Professional Documents

Culture Documents

0700P Regulator Products

0700P Regulator Products

Uploaded by

Zoran JankovCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0700P Regulator Products

0700P Regulator Products

Uploaded by

Zoran JankovCopyright:

Available Formats

Catalog 0700P-8 Air Preparation Products

Parker Pneumatic Contents - www.parker.com/pneu/frl

Air Preparation Products

Regulators Products

General K2-K41

Dial K42-K49

Pilot K50-K63

Proportional K64-K87

Precision K88-K103

Water K104-K109

Regulator

Products

K

K1 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

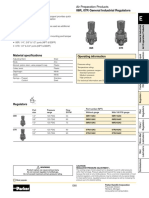

Miniature Regulators Regulator Products

14R Regulators – Miniature

General

• Unbalanced poppet standard

• Solid control piston with lip seal for extended life

• Non-rising adjusting knob

• Compact design

• Very easy to service

Dial

• 1/8", 1/4" ports (NPT, BSPP, BSPT)

Pilot

Operating information

Supply pressure (max): 0 to 300 psig (0 to 20.7 bar)

Secondary pressure ranges

Standard 2 to 125 psig (0 to 8.6 bar)

Port Medium 1 to 60 psig (0 to 4.1 bar)

Proportional

size Description Part number Medium 1 to 30 psig (0 to 2.1 bar)

1/8" Without gauge 14R013FC Low 1 to 15 psig (0 to 1 bar)

Operating temperature: 32°F to 125°F (0°C to 52°C)

1/8" With gauge 14R018FC

Low temperature -4°F to 125°F (-20°C to 52°C)

1/4" Without gauge 14R113FC Flow capacity†:

1/4" With gauge 14R118FC High flow 1/8" 13 scfm (6.1 dm3/s, ANR)

1/4" 15 scfm (7.1 dm3/s, ANR)

Precision

NOTE: 1.218 Dia. (31 mm) hole required for panel mounting. Gauge ports (2): 1/8 or 1/4 inch

Weight: 0.3 lb (0.14 kg)

†

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow secondary

setting and 10 psig pressure drop.

Ordering information:

14R 1 13 F C

Water

Port Size Port Type Preset / Pressure Limited

1/8 inch pipe, 1/8 inch gauge port 0 Blank NPT Blank None

1/4 inch pipe, 1/8 inch gauge port 1 1 BSPP XXX* Preset pressure

K 1/4 inch pipe, 1/4 inch gauge port

1/8 inch pipe, no gauge port

B

C

2 BSPT

Engineering Level

XXX* Pressure limited

* Available preset / pressure limited

range, 10 to 90 psig in 5 psig

Manifold mounting M

C Current increments. For higher pressures,

Products

Regulator

contact factory.

Pressure Range (Example: 065 = 65 psig)

Yellow Knob Black Knob Relief

Without gauge F Relieving Options

30 psig 10 30 psig B0 G Non-relieving Blank No options

60 psig 11 60 psig B1 H Low temp. relieving L† Preset non-adjustable

15 psig 12 15 psig B2 J Low temp. non-relieving P† Preset adjustable

125 psig 13 125 psig B3 S† Pressure limiter max. adjustable

With gauge* T† Pressure limiter max. non-adjustable

30 psig 15 30 psig B5 † Inlet pressure is 100 psig. For other pressures

contact factory.

60 psig 16 60 psig B6

15 psig 17 15 psig B7

Spring Type by Preset / Limited Pressure:

125 psig 18 125 psig B8 For Preset / Limited Pressure 10 to 25 use 30 psi spring

* Not available with BSPP or BSPT port types. For Preset / Limited Pressure 26 to 50 use 60 psi spring

For Preset / Limited Pressure 51 to 90 use 125 PSI Spring

Most popular.

K2 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting nut Brass

1/8" Ports

Adjusting stem & spring Steel

Relief And Flow Characteristics

Body Zinc 100

14R013F*

Bonnet, seat, piston & valve poppet Plastic

6

Secondary Pressure - (psig)

Secondary Pressure - (bar)

Seals Nitrile 80

5

60

Dial

Repair and Service Kits 4

3

Bonnet assembly kit L01369 40

Bonnet tamperproof kit P01265 2

20

30 psig gauge, 1/8" NPT (0 to 2.1 bar) K4515N18030 1

1/8 Inch Ports

100 psig (6.9 bar) Primary Pressure

60 psig gauge, 1/8" NPT (0 to 4.1 bar) K4515N18060 0 0

0 5 10 15 20 25 30 35 40

160 psig gauge, 1/8" NPT (0 to 11.0 bar) K4515N18160 Rated Flow - (scfm)

Pilot

0 2 4 6 8 10 12 14 16 18

60 psig gauge, 1/4" NPT (0 to 4.1 bar) K4520N14060 3

Flow - (dm /s)

160 psig gauge, 1/4" NPT (0 to 11.0 bar) K4520N14160 n

Mounting bracket kit* (includes panel mount nut) PS417BP

1/4" Ports

Plastic panel mount nuts* P78652

Relief And Flow Characteristics

Proportional

Metal panel mount nuts* P01531 14R113F*

100

Unbalanced non-relieving, poppet / piston kit PS428P

6

Secondary Pressure - (psig)

Secondary Pressure - (bar)

Unbalanced relieving, poppet / piston kit PS426P 80

5

1-15 psig spring (yellow) P01176

4 60

1-30 psig spring (black) P01175

1-60 psig spring (white) P01174 3

40

Precision

2-125 psig spring (gold) P01173 2

20

* Tighten panel mount nut 2.8 to 3.4 Nm (25 to 30 in-lbs) of torque. 1

1/4 Inch Ports

100 psig (6.9 bar) Primary Pressure

0 0

1.65 1.65 0 5 10 15 20 25 30 35 40

(42) (42) Rated Flow - (scfm)

0 2 4 6 8 10 12 14 16 18

3

1.56 Flow - (dm /s)

n

(40) 1.56

(40)

Water

! WARNING

1/8" NPT 2.50

Gauge Ports (63.5) 2.28 Product rupture can cause serious injury.

(2) 2.88 (57.9) Do not connect regulator to bottled gas.

(73) 2.68 Do not exceed Maximum primary pressure rating.

(68)

K

0.38 0.38

CAUTION:

14R 14R**L*

Regulator

Products

(10) (10) REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

2.36 regulators, and limiting devices may be obtained only by special design. For

(60) best performance, regulated pressure should always be set by increasing

2.98 the pressure up to the desired setting.

(73)

1.50 0.50 0.12

(38) (13) (0.003)

INLET 1.188

(30.18) OUTLET

0.594 (15)

1.188 1.50

(30.18) (38)

0.379 C'Bore

.048 / .056 Deep

2 Places 0.094 (0.002)

0.325 Roll Pin

0.180 (4.6mm) Dia.

4 Holes (8) 0.725

Inches (mm) 14RM (18)

K3 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

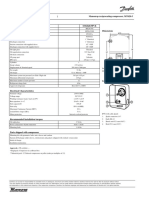

P3A-R Regulators – Miniature

General

• Lightweight plastic body

• Non-rising adjusting knob

• Solid control piston with lip seal for extended life

• Unbalanced poppet standard

• Two full flow 1/8" gauge ports

Dial

• Reverse flow capability

• 1/8", 1/4" ports (NPT)

Operating information

Pilot

Supply pressure (max): 120 psig (8.3 bar)

Secondary pressure:

15 psig spring 1 to 15 psig (0.07 to 1.0 bar)

Port 30 psig spring 6 to 30 psig (0.4 to 2.1 bar)

size Description Part number 60 psig spring 6 to 60 psig (0.4 to 4.1 bar)

Proportional

1/8" Without gauge P3A-RN91YNNN 110 psig spring 6 to 110 psig (0.4 to 7.6 bar)

1/8" With gauge P3A-RN91YGNN Operating temperature: 32°F to 125°F (0°C to 52°C)

Flow capacity†:

1/4" Without gauge P3A-RN92YNNN High flow 1/8" 13 scfm (6.1 dm3/s, ANR)

1/4" With gauge P3A-RN92YGNN 1/4" 15 scfm (7.1 dm3/s, ANR)

Gauge ports (2): 1/8 inch

NOTE: 1.218 Dia. (31 mm) hole required for panel mounting.

Weight: 0.3 lb (0.14 kg)

Precision

†

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow secondary

setting and 10 psig pressure drop.

Ordering information:

P3A-RN 9 1 Y N N N

Water

Port Type Preset / Pressure Limited

NPT Female 9 Blank None

XXX* Preset pressure

Port Size

XXX* Pressure limited

1/8 inch 1

* Available preset / pressure limited

K 1/4 inch

Relief

2 range, 10 to 90 psig in 5 psig

increments. For higher pressures,

contact factory.

Non-relieving, black knob B (Example: 065 = 65 psig)

Products

Regulator

Relieving, black knob N

Non-relieving, yellow knob Q Option

Relieving, Yellow knob Y N None

Pressure / Gauge Options

Without gauge

N No options

15 psig (0 to 1 bar) A

L† Preset non-adjustable

30 psig (0 to 2 bar) Y

P† Preset adjustable

60 psig (0 to 4 bar) L

S† Pressure limiter max. adjustable

120 psig (0 to 8 bar) N

T† Pressure limiter max. non-adjustable

With gauge † Inlet pressure is 100 psig. For other pressures

15 psig (0 to 1 bar) B contact factory.

30 psig (0 to 2 bar) Z

60 psig (0 to 4 bar) M

120 psig (0 to 8 bar) G

Most popular.

K4 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting nut Brass

1/8" port

Adjusting stem & spring Steel

Relief And Flow Characteristics

Poppet return spring Stainless Steel P3A-RN91YNN

100

Body Plastic 6

1/8 Inch Ports

100 psig (6.9 bar)

Secondary Pressure - (psig)

Secondary Pressure - (bar)

Primary Pressure

Bonnet, seat & piston Plastic 80

5

Seals Nitrile

Dial

4 60

Valve poppet Plastic & nitrile

3

40

2

Repair and Service Kits 20

1

30 psig gauge, 1/8" NPT (0 to 2.1 bar) K4515N18030

0 0

60 psig gauge, 1/8" NPT (0 to 4.1 bar) K4515N18060 =5 0 5 10 15 20 25 30 35

Pilot

Rated Flow - (scfm)

160 psig gauge, 1/8" NPT (0 to 11.0 bar) K4515N18160 2 0 2 4 6 8 10 12 14 16

3

Mounting bracket kit* (includes panel mount nut) PS417BP Flow - (dm /s)

n

Panel mount nut* P78652

1/4" port

Unbalanced non-relieving, poppet / piston kit PS428P

Proportional

Relief And Flow Characteristics

Unbalanced relieving, poppet / piston kit PS426P P3A-RN92YNN

100

1/4 Inch Ports

1-15 psig Spring (yellow) P01176 6 100 psig (6.9 bar)

Secondary Pressure - (psig)

Secondary Pressure - (bar)

80 Primary Pressure

1-30 psig spring (black) P01175 5

1-60 psig spring (white) P01174 60

4

5-110 psig spring (gold) P01173

3

40

* Tighten panel mount nut 2.8 to 3.4 Nm (25 to 30 in-lbs) of torque.

Precision

2

20

1

0 0

-5 0 5 10 15 20 25 30 35

1.57 Rated Flow - (scfm)

(40) 2 0 2 4 6 8 10 12 14 16

3

Flow - (dm /s)

n

Water

1.57

(40)

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

1/8" NPT

Gauge Ports

K

(2) 2.46 CAUTION:

(63) 2.92

Regulator

Products

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

(74) adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

regulators, and limiting devices may be obtained only by special design. For

0.46 best performance, regulated pressure should always be set by increasing

(12) the pressure up to the desired setting.

Inches (mm)

K5 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

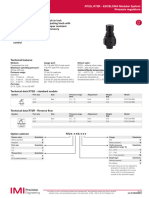

R34 Regulators – Miniature

General

• Diaphragm operated for fast response

• Large diaphragm to valve area ratio for precise regulation

and high flow capacity

• Balanced valve design for precise regulation

• Available in 2 or 4 port design

Dial

• Available with a manifold mount to minimize plumbing

• Suitable for low temperature applications

• Non-rising adjusting knob

• 1/8", 1/4" ports (NPT, BSPP)

Pilot

R344-02C R342-0MC

Relieving Non-Relieving

Part number

Proportional

Port

size Description Without gauge With gauge

Operating information

1/8" Relieving, 0 to 30 psig R344-01A R344-01AG Supply pressure (max): 300 psig (0 to 20.7 bar)

1/8" Relieving, 0 to 60 psig R344-01B R344-01BG Operating temperature: -40°F to 150°F (-40°C to 65.5°C)

Flow capacity†:

1/8" Relieving, 0 to 125 psig R344-01C R344-01CG

High flow 1/8" 17 scfm (8.0 dm3/s, ANR)

1/4" Relieving, 0 to 30 psig R344-02A R344-02AG 1/4" 19 scfm (8.9 dm3/s, ANR)

Precision

1/4" Relieving, 0 to 60 psig R344-02B R344-02BG Gauge ports (2): 1/8 inch

(no gauge port version available)

1/4" Relieving, 0 to 125 psig R344-02C R344-02CG

Weight: 0.25 lb (0.11 kg)

Manifold Relieving, 0 to 30 psig R342-0MA – †

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow

Manifold Relieving, 0 to 60 psig R342-0MB – secondary setting and 10 psig pressure drop.

Manifold Relieving, 0 to 125 psig R342-0MC –

Water

Ordering information:

R34 4 – 02 C G

Number of Ports Preset

K 2 Ports

4 Ports

2

4*

Blank

XXX*

None

Preset pressure

* Not available with manifold mount. * Available preset / pressure limited range,

Products

Regulator

10 to 90 psig in 5 psig increments. For

Thread higher pressures, contact factory.

(Example: 065 = 65 psig)

NPT –

BSPP G Options

Blank No options

Port L† Preset non-adjustable

1/8 inch 01 M† Preset adjustable

1/4 inch 02 † Inlet pressure is 100 psig. For other

Manifold mount 0M pressures contact factory.

Options

Pressure range Blank No option

0 to 30 psi A G Gauge

0 to 60 psi B K Non-relieving diaphragm

0 to 125 psi C N Unbalanced

P Panel mount nut

X64 Fluorocarbon elastomers

Most popular.

K6 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

Material Specifications Flow Charts

General

Body Aluminum

1/8" Manifold Mount

Bonnet Acetal Relief And Flow Characteristics

R342-0MC

Diaphragm & seals Nitrile 100

1/8 Inch Ports

Valve assembly Brass 90 100 psig (6.9 bar) Primary Pressure

Secondary Pressure - (psig)

6

Secondary Pressure - (bar)

80

Springs Steel

5 70

Panel Nut Acetal

60

4

Dial

50

Repair and Service Kits 3

40

30

Diaphragm assembly, non-relieving GRP-96-726 2

20

Diaphragm assembly, relieving GRP-96-725 1

10

0 to 30 psig (0 to 2.1 bar), spring, regulating GRP-95-111 0 0

0 5 10 15 20 25

0 to 60 psig (0 to 4.1 bar) spring, regulating GRP-96-718 Rated Flow - (scfm)

Pilot

0 to 125 psig (0 to 8.6 bar) spring, regulating GRP-96-717 0 2 4 6

3

8 10

Flow - (dm /s)

Panel mount nut, aluminum R05X51-A n

Panel mount nut, plastic R05X51-P 1/8" Port

Relief And Flow Characteristics

Mounting bracket kit (includes panel mount nut) SA161X57 R344-01C

Proportional

100

1-1/2" Dial Face, 1/8 NPT, CBM, 1/8 Inch Ports

90 100 psig (6.9 bar)

0 to 60 psig (0 to 4.1 bar), gauge K4515N18060

Secondary Pressure - (psig)

6

Secondary Pressure - (bar)

Primary Pressure

80

1-1/2" Dial Face, 1/8 NPT, CBM, 5 70

0 to 160 psig (0 to 11.0 bar), gauge K4515N18160

60

4

Tamperproof knob kit P31KB00AT 50

3

40

1.54 2 30

R342 / R344

Precision

(39.2) 20

1

10

0 0

0 5 10 15 20 25

Rated Flow - (scfm)

0 2 4 6 8 10

3

Flow - (dm /s)

n

1/4" Port

Water

Relief And Flow Characteristics

2.70 R344-02C

100

(68.6) 1/4 Inch Ports

90 100 psig (6.9 bar)

Secondary Pressure - (psig)

3.25 6

Secondary Pressure - (bar)

Primary Pressure

80

(82.6)

5 70

I 60

N 4

3

50

40

30

K

2

Regulator

Products

20

R342-0MC 1

10

0 0

2.75 0 5 10 15 20 25

(69.9) Rated Flow - (scfm)

3.25 0 2 4 6 8 10

(82.6) 3

Flow - (dm /s)

n

! WARNING

.50 (12.7) Product rupture can cause serious injury.

1.20 Do not connect regulator to bottled gas.

(30.5) 4.57 (116.08mm) Dia. Do not exceed Maximum primary pressure rating.

.60

(15.2) 4 Holes

.60 CAUTION:

1.50 (15.2) 1.188

(38.1) REGULATOR PRESSURE ADJUSTMENT – The working range of knob

(30.18) adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

INLET OUTLET is not a limiting device. This is a common characteristic of most industrial

0.32 regulators, and limiting devices may be obtained only by special design. For

(8.1) 0.73

(18.5) best performance, regulated pressure should always be set by increasing

Inches (mm) the pressure up to the desired setting.

K7 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

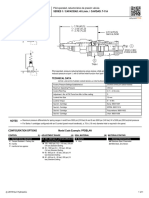

R25 Regulators – Miniature

General

• Lightweight plastic body

• Unbalanced poppet standard

• Non-rising, push-to-lock adjusting knob

• Compact, 3.10 Inch (79 mm) high by 1.60 Inch (41 mm)

wide

Dial

• Lightweight

• Diaphragm operated

• 1/8", 1/4" ports (NPT)

Pilot

Operating information

Proportional

Supply pressure (max): Inlet 150 psig (10.0 bar)

Port Operating temperature: 40°F to 125°F (4°C to 52°C)

size Description Part number

Gauge ports (2): 1/8 inch

Relieving, 0-125 reduced pressure, (can be used for full flow)

1/8" R25-01C

without gauge Weight: 0.25 lb (0.11 kg)

Relieving, 0-125 reduced pressure,

Precision

1/4" R25-02C

without gauge

NOTE: 1.250 Dia. (31.8 mm) hole required for panel mounting.

Water

Ordering information:

R25 – 02 C

K Type

Buna Elastomers R25 Blank

Relief

Relieving

P Panel Mount Nut

Products

Regulator

Port Size

1/8 inch 01 Pressure Range

1/4 inch 02 A 0 to 25 psig (0 to 2 bar)

B 0 to 60 psig (0 to 4 bar)

C 0 to 125 psig (0 to 125 (0 to 8 bar)

Most popular.

K8 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting screw Steel

Air Flow Characteristics

Body Acetal R25-02CK

100

Bonnet and seat Acetal

100 psig (6.9 bar)

Diaphragm Buna N Primary Pressure

Reduced Pressure (psig)

75

Seals Buna N

Springs Stainless steel

50

Dial

Valve poppet Buna N

25

Repair and Service Kits

0

Panel mount nut, plastic R05X51-P 0 5 10 15

Rated Flow - (scfm)

Panel mount nut, aluminum R05X51-A

Pilot

0 2 4 6

Mounting bracket and nut SA161X57 Flow - (dm /s)

3

n

Relieving (Buna) RKR25Y

Non-Relieving (Buna) RKR25KY

0-25 psig spring SPR-375-1

Proportional

0-60 psig spring SPR-376 ! WARNING

0-125 psig spring SPR-377 Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

CAUTION:

Precision

1.60 REGULATOR PRESSURE ADJUSTMENT – The working range of knob

(41)

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

regulators, and limiting devices may be obtained only by special design. For

- + 1.60 best performance, regulated pressure should always be set by increasing

(41)

PU

CK

SH the pressure up to the desired setting.

–L O

Water

1/8" NPT 2.61

Gauge Ports (66)

(2) 3.10

(79)

K

Regulator

Products

0.49

Inches (mm) (13)

K9 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

R45 Regulators – Miniature

General

• Lightweight plastic body

• Unbalanced poppet standard

• Non-rising, push-to-lock adjusting knob

• Compact, 3.43 inch (87.1 mm) high by 2.06 inch (52.3 mm)

wide

Dial

• Lightweight

• Diaphragm operated

• 1/4", 3/8" ports (NPT, BSPP)

Pilot

Operating information

Proportional

Port Supply pressure (max): Inlet 150 psig (10.0 bar)

size Description Part number

Operating temperature: 40°F to 125°F (4°C to 52°C)

Relieving, 0-125 reduced pressure, Gauge ports (2): 1/4 inch

1/4" R45-02C

without gauge (can be used for full flow)

Relieving, 0-125 reduced pressure, Weight: 0.38 lb (0.17 kg)

3/8" R45-03C

without gauge

Precision

NOTE: 1.250 Dia. (31.8 mm) hole required for panel mounting.

Water

Ordering information:

R45 – 02 C

K Type

Buna Elastomers R45 Blank

Relief

Relieving

P Panel Mount Nut

Products

Regulator

Port Size

1/4 inch 02 Pressure Range

3/8 inch 03 A 0 to 25 psig (0 to 2 bar)

B 0 to 60 psig (0 to 4 bar)

C 0 to 125 psig (0 to 8 bar)

Most popular.

K10 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Miniature Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting screw Steel

Body Acetal Air Flow Characteristics

R45

100

Bonnet and seat Acetal

6 100 psig (6.9 bar)

Diaphragm Buna N Primary Pressure

Secondary Pressure - (psig)

Secondary Pressure - (bar)

80

5

Seals Buna N

4

Springs Stainless steel 60

Dial

Valve Poppet Buna N 3

40

20

Repair and Service Kits 1

Panel mount nut, plastic R05X51 0 0

0 5 10 15 20 25 30 35 40 45 50 55 60

Panel mount nut, aluminum R05X51-A Rated Flow - (scfm)

Pilot

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28

Mounting bracket and nut SA161X57 3

Flow - (dm /s)

n

Relieving RKR45Y

Non-Relieving RKR45KY

0-25 psig spring SPR-46 ! WARNING

Proportional

0-60 psig spring SPR-47 Product rupture can cause serious injury.

0-125 psig spring SPR-48 Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

2.06 CAUTION:

(52)

Precision

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

regulators, and limiting devices may be obtained only by special design. For

- + 2.06 best performance, regulated pressure should always be set by increasing

(52)

PU

CK

SH

–L O

the pressure up to the desired setting.

Water

1/4" NPT

Gauge Ports 2.90

(2) (74)

3.43

(87)

K

Regulator

Products

0.53

(14)

Inches (mm)

K11 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Economy Regulators Regulator Products

15R Regulators – Economy

General

• Solid control piston with resilient seat for service-free

operation

• Non-rising “locking” adjusting knob

• Compact, 3.30 inch (84 mm) high by 2.12 inch (54 mm) wide

• Easily serviced

Dial

• 1/4", 3/8" ports (NPT)

Pilot

Operating information

Port

size Description Part number Supply pressure (max): 0 to 250 psig (0 to 17.2 bar)

Secondary pressure ranges

Proportional

1/4" Without gauge 15R113FB

Standard 2 to 125 psig (0 to 8.6 bar)

1/4" With gauge 15R118FB Medium 1 to 60 psig (0 to 4.1 bar)

Medium 1 to 30 psig (0 to 1.7 bar)

3/8" Without gauge 15R213FB Low 1 to 15 psig (0 to 1 bar)

3/8" With gauge 15R218FB Operating temperature: 32°F to 125°F (0°C to 52°C)

Low temperature -4°F to 125°F (-20°C to 52°C)

NOTE: 1.218 Dia. (31 mm) hole required for panel mounting.

Flow capacity†:

High flow 1/4" 21 scfm (9.9 dm3/s, ANR)

Precision

3/8" 28 scfm (13.2 dm3/s, ANR)

Gauge ports (2): 1/4 inch

(can be used at full flow)

Weight: 0.5 lb (0.23 kg)

†

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow secondary

setting and 10 psig pressure drop.

Water

Ordering information:

15R 1 13 F B

K Port Size Engineering Level

1/4 inch 1 B Current

Products

Regulator

3/8 inch 2

Relief

Pressure Range F Relieving

Without gauge G Non-relieving

15 psig 12 H Low temp relieving

30 psig 10 J Low temp non-relieving

60 psig 11

125 psig 13

With gauge

15 psig 17

30 psig 15

60 psig 16

125 psig 18

Most popular.

K12 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Economy Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting nut Brass

Adjusting stem & spring Steel 1/4" Regulator

Relief And Flow Characteristics

Body Zinc 15R113F*

100

Bonnet, seat, piston & valve poppet Plastic

Secondary Pressure - (psig)

6

Secondary Pressure - (bar)

Seals Nitrile 80

5

Dial

4 60

Repair and Service Kits 3

40

Body Service Kit – Unbalanced PS424BP

2

Bonnet Assembly Kit L01369 20

1

1/4 Inch Ports

30 psig, 1/8" NPT (0 to 2.1 bar) gauge K4515N18030 100 psig (6.9 bar) Primary Pressure

0 0

60 psig, 1/8" NPT (0 to 4.1 bar) gauge K4515N18060 -7 0 7 14 21 28 35 42 49 56

Rated Flow - (scfm)

Pilot

160 psig, 1/8" NPT (0 to 11.0 bar) gauge K4515N18160 2 0 2 4 6 8 10 12 14 16 18 20 22 24 26

3

Flow - (dm /s)

60 psig, 1/4" NPT (0 to 4.1 bar) gauge K4520N14060 n

160 psig, 1/4" NPT (0 to 11.0 bar) gauge K4520N14160

3/8" Regulator

Mounting bracket kit* (Includes panel mount nut) PS417BP Relief And Flow Characteristics

Proportional

15R213F*

Panel mount nuts*, plastic P78652 100

Panel mount nuts*, metal P01531

Secondary Pressure - (psig)

6

Secondary Pressure - (bar)

80

Poppet / piston kit, unbalanced, non-relieving PS428P 5

Poppet / piston kit, unbalanced, relieving PS426P 60

4

Seal, unbalanced PS454B

3

40

1-15 psig spring (yellow) P01176

Precision

2

1-30 psig spring (black) P01175 20

1

1-60 psig spring (white) P01174 3/8 Inch Ports

100 PSIG (6.9 bar) Primary Pressure

0 0

2-125 psig spring (gold) P01173 -7 0 7 14 21 28 35 42 49 56

Rated Flow - (scfm)

* Tighten panel mount nut 2.8 to 3.4 Nm (25 to 30 in-lbs) of torque. 2 0 2 4 6 8 10 12 14 16 18 20 22 24 26

3

Flow - (dm /s)

n

Water

2.12

(54)

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

2.00 Do not exceed Maximum primary pressure rating.

(51)

K

Regulator

Products

CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

2.60 is not a limiting device. This is a common characteristic of most industrial

1/4" NPT regulators, and limiting devices may be obtained only by special design. For

Gauge Ports (66)

(2)

best performance, regulated pressure should always be set by increasing

3.30

(84)

the pressure up to the desired setting.

0.70

Inches (mm) (18)

K13 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Semi-Precision Regulators Regulator Products

27R Regulators – Semi-Precision

General

• Fine adjustment sensitivity

• Good repeatability and minimal pressure drop

• High flow capacity

• Two 1/4" gauge ports

• Brass Poppet for long life

Dial

• Modular with 05 Series FRL

• Non-rising, removable knob

• Multiple porting options

• 1/4", 3/8" ports (NPT, BSPP, BSPT)

Pilot

Operating information

Bleed rate: 0.033 scfm (0.016 dm3/s, ANR)

Effect of supply variation: 0.5 psig (0.04 bar) for

25 psig (1.7 bar) change P1

Proportional

Relief capacity: 0.5 scfm (0.24 dm3/s, ANR) @

5 psig (0.4 bar) increase P2

Port Flow capacity†: 28 scfm (13.2 dm3/s, ANR) @

size Description Part number 100 psig (6.9 bar) P1 and

20 psig (1.4 bar) P2

1/4" 15 psig 27R112AD

Inlet pressure (max): 250 psig (17.2 bar)

1/4" 30 psig 27R110AD Temperature rating: 32°F to 175°F (0°C to 80°C)

Precision

1/4" 60 psig 27R114AD Relief flow: 5.0 scfm (2.4 dm3/s, ANR)

1/4" 125 psig 27R113AD Repeatability: .5 psig (0.034 bar)

NOTE: 1.53 Dia. (39 mm) hole required for panel mounting. Max panel Response: 510 ms

thickness 1/4" The valve will open to full flow and

fill a volume of 100 in3

Gauge ports (2): 1/4 inch

Weight: 1.0 lb (0.45 kg)

Water

†

scfm = Standard cubic feet per minute at 150 psig inlet, 90 psig no flow

secondary setting and 5 psig pressure drop.

Ordering information:

27R 1 10 A D

K Port Size Engineering Preset / Pressure Limited

1/4 inch 1 Level Blank None

Products

Regulator

3/8 inch 2 Current D XXX* Preset pressure

XXX* Pressure limited

Pressure Range * Available preset / pressure

limited range, 10 to 90 psig in

Without gauge

5 psig increments. For higher

15 psig 12 Port Type pressures, contact factory.

30 psig 10 NPT Blank (Example: 065 = 65 psig)

60 psig 14 BSPP 1

125 psig 13 BSPT 2 Options

Blank No options

Relief L† Preset non-adjustable

Relieving A P† Preset adjustable

S† Pressure limiter max. adjustable

T† Pressure limiter max. non-adjustable

† Inlet Pressure is 100 psig. For other pressures, contact

factory.

Most popular.

K14 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Semi-Precision Regulators Regulator Products

Material Specifications Flow Charts

General

Poppet Brass

1/4" Regulator

Bonnet Plastic 30 psig spring Flow Characteristics

27R110A* 1/4 Inch Ports

Body Zinc 100 psig (6.9 bar) Primary Pressure

30

Collar, knob Plastic 2.0

Secondary Pressure - (psig)

Diaphragm Nitrile

Secondary Pressure - (bar)

25

1.5

Bottom Cap Plastic 20

Dial

Seals Nitrile

1.0 15

Springs – poppet & control Steel

10

.5

Repair and Service Kits 5

Bonnet assembly kit PS910P

0 0

Pilot

0 5 10 15 20 25 30

Control knob P0442001 Rated Flow - (scfm)

1-1/2" dial face 30 psig (0 to 2.1 bar), gauge K4515N14030 0 2 4 6 8 10 12 14

3

1-1/2" dial face 60 psig (0 to 4.1 bar), gauge K4515N14060 Flow - (dm /s)

n

1-1/2" dial face 160 psig (0 to 11.0 bar), gauge K4515N14160

1/4" Regulator

Proportional

1-1/2" dial face 300 psig (0 to 20.7 bar), gauge K4515N14300

60 psig spring Flow Characteristics

2" dial face 60 psig (0 to 4.1 bar), gauge K4520N14060 27R114A* 1/4 Inch Ports

100 psig (6.9 bar) Primary Pressure

2" dial face 160 psig (0 to 11.0 bar), gauge K4520N14160 45

3.0

2" dial face 300 psig (0 to 20.7 bar), gauge K4520N14300

Secondary Pressure - (psig)

Secondary Pressure - (bar)

37.5

Mounting bracket kit PS963P

30

2.0

Panel mount nut, metal PS964P

Precision

Service kit PS907P 22.5

1-30 psig spring P04427 1.0 15

1-15 psig spring P04428

7.5

0-60 psig spring P04426

0 0

2-125 psig spring P04425 0 5 10 15 20 25 30

Rated Flow - (scfm)

0 2 4 6 8 10 12 14

Water

3

2.00 Flow - (dm /s)

(51) n

1/4" Regulator

125 psig spring

2.06 Flow Characteristics

(52) 27R113A* 1/4 Inch Ports

U 100 psig (6.9 bar) Primary Pressure

P

K

K

SH C

TO L O 90

6.0

Secondary Pressure - (psig)

Secondary Pressure - (bar)

75

5.0

Regulator

Products

60

1/4" NPT 4.0

Gauge Ports

(2) 3.0 45

3.16 30

2.0

(80)

4.44 1.0 15

(113)

0 0

0 5 10 15 20 25 30

Rated Flow - (scfm)

0 2 4 6 8 10 12 14

1.28

3

(32) Flow - (dm /s)

n

CAUTION:

! WARNING REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Product rupture can cause serious injury. Pressure adjustment beyond this range is also possible because the knob

Do not connect regulator to bottled gas. is not a limiting device. This is a common characteristic of most industrial

Do not exceed Maximum primary pressure rating. regulators, and limiting devices may be obtained only by special design. For

best performance, regulated pressure should always be set by increasing

the pressure up to the desired setting.

K15 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Mini Regulators Regulator Products

P31 Regulators – Mini

General

• Integral 1/4" ports (NPT, BSPP & BSPT)

• Robust but lightweight aluminum construction

• Secondary pressure ranges

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation.

Dial

• Relieving & non-relieving types

• Non-rising knob

Pilot

3

Operating information

1 2

1 2 Flow capacity*: 1/4 68 scfm (32 dm3/s, ANR)

†

Operating temperature : -4°F to 150°F (-20°C to 65.5°C)

Self relieving regulator Non-relieving regulator Supply pressure (max): 300 psig (20 bar)

Proportional

with gauge Adjusting range pressure: 30 psig (0-2 bar)

60 psig (0-4 bar)

125 psig (0-8 bar)

232 psig (0-16 bar)

Port Description Gauge port (2 each)** 1/8 BSPP, BSPT, NPT

size (relieving) Gauge Part number Weight: 0.37 lb (0.17 kg)

1/4" 125 psig (8 bar) None P31RB92BNNP * Inlet pressure 145 psig (10 bar). Secondary pressure 91.3 psig (6.3 bar).

Precision

** Non-gauge option only.

1/4" 125 psig (8 bar) Square P31RB92BN5P † Units with square gauges: 5°F to 150°F (-15°C to 65.5°C)

Ordering Information:

Water

P31RB 9 2 B N 5 P

Basic series Thread type Mounting

Global modular BSPP 1 P Plastic panel mount nut

K mini regulator

P31RB

BSPT

NPT

2

9

Adjustment range

With square gauge With round gauge

Products

Regulator

Port size psig bar Z 30 psig; 2 bar; 0.2 MPa

1/4 2 1 = 30* V = 2* M 60 psig; 4 bar; 0.4 MPa

3 = 60 S = 4 G 125 psig; 8 bar; 0.8 MPa

Relief

5 = 125 T = 8 J 232 psig; 16 bar; 1.6 MPa

Relieving B

* Regulator comes with gauge respective Without gauge

Non-relieving N

to the adjustment range selected. Y 30 psig; 2 bar; 0.2 MPa

Reverse flow-relieving R

L 60 psig; 4 bar; 0.4 MPa

Adjustment N 125 psig; 8 bar; 0.8 MPa

N Non-rising knob H 232 psig; 16 bar; 1.6 MPa

Most popular.

K16 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Mini Regulators Regulator Products

Material Specifications Flow Charts

General

Body Aluminum

1/4 Regulator

Adjustment knob Acetal Inlet Pressure - 10 bar (145 psig)

10

140

Bonnet PBT 9

Secondary Pressure - (psig)

120

Secondary Pressure - (bar)

8

Diaphragm assembly Brass / Nitrile 8.0 bar

100 7

116 psig

Valve assembly Brass / Nitrile 6

80 6.3 bar

Springs Steel 5 91.4 psig

60

Dial

4

Seals Nitrile 40 3

4.0 bar

Panel nut Acetal 2 58 psig

20 2.5 bar

1 36.3 psig

0 0

0 5 10 15 20 25 30 35 40

Repair and Service Kits Flow - (dm 3/s)

n

0 10 20 30 40 50 60 70 80

Diaphagm repair kit - relieving P31KB00RB Flow - (scfm)

Pilot

Diaphagm repair kit - non-relieving P31KB00RC

Panel mount nut - aluminum P31KA00MM

Panel mount nut - plastic P31KA00MP ! WARNING

Angle bracket (attaches via panel nut) P31KB00MR Product rupture can cause serious injury.

Proportional

C-bracket (fits to body) P31KA00MW Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

T-bracket with body connector P31KA00MT

Body connector P31KA00CB

CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

Precision

regulators, and limiting devices may be obtained only by special design. For

best performance, regulated pressure should always be set by increasing

3.00 Round

the pressure up to the desired setting.

(76.3) Gauge

2.41 Square

(61.3) Gauge

1.58

(40)

1.58 0.79

Gauges

(40) (20) Square flush 0-4 bar K4511SCR04B

Water

mount gauge 0-11 bar K4511SCR11B

1.20

(30.6) 0-60 psig K4511SCR060

2.24 0-160 psig K4511SCR160

(56.8)

4.10

Square with 0-4 bar P6G-PR10040

(104.1) adapter kit 0-11 bar P6G-PR10110

0-60 psig P6G-PR90060 K

0-160 psig P6G-PR90160

Regulator

Products

1.00" Round 1/8" 0-60 psig / 0-4 bar K4510N18060

center back mount 0-160 psig / 0-11 bar K4510N18160

Inches (mm) 40mm Round 1/8" 0-30 psig / 0-2 bar K4515N18030

center back mount 0-60 psig / 0-4 bar K4515N18060

NOTE: 1.20 in. (30mm) hole required (Not for use with common

for panel nut mounting. port regulators) 0-160 psig / 0-11 bar K4515N18160

For best performance, regulated pressure should always be set by increasing the

pressure up to the desired setting.

K17 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Mini Common P1 Regulators Regulator Products

P31 Common P1 Regulators – Mini

General

P2

P2

• Manifold style regulator with line pressure on both sides P2

P2

• Pressure output is at front or rear

P1

• Inlet port 1/4" (NPT, BSPP & BSPT)

• Working port 1/8" P1

• Robust construction

Dial

• Secondary pressure ranges

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation

• Relieving & non-relieving types

• Non-rising knob

Pilot

P1

P2 P2 P2 P2

Proportional

3 1 2

1 2 Operating information

Flow capacity*:

Self relieving regulator Non-relieving regulator 1/4 42 scfm (20 dm3/s, ANR)

with gauge Operating temperature: -4°F to 150°F (-20°C to 65.5°C)

Supply pressure (max): 300 psig (20 bar)

Precision

Adjusting range pressure: 30 psig (0-2 bar)

60 psig (0-4 bar)

125 psig (0-8 bar)

232 psig (0-16 bar)

Port Description P1 port size (inlet/outlet) 1/4 NPT, BSPP, BSPT

size (relieving) Gauge Part number

P2 regulated ports (2 ea.) 1/8 NPT, BSPP, BSPT

1/4" 125 psig (8 bar) None P31HB92BNNP Weight: 0.66 lb (0.30 kg)

Water

1/4" 125 psig (8 bar) Square P31HB92BN5P * Inlet pressure 145 psig (10 bar). Secondary pressure 91.3 psig (6.3 bar).

Ordering Information:

K P31HB 9 2 B N 5 P

Products

Regulator

Basic series Thread type Mounting

Global modular mini BSPP 1 P Plastic panel mount nut

P31HB

common regulator BSPT 2

Adjustment range

NPT 9

With square gauge With round gauge

Port size † psig bar Z 30 psig; 2 bar; 0.2 MPa

1/4 2 1 = 30* V = 2* M 60 psig; 4 bar; 0.4 MPa

† Working port 1/8". 3 = 60 S = 4 G 125 psig; 8 bar; 0.8 MPa

Relief 5 = 125 T = 8 J 232 psig; 16 bar; 1.6 MPa

Relieving B * Regulator comes with gauge respective Without gauge

to the adjustment range selected. Y 30 psig; 2 bar; 0.2 MPa

Non-relieving N

Reverse flow-relieving R L 60 psig; 4 bar; 0.4 MPa

Adjustment

N 125 psig; 8 bar; 0.8 MPa

N Non-rising knob

H 232 psig; 16 bar; 1.6 MPa

Most popular.

K18 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Mini Common P1 Regulators Regulator Products

Materials of Construction Flow Charts

General

Body Aluminum

1/4 Common Regulator

Adjustment knob Acetal

Inlet Pressure - 10 bar (145 psig)

10

Bonnet Glass-filled PBT 140

9

Secondary Pressure - (psig)

Diaphragm assembly Brass / Nitrile 120

Secondary Pressure - (bar)

8

100 7

Valve assembly Brass / Nitrile

6

80

5

8.0 bar

Dial

60 4 116 psig

Repair and Service Kits 40 3 6.3 bar

91.4 psig

2

Diaphagm repair kit - relieving P31KB00RB 20 2.5 bar 4.0 bar

1

36.3 psig 58 psig

Diaphagm repair kit - non-relieving P31KB00RC 0 0

0 5 10 15 20 25 30 35

Flow - (dm 3/s)

Panel mount nut - aluminum P31KA00MM n

0 10 20 30 40 50 60 70

Panel mount nut - plastic P31KA00MP Flow - (scfm)

Pilot

Angle bracket (attaches via panel nut) P31KB00MR

T-bracket with body connector P31KA00MT

Body connector P31KA00CB ! WARNING

Product rupture can cause serious injury.

Proportional

Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

1.58 is not a limiting device. This is a common characteristic of most industrial

Precision

(40) regulators, and limiting devices may be obtained only by special design. For

1.58 0.79 best performance, regulated pressure should always be set by increasing

(40) (20) the pressure up to the desired setting.

1.20

(30.6)

2.24 Gauges

(56.8)

Square with 0-4 bar P6G-PR10040

4.10

Water

(104.1) adapter kit 0-11 bar P6G-PR10110

0-60 psig P6G-PR90060

0-160 psig P6G-PR90160

1.00" round 1/8" 0-60 psig / 0-4 bar K4510N18060

center back mount 0-160 psig / 0-11 bar K4510N18160

Inches (mm)

For best performance, regulated pressure should always be set by increasing the

pressure up to the desired setting. K

NOTE: 1.20 in. (30mm) hole required

Regulator

Products

for panel nut mounting.

K19 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Economy Regulators Regulator Products

05R Regulators – Economy

General

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation.

• Rolling diaphragm for extended life.

• Removable non-rising knob for panel mounting

and tamper resistance.

Dial

• Easily serviced.

• Reverse Flow.

• 1/4", 3/8" ports (NPT, BSPP)

Pilot

Operating information

Supply pressure (max): 0 to 300 psig (0 to 20.7 bar)

Proportional

For secondary pressure ranges see charts next page.

Port Operating temperature: 32°F to 175°F (0°C to 80°C)

size Description Part number Low temperature -4°F to 125°F (-20°C to 52°C)

1/4" Without gauge 05R113A* Flow capacity†:

High flow 1/4" 30 scfm (14.2 dm3/s, ANR)

1/4" With 160 psi gauge 05R118A* 3/8" 40 scfm (18.9 dm3/s, ANR)

3/8" Without gauge 05R213A* Gauge ports (2): 1/4 inch

Weight: 1.1 lb (0.49 kg)

Precision

3/8" With 160 psi gauge 05R218A*

†

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow secondary

NOTE: 1.53 Dia. (39 mm) hole required for panel mounting. setting and 10 psig pressure drop.

Ordering information:

Water

05R 1 13 A D

Port Size Port Type

K 1/4 inch

3/8 inch

1

2

Blank NPT

Engineering Level

Products

Regulator

Pressure Range D Current

Without gauge

30 psig 10

Relief

60 psig 11

A Relieving

125 psig 13

200 psig 14

With gauge*

30 psig 15

60 psig 16

125 psig 18

200 psig 19

* Includes 1-1/2" dial face

gauge.

Most popular.

K20 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Economy Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting stem Brass

Bonnet Plastic 1/4" Regulator

Relief and Flow Characteristics

Body Zinc 05R113A*

120

Collar, Knob Plastic 8

Secondary Pressure - (psig)

105

Secondary Pressure - (bar)

7

Diaphragm Nitrile

6 90

Poppet & cap Plastic

Dial

5 75

Seals Nitrile

4 60

Springs – poppet & control Steel

3 45

2 30

Repair and Service Kits 1/4 Inch Ports

1 15

Bonnet assembly kit PS915P Primary Pressure 100 psig (6.9 bar)

0 0

Pilot

-10 0 10 20 30 40 50 60 70 80

Control knob P04420

Rated Flow - (scfm)

1-1/2" dial face 30 psig (0 to 2.1 bar), gauge K4515N14030 5 0 5 10 15 20 25 30 35

3

1-1/2" dial face 60 psig (0 to 4.1 bar), gauge K4515N14060 Flow - (dm /s)

n

1-1/2" dial face 160 psig (0 to 11.0 bar), gauge K4515N14160

Proportional

1-1/2" dial face 300 psig (0 to 20.7 bar), gauge K4515N14300 3/8" Regulator

2" dial face 60 psig (0 to 4.1 bar), gauge K4520N14060 Relief and Flow Characteristics

05R213A*

2" dial face 160 psig (0 to 11.0 bar), gauge K4520N14160 120

8

2" dial face 300 psig (0 to 20.7 bar), gauge K4520N14300 105

Secondary Pressure - (psig)

7

Secondary Pressure - (bar)

Mounting bracket kit PS963P 6 90

Panel mount nut – metal PS964P 5 75

Precision

1-30 psig spring P04427 4 60

1-60 psig spring P04426 3 45

2-125 psig spring P04425 2 30

2-200 psig spring P02934 1 15 3/8 Inch Ports

Primary Pressure 100 PSIG (6.9 bar)

Relieving service kit PS908P 0 0

-10 0 10 20 30 40 50 60 70 80

Rated Flow - (scfm)

Water

5 0 5 10 15 20 25 30 35

3

Flow - (dm /s)

n

2.00

(51)

2.06

U

(52)

K

P

! WARNING

K

SH C

TO L O

Product rupture can cause serious injury.

Regulator

Products

Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

1/4" NPT

Gauge Ports 3.16

(2) (80)

4.44

(133) CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

1.28 is not a limiting device. This is a common characteristic of most industrial

(32) regulators, and limiting devices may be obtained only by special design. For

best performance, regulated pressure should always be set by increasing

Inches (mm) the pressure up to the desired setting.

K21 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 (Revised 02-01-17) Air Preparation Products

Compact Regulators Regulator Products

06R Regulators – Compact

General

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation

• Rolling diaphragm for extended life

• Two high flow 1/4" gauge ports can be used as additional

outlets

Dial

• Easily serviced

• Removable non-rising knob for panel mounting

and tamper resistance

• 1/4", 3/8", 1/2" ports (NPT, BSPP)

Operating information

Pilot

Supply pressure (max): 250 psig (17.2 bar)

Secondary pressure ranges:

Standard 2 to 125 psig (0 to 8.6 bar)

Low 1 to 60 psig (0 to 4.1 bar)

Proportional

Port High 5 to 250 psig (0.4 to 17.2 bar)

size Description Part number Operating temperature: 32°F to 175°F (0°C to 80°C)

1/4" Without gauge 06R113AC Low temperature -4°F to 125°F (-20°C to 52°C)

Flow capacity†:

1/4" With 160 psi gauge 06R118AC High flow 1/4" 53 scfm (25 dm3/s, ANR)

3/8" Without gauge 06R213AC 3/8" 60 scfm (28.3 dm3/s, ANR)

1/2" 75 scfm (35.4 dm3/s, ANR)

3/8" With 160 psi gauge 06R218AC

Gauge ports (2): 1/4 inch

Precision

1/2" Without gauge 06R313AC (can be used as additional full

flow 1/4 inch outlet ports)

1/2" With 160 psi gauge 06R318AC

Weight: 1.6 lb (0.7 kg)

NOTE: 2.0 Dia. (51 mm) hole required for panel mounting. †

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow secondary

setting and 10 psig pressure drop.

Ordering information:

Water

06R 1 13 A C

Port Size Preset / Pressure Limited

1/4 inch 1 Blank None

K 3/8 inch

1/2 inch

2

3

XXX* Preset pressure

* Available preset / pressure limited range,

10 to 90 psig in 5 psig increments. For

Pressure Range higher pressures, contact factory.

Products

Regulator

(Example: 065 = 65 psig)

Without gauge

60 psig 11

Options

125 psig 13

Blank No option

250 psig 15

L† Preset non-adjustable

With gauge*

P† Preset adjustable

60 psig 16

R Reverse Flow

125 psig 18

† Inlet Pressure is 100 psig. For

250 psig 21 other pressures, contact factory.

* Includes 1-1/2" dial face gauge.

Relief Port Type

Spring Type by Preset / Limited Pressure: Relieving A Blank NPT

For Preset / Limited Pressure 26 to 50 use Non-relieving L 1* BSPP

60 psi spring * 1/4 & 3/8 inch meet

For Preset / Limited Pressure 51 to 90 use Engineering Level ISO 1179-1 Standard.

125 psi spring Current C

Most popular.

K21a Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 (Revised 02-01-17) Air Preparation Products

Compact Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting stem Steel 06R 1/4" Regulator

Body Zinc Relief And Flow Characteristics

06R113A*

Bonnet, piston stem, valve poppet & cap Plastic 100

6

Collar, knob Plastic

Secondary Pressure - (psig)

Secondary Pressure - (bar)

80

Diaphragm Nitrile 5

Seals Nitrile 4 60

Dial

Spring, poppet Stainless 3

40

Spring, control Steel 2

20

1

Repair and Service Kits 1/4 Inch Ports

100 psig (6.9 bar) Primary Pressure

0 0

Bonnet assembly kit PS715P -10 0 10 20 30 40 50 60 70

Rated Flow - (scfm)

Pilot

Control knob P04069B 5 0 5 10 15 20 25 30

3

Flow - (dm /s)

2" dial face 60 psig (0 to 4.1 bar), gauge K4520N14060 n

06R 3/8" Regulator

2" dial face 160 psig (0 to 11.0 bar), gauge K4520N14160 Relief And Flow Characteristics

06R213A*

2" dial face 300 psig (0 to 20.7 bar), gauge K4520N14300 100

Proportional

1-3/4" digital round face 6

Secondary Pressure - (psig)

K4517N14160D

Secondary Pressure - (bar)

160 psig (0 to 11.0 bar) gauge 80

5

Mounting bracket kit (includes panel mount nut) PS707P

60

Panel mount nut, plastic P04082 4

Panel mount nut, metal P04079B 3

40

Reverse flow service conversion kit, relieving PS708RP 2

PS708P

20

Precision

Relieving (includes poppet) 1

3/8 Inch Ports

100 psig (6.9 bar) Primary Pressure

Non-relieving (includes poppet) PS709P 0 0

-10 0 10 20 30 40 50 60 70

1-30 psig spring P01698 Rated Flow - (scfm)

1-60 psig spring P04062 5 0 5 10 15 20 25 30

Flow - (dm3/s)

2-125 psig spring P04063 n

06R 1/2" Regulator

5-250 psig spring P04064 Relief And Flow Characteristics

06R313A*

Water

Tamperproof kit PS737P 100

Secondary Pressure - (psig)

6

Secondary Pressure - (bar)

80

2.81 5

(71)

4 60

K

3

40

2.74 2

(70)

PU

CK

SH 20

TO LO 1

1/2 Inch Ports

Regulator

Products

100 psig (6.9 bar) Primary Pressure

0 0

-10 0 10 20 30 40 50 60 70 80 90

Rated Flow - (scfm)

5 0 5 10 15 20 25 30 35 40

3

Flow - (dm /s)

n

1/4" NPT

Gauge Ports

(2)

4.69

(119)

! WARNING

6.08

(154) Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating.

1.39

(35) CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

Inches (mm) adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

regulators, and limiting devices may be obtained only by special design. For

best performance, regulated pressure should always be set by increasing

the pressure up to the desired setting.

K21b Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Compact Regulators Regulator Products

P32 Regulators – Compact

General

• Integral 1/4", 3/8" or 1/2" ports (NPT, BSPP & BSPT)

• Robust but lightweight aluminum construction

• Secondary pressure ranges

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation

Dial

• Relieving & non-relieving types

• Non-rising knob

• Available T-handle

Pilot

3 1 2

1 2

Self relieving regulator Non-relieving regulator

Operating information

Proportional

with gauge

Flow capacity*:

1/4 148 scfm (70 dm3/s, ANR)

3/8, 1/2 165 scfm (78 dm3/s, ANR)

Port Description Operating temperature: -13°F to 150°F (-25°C to 65.5°C)

size (relieving) Gauge Part number

Supply pressure (max): 300 psig (20 bar)

1/4" 125 psig (8 bar) None P32RB92BNNP

Adjusting range pressure: 30 psig (0-2 bar)

Precision

1/4" 125 psig (8 bar) Round P32RB92BNGP 60 psig (0-4 bar)

125 psig (0-8 bar)

3/8" 125 psig (8 bar) None P32RB93BNNP

250 psig (0-17 bar)

3/8" 125 psig (8 bar) Round P32RB93BNGP Gauge port (2 each) 1/4 NPT, BSPP, BSPT

1/2" 125 psig (8 bar) None P32RB94BNNP Weight: 0.90 lb (0.41 kg)

1/2" 125 psig (8 bar) Round P32RB94BNGP * Inlet pressure 145 psig (10 bar). Secondary pressure 91.3 psig (6.3 bar).

Water

Ordering Information:

P32RB 9 2 B N G P

K Basic series Thread type Mounting

Global modular BSPP 1 P Plastic panel mount nut

Products

Regulator

P32RB

compact regulator BSPT 2

Adjustment range

NPT 9

With square gauge With round gauge

Port size psig bar Z 30 psig; 2 bar; 0.2 MPa

1/4 2 1 = 30* V = 2* M 60 psig; 4 bar; 0.4 MPa

3/8 3 3 = 60 S = 4 G 125 psig; 8 bar; 0.8 MPa

1/2 4 5 = 125 T = 8 J 250 psig; 17 bar; 1.7 MPa

* Regulator comes with gauge respective Without gauge

Relief to the adjustment range selected. Y 30 psig; 2 bar; 0.2 MPa

Relieving B

Non-relieving N Adjustment L 60 psig; 4 bar; 0.4 MPa

N Non-rising knob N 125 psig; 8 bar; 0.8 MPa

T T-Handle H 250 psig; 17 bar; 1.7 MPa

Most popular.

K22 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Compact Regulators Regulator Products

Material Specifications Flow Charts

General

Body Aluminum

1/4 Regulator

Adjustment knob Acetal 10

Inlet Pressure - 10 bar (145 psig)

140

Bonnet Glass-filled nylon 9

Secondary Pressure - (psig)

120

Secondary Pressure - (bar)

8

Diaphragm assembly Nitrile / Zinc 100 7

6 8.0 bar

Valve assembly Brass / Nitrile 80 116 psig

5

6.3 bar

Springs Steel, stainless steel 60 4 91.4 psig

Dial

3 4.0 bar

Seals Nitrile 40

58 psig

2

20 2.5 bar

Panel nut Acetal 1 36.3 psig

0 0

0 10 20 30 40 50 60 70 80 90

Flow - (dm 3/s)

Repair and Service Kits n

0 20 40 60 80 100 120 140 160 180

Diaphagm repair kit - relieving P32KB00RB Flow - (scfm)

Diaphagm repair kit - non-relieving P32KB00RC

Pilot

3/8 Regulator

Panel mount nut - aluminum P32KA00MM Inlet Pressure - 10 bar (145 psig)

10

140

Panel mount nut - plastic P32KA00MP 9

Secondary Pressure - (psig)

120 8.0 bar

Secondary Pressure - (bar)

8

Angle bracket (attaches via panel nut) P32KB00MR 116 psig

100 7

T-bracket with body connector P32KA00MT 6

Proportional

80 6.3 bar

5 91.4 psig

T-bracket P32KA00MB 60 4

4.0 bar

3 58 psig

Body connector P32KA00CB 40

2 2.5 bar

20 36.3 psig

1

0 0

0 10 20 30 40 50 60 70 80 90

! WARNING Flow - (dm 3/s)

n

0 20 40 60 80 100 120 140 160 180

Product rupture can cause serious injury. Flow - (scfm)

Precision

Do not connect regulator to bottled gas.

Do not exceed Maximum primary pressure rating. 1/2 Regulator

Inlet Pressure - 10 bar (145 psig)

10

140

9

CAUTION:

Secondary Pressure - (psig)

120 8.0 bar

Secondary Pressure - (bar)

8

116 psig

REGULATOR PRESSURE ADJUSTMENT – The working range of knob 100 7

adjustment is designed to permit outlet pressures within their full range. 6

80 6.3 bar

Pressure adjustment beyond this range is also possible because the knob 5 91.4 psig

Water

is not a limiting device. This is a common characteristic of most industrial 60 4

4.0 bar

regulators, and limiting devices may be obtained only by special design. For 40 3 58 psig

best performance, regulated pressure should always be set by increasing 2 2.5 bar

20 36.3 psig

the pressure up to the desired setting. 1

0 0

0 10 20 30 40 50 60 70 80 90

Flow - (dm 3/s)

n

3.66 Round 0 20 40 60 80 100 120 140 160 180

K

Flow - (scfm)

(93) Gauge

3.19 Square

(81) Gauge

2.36

Gauges

Regulator

Products

(60) Square flush 0-4 bar K4511SCR04B

2.36 1.18

(60) (30) mount gauge 0-11 bar K4511SCR11B

0-60 psig K4511SCR060

1.52

(38.5) 0-160 psig K4511SCR160

2.91

(73.8) Square with 0-4 bar P6G-PR10040

adapter kit

0-11 bar P6G-PR10110

5.36

(136.1) 0-60 psig P6G-PR90060

0-160 psig P6G-PR90160

50mm (2") round 0-30 psig / 0-2 bar K4520N14030

1/4" center back

0-60 psig / 0-4 bar K4520N14060

mount

0-160 psig / 0-11 bar K4520N14160

0-300 psig / 0-20 bar K4520N14300

For best performance, regulated pressure should always be set by increasing the

Inches (mm) pressure up to the desired setting.

NOTE: 1.90 in. (48mm) hole

required for panel nut mounting.

K23 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Compact Common P1 Precision Regulator Regulator Products

P32 Common - P1 Regulator – Compact

General

• Manifold style regulator with line pressure on both sides.

• Pressure output is at front or rear.

• Inlet ports 1/4", 3/8" or 1/2" (NPT, BSPP & BSPT)

• Working port 1/4" P2 P1

• Robust construction

Dial

• Secondary pressure ranges

• Secondary aspiration plus balanced poppet provides quick P1

response and accurate pressure regulation

• Relieving & non-relieving types

• Non-rising knob

Pilot

P1

Proportional

P2 P2 P2 P2

3 1 2

1 2

Operating information

Self relieving regulator Non-relieving regulator Flow capacity*:

with gauge 1/4, 3/8, 1/2 30 dm3/s (64 scfm)

Operating temperature: -25°C to 65.5°C (-13°F to 150°F)

Precision

Supply pressure (max): 300 psig (20 bar)

Adjusting range pressure: 0 to 30 psig (0 to 2 bar)

Port Description 0 to 60 psig (0 to 4 bar)

size (relieving) Gauge Part number 0 to 125 psig (0 to 8 bar)

0 to 232 psig (0 to 16 bar)

1/4" 125 psig (8 bar) None P32HB92BNNP

Gauge port (2 each): 1/4 NPT, BSPP, BSPT

3/8" 125 psig (8 bar) None P32HB93BNNP Weight: 0.50 lb (1.10 kg)

Water

1/2" 125 psig (8 bar) None P32HB94BNNP * Inlet pressure 145 psig (10 bar). Secondary pressure 91.3 psig (6.3 bar).

Ordering Information:

K P32HB 9 2 B N N P

Products

Regulator

Basic series Thread type Mounting

Global modular BSPP 1 P Plastic panel mount nut

P32HB

compact regulator BSPT 2

Adjustment range

NPT 9

With square gauge With round gauge

Port size † psig bar Z 30 psig; 2 bar; 0.2 MPa

1/4 2 1 = 30* V = 2* M 60 psig; 4 bar; 0.4 MPa

3/8 3 3 = 60 S = 4 G 125 psig; 8 bar; 0.8 MPa

1/2 4 5 = 125 T = 8 J 250 psig; 17 bar; 1.7 MPa

† Working port 1/4". Without gauge

* Regulator comes with gauge respective

Relief to the adjustment range selected. Y 30 psig; 2 bar; 0.2 MPa

Relieving B L 60 psig; 4 bar; 0.4 MPa

Adjustment N 125 psig; 8 bar; 0.8 MPa

Non-relieving N

N Non-rising knob H 250 psig; 17 bar; 1.7 MPa

T T-Handle

Most popular.

K24 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Compact Common P1 Precision Regulator Regulator Products

Material Specifications Flow Charts

General

Body Aluminum

P32 Common Port Regulator

Adjustment knob Acetal

Inlet Pressure - 10 bar (145 psig)

Bonnet Glass-filled nylon 140

10

9

Diaphragm assembly Nitrile / zinc

Secondary Pressure - (psig)

120

Secondary Pressure - (bar)

8

7

Valve assembly Brass / nitrile 100

6

80

Springs Steel, stainless steel 5 8.0 bar

116 psig

Dial

60 4

Seals Nitrile 6.3 bar

40 3 91.4 psig

4.0 bar

Panel nut Acetal 2

58 psig

20 2.5 bar

1

36.3 psig

0 0

0 10 20 30 40 50 60 70 80 90

Flow - (dm 3/s)

Repair and Service Kits n

0 20 40 60 80 100 120 140 160 180

Diaphagm repair kit - relieving P32KB00RB Flow - (scfm)

Pilot

Diaphagm repair kit - non-relieving P32KB00RC

Panel mount nut - aluminum P32KA00MM

Panel mount nut - plastic P32KA00MP ! WARNING

Angle bracket (attaches via panel nut) P32KB00MR Product rupture can cause serious injury.

Proportional

Do not connect regulator to bottled gas.

T-bracket with body connector P32KA00MT Do not exceed Maximum primary pressure rating.

T-bracket P32KA00MB

Body connector P32KA00CB

CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

Precision

is not a limiting device. This is a common characteristic of most industrial

regulators, and limiting devices may be obtained only by special design. For

best performance, regulated pressure should always be set by increasing

2.36 the pressure up to the desired setting.

(60)

2.36

1.18

(60)

(30)

1.52 Gauges

(38.5)

Water

Square flush 0-4 bar K4511SCR04B

2.91

(73.8) mount gauge 0-11 bar K4511SCR11B

5.36 0-60 psig K4511SCR060

(136.1) 0-160 psig K4511SCR160

Square with 0-4 bar P6G-PR10040

adapter kit

0-11 bar

0-60 psig

P6G-PR10110

P6G-PR90060

K

0-160 psig P6G-PR90160

Regulator

Products

50mm (2") round 0-30 psig / 0-2 bar K4520N14030

1/4" center back

0-60 psig / 0-4 bar K4520N14060

mount

Inches (mm) 0-160 psig / 0-11 bar K4520N14160

0-300 psig / 0-20 bar K4520N14300

NOTE: 1.90 in. (48mm) hole required

for panel nut mounting. For best performance, regulated pressure should always be set by increasing the

pressure up to the desired setting.

K25 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Standard Regulators Regulator Products

07R Regulators – Standard

General

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation

• Rolling diaphragm for extended life

• Two high flow 1/4" gauge ports can be used as additional

outlets

Dial

• Easily serviced

• Removable non-rising knob for panel mounting

and tamper resistance

• 1/2", 3/4" ports (NPT, BSPP)

Pilot

Operating information

Supply pressure (max): 250 psig (17.2 bar)

Secondary pressure ranges

Standard 2 to 125 psig (0 to 8.6 bar)

Proportional

Low 1 to 60 psig (0 to 4.1 bar)

High 5 to 250 psig (0.4 to 17.2 bar)

Port Operating temperature: 32°F to 175°F (0°C to 80°C)

size Description Part number Low temperature -4°F to 125°F (-20°C to 52°C)

1/2" Without gauge 07R313AC Flow capacity†:

High flow 1/2" 90 scfm (42.5 dm3/s, ANR)

1/2" With 160 psi gauge 07R318AC 3/4" 90 scfm (42.5 dm3/s, ANR)

3/4" Without gauge 07R413AC Gauge ports (2): 1/4 inch

Precision

(can be used as additional full

3/4" With 160 psi gauge 07R418AC flow 1/4 inch outlet ports)

NOTE: 2.0 Dia. (51 mm) hole required for panel mounting. Weight: 2.5 lb (1.1 kg)

†

scfm = Standard cubic feet per minute at 100 psig inlet, 90 psig no flow secondary

setting and 10 psig pressure drop.

Ordering information:

Water

07R 3 13 A C

Port Size Preset / Pressure Limited

1/2 inch 3 Blank None

K 3/4 inch 4

Pressure Range

XXX* Preset pressure

* Available preset / pressure limited range,

10 to 90 psig in 5 psig increments. For

higher pressures, contact factory.

Products

Regulator

Without gauge

(Example: 065 = 65 psig)

60 psig 11

125 psig 13 Options

250 psig 15 Blank No option

With gauge* L† Preset non-adjustable

60 psig 16 P† Preset Adjustable

125 psig 18 R Reverse Flow

250 psig 21 † Inlet Pressure is 100 psig. For

* Includes 1-1/2" dial face gauge. other pressures, contact factory.

Relief Port Type

Relieving A Blank NPT

Spring Type by Preset / Limited Pressure:

Non-relieving L 1* BSPP

For Preset / Limited Pressure 26 to 50 use

60 psi spring * 1/4 & 3/8 inch meet

ISO 1179-1 Standard.

For Preset / Limited Pressure 51 to 90 use Engineering Level

125 psi spring Current C

Most popular.

K26 Parker Hannifin Corporation

For inventory, lead times, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Standard Regulators Regulator Products

Material Specifications Flow Charts

General

Adjusting stem Steel 1/2" Regulator

Body Zinc Relief And Flow Characteristics

07R313A*

Bonnet, piston stem, valve poppet & cap Plastic 100

Collar, knob Plastic 6

Secondary Pressure - (psig)

Secondary Pressure - (bar)

80

Diaphragm Nitrile 5

Seals Nitrile 4 60

Dial

Spring, poppet Stainless

3

40

Spring, control Steel

2

20

1 1/2 Inch Ports

Repair and Service Kits 100 psig (6.9 bar) Primary Pressure

0 0

Bonnet assembly kit PS715P -10 0 10 30 50 70 90 110 130

Rated Flow - (scfm)

Pilot

Control knob P04069B

5 0 5 15 25 35 45 55

3

2" dial face 60 psig (0 to 4.1 bar), gauge K4520N14060 Flow - (dm /s)

n

2" dial face 160 psig (0 to 11.0 bar), gauge K4520N14160

3/4" Regulator

2" dial face 300 psig (0 to 20.7 bar), gauge K4520N14300

Relief And Flow Characteristics

Proportional

1-3/4" digital round face 07R413A*

100

160 psig (0 to 11.0 bar), gauge K4517N14160D

Mounting bracket kit (includes panel mount nut) PS807P 6

Secondary Pressure - (psig)

Secondary Pressure - (bar)

80

Panel mount nut, plastic P04082 5

Panel Mount nut, metal P04079B 4 60

Reverse flow service conversion kit, relieving PS808RP 3

40

Precision

Relieving (includes poppet) PS808P 2

Non-relieving (includes poppet) PS809P 20

1 3/4 Inch Ports

1-30 psig spring P01698 100 psig (6.9 bar) Primary Pressure

0 0

-10 0 10 30 50 70 90 110 130 150 170

1-60 psig spring P04062 Rated Flow - (scfm)

2-125 psig spring P04063 5 0 5 15 25 35 45 55 65 75

3

Flow - (dm /s)

5-250 psig spring P04064 n

Water

Tamperproof kit PS737P

3.24

(82)

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

3.74

(70)

Do not exceed Maximum primary pressure rating.

K

PU

CK

SH

TO LO

Regulator

Products

CAUTION:

REGULATOR PRESSURE ADJUSTMENT – The working range of knob

adjustment is designed to permit outlet pressures within their full range.

Pressure adjustment beyond this range is also possible because the knob

is not a limiting device. This is a common characteristic of most industrial

1/4" NPT

regulators, and limiting devices may be obtained only by special design. For

Gauge Ports best performance, regulated pressure should always be set by increasing

4.79 the pressure up to the desired setting.

(2) (122)

6.40

(163)

1.61

(41)

Inches (mm)

K27 Parker Hannifin Corporation

For inventory, lead time, and kit Pneumatic Division

lookup, visit www.pdnplu.com Richland, Michigan

www.parker.com/pneumatics

Catalog 0700P-8 Air Preparation Products

Standard Regulators Regulator Products

P33 Regulators – Standard

General

• Integral 1/2" or 3/4" ports (NPT, BSPP & BSPT)

• Robust but lightweight aluminum construction

• Secondary pressure ranges

• Secondary aspiration plus balanced poppet provides quick

response and accurate pressure regulation

Dial

• Relieving & non-relieving types

• Non-rising knob

Pilot

3 1 2

1 2

Operating information

Self relieving regulator Non-relieving regulator

with gauge Flow capacity*:

Proportional

1/2, 3/4 233 scfm (110 dm3/s, ANR)

Operating temperature: -13°F to 150°F (-25°C to 65.5°C)

Supply pressure (max): 300 psig (20 bar)

Port Description Adjusting range pressure: 0 to 30 psig (0 to 2 bar)

size (relieving) Gauge Part number 0 to 60 psig (0 to 4 bar)

0 to 125 psig (0 to 8 bar)

1/2" 125 psig (8 bar) None P33RA94BNNP

0 to 250 psig (0 to 17 bar)

Precision

1/2" 125 psig (8 bar) Round P33RA94BNGP Gauge port (2 each): 1/4 NPT, BSPP, BSPT