Professional Documents

Culture Documents

Disclaimer:: Safe Operation Card (SOC)

Disclaimer:: Safe Operation Card (SOC)

Uploaded by

ramkumardotg_5807772Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disclaimer:: Safe Operation Card (SOC)

Disclaimer:: Safe Operation Card (SOC)

Uploaded by

ramkumardotg_5807772Copyright:

Available Formats

Disclaimer: These safety resources, prepared solely for the use of The Dow Chemical Company

were provided by a variety of sources. It is your responsibility to customize the

information to match your specific operations. Neither The Dow Chemical Company

nor any of its employees, makes any warranty, express or implied, or assumes any

legal liability or responsibility for the accuracy, completeness, or usefulness of any

information, or represents that its use would not infringe privately owned rights.

Reference herein to any specific commercial product, process, or service by trade

name, trademark, manufacturer, or otherwise, does not necessarily constitute or

imply its endorsement, recommendation, or favoring by The Dow Chemical

Company. The views and opinions of authors expressed herein do not necessarily

state or reflect those of The Dow Chemical Company, and shall not be used for

advertising or product endorsement purposes.

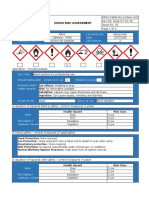

Safe Operation Card (SOC)

Introduction: The Safe Operation Card (SOC) is used as a tool to complete hazard assessment and

planning for research activities as defined in The Dow Chemical Company R&D

Management of Change Work Process.

Page 1 Last Revised: 6/6/12

SAFE OPERATION CARD TEMPLATE

OWNER & CELL PHONE: APPROVED BY (TBD BY DEPT):

OTHER PERSONNEL APPROVED TO RUN THIS REACTION OR OPERATION:

REVIEW PROCEDURE EVERY XX months. In-service date: ___________ REVIEW BY DATE: __________________________

REACTION OR TYPE OF OPERATION (If synthesis, include: structures, names, and concentrations of chemicals to be used or made including reagents, catalysts,

solvents, products, potential by-products if known), acceptable and “never exceed” ranges for temperatures & pressures, and comments on sampling and workups)

EMERGENCY SHUTDOWN PROCEDURES: Include

location of plugs and devices, and label them.

CHEMICAL EXPOSURE HAZARDS & RESPONSE: EYECONTACT: (example: may cause corneal irritation. Wash with water

(Use worse case for each material used) minimum of 15 minutes, contact emergency services (9-1-1))

SKIN CONTACT:

INHALATION:

PERSONAL PROTECTIVE EQUIPMENT EYE PROTECTION: (example: safety glasses for routine work, chemical

goggles while pouring solvent into flask)

BODY PROTECTION:

REPSIRATORY PROTECTION:

SPILL CLEANUP/EQUIPMENT DECONTAMINATION

RESPONSE:

Are clean-up or decontamination supplies compatible and readily available?

CHEMICAL, PHYSICAL OR MECHANICAL HAZARDS

- Consider chemical compatibility, reactivity, flammability, explosion

potential, toxicity. Can your equipment handle rapid evolution of volumes

of gas? Are you inerting equipment if you are operating at temperatures

above the flash point of a solvent?

- Consider Pressure, Temperature, Corrosivity, Electrical Hazards,

Cylinder Storage/Use

Page 2 Last Revised: 6/6/12

HAZARD EVALUATION TOOLS

Hazard Level Assessment for Synthesis or Operation: Reactive ChemicalsChecklists

Classified as “HIGH” if any of the following is YES: MSDS (Material Safety Data Sheets) Reviewed Yes / No

High Toxicity / Low exposure limits (Use MSDS for

Yes / No You have received training on this SOC card Yes / No

information)

High/Moderate Hazard Reaction performed < 2 times – Do reactants or products contain functional groups or atom

See Tables 3 & 5 below. Yes / No groupings that confer explosive properties to the molecule (R1,

R2, R3, R6, R8, R9)? Complete Reactive Chemicals Checklist for Yes / No

HOT chemistry (> 400 J/g mixture if <1L, > 200 J/g

mixture if 1-5L, > 100 J/g mixture if >5 L). The rate of Explosibility Potential.

reaction could increase to a thermal explosion if any of the Yes / No Are you working with R4, R5, R16, R19 or R44 chemicals?

control systems fail (cooling, agitation, addition Complete Reactive Chemicals Checklist for R4, 5, 16, 19, 44 Yes / No

controllers, etc)

Using flammable gases, liquids, or solids (FP <38C, LFL Overall Hazard Mitigation / Risk Reduction Assessment

<10 vol% in air, AIT < 200C) Yes / No

OVERALL Hazard Level Assessment: If “HIGH”, VERIFY that the

High Hazard Reaction or Functional Group (See Table 6) Yes / No planned activity has been reevaluated using the high level Yes / No /

Chemicals are: air/moisture sensitive, pyrophoric, review checklist and additional reviews were held as appropriate NA

combustible dusts, impact sensitive, polymerizable, water to identify additional protective measures – Circle Yes or No.

reactive, corrosive, require an inhibitor, heat sensitive, or Yes / No Reactive Chemicals Checklist (R1, R2, R3, R6, R8, R9) -

may react explosively? I have put controls in place to manage or mitigate the hazards to Yes / No /

reduce the risk of an unplanned event NA

Extreme Reaction Temperature (>150C or < -30C)? Yes / No

Reactive Chemicals Checklist (R4, R5, R16, R19, R44) -

High Temperature Feed (>50 C)? Yes / No I have put controls in place to manage or mitigate the hazards to Yes / No /

reduce the risk of an unplanned event NA

High Pressure Reaction (>10 bar) or Feed (>2 bar)? Yes / No

When prompted to STOP, I have reevaluated my planned activity

OVERALL Hazard Level Assessment – Circle High if High / Not High and sought additional review(s) to to identify additional Yes / No /

any of the above are “Yes” protective measures and mitigate hazards before proceeding. NA

Reactive Chemicals Checklist - Explosivity Potential

Specific Hazard (with European Union R-Phrase) “N” is Prompt to STOP and Control/Mitigate Hazard Y N NA

(R1) – Explosive when dry (R1, 2, 3, 6, 8, 9) If “yes” or “I’m not sure” to ANY of these check boxes,

then STOP! Reevaluate planned activity and modify as appropriate to

(R2) – Risk of explosion by shock, friction, fire or other sources of ignition mitigate the hazard before proceeding.

Are there any credible hazardous scenarios with handling the material neat or dry such

(R3) – Extreme risk of explosion by shock, friction, fire or other sources of ignition that all the potential energy can be released?

When handling heat sensitive or shock sensitive materials, I could accidently initiate

(R6) – Explosive with or without contact with air an explosion from heat or frictional force.

The pressure I could generate from an unintended event can exceed the burst

(R8) – Contact with combustible material may cause fire pressure of my equipment, instrument, or reaction vessel.

I could isolate neat, energetic intermediates or products with these properties during

(R9) – Explosive when mixed with combustible substances my reaction, work-up, or subsequent reaction steps.

(e.g. Peroxides, Diazo Compounds, Nitro, Nitrite, Nitrate, Chlorates, Perchlorates or Bromates) I could injure myself or cause structural damage if an explosion occurs.

Circle which apply. If any do apply, use next column and assess if controls are in place I could accidentally mix incompatible chemicals, absorbents, or contact incompatible

to manage or mitigate the hazards. metals during storage, use, and disposal.

Page 3 Last Revised: 6/6/12

HAZARD EVALUATION TOOLS (CONTINUED)

Reactive Chemicals Checklist - R4, R5, R16, R19, R44

Specific Hazard (with European Union R-Phrase) N Specific Hazard (with European Union R-Phrase)

Y N Y N NA

“N” is Prompt to STOP and Control/Mitigate Hazard A “N” is Prompt to STOP and Control/Mitigate Hazard

(R4) - Forms very sensitive explosive metallic compounds - (R16) - Explosive when mixed with oxidizing substance -

For example, metal azides (M-N3), metal hydrazines (M-N=N), metal acetylides (M- - but you can you mitigate this hazard. Check Y=Yes or

C=C) , metal fulminates (M-C=N-O or C=N-O-M) N=No. NA if R16 does not apply.

Ag (silver metal) + HNO3 (nitric acid) + ROH (alcohol) -> Ag(+)R=N-O (silver fulminate)

or Hazard mitigation is YES if any of these inherently safe practices apply:

AgNO3 (silver nitrate) + ROH (alcohol) -> Ag(+)R=N-O (silver fulminate) (Indicate which will be used)

No credible scenarios with accidental or intended mixing with oxidizers

during storage, use, and disposal.

- but you can you prevent accidental or intended mixing of samples, Equipment, instrument, or vessel will contain or safely relieve, not

reagents, standards, or wastes that may cause the formation of rupture, from worst-case pressures or pressure rates.

Segregate reactive wastes

explosive, highly unsaturated R4 metal compounds. Check Y=Yes or

Always use dilute vs. neat energetic materials

N=No. NA if R4 does not apply.

If “No”, STOP! Reevaluate planned activity and modify as

If “No”, STOP! Reevaluate planned activity and modify as appropriate to appropriate to mitigate the hazard before proceeding.

mitigate the hazard before proceeding.

N

Y N Y N NA

A

(R5) - Heating may cause an explosion - (R19) - May form explosive peroxides -

Examples of R5 materials with this property include: hydroxylamine, perchloric acid, Check Y=Yes or N=No. NA if R19 does not apply.

hydrogen peroxide, etc. - but there is a low risk because the bottle been opened < 3 months,

- but you can you store, use, and dispose of the R5 material in a manner the chemical has been stored under an inert atmosphere, or it has

shown negative in a peroxide test

to prevent it from releasing all its energy at once. Check Y=Yes or N=No.

NA if R5 does not apply. If “No”, STOP! Reevaluate planned activity and modify as

appropriate to mitigate the hazard before proceeding.

This is YES if any of these inherently safe practices apply: (Indicate which will be used)

Temperature monitoring and control during storage and use to avoid fast rates of reaction or - but you can you PREVENT forming or concentrating peroxides as a

decomposition that may cause reaction vessels or sample containers to rupture. reaction by-product or in distillation overheads

Segregate from incompatible chemicals or materials of construction which, upon mixing, could If “No”, STOP! Reevaluate planned activity and modify as

result in heat or pressure generation. appropriate to mitigate the hazard before proceeding.

Excess solvent (providing ebullient cooling)

Using dilute vs. neat energetic materials (R44) - Risk of explosion if heated under confinement -

Examples: propane cylinders, mixed compressed gases, etc.

If “No”, STOP! Reevaluate planned activity and modify as appropriate to - but you can PREVENT heating liquid or compressed

mitigate the hazard before proceeding. gases under confinement. Check Y=Yes or N=No. NA if

R44 does not apply.

If “No”, STOP! Reevaluate planned activity and modify as

appropriate to mitigate the hazard before proceeding.

Page 4 Last Revised: 6/6/12

HAZARD EVALUATION TOOLS (CONTINUED)

TABLE 3. Reactions Having a High Hazard Potential

Reference Guide for Hazard Level Assessment [1] - No Need to Post with SOC Card.

Reaction Example of concern

Curtis Rearrangements Use of acyl azides, nitrous acid or hydrazine.

Decarboxylation Removal of -COOH with CO2 evolution. Possible over-pressure hazard.

Diazotizations Especially if followed by reduction to the hydrazine (SnCl2 reaction); replacement with a –OH, or to replace -NH2 with -H

Displacements Uses oxalyl chloride to displace -OH. (CO2, CO, HCl generated)

Epoxidations Epoxides are high energy strained rings

Esterification When using oxalyl chloride

Friedel Crafts (AlCl3) Friedel Crafts reactions and their quenches due to use of AlCl3, BCl3, H2SO4, HF.

Grignard reactions Reactions require an activation period and are highly exothermic.

Hydrolysis Hydrolysis of a cyano to an amide oxidatively using H2O2

Metallations Uses n-BuLi, t-BuLi, LDA, NaHMDS

Uses nitric acid and strong acids like sulfuric or triflic acid (trifluoromethylsulfonic acid). Nitrations are very exothermic. Potential exists for thermal

Nitrations

runaway, initiating violent decompositions and explosions.

Oxidations Use of Jones reagent [K2Cr2O7/H2SO4], O3, H2O2, KMnO4 (with large exotherms), peroxo acids, cleavage using sodium periodate

Peptide formations Use of HOBT (Hydroxybenzotriazole hydrate).

Quenches When PCl5 or POCl3 have been used in a previous step and water is the quench

Any nitro compound or high energy functional group reduction. Reductions using LiAlH 4, Fe or Zn powder with HCl or acetic acid, hydrazine in

Reductions

caustic; hydrogenations by generating H2 in-situ using hydrazine, NaBH4 in CH3OH or C6H12

Sulfonation Sulfonation of an amine to form sulfonamide

[1] Leggett, D.; “Chemical Reactivity Assessments in R&D”, Journal of Hazardous Materials, 115(1–3), 63-70 (2004). A Collection of Papers Presented at the Annual Symposium of the

Mary Kay O'Connor Process Safety Centre, Texas A and M University, College Station, TX, United States, 28-29 October, 2003

Page 5 Last Revised: 6/6/12

HAZARD EVALUATION TOOLS (CONTINUED)

TABLE 5. Reactions Having a Moderate Hazard Potential

Reference Guide for Hazard Level Assessment [1] - No Need to Post with SOC Card.

Reaction Examples of concern

Acylations Use of acetic anhydride or acid chloride acylations of amines.

Additions Additions of alkyl metals to ketones or aldehydes, cyano groups, carboxylic acids or esters, or any other functionalities.

Alkylations Alkyl halide or amine (aromatic or aliphatic) used with a phenol.

BOC protections-

BOC (t-butoxycarbonyl) used to protect/deprotect amines. Unreacted BOC anhydride in waste streams can liberate CO 2 and isobutylene.

deprotections

Condensations

-phosphine)4; Suzuki coupling;

Cross coupling reactions

zincate coupling by transmetalating a Grignard or a lithium species with zinc chloride.

Dealkylation Demethylation of methoxy group using HBr or HCl to generate methyl bromide or methyl chloride. BBr 3 and BC13 used at low temperatures.

Displacement of -OH with -Cl using PCl5; reactions are heated, the distilled PCl5 is difficult to quench due to the delayed water reaction. Use of

Displacement

LiCl in NMP to displace a triflate (CF3SO3−).

Using oxalyl chloride and acid followed by alcohol addition. Reaction liberates CO and HCl–pressure hazard. Also by using acid and SOCl2 and then

Esterification

adding the alcohol.

Ether formations Ethers formed via Williamson synthesis by alkylating with alkylhalide.

Halogenations Reactions of alkyl or aryl groups with halogens such as Br2 Cl2 or I2.

Hydrolysis Reaction of a cyano with Lewis acid (e.g. BF3). See other categories for hydrolysis/quench reactions.

Coupling of an amine with an acid using EDC, EEDQ (N-ethoxycarbonyl-2-ethoxy-1,2-dihydroquinoline), or alkyl-chloroformate mediated peptide

Peptide formations

coupling, or N-hydroxy succinamide.

Use of triethylsilane, NaBH4 (except with methanol), tri-acetoxyborohydride, B2H6 generated in-situ via BF3/NaBH4. Birch reductions with Na or K

Reductions

is category. Reductions using H2 and Pd, Pt, Raney Ni, Ru, Ir.

Sulfonation Use of SO2Cl2 with an alcohol (plus base) to form a mesylate or tosylate. Use of triflic anhydride to form a triflate

[1] Leggett, D.; “Chemical Reactivity Assessments in R&D”, Journal of Hazardous Materials, 115(1–3), 63-70 (2004). A Collection of Papers Presented at the Annual Symposium of the

Mary Kay O'Connor Process Safety Centre, Texas A and M University, College Station, TX, United States, 28-29 October, 2003.

Page 6 Last Revised: 6/6/12

HAZARD EVALUATION TOOLS (CONTINUED)

TABLE 6. Atomic Groupings in a Molecule Indicating Potentially Explosive Characteristics

Reference Guide for Hazard Level Assessment [1] No Need to Post with SOC Card.

[1] Leggett, D.; “Chemical Reactivity Assessments in R&D”, Journal of Hazardous Materials, 115(1–3), 63-70 (2004). A Collection of Papers Presented at

the Annual Symposium of the Mary Kay O’Connor Process Safety Centre, Texas A and M University, College Station, TX, United States, 28-29 October, 2003.

Page 7 Last Revised: 6/6/12

NOTE: This list of atomic groupings is not exhaustive. For more information about specific explosive

reactivity hazards indexed by chemical or class of chemicals, see Bretherick's Handbook of Reactive

Chemical Hazards, Volumes 1-2 (7th Edition) Edited by: Urben, Peter G. © 2007 Elsevier

Page 8 Last Revised: 6/6/12

You might also like

- SOP TemplateDocument4 pagesSOP TemplateBill ChenNo ratings yet

- The Massage Connection Anatomy and Physiology - Lecture Notes, Study Material and Important Questions, AnswersDocument63 pagesThe Massage Connection Anatomy and Physiology - Lecture Notes, Study Material and Important Questions, AnswersM.V. TV100% (1)

- COSHH Risk Assessment FormDocument6 pagesCOSHH Risk Assessment FormHalimNo ratings yet

- Astm F3001 - 14Document6 pagesAstm F3001 - 14SergiyNo ratings yet

- Laboratory Risk Assessment FormDocument8 pagesLaboratory Risk Assessment FormReni Swara Mahardika50% (2)

- Risk AnalysisDocument125 pagesRisk AnalysisDennise ShughniNo ratings yet

- Stephan Staxel 1.5-3.5 - Service Manual PDFDocument41 pagesStephan Staxel 1.5-3.5 - Service Manual PDFandreu39No ratings yet

- CoSHH RA ZM - RNA IVT Production & PurificationDocument5 pagesCoSHH RA ZM - RNA IVT Production & PurificationZak MarshallNo ratings yet

- Introduction To Chemical Health Risk Assessment (Chra) : CHE 301 Occupational Safety and Health Act Assignment 3Document15 pagesIntroduction To Chemical Health Risk Assessment (Chra) : CHE 301 Occupational Safety and Health Act Assignment 3Hazimah MadzakiNo ratings yet

- Managing Hazardous Chemicals in Department of Education Workplaces Risk AssessmentDocument10 pagesManaging Hazardous Chemicals in Department of Education Workplaces Risk AssessmentNur E Alam NuruNo ratings yet

- Environmental Health Risk AssessmentDocument7 pagesEnvironmental Health Risk Assessmentdu dungNo ratings yet

- Safe Storage HC PDFDocument65 pagesSafe Storage HC PDFSahanara shaikhNo ratings yet

- Chemical Risk Assessment Template Pack Round 2 PDFDocument7 pagesChemical Risk Assessment Template Pack Round 2 PDFSebastian iacopiNo ratings yet

- General RA TemplateDocument2 pagesGeneral RA TemplateGeorgeNo ratings yet

- Is 106Document35 pagesIs 106yoyoamit9051846812No ratings yet

- Department of Engineering Risk Assessment Form - This Is An Active Document and Must Be MaintainedDocument4 pagesDepartment of Engineering Risk Assessment Form - This Is An Active Document and Must Be MaintainedRadhaKrishnan RNo ratings yet

- Laboratory Risk Assessment Tool: Procedure: Lab Group: Completed By: DateDocument6 pagesLaboratory Risk Assessment Tool: Procedure: Lab Group: Completed By: DatetafouzeltNo ratings yet

- Sample Risk Management ProcedureDocument7 pagesSample Risk Management ProcedureSCDC BIRNo ratings yet

- SMB013 Risk Assessment Use Storage and Disposal of Flammable LiquidsDocument6 pagesSMB013 Risk Assessment Use Storage and Disposal of Flammable LiquidsRias SahulNo ratings yet

- Risk Assessment WorksheetDocument5 pagesRisk Assessment WorksheetThy Random UserNo ratings yet

- How To Prepare A Chemical RegisterDocument29 pagesHow To Prepare A Chemical RegisterRAZMAN BIN MOHD MAULOTNo ratings yet

- Aeroshell Grease 33MSDocument2 pagesAeroshell Grease 33MSMahammadNo ratings yet

- Cossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberDocument4 pagesCossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberRocky BisNo ratings yet

- RPSG-CAT-FSMS-COSHH-28 - Caustic Soda FlakesDocument6 pagesRPSG-CAT-FSMS-COSHH-28 - Caustic Soda FlakesRocky BisNo ratings yet

- Transes MLSP-112Document60 pagesTranses MLSP-112Hermione GrangerNo ratings yet

- C6 P19-39 L1 SafetyDocument21 pagesC6 P19-39 L1 Safetythrowaway0620239201No ratings yet

- Crude Tall OilDocument8 pagesCrude Tall OilCarlos Andres Rios Barra100% (1)

- Cossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberDocument2 pagesCossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberRocky BisNo ratings yet

- RPSG-CAT-FSMS-COSHH-19-Venus - Scale and Lime RemoverDocument2 pagesRPSG-CAT-FSMS-COSHH-19-Venus - Scale and Lime RemoverRocky BisNo ratings yet

- Safety AssiginmentDocument4 pagesSafety AssiginmentLOKESHWARAN K CHEM-UG- 2017 BATCHNo ratings yet

- Laboratory Risk Assessment ToolDocument8 pagesLaboratory Risk Assessment Toolsheila marie canibasNo ratings yet

- HPD HIGH PRESSURE LAMINATE by LAMITECHDocument5 pagesHPD HIGH PRESSURE LAMINATE by LAMITECHMario HenaoNo ratings yet

- Hazardous Chemical Risk Assessment Checklist 2014Document8 pagesHazardous Chemical Risk Assessment Checklist 2014NavinNo ratings yet

- 16 HAZOP Basics3Document24 pages16 HAZOP Basics3BharatNo ratings yet

- COSHH Risk Assessment FormDocument6 pagesCOSHH Risk Assessment FormasanNo ratings yet

- Chemical Risk Assessment GuideDocument3 pagesChemical Risk Assessment GuideDenny Hartanto KosenNo ratings yet

- Cossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberDocument2 pagesCossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberRocky BisNo ratings yet

- RPSG-CAT-FSMS-COSHH-06-Super Layan Multi Purpose DeodoriserDocument2 pagesRPSG-CAT-FSMS-COSHH-06-Super Layan Multi Purpose DeodoriserNiraNo ratings yet

- Identifying Chemical Reactivity HazardsDocument5 pagesIdentifying Chemical Reactivity HazardsG NavarNo ratings yet

- Lab Risk Assessment Workbook BetaDocument8 pagesLab Risk Assessment Workbook BetaEtibar AliyevNo ratings yet

- SH5108 - 1a Design For SHEDocument22 pagesSH5108 - 1a Design For SHEtaaouicha mujahidNo ratings yet

- Health Risk Assessment: Controlling Health Risks at WorkDocument75 pagesHealth Risk Assessment: Controlling Health Risks at WorkDaniel Valdes JamettNo ratings yet

- HSE-CA - AcetoneDocument2 pagesHSE-CA - AcetoneRobert PilloraNo ratings yet

- Cossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberDocument2 pagesCossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberRocky BisNo ratings yet

- Environmental Health and Safety Management SystemDocument72 pagesEnvironmental Health and Safety Management SystemRAHUL MOTGHARENo ratings yet

- Cossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberDocument2 pagesCossh Risk Assessment: Carried Out By: Department: Date: Substance Name: CRA NumberNiraNo ratings yet

- Risk Assessment FormDocument50 pagesRisk Assessment FormAndre Porles100% (1)

- SAH LAB Risk Assesssment ToolDocument10 pagesSAH LAB Risk Assesssment ToolRazel Ann Elagio100% (1)

- Instrument Decon FormDocument2 pagesInstrument Decon FormJimmy ChaoNo ratings yet

- HSE-CA - Polyster Catalyst MEKPDocument3 pagesHSE-CA - Polyster Catalyst MEKPRobert PilloraNo ratings yet

- Lab Risk AssessmentDocument8 pagesLab Risk Assessmentaqilah haronNo ratings yet

- Chemical ChecklistDocument2 pagesChemical ChecklistRatna TryNo ratings yet

- Cationic Poly Electrolyte Chemical MSDSDocument5 pagesCationic Poly Electrolyte Chemical MSDSsrinivas50% (2)

- Msds Chem Crest 715Document4 pagesMsds Chem Crest 715esthefaniaNo ratings yet

- Quantitative Risk Assessment CalculationsDocument11 pagesQuantitative Risk Assessment CalculationsTharindu Nuwan JayakodyNo ratings yet

- Hazard Control Plan Template 4-19-2024Document13 pagesHazard Control Plan Template 4-19-2024GladyNo ratings yet

- ChemicalReactivityHazards (Compatibility Mode)Document101 pagesChemicalReactivityHazards (Compatibility Mode)Rmz ExeNo ratings yet

- RPSG-CAT-FSMS-COSHH-02-Alcohol Gel SanitizerDocument6 pagesRPSG-CAT-FSMS-COSHH-02-Alcohol Gel SanitizerRocky BisNo ratings yet

- RPSG CAT FSMS COSHH 05 Bivvy Liquid Fabric SoftnerDocument2 pagesRPSG CAT FSMS COSHH 05 Bivvy Liquid Fabric SoftnerRocky BisNo ratings yet

- RPSG CAT FSMS COSHH 05 Bivvy Liquid Fabric SoftnerDocument2 pagesRPSG CAT FSMS COSHH 05 Bivvy Liquid Fabric SoftnerRocky BisNo ratings yet

- RPSG-CAT-FSMS-COSHH-05-Bivvy - Liquid Fabric SoftnerDocument2 pagesRPSG-CAT-FSMS-COSHH-05-Bivvy - Liquid Fabric SoftnerNiraNo ratings yet

- Safety Case TemplateDocument23 pagesSafety Case TemplateOluwagbemi SundayNo ratings yet

- 5 Cold-Weather Health Hazards, and How To Stay SafeDocument31 pages5 Cold-Weather Health Hazards, and How To Stay Saferamkumardotg_5807772No ratings yet

- Safety Everyday Safety Pep - Talk: Wrigley BangaloreDocument34 pagesSafety Everyday Safety Pep - Talk: Wrigley Bangaloreramkumardotg_5807772No ratings yet

- TV Show 21 Disaster Prep. GuideDocument49 pagesTV Show 21 Disaster Prep. Guideramkumardotg_5807772No ratings yet

- Convince MeDocument97 pagesConvince Meramkumardotg_5807772No ratings yet

- Spot The HazardDocument15 pagesSpot The Hazardramkumardotg_5807772No ratings yet

- Strains and SprainsDocument1 pageStrains and Sprainsramkumardotg_5807772No ratings yet

- Attitude 2Document16 pagesAttitude 2ramkumardotg_5807772No ratings yet

- Hazard AssessmentDocument1 pageHazard Assessmentramkumardotg_5807772No ratings yet

- Sample Budget Worksheet: HousingDocument4 pagesSample Budget Worksheet: Housingramkumardotg_5807772No ratings yet

- Back Safety PDFDocument3 pagesBack Safety PDFramkumardotg_5807772No ratings yet

- YLA Injury Illness Prevention Program IIPPDocument7 pagesYLA Injury Illness Prevention Program IIPPramkumardotg_5807772No ratings yet

- Working Around ForkliftsDocument1 pageWorking Around Forkliftsramkumardotg_5807772No ratings yet

- Niversal Aste: KU Procedures For The Management ofDocument6 pagesNiversal Aste: KU Procedures For The Management oframkumardotg_5807772No ratings yet

- Quiz On Bacteria: AnswersDocument1 pageQuiz On Bacteria: Answersramkumardotg_5807772No ratings yet

- Legal Requirement Related To Environment, Health and Safety Based On ISO 14001 and OHSAS 18001 Management SystemDocument7 pagesLegal Requirement Related To Environment, Health and Safety Based On ISO 14001 and OHSAS 18001 Management Systemramkumardotg_5807772No ratings yet

- 2008 Risk Factors CulturalDocument1 page2008 Risk Factors Culturalramkumardotg_5807772No ratings yet

- 6d5a PDFDocument7 pages6d5a PDFramkumardotg_5807772No ratings yet

- 04 - Truta 2-2013Document6 pages04 - Truta 2-2013ramkumardotg_5807772No ratings yet

- External Lab Hazard Trigger GridDocument2 pagesExternal Lab Hazard Trigger Gridramkumardotg_5807772No ratings yet

- Appendix P Accident Investigation Guidelines and Supervisors ReportDocument4 pagesAppendix P Accident Investigation Guidelines and Supervisors Reportramkumardotg_5807772No ratings yet

- SafetyAccidentInvestigationQuestionsandNeededInfo tcm36-208795 PDFDocument2 pagesSafetyAccidentInvestigationQuestionsandNeededInfo tcm36-208795 PDFramkumardotg_5807772No ratings yet

- SafetyAccidentInvestigationQuestionsandNeededInfo tcm36-208795 PDFDocument2 pagesSafetyAccidentInvestigationQuestionsandNeededInfo tcm36-208795 PDFramkumardotg_5807772No ratings yet

- PNSDW-limit TableDocument7 pagesPNSDW-limit TablefsafasdgdsgdfhNo ratings yet

- Company Profile of TATA Steel by (Anindya S Kundu)Document16 pagesCompany Profile of TATA Steel by (Anindya S Kundu)anindya_kundu100% (5)

- ASTM D5865 2013 Gross Calorific Value of Coal and CokeDocument19 pagesASTM D5865 2013 Gross Calorific Value of Coal and CokeWinnjone YinNo ratings yet

- By Abhisam Software: The Practical Guide To Hazardous Area ClassificationDocument14 pagesBy Abhisam Software: The Practical Guide To Hazardous Area Classificationjayand_netNo ratings yet

- Sieving Methods of Sieve AnalysisDocument6 pagesSieving Methods of Sieve AnalysisAlyssa Joy Santos PaguioNo ratings yet

- Tec 303 HFG: Highly Fluid Post-Tensioning GroutDocument2 pagesTec 303 HFG: Highly Fluid Post-Tensioning Groutmanikandan4strlNo ratings yet

- Investigation of The Effect of Glass Fiber Content On The Mechanical Properties of Cast PolyamideDocument8 pagesInvestigation of The Effect of Glass Fiber Content On The Mechanical Properties of Cast PolyamideIndra JayaNo ratings yet

- KopakDocument1 pageKopakXohaib3187No ratings yet

- Boiling ChipsDocument3 pagesBoiling Chipskyra_kay226No ratings yet

- JHM V165, 1-3, 751-758 AN - PyriteDocument8 pagesJHM V165, 1-3, 751-758 AN - PyriteGonzalo O'ortiz Araneda's IIINo ratings yet

- Customer SegmentationDocument10 pagesCustomer SegmentationGirish GhorpadeNo ratings yet

- 5 PolarizationDocument29 pages5 PolarizationIshan RatnakarNo ratings yet

- A Review of The Clinical Toleration Studies of PolydextroseDocument12 pagesA Review of The Clinical Toleration Studies of PolydextroseJuliana Quiroz CalderonNo ratings yet

- AFEX - Clean Agent PDFDocument1 pageAFEX - Clean Agent PDFeduardo gonzalezavNo ratings yet

- Ast (Got) Ifcc LS BXC0203 A25a15Document2 pagesAst (Got) Ifcc LS BXC0203 A25a15jef1234321No ratings yet

- 2017 Syllabus - MVH Modular Sedation SeriesDocument11 pages2017 Syllabus - MVH Modular Sedation SeriesyalahopaNo ratings yet

- Well Logs: Prof. Dr. Hassan Z. HarrazDocument80 pagesWell Logs: Prof. Dr. Hassan Z. HarrazEzzadin BabanNo ratings yet

- Noa Women Cachare. - Imf168Document2 pagesNoa Women Cachare. - Imf168mohamed tharwatNo ratings yet

- Abb - Industria Del Agua: Agua Potable Y EfluentesDocument154 pagesAbb - Industria Del Agua: Agua Potable Y EfluentesJuan PercNo ratings yet

- Outokumpu Handbook of Stainless Steel 2017 EditionDocument92 pagesOutokumpu Handbook of Stainless Steel 2017 EditionRavindra BarangeNo ratings yet

- Therapeutic Drug MonitoringDocument43 pagesTherapeutic Drug MonitoringMohammad AdibNo ratings yet

- Reference HarvDocument15 pagesReference HarvBlessy GabaynoNo ratings yet

- White Conduit Pipe (ULBS) PDFDocument8 pagesWhite Conduit Pipe (ULBS) PDFAkbar TrilaksonoNo ratings yet

- DETA生产工艺Document3 pagesDETA生产工艺GakkyNo ratings yet

- Fiber-Reinforced Asphalt-Concrete - A ReviewDocument7 pagesFiber-Reinforced Asphalt-Concrete - A ReviewAlberto GaxiolaNo ratings yet

- Group 1 Tle PresentationDocument37 pagesGroup 1 Tle PresentationKaren BaloloyNo ratings yet

- Full Ebook of One World Now The Ethics of Globalization Peter Singer Online PDF All ChapterDocument24 pagesFull Ebook of One World Now The Ethics of Globalization Peter Singer Online PDF All Chapterclcudinegoct100% (5)