StmicroelectronicsfaujohnNo ratings yet

- Yogeshwar BrochureDocument16 pagesYogeshwar BrochureDanish KhandelwalNo ratings yet

- Volvo Penta D13B-C MP (IPS)Document132 pagesVolvo Penta D13B-C MP (IPS)Alexander GrandaNo ratings yet

- Audit:: The Tipping Point Is NowDocument14 pagesAudit:: The Tipping Point Is NowjonaNo ratings yet

- Specifications For Motorization of Rolling Shutters in The FEL ComplexDocument4 pagesSpecifications For Motorization of Rolling Shutters in The FEL Complexsri projectssNo ratings yet

- 1.270219lecture 1 Vtu Semiconductor DiodesDocument23 pages1.270219lecture 1 Vtu Semiconductor Diodeseesha sabnisNo ratings yet

- Compiled Finals StsDocument63 pagesCompiled Finals StsMaricel DefiestaNo ratings yet

- FN - Brochure - EN - Nijhuis Pumpen PDFDocument44 pagesFN - Brochure - EN - Nijhuis Pumpen PDFDione100% (1)

- Commandcentral Body Worn and In-Car Video Deployment User GuideDocument43 pagesCommandcentral Body Worn and In-Car Video Deployment User GuideRichard Jagan Graham SnrNo ratings yet