Professional Documents

Culture Documents

Atb209 Isuzu 4l80-E ...... High or Low Pressure

Atb209 Isuzu 4l80-E ...... High or Low Pressure

Uploaded by

AleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Atb209 Isuzu 4l80-E ...... High or Low Pressure

Atb209 Isuzu 4l80-E ...... High or Low Pressure

Uploaded by

AleCopyright:

Available Formats

Technical Bulletin #209

Transmission: 4L80-E

Subject: High or low pressure

Application: GM, Jaguar, Isuzu, Rolls Royce, Hummer

Issue Date: January, 1994

4L80-E

High or Low Pressure

No line pressure rise of uncontrollable high pressure (400 psi or more) may be caused by defective or mis-

matched parts.

It is imperative that the case, spacer plate, and valve body gaskets be compatible to prevent complaints of very

high or low pressure.

Use figures 1, 2, & 3 to positively identify the components. Once you have identified the components refer to

the parts matching lists in figure 4.

It is also necessary to verify that the force motor is not sticking (figure 5), and that the valve body is checked for

a broken screen (figure 6). A missing cup plug can also create a no line rise. Be sure to check all of these areas

whenever you are looking for the cause of any high/low pressure complaints.

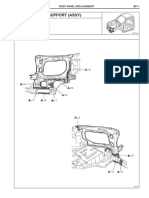

Figure 1

Copyright © 2003 ATRA. All Rights Reserved. ! Page 1 of 3

Technical Bulletin #209

Figure 2

Figure 3

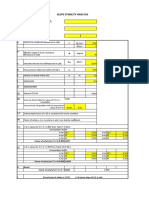

Parts Matching List

These parts combinations will work

1st design case 1st design case 1st design case 1st design case 2nd design case 2nd design case

1st design plate 1st design plate 2nd design plate 2nd design plate 2nd design plate 1st design plate

1st design gaskets 2nd design gaskets 1st design gaskets 2nd design gaskets 2nd design gaskets 1st design gaskets

These parts combinations will not work

2nd design case 2nd design case

2nd design plate 1st design plate

1st design gaskets 2nd design gaskets

Figure 4

! Page 2 of 3 Copyright © 2003 ATRA. All Rights Reserved.

Technical Bulletin #209

A defective force motor can also create no line rise and/or maximum mainline pressure. To determine if the

force motor valve is sticking, follow the procedure below.

Poke a fine sewing

Make sure the screens are not clogged. needle through the

center of the screen to

Apply 12 volts to one

feel the valve move

terminal and ground to

back and forth when

the other.

the solenoid is turned

on and off.

Catution: Do not leave

the solenoid ‘on’ for

Force Motor

more than five seconds You should be able to move the valve back

at a time. and forth when the solenoid is turned on

and off. If the valve is stuck, replace it

Figure 5

with GM part # 8677314

No line rise (even with matching parts and a good force motor) may be caused by a missing cup plug in the

accumulator housing.

BEWARE: New accumulator housings may not come with a cup plug installed in the hole shown below.

Be sure this cup plug is

It is not uncommon for the bottom of the shift solenoid

not missing.Cup

feed screen to blow out when it gets old. This may cre-

ate no line rise, low mainline, and most of all, no shifts

Plug (.250 dia)…GM part #8611710

even when electrical systems are working. To be safe,

stock new screens and replace them during overhaul

with Shift Solenoid Feed Screen, GM part # 8661709.

Figure 7 Figure 6

Copyright © 2003 ATRA. All Rights Reserved. ! Page 3 of 3

You might also like

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- 308-03b-I Manual Transaxle/Transmission - TR6060 308-03b-IDocument21 pages308-03b-I Manual Transaxle/Transmission - TR6060 308-03b-IdavidNo ratings yet

- Atb1571 Nissan RE4F04B PDFDocument1 pageAtb1571 Nissan RE4F04B PDFAle100% (6)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- AODEDocument112 pagesAODEragnar lothbrokNo ratings yet

- 4L60E Converter Valves:: Operation, Test Procedures and The Effects of WearDocument5 pages4L60E Converter Valves:: Operation, Test Procedures and The Effects of WeartranstechozNo ratings yet

- 2006-02 4R70W No ReverseDocument13 pages2006-02 4R70W No ReverseAleNo ratings yet

- ATRA Seminar Book TableDocument82 pagesATRA Seminar Book Tableossoski50% (2)

- Bulletin 6l90 PDFDocument4 pagesBulletin 6l90 PDFAnonymous WzR5h9g8VNo ratings yet

- Transmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesDocument5 pagesTransmission 4R70W Main Control Valve Body Disassembly and Assembly of SubassembliesFDONo ratings yet

- 02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCDocument16 pages02-2009 4t65e, F4a23-33, A246e Check Ball, Ax4s-Ax4n-4f50n Codes DTCAleNo ratings yet

- 2006-02 4R70W No ReverseDocument13 pages2006-02 4R70W No ReverseAleNo ratings yet

- Atb1571 Nissan RE4F04B PDFDocument1 pageAtb1571 Nissan RE4F04B PDFAle100% (1)

- Journal Bearing VibrationDocument10 pagesJournal Bearing Vibrationalex roNo ratings yet

- Atb264 Isuzu 4l80-E Alta Presion en La Linea (Broken Direct Clutch or Case)Document3 pagesAtb264 Isuzu 4l80-E Alta Presion en La Linea (Broken Direct Clutch or Case)AleNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- 4R100 NonPTO VBDocument2 pages4R100 NonPTO VBGina LópezNo ratings yet

- Input Drum Reinforcement Kit 77733-02KDocument2 pagesInput Drum Reinforcement Kit 77733-02KMichel Le DocteNo ratings yet

- Atb 003Document2 pagesAtb 003Tejon Aguilar100% (1)

- Technical Service Information: DODGE 45/545/68RFEDocument14 pagesTechnical Service Information: DODGE 45/545/68RFEjulio montenegroNo ratings yet

- 47re To 48 UpgradeDocument1 page47re To 48 UpgradeWilliam Richason100% (2)

- Application: 1990 Ford Bronco 1990 Ford BroncoDocument43 pagesApplication: 1990 Ford Bronco 1990 Ford BroncoWin CardonaNo ratings yet

- Torqshift 6Document8 pagesTorqshift 6acmemail583100% (1)

- Dodge Ram 42re Throttle Valve ReplacementDocument2 pagesDodge Ram 42re Throttle Valve ReplacementHuuf ArtedNo ratings yet

- VBP Catalog Solenoids Vers4 2 PDFDocument137 pagesVBP Catalog Solenoids Vers4 2 PDFDennis Baumann100% (1)

- 06 67 RWD Dodge Jeep Lube Failures PDFDocument6 pages06 67 RWD Dodge Jeep Lube Failures PDFeurospeed2No ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument7 pagesTechnical Service Information: Automatic Transmission Service GroupLUISNo ratings yet

- 345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224Document9 pages345S Operators Manual: 511bailey Ave PO Box 324 New Hampton, IA 50659 Fax: 1-641-394-6224valangelofNo ratings yet

- 4T40E / 4T45E: Multiple Codes, Slips, FailsafeDocument4 pages4T40E / 4T45E: Multiple Codes, Slips, FailsafeCo Kl100% (1)

- Technical Service Information: Automatic Transmission Service GroupDocument1 pageTechnical Service Information: Automatic Transmission Service GroupAranza SuNo ratings yet

- 4L80E (MT-1), 4L85E (MN8) : 4 SPEED RWD (Electronic Control)Document6 pages4L80E (MT-1), 4L85E (MN8) : 4 SPEED RWD (Electronic Control)Juan IdrovoNo ratings yet

- Technical Bulletin #118: Valve Body InterchangeDocument4 pagesTechnical Bulletin #118: Valve Body InterchangeRaul100% (1)

- CatalogDocument16 pagesCatalogcherokewagNo ratings yet

- 30 80le PDFDocument120 pages30 80le PDFJhonnyNo ratings yet

- Atb1128 DodgeDocument6 pagesAtb1128 Dodgeภูเก็ต เป็นเกาะNo ratings yet

- Index: Fordc-6Document78 pagesIndex: Fordc-6cjmNo ratings yet

- Technical Service Information: Automatic Transmission Service GroupDocument2 pagesTechnical Service Information: Automatic Transmission Service GroupLojan Coronel José HumbertoNo ratings yet

- At Service E40dDocument5 pagesAt Service E40ds.e. e.p.No ratings yet

- 4l80e HD Shift Recalibration Kit InstructionsDocument8 pages4l80e HD Shift Recalibration Kit InstructionsGuntherMizen100% (2)

- Sonnax TS Report V6N3Document8 pagesSonnax TS Report V6N3Виталий ЧерненкоNo ratings yet

- AltoPistonKitsCatalog PDFDocument18 pagesAltoPistonKitsCatalog PDFtony917No ratings yet

- TH350 GDDocument1 pageTH350 GDJose CencičNo ratings yet

- THM 200CDocument80 pagesTHM 200CjuanNo ratings yet

- Index: Fordc-6Document78 pagesIndex: Fordc-6cjmNo ratings yet

- A760E F H VBL InteractiveDocument1 pageA760E F H VBL InteractivehaddadiNo ratings yet

- Band Adjustment Chart: Technical Bulletin # 1151Document5 pagesBand Adjustment Chart: Technical Bulletin # 1151corie132No ratings yet

- 6L80 Technical Tips PDFDocument6 pages6L80 Technical Tips PDFK BNo ratings yet

- TD201404 Abril PDFDocument68 pagesTD201404 Abril PDFcherokewagNo ratings yet

- Sonnax Planet Rebuild KitsDocument4 pagesSonnax Planet Rebuild Kitsacmemail583No ratings yet

- Technical Service Information: FORD 4R44E/4R55E/5R55EDocument3 pagesTechnical Service Information: FORD 4R44E/4R55E/5R55EJOSE GARVCVIANo ratings yet

- th400 Forward Clutch Piston Identification and InterchangeDocument6 pagesth400 Forward Clutch Piston Identification and Interchangekkg4782No ratings yet

- GM 4L60-E, 4L65-E, 4L70-E Sure Cure KIT: Installation DiagramDocument13 pagesGM 4L60-E, 4L65-E, 4L70-E Sure Cure KIT: Installation DiagramHola ValdeNo ratings yet

- Trasmision ChrysleyDocument1 pageTrasmision ChrysleyLUIS ALEJANDRONo ratings yet

- Auto519 PDFDocument275 pagesAuto519 PDFArliel John GarboNo ratings yet

- 4 L 80 eDocument8 pages4 L 80 eeman123456100% (1)

- 4t40e - 4t45eDocument6 pages4t40e - 4t45eJD DionisioNo ratings yet

- Gears May 2017Document68 pagesGears May 2017Rodger BlandNo ratings yet

- Jatco Tranny Part 3 of 3 2007-04-40Document5 pagesJatco Tranny Part 3 of 3 2007-04-40cec985458100% (1)

- Eti 4M09 4 09 04 29 GM TacDocument8 pagesEti 4M09 4 09 04 29 GM TaclaurianNo ratings yet

- Four Wheel Drive (4WD) Controls - TaggedDocument40 pagesFour Wheel Drive (4WD) Controls - TaggedNatty NuggetNo ratings yet

- Antique Automatic Transmission PartsDocument16 pagesAntique Automatic Transmission PartsMiroslav GojicNo ratings yet

- 700r4 Cable Adjustment InstructionsDocument3 pages700r4 Cable Adjustment InstructionsTito Tales100% (2)

- Sonnax HP 4L60E Catalog v1Document12 pagesSonnax HP 4L60E Catalog v1Brad Franc100% (2)

- Atb1758 U341E TOYOTA NO FORWARD AFTER VALVE BODY WORKDocument2 pagesAtb1758 U341E TOYOTA NO FORWARD AFTER VALVE BODY WORKAleNo ratings yet

- Technical Bulletin Listing: Transmission # # Pages SubjectDocument17 pagesTechnical Bulletin Listing: Transmission # # Pages SubjectAleNo ratings yet

- 12-2010 09a, Jf506eDocument17 pages12-2010 09a, Jf506eAleNo ratings yet

- 2019 - 041 Tag InformationDocument1 page2019 - 041 Tag InformationAleNo ratings yet

- Technical Bulletin #868: 2.4L Engine PCM Reprogramming For Harsh 3-2 DownshiftDocument1 pageTechnical Bulletin #868: 2.4L Engine PCM Reprogramming For Harsh 3-2 DownshiftAleNo ratings yet

- Technical Bulletin #867: A/T Harsh 3-2 Downshift - New TCMDocument3 pagesTechnical Bulletin #867: A/T Harsh 3-2 Downshift - New TCMAleNo ratings yet

- Atb852 RE4F04B, RE4F04W CHECK BALL LOCATIONSDocument1 pageAtb852 RE4F04B, RE4F04W CHECK BALL LOCATIONSAle100% (4)

- Atb164 Re4r01a, R4a-El Nissan ...... Planetary FailureDocument4 pagesAtb164 Re4r01a, R4a-El Nissan ...... Planetary FailureAleNo ratings yet

- Atb747 RL4F03A Harsh Shifts and Lack of Power PDFDocument1 pageAtb747 RL4F03A Harsh Shifts and Lack of Power PDFAleNo ratings yet

- KM175 Series: Technical Bulletin #263Document1 pageKM175 Series: Technical Bulletin #263AleNo ratings yet

- Atb153 Nissan Re4f02a ... Shifts 1-2-NeutralDocument1 pageAtb153 Nissan Re4f02a ... Shifts 1-2-NeutralAle100% (1)

- Atb469 4l30e Isuzu Codes 32 33 34 and 43Document3 pagesAtb469 4l30e Isuzu Codes 32 33 34 and 43AleNo ratings yet

- M PC 0015 PDFDocument2 pagesM PC 0015 PDFAleNo ratings yet

- Radiator Side Support (Assy) : Body Panel Replacement BP-1Document3 pagesRadiator Side Support (Assy) : Body Panel Replacement BP-1AleNo ratings yet

- Vector Network AnalyzerDocument2 pagesVector Network Analyzerkpgs12No ratings yet

- A Critical Look at StringsDocument7 pagesA Critical Look at StringsMark_DVNo ratings yet

- Rib and Timber Infill LoadsDocument2 pagesRib and Timber Infill LoadsKesavan DhuraiNo ratings yet

- Cross Compile Python For Embedded LinuxDocument3 pagesCross Compile Python For Embedded LinuxKuma Akira100% (1)

- Design Planning Records Center of The Future 2004-10Document29 pagesDesign Planning Records Center of The Future 2004-10Talam KeladiNo ratings yet

- Group 7 Final Project Report - Automatic Night LightDocument15 pagesGroup 7 Final Project Report - Automatic Night LightBen RileyNo ratings yet

- AEC Drying Brochure AEC2-115.1Document12 pagesAEC Drying Brochure AEC2-115.1serdigital0No ratings yet

- 2022 Msi-3460Document2 pages2022 Msi-3460Merced Alfonso Cepeda DíazNo ratings yet

- Roofing Sheet MetalDocument15 pagesRoofing Sheet MetalKim AnneNo ratings yet

- TP Seating - 13 - Nov ANDocument5 pagesTP Seating - 13 - Nov ANNitish KumarNo ratings yet

- Quinsyn Compressor FluidsDocument6 pagesQuinsyn Compressor FluidsRoberto AlfaroNo ratings yet

- Pajero Catalogue2Document13 pagesPajero Catalogue2almirb7100% (1)

- Surfcam 2014 r2 - 32bitDocument152 pagesSurfcam 2014 r2 - 32bitClaudio HinojozaNo ratings yet

- Sustainable DevelopmentDocument5 pagesSustainable DevelopmentRaghav KaamraNo ratings yet

- SDD 048 ML 12xx DocumentDocument12 pagesSDD 048 ML 12xx DocumentRomiNo ratings yet

- Skyblivion Architecture GuidelinesDocument11 pagesSkyblivion Architecture GuidelinesBrody EvensonNo ratings yet

- SDI Kit ManualDocument2 pagesSDI Kit ManualMubarak AhmadNo ratings yet

- HDFC ERGO General Insurance Company Limited: Policy No. 2312 1005 0512 8700 000Document3 pagesHDFC ERGO General Insurance Company Limited: Policy No. 2312 1005 0512 8700 000rajkumargiritekarNo ratings yet

- Ti CQDocument4 pagesTi CQPradeepNo ratings yet

- Eis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abDocument5 pagesEis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abhastmishNo ratings yet

- Is 210-1993Document12 pagesIs 210-1993Amal SamantaNo ratings yet

- Software Slope Stabilty Analysis FinalDocument1 pageSoftware Slope Stabilty Analysis FinalETTL UDAIPURNo ratings yet

- Ceiling Grid-Test ReportDocument6 pagesCeiling Grid-Test ReportJaime Renan Negrete BecerraNo ratings yet

- Dektec DTU 215Document5 pagesDektec DTU 215Alexander WieseNo ratings yet

- Transistor MCQDocument5 pagesTransistor MCQMark BelasaNo ratings yet

- Failures in Subgrade: Properties of The Subgrade Soil Subgrade With Lower StabilityDocument2 pagesFailures in Subgrade: Properties of The Subgrade Soil Subgrade With Lower StabilityRajesh KhadkaNo ratings yet

- Intake-Air System (ZM)Document13 pagesIntake-Air System (ZM)Sebastian SirventNo ratings yet

- Coalbrookdale Darby Stove (Boiler Model) : Spare Parts ManualDocument7 pagesCoalbrookdale Darby Stove (Boiler Model) : Spare Parts ManualDavid Mark JonesNo ratings yet

- MusicPal Manual Musicpal enDocument120 pagesMusicPal Manual Musicpal enzocanNo ratings yet